The Project Gutenberg EBook of Cork: Its Origin and Industrial Uses, by

Gilbert E. Stecher

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org/license

Title: Cork: Its Origin and Industrial Uses

Author: Gilbert E. Stecher

Release Date: October 24, 2012 [EBook #40376]

Language: English

Character set encoding: UTF-8

*** START OF THIS PROJECT GUTENBERG EBOOK CORK: ITS ORIGIN AND ***

Chris Curnow, Fred Salzer and the Online Distributed

Proofreading Team at http://www.pgdp.net (This file was

produced from images generously made available by The

Internet Archive)

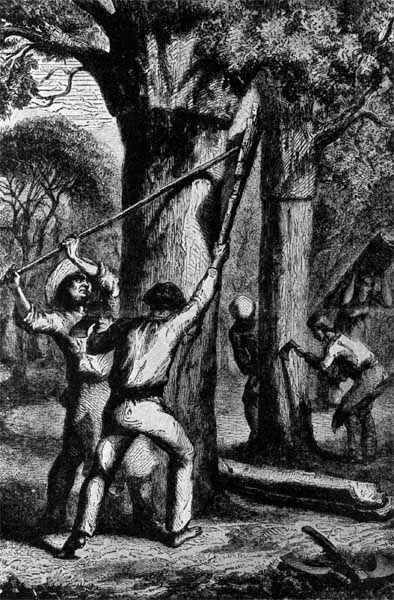

GATHERING CORKWOOD

CORK:

Its Origin and Industrial Uses

BY

GILBERT E. STECHER

Illustrated

NEW YORK

D. VAN NOSTRAND COMPANY

25 Park Place

1914

COPYRIGHT, 1914, BY

D. VAN NOSTRAND COMPANY

[iii]

THIS monograph is not an attempt to put

before the reading public a scientific exposition of the merits and qualities

of the Quercus Suber or Quercus Liber (Linnæus), and carry it up

into the heights of learning where none but the learned may go; but to

set forth in as concise a manner as possible, the plain story of the

corkwood stopper so well known to all. The corkwood as seen in the stopper

and in many other articles of trade, has long been of service to man,

and remained unnoticed in journals of science, but for a word here and

there—and in trying to acquaint myself with its generalities, found

it most difficult to get even these. This rather impressed me as being

singular, a material so largely used and so little to its credit, in

literature, that I pressed my investigations only to find that the farther

I searched the less I found.

The few facts gleaned were of interest, and it occurred to me to put

them together in some readable form, for future reference. But as I reflected

upon the unsuccessful attempt to get information, which was made in behalf

of my studies, I promptly decided to go into the subject deep [iv]enough

to cover all the facts and the result is this monograph—Quercus

Suber—

It is presented with the hope that it will help others who seek a knowledge

of corkwood and is only intended as a résumé of a very

interesting subject. I have endeavored to give credit to those to whom

it is due and offer my results as a tribute to a material that stands

in a class worthy of the scientists’ as well as the commercialists’ esteem.

G. E. STECHER.

June 15, 1914.

[v]

[3]

Its Origin and Industrial Uses

“Cork”

THE material of which this monograph treats

has become of double interest because of its shrouded mystery, which

has never been pierced to the extent of giving the world a complete and

comprehensive story. The mysticism does not encompass its utility and

general uses nor its native land, as these are well known, but is more

associated with its character, composition and chemical makeup.

Its uses may be traced far back into the misty past that is dim to us,

but from the faint scroll of history looms up in the mind’s eye

as an epoch that we may have been glad to know, and although the references

are few, by carefully analyzing them we may glean somewhat of its lineage.

[4]The

arcana attending it have been revealed to a few, who no doubt, through

curiosity, have endeavored to penetrate its obscurity, but unfortunately

have not written extensively upon the subject, instead leaving a meager

memorandum of their findings. The years of its use have given very little

knowledge of it to us, the reason perhaps being the lack of competition

and therefore no necessity for a close scrutiny to find additional qualities

to recommend it above others. And an additional mystery is that it has

been in use for so many years and so little said about it. Its latent

qualities have mystified those who have handled it for years, and from

them we can learn very little; so it will be of interest to peruse practically

all that has been written, incorporated in this treatise, with the addition

of the latest investigations upon the subject. To present this in a form

which will give credit to the small but authoritative references and

place them in their proper order, together with other recent data, was

no small task, and in presenting the total matter in concise style meant

the weeding out of all extraneous language or superfluous description.

In considering this material, it may be well to start with a few precursory

remarks as to the etymology of the words by which it has been designated

in the past and is now known, as by so doing it will convey a better

understanding of the material to follow.

[5]

The above name is the true one of the material under discussion and

is derived from the Latin. Quercus; Italian or esculent oak sacred to

Jupiter. Liber; binding or surrounding; hence surrounding of the oak

or bark of the oak, sacred to Jupiter.

“Quercus Suber”

This, its definite name, undoubtedly conveyed some particular meaning

to the ancients, but research fails to reveal any definition of the word

“Suber.”[1] “The

word is so far a puzzle to philologists. Forcellini in his great dictionary

of Latin says that it is perhaps connected with the Greek word (συφαρ

= suphar), which means ‘an old wrinkled skin, as, for instance,

the cast-off skin of a snake.’ If this derivation be sound, the

Romans, in using the word, thought at the outset primarily of the rough

bark of the tree and then of the tree as a whole. Forcellini quotes also

an opinion of Isidorus Hispalensis upon the longer form of ‘Suber,’ i.e.,

Suberies, to the effect that this form is derived from ‘sus’ (swine)

and ‘edo’ (eat) because swine eat the acorns. But this is

a purely popular etymology. I find too that Scaliger derived it from

the verb ‘Subio’ ‘to come up from below’ because

cork will not stay down in water. Vaniçek, in his Etymologisches

Wörterbuch, classes [6] ‘Suber’ among

the dunkel words, and in the new and most elaborate Historische Grammatic

of Stolz the word is not mentioned at all in the treatment of roots.

Even Otto Keller in his work on Etymologies has nothing to say about

it.”

[7]

This name is as much of a mystery as the word

“Suber” and its origin can only be guesswork. In the opinion

of the writer it is the broadening of the first syllable of the word “Quercus” and

has no bearing upon its usage, composition or lineage. Some dictionaries

give other derivations, such as the mutilation of the Spanish

“Corcho” or the French “Calk,” and others that

it is taken from the Latin Cortex,[2] meaning

the outer shell or husk, the external part, but they do not present any

convincing argument.

The meaning of the word “cork” as applied to-day is derived

from the Arabic “Kalafa,” to stop the seams of ships; the

Latin “Stipo,” to suppress; the French, “Calfeutrer,” to

stop. But these do not bear upon the origin of the word

“cork,” as in all probability the word was coined independent

of these sources, but as we apply the word to a definite act, that of “stopping,” the

definition as given above is applicable, although the proper name would

be “stopper,” regardless of what material it is made. It

is therefore plain that the word “cork” is a Latin phonetic

abbreviation, for it appears to be the only logical root for the word.

[8]The

cork tree is called “Alcornoque” in Castilian language; Surn

in Castalan; Sobreiro, Gallician; Suvi y Sioure in provincialism; Chêne

Liège in French; Keonge fernam or only fernam, in Argeline; Kork-baum

or Korkeiche in German; and, as before stated, cork in English. [3]

[9]

The study of its origin leads us to that romantic part of the world

bordering the Mediterranean Sea from which we have already received so

much in all branches. The cork-producing country practically covering

the whole of Portugal sweeping toward the East through the southern districts

known as Andalusia and Estremadura, thence northeast, embracing thousands

of acres of forests in Catalonia. Spain and Portugal dividing honors

among the nations in the annual yield of raw material, with perhaps the

advantage leaning slightly to the latter.[4] This

being partly due to increased area, no doubt, as the geographical situation

is the same but with the irrigation feature slightly in favor of Spain,

as through the corkwood country flows the Guadalquivir River in addition

to the three which also pass through Portugal, consisting of the Douro,

Tagus and Guadiana in the west, and the Ebro in the Gerona district.

