Title: Vacuum cleaning systems

A treatise on the principles and practice of mechanical cleaning

Author: M. S. Cooley

Release date: March 29, 2023 [eBook #70409]

Language: English

Original publication: United States: Heatin and Ventilation Magazine Company

Credits: deaurider, Harry Lamé and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

Please see the Transcriber’s Notes at the end of this text.

A Treatise on the Principles and

Practice of Mechanical Cleaning

BY

M. S. COOLEY, M. E.

Mechanical Engineer in Office of the Supervising

Architect, Treasury Department, Washington, D. C.

FIRST EDITION

New York:

Heating and Ventilating Magazine Company,

1123 Broadway

Copyright, 1913,

BY

Heating and Ventilating Magazine Co.

[iii]

| CHAPTER I. | ||

| History of Mechanical Cleaning. | ||

| PAGE | ||

|---|---|---|

| Early Attempts | 3 | |

| Limitations of the Carpet Sweeper | 4 | |

| Compressed Air Cleaners | 5 | |

| Vacuum Produced by Compressed Air | 7 | |

| Compressed Air Supplemented by Vacuum | 7 | |

| Piston Pump the First Satisfactory Vacuum Producer | 9 | |

| Systems Using Vacuum Only | 11 | |

| Renovator with Inrush Slot | 13 | |

| Steam Aspirators Used as Vacuum Producers | 14 | |

| Piston Pump Used Without Separators | 15 | |

| First Portable Vacuum Cleaner | 15 | |

| First Use of Stationary Multi-Stage Turbine Blowers | 16 | |

| Separators Emptying to Sewer by Air Pressure | 18 | |

| Machines Using Root Blowers as Vacuum Producers | 18 | |

| CHAPTER II. | ||

| Requirements of an Ideal Vacuum Cleaning System. | ||

| Necessity and Proper Location of Stationary Parts | 24 | |

| CHAPTER III. | ||

| The Carpet Renovator. | ||

| Four Important Parts of Vacuum Cleaning System | 25 | |

| The Straight Vacuum Tool | 26 | |

| Renovator with Auxiliary Slot Open to Atmosphere | 27 | |

| Renovator with Two Cleaning Slots | 30 | |

| Renovator with Inrush Slots on Each Side | 30 | |

| Tests on Dirty Carpets | 30 | |

| Type A Renovator Most Efficient on Dirty Carpets[iv] | 36 | |

| Tests of Carpets “Artificially” Soiled | 36 | |

| Effort Necessary to Operate Various Type of Renovators | 51 | |

| Relative Damage to Carpets with Various Type of Renovators | 52 | |

| CHAPTER IV. | ||

| Other Renovators. | ||

| Different Form of Renovator Necessary to Clean Walls, Ceilings and Similar Flat Surfaces | 60 | |

| Upholstery Renovators Disastrous to Surfaces Cleaned | 64 | |

| Attempts to Overcome Destructive Tendency of Straight-Slot Upholstery Renovator | 64 | |