Tunis and Algeria[5] rank

next in importance with Southern France, including Corsica following

closely. Italy (Tuscany) too with the help of Sardinia and Sicily continuing

to be quite a factor in meeting [10]the

demand for the crude material, while across the Strait of Gibraltar the

sun-scorched forests of Morocco at El-araish are as yet undeveloped,

although rapidly being pressed into service.

The geographical formation of Portugal is extremely favorable for the

rearing of cork trees, every evidence of this characteristic being well

marked by the densely thick groups of cork trees to be seen in certain

regions, especially in the Valley of the Tagus and the Sierra de Portalegre

provinces of Alemtejo and Algarve, which are the chief bearing centers

of this country,[6] the

area devoted to their cultivation being approximately 366,000 hectares.

In Spain it is found in the Provinces of Gerona, Caceres, Andalusia,

Huelvas, Seville, Cadiz, Ciudad Real, Malaga, Cordoba and Toledo in the

order named.

According to a calculation made by the administration of forests the

extent of cork forests in Spain is about 255,000 hectares,[7] viz.

80,000 in the Province of Gerona, 54,000 in Huelvas, 32,500 in Caceres,

28,000 in Seville, 20,000 in Cadiz, 11,500 in Ciudad Real and 9500 in

Cordoba. The remainder is distributed between ten other provinces. [8]

In the Province of Gerona is included a large territory stretching northward

towards the Pyrenees to the Valley of the Muge and Ter. In France, [11]according

to Consul Goldschmidt of Nantes, the cork-producing territory is divided

as follows: Var, 280 acres; Lot-et-Garonne, 27 acres; Landes, 32 acres;

Corsica, 40 acres; making about 379 acres in all.

This résumé of the cork-producing countries of Europe

will convey some idea of the extent of the forests, and will also show

the climate sort by the tree; for it is proven that it flourishes best

in an altitude of 1600 to 3000 feet, in an average mean temperature of

55° Fahrenheit; and at points beyond 45° north latitude its successful

propagation is doubtful.

The Mediterranean Basin is particularly

suitable for the rearing of corkwood, and although many attempts have

been made to transplant the seed, the results have proven fatal.

Notable among these attempts being the American ambition to introduce

the tree in the United States. Portuguese acorns were brought to Wayne

County, Mississippi, and planted in 1859; the result, as far as the growth

was concerned, was splendid; but after a wait of eleven years, the final

crop was not a commercial success. Another attempt was made in 1872,

in southern California, but with no better outcome than the first, in

which some of the trees attained to a height of thirteen feet (3.965

meters) and the stem, to a diameter of eleven inches (2.794 decimeters),

including the cork, which attained a thickness of one inch (2.540 centimeters).

This evidently rapid growth would infer that the [12]American

zone was all that could be desired for the favorable rearing of cork

trees; but strange to say this was not the case. Although the growth

of the tree had been exceptionally strong, the quality of its salient

product turned out to be of an inferior character. The cork generally

improves with the age of the tree; in this instance, however, even after

years of maturity the cork harvest did not improve to any great extent,

and indeed is still of a second-rate quality.[9] And

Consul S. C. Reat, writing from Tamsui, recently reports the efforts

of the Japanese Government to plant cork trees in Formosa and the Ogasawara

Isles, in the endeavor to supply small corks to the Japanese merchants,

the result of which, is yet to be learned.

Many botanists consider the cork oak of Europe as belonging to two species,

one chiefly characterized by annual fructification and the persistence

of the leaves for two or three years (Quercus Suber, Linnæus);

the other by biennial fructification and annual persistence of the leaves

(Quercus Occidentalis, Gay). [10]

In the French departments of the Landes and Gironde the Quercus Occidentalis

forms extensive woods, as also in Spain, Algeria and in some parts of

Italy, while the Quercus Suber is a native of the Atlantic side of France

and Portugal, where this [13]tree

grows to the greatest perfection, and to which countries we are indebted

for the major part of our supply. The cork tree bears a general resemblance

to the broad-leaved kind of (Quercus Ilex, Holm) or evergreen oak, of

which species some authors consider it only a variety; but when full

grown it forms a much handsomer tree.

“In the localities to the north the cork is better than those

exposed to the south. It grows and develops in ground of very little

depth, and sometimes in ground, in appearance very stony. It is seldom

found in calcareous soil, preferring always a soil of feldspar, and like

the chestnut flourishes best in a sandy one.” [11]

The cork-oak attains a height of from six to eighteen meters, at times

reaching fifty meters[12] and

measures as much as 1.22 meters in diameter.[13] Its

branches are covered with small evergreen leaves, which are rather spongy

and velvety to the touch, have a glossy appearance and a saw-tooth edge,

measuring about three to five centimeters[14] long

and one and one-half to two wide. The roots are strong and spread considerably,

and frequently are to be seen [14]on

the surface of the ground. The flowers or blossoms make their appearance

in May; the fruit ripens in the fall or winter, from September to January,

and falling from the tree as soon as ripe. Three qualities of acorns

are to be observed according to their time of ripening and are called,

“brevas primerizas de San Miguel,” which ripen in September;

the second or middling “Martinencas,”

which ripen in October and November; and finally the “tardias Ó palo-Meras,” which

ripen in December and January. These acorns form one of the forest’s

chief sources of revenue, since fed to swine, they give a peculiarly

piquant flavor to the meat, Spanish mountain hams being noted for their

excellence. [15]

In the following paragraphs I will quote principally from Consul Schenck’s

Report, 1890, relating to the growing and procuring of the bark for shipment,

with interpolated sentences and slight changes, made necessary by other

data at hand. The most common practice is to cultivate this plant by

sowing, which is frequently done, above all, in ground somewhat manured,

making alternate furrows with vines. Up to their twentieth or twenty-fifth

year the ground is cultivated as if it were a vineyard, rooting up at

that age the vines on account of producing less fruit, and also on account

of the cork trees being pretty well grown up and no longer requiring

the shelter of the vines. At the end of even one year it is difficult

to transplant the cork [15]tree

on account of the length of the roots, principally the central one, and

if the trees are put out with the intention of transplanting they are

generally sewn in a false ground bottom made artificially at a certain

depth with layers of stones or bricks. French silviculturists recommend

about 110 to 120 trees to the hectare (2.471 acres).

The cork tree gives but little shade, which contributes greatly in causing

the soil to become dry. To avoid all these inconveniences, which are

highly unfavorable to the good production of cork, it is requisite that

young plants grow up with sufficient foliage, so that the branches touch

each other, and even overreach, till they are about twenty-five years

old. It may be convenient, if there is not sufficient foliage from the

cork trees themselves, to introduce secondary species, such as the elm

tree, ash and pine, known as (pi meli), these being depended upon to

supply the requisite coolness and manure to the ground. If the soil is

poor, the cork is thin but of fine quality and very appropriate to make

the best stoppers. If, on the contrary, it is rich, the cork is thick

but spongy. Consequently it is requisite to treat the cork tree in such

a manner that whilst the cork grows thick it will at the same time be

fine in texture. This is of course an agricultural problem and may differ

from year to year in the necessary details.

[16]

The cork tree has in no wise escaped from disease and infections; on

the contrary it has its full allotted share which worries the growers

more than the acquiring of a perfect texture, and unless great care is

taken will greatly reduce the value of a crop. The larva of the Coroebus

undatus (corch) attacks the interior of the cork, penetrating frequently

into the tree itself, which causes an undervaluation in the quality of

the cork, and, moreover, these perforations unite so closely and in such

a manner even in the trunk of the tree that in peeling off the cork,

part of the skin of the trunk itself comes off, causing much damage to

the tree.

The larva of the Cerambyx cerdo, as well as the ant, Formica rufa L.

hormigas, destroys the fine cork with their numerous borings and galleries.

Jaspered (Jasperado) is the name by which is known one of the defects

of the cork which reduces it greatly in value and as far as can be learned

comes from the tree itself. The porosity of cork is greatly increased

by the presence of cork-meal, resulting from the disintegration of the

Sclerenchyma, or stone cells, which penetrate the cork fiber and falling

to a powder facilitate the entrance of infection.[16]

[17]

[17]The

corkwood or cork of commerce is the external part or “periderm” of

the cork-oak; and when it has attained a diameter of approximately 12.7

centimeters or the tree measures forty centimeters in circumference according

to the Spanish governmental regulations, which the tree does usually

by the time it is twenty years old, the bark may be removed. The stripping

generally takes place during July and August, and it is a process which

demands skill and care, if injury to the bark is to be avoided. In Algeria

the French strippers sometimes use crescent-shaped saws, but under the

usual Spanish method a hatchet, with a long handle, is the only implement

employed. The bark is cut clear through, around the base of the tree,

and a similar incision is made around the trunk, just below the spring

of the main branches; the two incisions are then connected by one or

two longitudinal cuts, following, so far as possible, the deepest of

the natural cracks in the bark. Inserting the wedge-shaped handle, the

tree’s covering is then pried off. The larger branches are stripped

in the same manner, yielding, generally, a finer grade of cork than that

of the trunk. The thickness of the bark ranges from 1.27 centimeters

to 6.85 centimeters, while the yield also varies greatly [18]from

twenty to 75 kilograms[18] per

tree, depending upon its size and age. After the first stripping the

tree is left in the juvenescent state to regenerate, and great care must

be taken in the stripping not to injure the inner skin or epidermis at

any stage of the process, for the life of the tree depends upon its proper

preservation, for if injured at any point, growth there ceases and the

spot remains forever afterward scarred and uncovered. It is also necessary

to avoid stripping during the prevalence of a sirocco, which would dry

the inner skin too rapidly and therefore exclude all further formation

of cork.

The Capgrand-Mothe system, which, as known, consists of dressing the

trunk with the same cork just removed, and leaving it so dressed for

a couple of months, has not met with approval, as being impracticable

on a large scale. After the stripping, the phellogen, the seat of the

growing processes, undertakes at once the formation of a new covering

of finer texture, and each year this, the real skin, with its life-giving

sap, forms two layers of cells, one within, increasing the diameter of

the trunk, the other without, adding thickness to the sheathing of bark.

After eight or ten years this sheathing is removed, and while more valuable

than the first stripping, it is not as fine in quality as that of the

third and subsequent strippings, which follow at regular intervals of

about nine years. At the age of about forty years the oak begins to yield

its best bark, continuing productive as a rule for [19]almost

a century.[19] The

cork of the first barking is called Corcho-Bornio, Borniza or virgin,

and is so coarse, rough, and dense in texture that it is of little commercial

value. The second barking is called “pelas,” or secondary

cork, and this and subsequent barkings constitute the cork of commerce.

As the bark is removed it is gathered up in piles (rusque) and left for

a few days to dry. Having been weighed, it is next carried either in

wagons or on the backs of burros to the boiling station, where it is

stacked and allowed to season for a few weeks. It is then ready for the

boiling process. The outside of the bark in its natural state is, as

may well be imagined, rough and woody, owing to exposure to the weather.

After boiling this useless outer coating is readily scraped off, thereby

reducing the weight of the material almost twenty per cent. The boiling

process also serves to remove the tannic acid, increases the volume and

elasticity of the bark, renders it soft and pliable and flattens it out

for convenient packing. After being roughly sorted as to quality and

thickness, the bark is then ready for its first long journey, and as

the forests are generally located in hilly or even mountainous country,

the faithful burro must again be called into service. Truly the [20]Spaniards’

best friend, though the worst treated of all, these patient little animals

present a most grotesque appearance when loaded from head to hind quarters

with a huge mass of the light bark. Down from the hills they go in trains

of thirty, forty or even a hundred, threading the rocky bridle paths

in single file and wending their way through the narrow streets of quaint

villages where traces of Moorish occupancy may still be seen, to the

nearest railway station. The corkwood is there freighted to the various

sea-port warehouses in Spain and Portugal, Seville, Spain being perhaps

the largest depository and user of raw material.[20] This

historic city, situated on the banks of the Guadalquivir, presents a

very animated sight in the summer months, and plays a very important

part in the cork industry, for besides the numerous warehouses for storing

and shipping there are factories for the manipulation of cork and its

conversion into the many useful forms in which it has proven of value.

Before shipping, the bales are opened, the edges of the bark trimmed

and the bark then sorted into the various grades of quality and thickness

again. The importance of this last mentioned operation cannot be overemphasized,

as the whole problem of the successful and economical manufacture of

corks center about it. After sorting it is ready to be rebaled for shipment,

this generally being done by placing the large, flat pieces called planks

or tables, at the bottom of the [21]bales,

and above them the small pieces which are covered in turn with larger

sections; then the whole mass being subjected to pressure to render it

compact, afterward being bound up securely with steel hoops or wires.

Each bale carefully marked indicating the grade or quality, loaded directly

into ocean-going steamers and shipped to the ports of the world.

From this meager description we at least can learn what “corkwood” is,

the limited sphere of its growth, the constant care necessary to insure

a successful harvest or gathering, the peculiarities of the tree, its

longevity and the general mode of preparing the bark for shipment; the

narration in no wise doing justice to this most interesting material,

in its natural state, for its growing is a fascinating tale in itself;

but for the purpose of this writing the foregoing has been deemed sufficient

to convey an understanding of it.

As we have now seen how this wonderful material grows, its haunts and

dwellings, we will look at it more closely and see what it really is,

how this particular formation comes about and its peculiarities.

[22]

IN considering “cork” for the

purpose of ascertaining its characteristics, texture and composition

we will, instead of analyzing the material after it has reached the market,

look at it from the standpoint of botany and learn of its formation upon

the tree, from which it is procured. It appears that the word “cork”[21] in

botany signifies a growth peculiar to all plants and pertaining to none

in particular, being described as “a peculiar tissue in the higher

plants forming the division of the bark (which name is sometimes restricted

to the dead tissues lying outside the cork); consisting of closely packed

air-cells nearly impervious to air and water and protects the underlying

tissues.”[22] Again, “It

is produced by the activity and division of certain merismatic cells

known as phellogen or cork cambium which are situated immediately within

the epidermal covering of the young growth. As the cork cells grow older,

their protoplasmic contents disappear and are replaced by air. In order

that this formation may be clearly understood, I will quote from a paragraph

entitled “Cork and Epidermal Formations Produced by It” contained

in

“A Text Book on Botany,” by Sacks.

[23]“When

succulent organs of the higher plants, no longer in the bud condition,

are injured, the wound generally becomes closed up by cork tissue, i.e.,

new cells arise near the wounded surface by repeated division of those

which are yet sound, and these forming a firm skin separate the inner

tissue from the outer injured layers of cells. The walls of this tissue

offer the strongest resistance to the most various agencies, similar

to the cuticular layers of the epidermis in their physical behavior,

flexible and elastic, permeable only with difficulty by air and water,

they for the most part soon lose their contents and become filled with

air. They are arranged in rows lying at right angles to the surface or

parallelopipedal form, and form a close tissue without intercellular

spaces. These are the general distinguishing features of cork tissue.

It is formed not only on wounded surfaces, but arises in much greater

mass where succulent organs require an effectual protection (e.g., potato

tubers) or where the epidermis is unable to keep up with the increase

of circumference where growth in thickness continues for a long period.

In these cases the cork tissue is formed even before the destruction

of the epidermis, and when this splits under the action of the weather

and falls off, the new envelope formed by the cork is already present.

The cork tissue is the result of repeated bipartitions of the cells by

partition walls, rarely in the epidermis cells themselves, more often

in the subjacent tissue. The partition walls lie parallel [24] to

the surface of the organ, divisions also taking place in a vertical direction,

by which the number of the rows of cells is increased. From the two newly

formed thin-walled cells of each radial row one remains thin walled and

rich in protoplasm, and in a condition capable of division; the other

becomes transformed into a permanent cork cell. Thus arises, usually

parallel to the surface of the organ, a layer of cells capable of division,

which continues to form new cork cells, the cork cambium or layer of

phellogen. In general this is the innermost layer of the whole cork tissue,

so that the production of cork advances outwardly and new layers of cork

are constantly formed out of the phellogen on the inner surface of those

already in existence. When in this manner a continuous layer of cork

arises, steadily increasing from the inside, it is termed “periderm.” As

the epidermis is at first replaced by the periderm, so in turn is this

replaced by cork (the dead tissue). The development and configuration

of the cork cells may change periodically during the formation of periderm.