| Upholstery Renovators Most Serviceable Clothing Cleaners | 65 | |

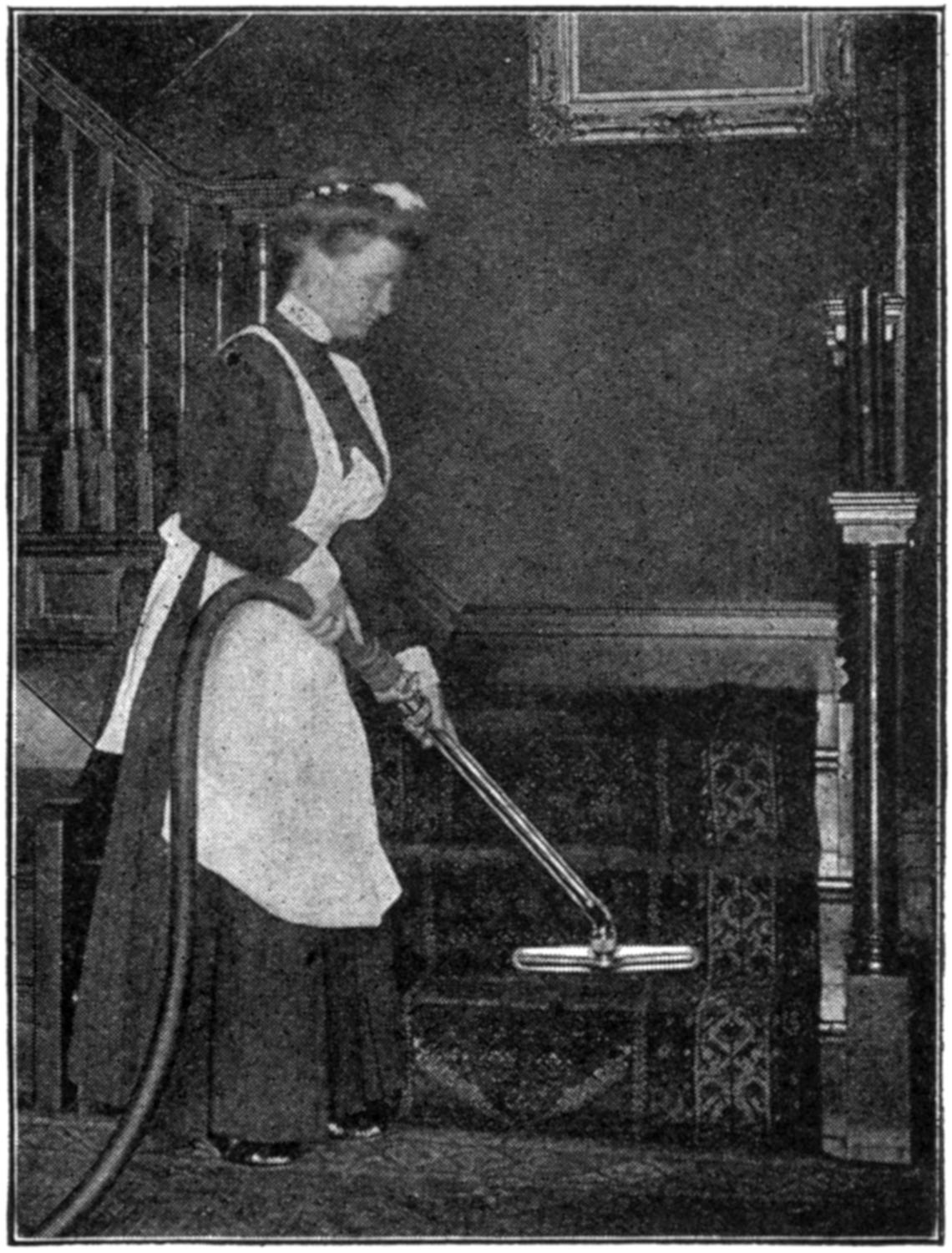

| Special Renovators for Cleaning Stairs | 66 | |

| Renovation of Furs | 66 | |

| Renovation of Pillows | 66 | |

| CHAPTER V. | ||

| Stems and Handles. | ||

| Use of Drawn Steel Tubing for Stems of Cleaning Tools | 70 | |

| Drawn Aluminum Tubing for Long Stems | 71 | |

| Swivel Joints Between Renovator and Stem | 72 | |

| Wear on Hose Near Stem | 74 | |

| Methods of Overcoming Wear of Hose | 74 | |

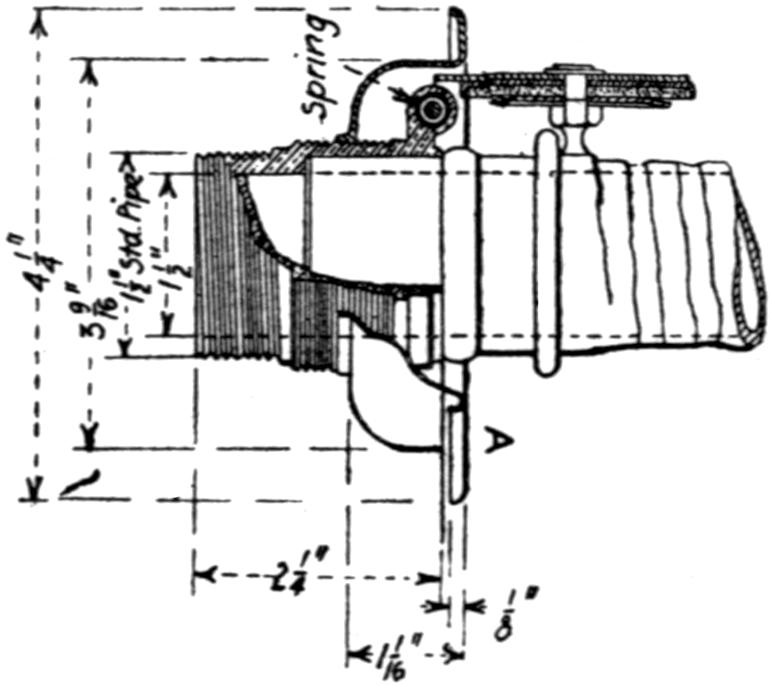

| Valves to Cut Off Suction | 78 | |

| CHAPTER VI. | ||

| Hose. | ||

| Early Types Made of Canvas-Wound Rubber Tubing | 80 | |

| Standard Weight Adopted | 80 | |

| First Type Produced Especially for Use in Vacuum Cleaning Work | 81 | |

| First Attempt to Produce Light-Weight Hose | 81 | |

| Other Types | 82 | |

| Hose Couplings[v] | 82 | |

| Hose Friction | 84 | |

| Effect of Hose Friction | 88 | |

| Most Economical Hose Size for Carpet and Floor Renovators | 93 | |

| Conditions for Plant of Small Power | 97 | |