Alternate layers of narrow, thick-walled and broad, thin-walled cork

cells are formed; the periderm then appearing stratified, like wood,

showing annual rings as in the periderm of the Quercus Suber, Betula

Alba, etc.”

Mr. Sacks, as a botanist, has clearly set forth the explanation of the

formation of the periderm of the Quercus Suber in the foregoing, and

although the story of the life producing this formation would [25] be

an acceptable sequel to this explanation, it would in no wise assist

in the ultimate findings, and therefore it is dispensed with. Mr. William

Anderson, in a paper read at the Royal Institution of Great Britain in

1886, has the following to say on cork formation, which is very interesting:

“In considering the properties of most substances, our search for

the cause of their properties is baffled by our imperfect powers and

the feeble instruments we possess for investigating molecular structure.

With cork, happily, this is not the case; an examination of its structure

is easy and perfectly explains the cause of its peculiar and valuable

properties. All plants are built up of minute cells of various forms

and dimensions. Their walls or sides are composed chiefly of a substance

called cellulose, frequently associated with lignine, or woody matter,

and with cork, which last is a nitrogenous substance found in many portions

of plants, but is especially developed in the outer cork of exogenous

trees, that is, belonging to an order, the stems of which grow by the

addition of layers of fresh cellulose tissue outside the woody part and

inside the bark. Between the bark and the wood is interposed a thin fibrous

layer, which in some trees is very much developed. The corky part of

the bark which is outside is composed of closed cells, exclusively, so

built together that no connection of a tubular nature runs up and down

the tree, although horizontal passages radiating toward the woody parts

of the tree are [26]numerous.

In the woody part of the tree, on the contrary, and in the inner bark,

vertical passages or tubes exist, while a connection is kept up with

the pith of the tree by means of medullary rays. In one species of tree,

known as the cork-oak, this is strongly developed.” It appears

that Mr. Anderson enlivened his lecture by microscopic projections, for

he goes on to say: “First I project on the screen a microscopic

section of the wood of the cork tree. It is taken in a horizontal plane,

and I ask you to notice the diversity of the structure and especially

the presence of large tubes or pipes. I next exhibit a section taken

in the same plane of the corky portion of the bark. You see the whole

substance is made up of minute many-sided cells about 1⁄750 of

an inch in diameter and about twice as long, the long way being disposed

radically to the trunk. The walls of the cells are extremely thin and

yet they are wonderfully impervious to liquids. Looked at by reflected

light, bands of silvery light alternate with bands of comparative darkness,

showing that the cells are built on end to end in regular order. The

vertical section next exhibited shows a cross section of the cells like

a minute honeycomb. In some specimens large crystals are found. These

could not be distinguished from the detached elementary spindle-shaped

cells, of which woody fiber is made up, were it not for the powerful

means of analysis we have in polarized light. I need hardly explain that

light passed through a Nicol’s prism becomes polarized, that is

to [27]say,

the vibrations of the luminiferous ether are all reduced to vibrations

in one plane and consequently if a second prism be interposed and placed

at right angles to the first, the light will be unable to get through;

but if we introduce between the crossed Nicol a substance capable of

turning the plane of vibration again, then a certain light will pass.

I have now projected on the screen the feeble light emerging from the

crossed Nicol. I introduce the microscopic preparation of cork cells

between them, and you see the crystals glowing with many colored lights

on a dark ground. Minute though these cells are, they are very numerous

and hard, and it is partly to them that is due the extraordinary rapidity

with which cork blunts the cutting instruments used in shaping it.” In

his research or experimentations Mr. Anderson was most deeply impressed

with the elasticity of cork, and has the following to say upon his findings: “It

would seem difficult to discover any new properties in a substance so

familiar as cork, and yet it possesses qualities which distinguish it

from all other solid or liquid bodies, namely, its power of altering

its volume in a very marked degree in consequence of change of pressure.

All liquids and solids are capable of cubical compression or extension,

but to a very small extent; thus water is reduced in volume by only .00005

part by the pressure of one atmosphere. Liquid carbonic acid yields to

pressure much more than any other fluid, but still the rate is very small.

Solid substances, with the exception of cork, offer [28] equally

obstinate resistance to change of bulk; even India rubber, which most

people would suppose capable of very considerable change of volume, we

find it really very rigid. Metals, when subjected to pressure which exceed

their elastic limits so that they are permanently deformed, as in forging

or wire drawing, remain practically unchanged in volume per unit of weight.

Not so with cork, its elasticity has not only a very considerable range,

but it is very persistent. Thus in the better kind of corks used in bottling

champagne and other effervescing wines, you are familiar with the extent

to which the corks expand the instant they escape from the bottles. I

have measured this expansion and find it to amount to an increase of

volume of seventy-five per cent; even after the corks have been kept

in a state of compression in the bottles for ten years.[23] When

cork is subjected to pressure, either in one direction or from every

direction, a certain amount of permanent deformation or permanent set

takes place. This property is common to all solid elastic substances

when strained beyond their elastic limits, but with cork the limits are

comparatively low.” To take advantage of the peculiar properties

of cork in mechanical applications it is necessary to determine accurately

the law of its resistance to compression, and for this purpose Mr. Anderson

instituted a series of experiments of this kind. Into a strong iron vessel

of five and one half gallons’ capacity he introduced a quantity

of cork [29] and

filled the interstices with water, carefully getting out all the air.

He then proceeded to pump in water until definite pressures up to one

thousand pounds per square inch had been reached, and at every one hundred

pounds the weight of the water pumped in was determined. In this way,

after many repetitions, he obtained the decrease of volume due to any

given increase of pressure. The observations have been plotted into the

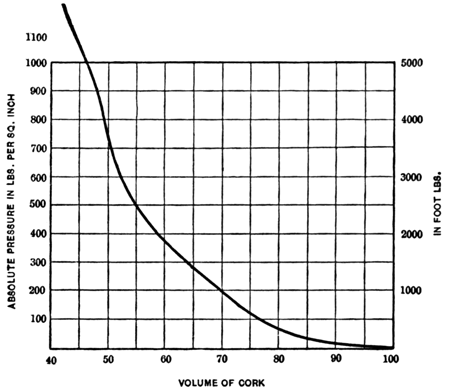

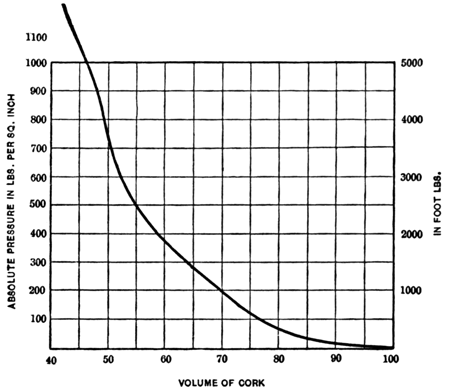

form of a curve which is discernible on the accompanying diagram.

The base line represents a cylinder containing one cubic foot of cork

divided by the vertical lines into ten parts; the black horizontal lines,

according to the scale on the left-hand side, represent the [30] pressures

in pounds per square inch which were necessary to compress the cork to

the corresponding volume. Thus to reduce the volume to one half, required

a pressure of two hundred and fifty pounds per square inch. At sixteen

hundred pounds per square inch the volume was reduced to forty-four per

cent, the yielding then becoming very little, showing that the solid

parts of the cells had come together and formed a solid, compact mass,

thus corroborating Mr. Ogston’s determination that the gaseous

part of cork constitutes about fifty-three per cent of its bulk.

In further study it has been found that no matter what compression is

used, providing there is no disintegration, the corkwood will retain

just that slight spongy character that so marks its growth.

In analyzing this solid matter, Ure found by treating it with nitric

acid the yielding was:

| White fibrous matter (cellulose) |

0.18 |

parts |

| Resin |

14.72 |

“ |

| Oxalic acid |

16.00 |

“ |

| Suberic acid |

14.4 |

“ |

|

45.30 |

parts |

Chevruel in an analysis of corkwood states that he found the following

constitutents, but he does not give percentages:

Cerin, a soft fragrant resin.

Yellow and red coloring matter.

Quercitannic acid.

Gallic acid.

[31]A

brown nitrogenous substance.

Salts of vegetable acids.

Calcium.

Water.

Suberic acid.

Suberin (cellulose).

I am inclined to think that Chevruel selected a poor grade of cork,

full of stone cells and Jasperado, as his findings include much that

would indicate that was the case.

In further defining the various substances which go to make up the body

of corkwood the one that is most impressive is that substance that is

peculiar to cork itself, the others being readily known, but suberic

acid is the one of interest, and this is described by Fownes as a product

of the oxidation of cork by nitric acid; is a white crystalline powder,

sparingly soluble in cold water, fusible and volatile by heat, the chemical

formula given being (C4H14O4). Suberic

acid is also described as a dibasic acid which forms small granular crystals

very soluble in boiling water, alcohol and ether. It fuses at 300 degrees

Fahrenheit and sublimes in acidular crystals. It is also produced when

nitric acid acts on stearic, margaric or oleic acid. The chemical analysis

is given as (C8H14O4) and I am inclined

to believe it is the truer one, as it is much later than Fownes’.

This suberic acid has been further broken up to ascertain its fundamental

characteristics and it was found to partake of the two compounds suberone

and suberate.

[32] Suberone

(C14H24O2) being regarded as the ketone

of suberic acid, an aromatic liquid compound obtained when suberic acid

is distilled with an excess of lime.[24] Also

described as a colorless oil with an odor of peppermint and a boiling

point of 179 to 181 degrees Centigrade, chemical formula, Suberone—Cycloheptanone—

CH2 . CH2 .

CH2

/

CO

\

CH2 . CH2 .

CH2

Suberate (C8H12M2O4) is

known as the salt of suberic acid having a metal cast,[25] and

Suberin or cellulose[26]—is

that portion remaining after nitration and is chemically expressed by

the formula (C6H10O5). Dr. Robert K.

Duncan, Prof. of Industrial Chemistry in the University of Kansas, informs

us that this material is the commonest of common things[27] and

when dry, forms one third of all the vegetable matter in the world. This

mysterious substance is the structural basis of the wood, but with all

its prominence and use, we know nothing more about it than that which

is expressed in the formula.

The presence of this cellulose is only a natural fact, as the greater

part of plant life is cellulose; nor is the list of elements that go

to make up the [33]solid

matter so strange and unaccountable, but the quality that makes it a

wonderful growth and so popular above its fellows is its lightness—this

is its commendable feature and it is light indeed.

Ure puts the specific gravity at .24 and this is concurred in by Brisbane.

Test of Corkwood for Ascertaining the Possible Presence

of an Essential Oil, by Steam Distillation

Two tests were made on this material to ascertain the presence of an

essential oil. The first showed the presence of an oily film, resplendent

in colorings, opalescent, variegated and beautiful, but odorless and

of such small quantity that it may safely be said “No Oil.”

The second proved the same as the first, and although the strong odor

of cork or suberic acid was present, no oil appeared.

The results of these tests indicate that there is no essential oil in

corkwood obtainable by steam distillation.

Test No. 1

4-4-1913.

A copper still, supported on two trunnions, fitted with a dome and goose-neck,

which terminated in a tin coil (water cooled), and with a perforated

bottom through which the steam passed, was used.

This measured two inches in diameter and two [34] inches

high, from the perforated plate to the top of the pot, the dome being

about one foot higher.

Into this still was placed 41 pounds of corkwood, as it comes from the

cutters and punchers (scrap pieces), no preliminary washing or preparing

being done; this 41 pounds filled the pot or the still.

All things made tight, using an asbestos packing, the steam was turned

on at 70 pounds and run for one hour.

Test No. 2

4-15-1913.

Same still used as in Test No. 1, thirty pounds of a clean, good grade

Granulated Cork, of a fineness to pass a 1⁄16″ mesh,

was put into the still—this half filling same.

Steam turned on at 70 pounds and run for one hour.

Tests made at A. J. Crombie & Co., Brooklyn, N.

Y.

Anderson, Ure, Chevruel, Fownes, Watts, Brisbane, men of science; to

these we are indebted for the little that is known of corkwood, and although

perhaps much more could be said by elaboration, it will suffice to record

the facts in this monograph for the purpose involved.

But to the data assembled may be added much in commentation, for the

material becomes more interesting the more it is studied, and most naturally

excites comparison with other materials and substitutes, as well as calling

forth a discussion as to the dangers involved by its presence in the

places [35] where,

by skill of hand and machinery, it is transformed into the many commercial

forms, noted in this article. We comment upon its growth, which is truly

wonderful and all-absorbing in its many interesting phases; it takes

us to the romance of the East and the enchantment of the Moorish occupation;

through which these forests of cork-producing trees passed and yet remain

to furnish the present generation. We comment upon its lightness and

buoyancy, due to the presence of air and excess of hydrogen, known to

be lighter than air; and the small percentage of other matter which,

being of less importance, make its other quality so renowned as to make

it the most wonderful growth of its kind. Its imperviousness to water

and other liquids have given us moments of reflection, upon this phenomenon,

but now known to be because of the cellulose composing the cell walls

and which, when the substance is under compression, practically is all

that remains, except for the small quantity of resin, etc., to resist

the passage of liquids or gases. But heretofore when these commentations

have reached the burning point, its physical nature was entirely eliminated

from the conjecturing and the important part neglected, that as the cork

contained fifty-three per cent of air, heat of 450 degrees expands to

the point of explosion, the contents of those cells nearest the surface,

which giving up their oxygen feed the flames and in their passage help

to disintegrate the cell walls and make them more easily ignited. Thus

causing a rapid [36]burning,

flash fire which, in its fury, Pluto could not rival, only racing over

the surface of the cork, burning but slightly, yet helped by other conditions,

resulting in a fire destructive and fierce. This rapid burning leaves

the outer surface of the cork charred and flaky and causes a discoloration

beneath it attributed to the dissolving of the resins, etc. Of course

where there is a large quantity of corkwood the extent of the burning

must necessarily be greater and the depth of the char increased. But

it appears that the first flash burning produces a sort of protection

coat of carbon around the remaining unburned portions which a subsequent

flame penetrates with difficulty. [28]

A simple experiment to show this depth of burning, and one that is easy

to do, is the flash and flame test which was found of interest.

Two pieces of cork were taken, having the following measurements—8⁄16″ × 7⁄16″ × 11⁄16″—and

the first piece held so that the flame of a gas jet would cause a flash

over its surface; then the second piece is taken and held within the

flame for a minute.

It will be found that the corkwood has expanded and the dimensions increased

to the following:

| Flash |

Flame |

| 8⁄16″ × 13⁄16″ × 11⁄16″ |

10⁄16″ × 14⁄16″ × 11⁄16″ |

[37]showing

the effects of the heat upon the tissue and contents of the cells.

Now in scraping these samples clean of all char the dimensions will

return to the following:

| Flash |

Flame |

| 6⁄16″ × 11⁄16″ × 11⁄16″ |

8⁄16″ × 10⁄16″ × 11⁄16″ |

clearly setting forth the fact that the char is comparatively light

in both cases, ranging from 1⁄8″ to 1⁄4″.

To this cause is ascribed the burnability of cork having by careful

observation and experiment, extending over a period of two years, studied

the results of numerous fires in premises where cork was being worked

and also conducted heat applications on various grades of cork[29] resulting

in the foregoing findings.[30] Thus

it is found that cork contains sufficient air to supply any fire in it

and precludes the necessity of free access to any outside supply which

makes it a material worthy to be watched. To its many qualities of great

service to man, giving him a material which from the ages past, till

now, has proven of such value, must be added this one, no less important

than others, [38] which

heretofore have been its commendable features.