| Limit of Length for Hose | 99 | |

| CHAPTER VII. | ||

| Pipe and Fittings. | ||

| Hose Inlets | 100 | |

| Pipe Friction | 107 | |

| Determination of Proper Size Pipe | 107 | |

| Determination of Number of Sweepers to be Operated | 113 | |

| Determination of Number of Risers to be Installed | 115 | |

| Size of Risers | 115 | |

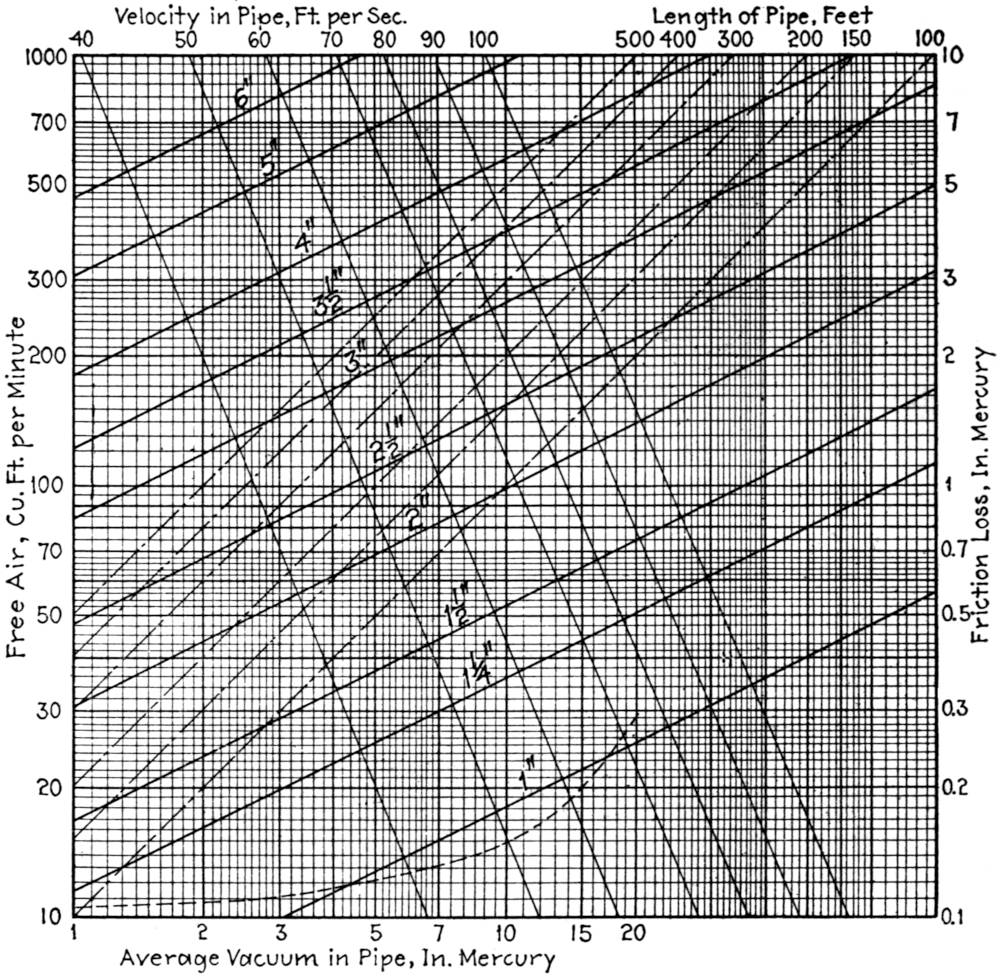

| Illustration of Effect of Long Lines of Piping | 120 | |

| CHAPTER VIII. | ||

| Separators. | ||

| Classification of Separators | 127 | |

| Primary Separators | 127 | |

| Secondary Separators | 130 | |

| Complete Separators | 134 | |

| Total Wet Separator | 138 | |

| CHAPTER IX. | ||

| Vacuum Producers. | ||

| Types of Vacuum Producers | 142 | |

| Displacement Type | 142 | |

| Centrifugal Type | 142 | |

| Power Required to Produce Vacuum | 142 | |

| Reciprocating Pumps | 143 | |

| Rotary Pumps | 148 | |

| Centrifugal Exhausters | 156 | |

| Steam Aspirators | 162 | |

| CHAPTER X.[vi] | ||

| Control. | ||

| First Type of Controller | 166 | |

| Second Form of Control | 168 | |

| Appliances for Varying Speed of Motor-Driven Vacuum Pump | 171 | |

| CHAPTER XI. | ||

| Scrubbing Systems. | ||

| First Real Mechanical Scrubbing Device | 176 | |

| Combining Scrubbing with Dry Cleaning | 177 | |

| Ideal Separator for Use with a Combined Cleaning and Scrubbing System | 178 | |

| CHAPTER XII. | ||

| Selection of Cleaning Plant. | ||

| Renovators | 179 | |

| Hose | 182 | |

| Pipe Lines | 182 | |

| Separators | 182 | |

| Vacuum Producers | 183 | |

| Control | 183 | |

| Selection of Appliances for Four Classes of Work | 184 | |

| Class 1.—Plant for Residence or Small Office or Departmental Building, to be Not More than One-Sweeper Capacity. | ||

| Class 2.—Large Office or Departmental Building Where Carpet Cleaning is Important and Pipe Lines are of Reasonable Length. | ||

| Class 3.—Large Building or Group of Buildings Where Carpet Cleaning is Important and Long Lines of Piping are Necessary. | ||

| Class 4.—Large or Small Plant Where Carpet Cleaning is Not an Important Function of the Cleaning System.[vii] | ||

| CHAPTER XIII. | ||

| Tests. | ||

| Early Methods of Testing | 187 | |

| Most Rational System of Testing | 189 | |

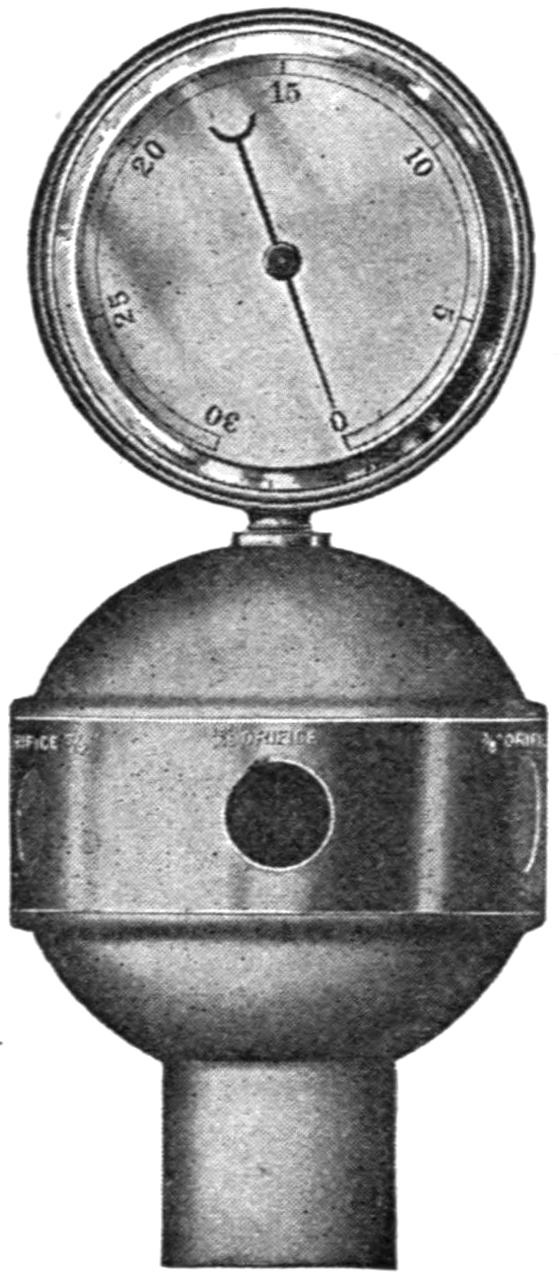

| Use of Vacometer | 190 | |

| Proper Orifice to be Used with Each Class of Plant | 191 | |

| CHAPTER XIV. | ||

| Specifications. | ||

| Award of Contracts on Evaluation Basis | 193 | |

| Determination Basis of Evaluation | 193 | |

| Specification for Class 1, Plant for Residence or Small Office Building of One-Sweeper Capacity | 194 | |

| Specification for Class 2, Plant for Large Office Building Having Pipe Lines of Moderate Length | 204 | |

| Specification for Class 3, Large Installation, with Unusually Long Pipe Lines | 209 | |

| Specification for Class 4, Large or Small Plant Where Carpet Cleaning is of Secondary Importance | 215 | |

| Specification for Class 5, To Give Widest Competition | 218 | |

| CHAPTER XV. | ||

| Portable Vacuum Cleaners. | ||

| Power Required | 228 | |

| Weight of Efficient Portable Cleaners | 228 | |

| Limit of Power Consumption When Attached to Lighting System | 229 | |

| Disadvantage of Having Dust Bag at Outlet of Fan | 230 | |

| Portables Equipped with Mechanically-Operated Brushes | 231 | |

| Portables Exhausting Air Inside of Building | 231 | |

| PAGE | ||

|---|---|---|

| 1. | Cleaning Tests of Dirty Carpets | 34 |

| 2. | Cleaning Tests of Carpets Filled with Quicksand | 38 |

| 3. | Cleaning Tests Using 1 oz. of Sand per Square Yard of Carpet | 40 |

| 4. | Comparison of Tests Made by Mr. Reeve and by the Author | 48 |

| 5. | Effort Necessary to Operate Cleaning Tools | 51 |

| 6. | Vacuum Required at Hose Cock to Operate Type A Renovators Attached to Varying Lengths of Different-Sized Hose | 89 |

| 7. | Air Quantities and Vacuum at Renovator with 1-in. Hose and 10 in. Vacuum at Hose Cock | 90 |

| 8. | Air Quantities and Vacuum at Renovator with 1¹⁄₄-in. Hose and 6 in. Vacuum at Hose Cock | 90 |

| 9. | Vacuum Required at Hose Cock to Operate Type C Renovators with Various Lengths of Three Sizes of Hose | 91 |

| 10. | Air Quantities Through Floor Brush with Various Sizes and Lengths of Hose, Operated on Same System with Type A Renovators | 92 |

| 11. | Horse Power Required at Hose Cock to Operate Bare Floor Brushes on Same System with Type A Renovators | 93 |

| 12. | Free Air Passing Brush Type of Bare Floor Renovator Operated on Same System with Type C Carpet Renovators | 94 |

| 13. | Horse Power at Hose Cock with Brush Type of Bare Floor Renovator Operated on Same System with Type C Carpet Renovators | 94 |

| 14.[x] | Cubic Feet of Free Air Passing the Felt-Covered Floor Renovator Operated on Same System with Type A Renovators | 96 |

| 15. | Horse Power Required at Hose Cock to Operate Felt-Covered Floor Renovators Operated on Same System with Type A Renovators | 96 |

| 16. | Vacuum at Hose Cock with 2 in. Vacuum at Type A Renovator | 97 |

| 17. | Air Quantities when Bristle Bare Floor Renovators are Used in Conjunction with Type A Carpet Renovators at 2 in. Mercury | 98 |

| 18. | Pipe Sizes Required, as Determined by Air Passing Renovators | 109 |

| 19. | Friction Loss in Pipe Lines, with Carpet Renovators in Use Exclusively | 109 |

| 20. | Pressure Losses from Inlet to Separator in System for Cleaning Railroad Cars | 121 |