Rather than attend the “cork” through the many passages

of commerce and manufacture, it is deemed propitious to deviate a little

from a natural course, i.e., from the growing to manufacture and rather

advance to a knowledge of the many uses to which this material is put

and its application to the innumerable arts, and then take up the manufacture.

[39]

MR. H. G. GLASSPOOLE,[31] writing

regarding the uses of cork by the ancients, states: “The cork-tree,

and the application of its bark to useful purposes, was well known to

the Egyptians, Greeks and Romans. The former used this material in the

construction of the coffins for their dead. Theophrastus, the Greek philosopher,

who wrote on botany four centuries B.C., mentions this

tree among the oaks, under the name of ‘Phellus’ in Book

Two of his

‘Historia Plantarum,’ and stated that it was a native of

the Pyrenees, having a thick fleshy bark which must be stripped off every

three years to prevent it from perishing. He adds that it was so light

as never to sink in water, and on that account might be used for many

purposes.” It is the opinion of the writer that the attention of

the ancients was undoubtedly called to this particular bark by its buoyancy,

and as their fisheries were extensive its usefulness became readily apparent

to float nets, etc., or to use even in the construction of their boats,

and its sponginess and water-repellent properties not escaping their

notice, it became a most likely material for stoppers of casks or amphorae

as noted by Horace in Ode iii, 8: “Corticem [40] adstrictum

pice dimovebit amphorae.” Pliny, in his “Natural History,” XVI,

18, describes the tree under the name of Suber and relates everything

said by Theophrastus of Phellus. From his account we learn that the Roman

fishermen used it as floats to their nets and fishing tackle, and as

buoys to their anchors. The use of these buoys in saving life appears

to have been well known to the ancients, for Lucian, Epist. i, 17, mentions

that when two men, one of whom had fallen into the sea, and another who

jumped after to afford him assistance, both were saved by means of an

anchor buoy. The use of this substance in assisting swimmers was not

unknown to the Romans, for Plutarch in his Life of Camillus, who flourished

in Rome 400 B.C., gives an account of its use by a messenger,

sent to the Capitol, then besieged by the Gauls: “Pontius Cominius

having dressed himself in mean attire under which he concealed some pieces

of cork. He could not pass the river by the bridge, therefore took off

his clothes, which he fastened upon his head, and having laid himself

upon the pieces of cork swam over and reached the city.” The use

of cork as stoppers was entirely unknown to the Romans, but instances

of its being employed may be seen in Cato’s “De Re Rustica,”

Cap. 120, but this did not happen frequently or more would be said of

it.

The convivial customs of those days had no connection with the bottle,

glass bottles being of a much later invention. Instead of having champagne [41]or

hock to be liberated from the bottle by the corkscrew at their feasts,

the guests filled their drinking cups of gold, silver, crystal or beechwood

from a two-handled amphora, a kind of earthenware pitcher, in which their

choice wines used to be kept. The mouths of these vessels were stopped

with wood and covered with a mastic, composed of pitch, chalk and oil

to prevent air spoiling the wine or evaporation taking place. Columella,

who wrote one of the earliest works on agriculture, gives directions

for preparing this cement.

The employment of cork for stoppers of bottles appears to have come

into use about the seventeenth century, when glass bottles, of which

no mention is made before the fifteenth century, began to be generally

introduced. Before that period apothecaries used stoppers of wax, which

were not only much more expensive but far more troublesome. In 1553,

when C. Stephanus wrote his

“Praedium Rusticum,” cork stoppers appear to have been very

little known in France, for he states that this material was used principally

for soles in that country. It is not known when cork and corks began

to be generally used, but in that very amusing and instructive diary

of Mr. Samuel Pepys the following entry is found: “14 July 1666” After

having written to the Duke of York for money for the fleet, I went down

Thames Street and there agreed for four or five tons of cork to be sent

to the fleet, being a new device to make barricados [42]with

instead of junts (old cable),” but he does not inform us how the

material answered.[32]

In Evelyn’s time (1664) cork was much used by old persons for

linings to the soles of their shoes, whence the German name for it, “Pantoffelholtz”

or slipper wood. The Venetian dames, Evelyn says, used it for their choppings

or high-heeled shoes to make them appear taller than nature intended

they should be. The poor of Spain lay planks of cork by their bedside

to tread on instead of carpets. Sometimes they line the inside of their

houses, built with stone, with this bark, which renders them very warm

and corrects the moisture of the air. Loudon relates that in the celebrated

convent at Cintra, Portugal, several articles of furniture are made of

this tree. Virgin cork, or the first bark of the tree, is now very much

used for window flower boxes, grottoes, etc., while the subsequent grades

are used for small architectural and geognostic models. Cork was formerly

employed in medicine even as far back as the time of Pliny, as he tells

us that the bark of the cork tree, pulverized and taken in warm water,

arrests hemorrhage at the mouth and nostrils, and the ashes of it taken

in warm wine are highly extolled as a cure for spitting blood (see Pliny, “Nat.

Hist.” b. 124). In modern time powdered cork has been applied as

a styptic and hung about the necks of nurses. It was thought to possess

the power of stopping the secretion of milk. Burnt cork mixed with [43]sugar

of lead has been used as an application to piles. See Pereira’s “Materia

Medica.”

Ground cork and India rubber formed the basis of Kamptulicon, the soft

unresounding material which covered the floor of the reading rooms of

the British Museum.” In further describing the many uses to which

cork is applied, reference is made to the résumé of Mr.

Good in “La Nature,” which is incorporated with a few slight

changes.

“The various applications of cork that we are now going to pass

in review are worthy of description, as each of such applications has

its raison d’être in one or more of the physical or

chemical properties of cork bark. The manufacture of stoppers utilizes,

in the first place, the impermeability of the bark, and, in the second,

the latter’s elasticity and imputrescibility, the remarkable lightness

playing no rôle therein.

Before entering upon a study of the industrial applications of cork,

in grouping them according to the various qualities of this product,

we must return to the “male” cork, derived from the first

barking of the tree. It has been said, because of its slight elasticity

and numerous fissures, this product has but little commercial value,

and shall have mentioned its principal application when we have stated

that it is used in the decoration of parks and gardens. An endeavor has

been made, but without success, to manufacture from it, mills for decorticating

rice.

Certain parts of it can be converted into small [44]stoppers.

In the country where it is produced, it is used for making water conduits,

beehives and shelves on which to preserve objects from dampness. Mixed

with a mortar of clay, the Kabyles use it for the walls of their dwellings,

and also, in lieu of tiles, as a roofing material for their primitive

habitations. It is used also by fishermen as floats for their nets.

These various applications were known to the Greeks and Romans, as shown

by the works of Theophrastus and Pliny. The latter says of the cork-oak: “Nothing

is utilized but its bark, which is very thick, and which is renewed in

measure as it is removed. This bark is often used for the buoys of anchors

and ships and of fishermen’s nets, for the bungs of casks, and

for women’s winter foot gear. The Greeks called the cork-oak the ‘bark

tree’.... Cork bark is used as a covering for roofs.” (“Hist.

Nat.,” xvi, 18.) As for the chips, they can be used as an isolating

material to prevent freezing. Reduced to fragments, they furnish an excellent

material for covering circus rings.

Let us return to “female” cork, which is much better adapted

for being worked, and the grain of which is much more homogeneous. In

this form cork bark constitutes a very bad conductor of heat and sound,

and renders valuable services in the industries as a material for preventing

the cooling of steam pipes and generators, and preventing the melting

of ice in ice houses, or the heating of apparatus for producing cold.

[45] It

is the basis of a certain number of cements, and coatings for preventing

the escape of heat, which are applied to pipes, steam domes, hot water

reservoirs, etc., and upon the composition of which we shall not dwell

here. As for jacketing with cork alone; the first method consists in

placing narrow strips of cork, whose edges touch each other, along steam

pipes and cylinders, and fastening them by means of wire. A pipe thus

jacketed is tangent internally to all these strips, and a section of

the whole shows a circle inscribed in a polygon. In the second system

thin strips of cork, fastened to canvas with India rubber cement, are

wound around the pipe spirally. Finally, a third method of jacketing

consists in the use of two half cylinders that exactly fit the exterior

of the steam pipe. These cylinders, which can be made of any desired

length, are made of powdered cork and starch, and are covered with a

spirally wound strip of calico, which may be coated with tar or any suitable

kind of paint. Each of these systems permits of obtaining a great saving

in fuel.

As cork is likewise a very bad conductor of sound, it is successfully

used on the doors of consulting rooms, and for making floors for hospitals,

etc. Finally, in the manufacture of certain stringed instruments, it

is used to prevent a loss of sound.

The slight density of cork, as compared with water, and its impermeability

to liquids, make it an excellent float, capable not only of remaining [46]on

the surface, but also of supporting quite heavy bodies thereon. We shall

be content to mention the annular cork float used in night lamps, the

square block in which bath thermometers are fixed, and the fisherman’s

dobber.

It is cork, too, that is used by preference in the manufacture of swimming

and life-saving apparatus, to which inventors have devoted much thought.

Very many vessels are provided with cork mattresses, which, in cases

of shipwreck, render the greatest services. For example, the ship Constant,

which sailed from Anvers for Brazil in 1845, was wrecked on the night

of October 12th, at twelve miles from St. Thanes, but, thanks to the

cork life preservers and mattresses that she had on board, not one of

the crew was lost. As for life-saving buoys, properly so called, they

consist of several cork planks which are given an annular form, and are

provided with free ropes that are knotted here and there so that they

may be easily grasped. From the stern of every vessel a buoy of this

kind is suspended by a rope that may be at once cut when the cry of “A

man overboard!” is heard. These buoys are usually covered with

canvas coated with a paint that serves to preserve it. It is also possible

to save a person who has fallen into the water at a certain distance

from a wharf by means of floats. This device consists of a piece of rattan

provided with points around which molten lead has been poured, and the

whole is then surrounded with cork in chips, and covered externally [47] with

canvas and a network to protect the affair against wear.

Fenders are canvas bags that are filled with cork and are placed along

the sides of ships or along docks in order to deaden the shock in case

of a collision. Such are the principal uses rendered to navigation by

cork.

It has already been seen, by the extract from Pliny, that Roman ladies

preserved their feet from cold by means of cork soles. Such a use of

cork is still in vogue. In addition to these soles, which are flat, there

are others that have nothing to do with hygiene, and are merely connected

with fashion. Such are the Louis Quatorze talonettes, designed to increase

the stature without exaggerating the heel of the shoe. Female dancers

wear linings of this kind in their shoes, which, as well known, have

flat soles. A thin sheet of cork enclosed in the sole of the shoe would,

we think, prove very useful to troops on a march during bad weather.

Cork is not only useful as an application to foot gear, but also renders

great service in head gear, and, in the form of helmets, has preserved

a large number of soldiers from death by sunstroke in tropical countries.

We find it again, in the form of very thin sheets, in the interior of

beaver hats, where it is used as a protection against heat. It is also

used in these same hats as a sweat band, in lieu of leather. In ladies’ toilets,

the cork serves to make the carcasses of the birds that decorate [48] their

head gear. Manufacturers of dress trimmings use cork molds, which they

cover with silk or cotton, for ornamenting cloaks, etc. The lightness

of cork can alone explain the great size of these balls, olives, etc.,

some of which are larger than a hen’s egg.

A few years ago, a Paris house sold cork cravats, and we have recently

seen, exposed in a show case, some children’s costumes, in which

the sailor’s collar was of thin sheet cork decorated with colored

designs. Although cork gowns have not yet appeared, we have waterproofs

composed of thin sheet cork cemented between two pieces of silk. These

cloaks have the advantage over those made of rubber of not allowing air

to pass through them.

There is also a curious application of cork in the manufacture of a

fabric that renders those who are clothed with it insubmergible.

We can mention but few of the many applications of cork, new ones of

which are being discovered every day, so shall confine ourselves to recalling

the services rendered by this valuable product in surgical prosthesis

and for the use of naturalists, etc. In domestic life, it is used for

bath steps, and for making rolling pins for crushing almonds without

absorbing the oils as wood would do. Thin sheets of it are used for making

fancy labels for wines. The ease with which it may be cut, turned and

worked causes it to be employed in the manufacture of small objects,

such as rural landscapes and the reproductions of [49] monuments,

some of which are genuine works of art. We may likewise mention, among

objects made of cork, cases of various forms for sending bottles by mail,

spools for allowing of the cheap carriage of silk, the old-fashioned

inkstand, the thick penholder for preventing writer’s cramp, the

cigar holder and many fancy objects that would take too long to enumerate.

There is perhaps no calling that does not have to make more or less use

of cork. Polishers of gold have used it from time immemorial, in the

form of narrow strips, for rubbing their work with rouge. The wheels

with which crystals are polished are faced with it, and watchmaker’s

lens mounted in cork, the lightness of which prevents the muscles of

the face from tiring.

In the industries, driving pulleys are now beginning to be provided

with cork in order to secure an adhesion of the belting. In carpenter

shops these bands of cork are now advantageously replacing rubber ones

for covering the pulleys over which the band saw runs. The stoppers of

nursing bottles are now being replaced by hygienic ones of cork, which,

being very cheap, can be changed as soon as the presence of ferments

is suspected. Cork is likewise employed in the manufacture of children’s

toys; it serves, for example, for fixing the wig on dolls’ heads.

Is it necessary to recall the cork of pop-guns and pistols, and the cork

battledores and shuttlecocks used for playing with indoors? These few

data will serve to show that [50] but

few products are capable of so many diverse applications as cork is;

and the question may be asked whether it would be possible to substitute

anything else for it, in case the supply should become exhausted.

The manufacture of stoppers and of the various objects that we have

just enumerated furnishes a considerable quantity of chips, which along

with the waste derived from the collecting of the material, and with

old, second-hand corks, constitutes the crude material destined to supply

certain important industries, which, for the sake of completeness, must

be mentioned.

We have first the cork powder industry, which manufactures powders of

various degrees of fineness. The coarsest powder is used for packing

fragile objects, on account of its elasticity, coupled with its lightness,

which permits of a great saving in freight charges.

The finest powder forms, “liegine” or “suberine,”

whose balsamic properties are well known to hygienists, and which may

be used as a substitute for lycopodium, starch and fecula as an application

to the skin of babes. Under the name of

“zifa powder,” an insect powder has been made composed of

cork and phenol. Fire lighters have likewise been made from cork powder;

but this and the last named application have not amounted to much.

We cannot enter into much detail in regard to the manufacture of linoleum,

notwithstanding the [51]interest

that it presents. The manufacture began in Scotland, and is tending to

settle in our own country. Linoleum is made by intimately mixing cork

powder with oxidized linseed oil. The paste thus prepared is spread over

canvas if the intention is to manufacture carpets, but over paper if

it is desired to make hangings. The color of linoleum, which is the same

as that of cork, only a shade darker, can be enlivened by colored designs.

When applied to damp walls, linoleum is capable of receiving oil paintings

of a more stable nature than those executed upon wood, which warps, or

upon other building materials, which crack, such as plaster, for example.

It can also be used for decorated ceilings for public halls, cafes, etc.;

and when such ceilings become black through smoke and dust, they can

be washed.

As a carpet, linoleum renders flooring perfectly insonorous. It converts

damp and unhealthy apartments into healthy and warm places of habitation.

Used in kitchens and offices, it has the advantage of not being spotted

by fatty matters. It has been generally adopted in our naval and merchant

ships, where the use of it has given a great setback to the oil cloth

industry.

A new decorative product, “lino-burgau,” obtained by embossing

linoleum, possesses the iridescent reflections of nacre, due to the application

of colored varnish along with a bronzing of certain parts. Notwithstanding

its expensive nature, we believe that there is a great future in store

for it.

[52] The

manufacture of agglomerates of cork is becoming very widespread in France.

We have already mentioned the use of artificial cork for jacketing steam

pipes, and we have stated that this product is obtained by mixing cork

powder and starch under pressure. This dried paste can be given the most

diverse forms, and be made of any thickness. Another substance, called

brick paste, is obtained by mixing the coarsest cork powder with milk

of lime, and, after compression and drying, constitutes, under the form

of bricks and slabs, an excellent material for the construction of party

walls, for covering damp walls and sloping roofs.

In the cellars of breweries, these bricks diminish the melting of the

ice. In gunpowder works, they prevent the caking of the powder through

dampness, and, in case of an explosion, their friability and lightness

lessen the importance of the catastrophe. They are also used as a foundation

for flooring in order to destroy its disagreeable sonorousness. In the

spinning mills of Alsace and the west of France, they have given excellent

results, both as regards their resistance to the passage of sound, heat

and cold, and their cheapness.

Cork chips and waste, when distilled, furnish an illuminating gas that

burns with more brilliancy than that made from coal, and does not, like

the latter, give off sulphureous emanations that tarnish frames and other

gilded objects. The city of Nerac was lighted with cork gas for a certain

length of time, but the use of it had to be given up on [53] account

of the difficulty of storing the chips, which, with but little weight,

took up an enormous space. This gas, in view of its slight density and

its purity, would prove an excellent one for the inflation of balloons.

Finally, cork parings and waste, properly carbonized, produce Spanish

or cork black, one of the most beautiful and durable blacks known in

painting.”

The recent uses for corkwood are, as a float in the carburetter of an

automobile, the cork insert in the periphery of a pulley,[33] cork

paper for cigarette tips, a wadding for shot-gun cartridges, cork-coated

fabric for balloons, as a filling for automobile tires, as a disk in

the non-refillable bottle, for the making of casks and barrels in which

to store wine, and the ground cork wood for shipping fruit, etc. in,

to prevent spoiling.

Of course, no matter what the substance, a substitute is always sought

for, and this has been the case with cork, but with very unfruitful results. “A

primitive material used for bottle stoppers consisted of the roots of

liquorice; the spongy substance of another tree called ‘Spondies

Lutea,’ which abounds throughout the marshy regions of South America

and there called ‘Monbia,’

was also used in the same way, as also a [54] product

called ‘Myssa,’ which contains some of the elements of cork.[34] Another

substitute is mentioned in Henley’s “Twentieth Century Receipts”

as follows: Wood pulp three parts; cornstarch pith one part; gelatin

one part; glycerine one part; water four parts; 20 per cent solution

formic aldehyde; and still another in the “Handyman’s ‘Inquire

Within,’” by Haslock, called “Phellosene,”

a French invention consisting of powdered cork mixed with a solution

of nitro-cellulose in acetone: compressed and dried. The wood of Anona

palustris growing in the West Indies, and called the alligator’s

apple, is used by the negroes to stop their jugs and calabashes also,

and a Mr. Brockedon invented a substitute as noted in “Knight’s

Cyclopedia,”

the core of which was cotton twisted into strands, wound with flax and

the whole covered with India rubber. Cork’s competitor in buoyancy,

“balsa wood,” is in no wise constituted to take its place,

although 20 per cent lighter; as it is a fibrous growth and hygroscopic,

requiring a coat of water-proofing solution before it can be used even

for life-preservers; rubber, its close second, in the manufacture of

stoppers is not to be compared with it, and although there have been

many patent devices for sealing bottles, such as the porcelain stopper,

crimped metal stoppers, etc., the cork stopper still reigns as the best

of them all.

[55]

IN describing the manner and process of

converting the corkwood into the various commercial forms, no attempt

will be made to give a scientific exposition of all the details, as being

inconsistent with the character of this monograph, nor will [56] any

other processes be described than the ones in which the material being

worked, is cork. This may exclude much of interest to the reader, but

the intent of this little work is purely a corkwood exposition, and the

desire to keep it so must prevail.

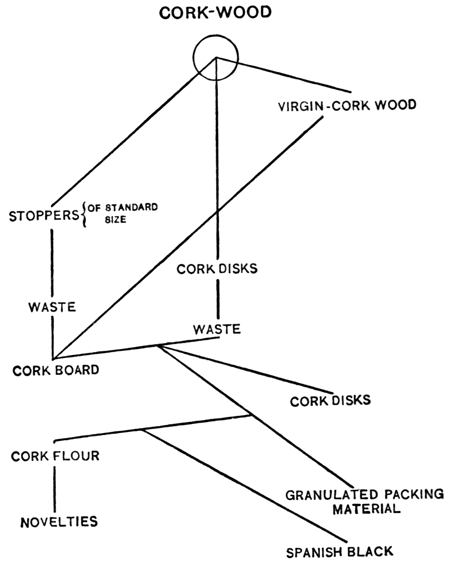

In taking up the processes of manipulation we naturally start from the

beginning, but the beginning in this case has a peculiar significance

as relating to the whole, for it is apparent to utilize corkwood to the

fullest extent its qualities must be studied and the best, used first,

so that the beginning of the corkwood industry is peculiar in this fact,

that it takes the best part and leaves but scrap, which must be studied

carefully to realize the value lost in the first process; therefore,

in the manufacture of one article of corkwood it is necessary to make

provision for the scrap created, and this is a characteristic of all

such establishments.

The baled cork, as received, is our first consideration, for its bulk,

being out of all proportion to its value, attracts the attention at once.

As in all business where the raw stock is conveyed from a distance and

there is a possibility of delay in shipments, a large stock must necessarily

be kept on hand, and this feature is very pronounced in and about a “cork

factory.” Great piles appear in the open or within large sheds, [57] covering

much space, and sometimes in the factory itself.

This stock is carefully watched and care taken to keep it large enough

to supply all needs for a long time as a shortage in raw material would

not only mean no work, but the loss of business, due to the inability

to supply first-grade material, for this is the prime factor, the various

other grades being compelled to await a favorable market. Appended is

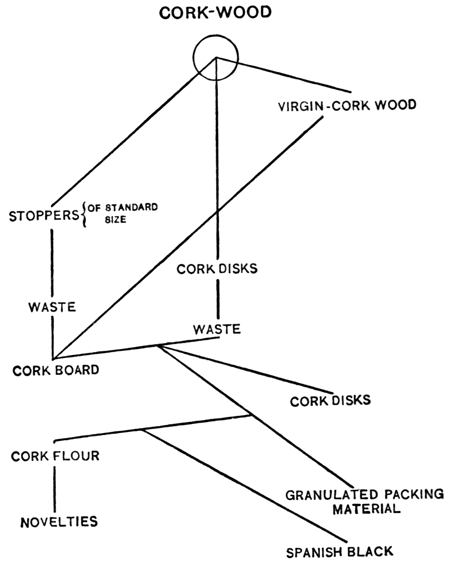

a diagram that will give some idea of the utilization of corkwood.

The corkwood bale as received, measures as a general rule 2′ × 2′7″ ×

4′ and is securely strapped with iron bands about one inch in width

and a thickness of 1⁄16″ to 1⁄32″,

and the weight depending upon the quality of corkwood ranging from 150

pounds to 200 pounds per bale.

The first operation, that is, the first thing done with the corkwood,

is the sorting. This is becoming more important as the uses of cork increase,

as various grades can be used for so many particular things now, without

the necessity of being called a by-product; but the principal divisions

are: superfine, fine, common and coarse.

These of course are now extended to many classes, and is resulting in

careful scrutiny of the shipments and stock, the sorter becoming an expert,

and an increasing factor in the business. His [58] knowledge

not only including the grades of corkwood, but the uses to which the

various grades may be put so that waste is avoided and the full value

gotten out of all.

After the sorting, the slabs are placed in steam boxes and subjected

to a steam bath, which it is claimed softens the material and also prepares

it for the scraper, who cleans and removes the dirt and callous or “raspa” accumulated

in its mountain home. This scraping is done either by hand or machine,

the handwork being done with a short handle, curved bladed knife called

a “doladera,”

raspador or raspeta: a workman being able to scrape from two to three

metric quintals of cork in a day, or ten hours. The scraper machine being

a vertical steel shaft carrying several knives placed at a very slight

helix and making about 1400 revolutions per minute and will scrape from

ten to twelve metric quintals[35] per