[xi]

| Fig. | Page. | |

|---|---|---|

| 1. | Early Type of Mechanical Cleaning Nozzle Using Compressed Air | 6 |

| 2. | Another Type of Compressed Air Cleaning Nozzle, Supplemented with Vacuum Pipe | 8 |

| 3. | Separators Used With Combined Compressed Air and Vacuum Machines | 9 |

| 4. | Piston Type of Vacuum Pump, Mounted Tandem With Air Compressor | 9 |

| 5. | Mr. Kenney’s First Renovators Vacuum Alone Being Used as Cleaning Agent | 10 |

| 6. | Air Compressors Arranged for Operation as Vacuum Pumps | 11 |

| 7. | Separators Installed by Mr. Kenney in Frick Building | 12 |

| 8. | Vacuum Renovator With Inrush Slot, Introduced by the Sanitary Devices Manufacturing Company | 13 |

| 9. | First Portable Vacuum Cleaner, Constructed by Dr. William Noe, of San Francisco, in 1905 | 16 |

| 10. | Late Type of Spencer Vacuum Cleaning Machine, Operated by Multi-Stage Turbine Blowers | 17 |

| 11. | Type A, the Straight Vacuum Tool | 26 |

| 12. | Type B, with Wide Slot and Wide Bearing Surface | 26 |

| 13. | Type C, with Auxiliary Slot, Open to Atmosphere | 28 |

| 14. | Type D, with Two Cleaning Slots | 28 |

| 15. | Type E, with Inrush Slot on Each Side of Vacuum Slot | 31 |

| 16. | Type F, an Exaggerated Form of Type B | 31 |

| 17. | Tests of Three Renovators on Dirty Carpets | 35 |

| 18. | Cleaning Tests of Carpets Filled with Quicksand | 39 |

| 19. | Cleaning Tests Using 1 oz. of Sand Per Square Yard of Carpet | 41 |

| 20. | Three Series of Tests with Kenney Type A Renovators | 45 |

| 21. | Tests by Mr. Reeve, Using Type C Renovator | 46 |

| 22. | Tests by Mr. Reeve, Using Type D Renovator | 47 |

| 23. | Tests Showing Efficiency of Different Types of Renovators at Different Degrees of Vacuum | 50 |

| 24. | Early Type of Bare Floor Renovator | 55 |

| 25. | Later Type of Bare Floor Renovator | 55 |

| 26. | Another Type of Bare Floor Renovator | 56 |

| 27. | Bare Floor Renovator with Felt Cleaning Surface | 57 |

| 28. | Bare Floor Renovator with Unusual Form of Slot | 58 |

| 29. | Bare Floor Renovator with Hard Felt or Composition Rubber Strips | 58 |

| 30. | Bare Floor Renovator with Rounded Wearing Surface[xii] | 59 |

| 30a. | The Tuec School Tool | 62 |

| 31. | Round Bristle Brush for Carved or Other Relief Work | 62 |

| 32. | Rubber-Tipped Corner Cleaner for Use on Carved or Other Relief Work | 62 |

| 33. | Early Type of Upholstery Renovator | 63 |

| 34. | Upholstery Renovator with Narrow Slots to Prevent Damage to Furniture | 64 |

| 35. | Another Type of Upholstery Renovator with Short Slots | 65 |

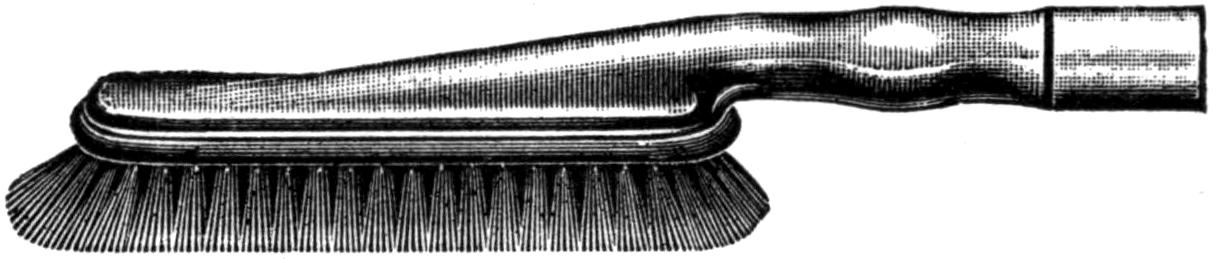

| 36. | Hand Brush Type of Renovator | 65 |

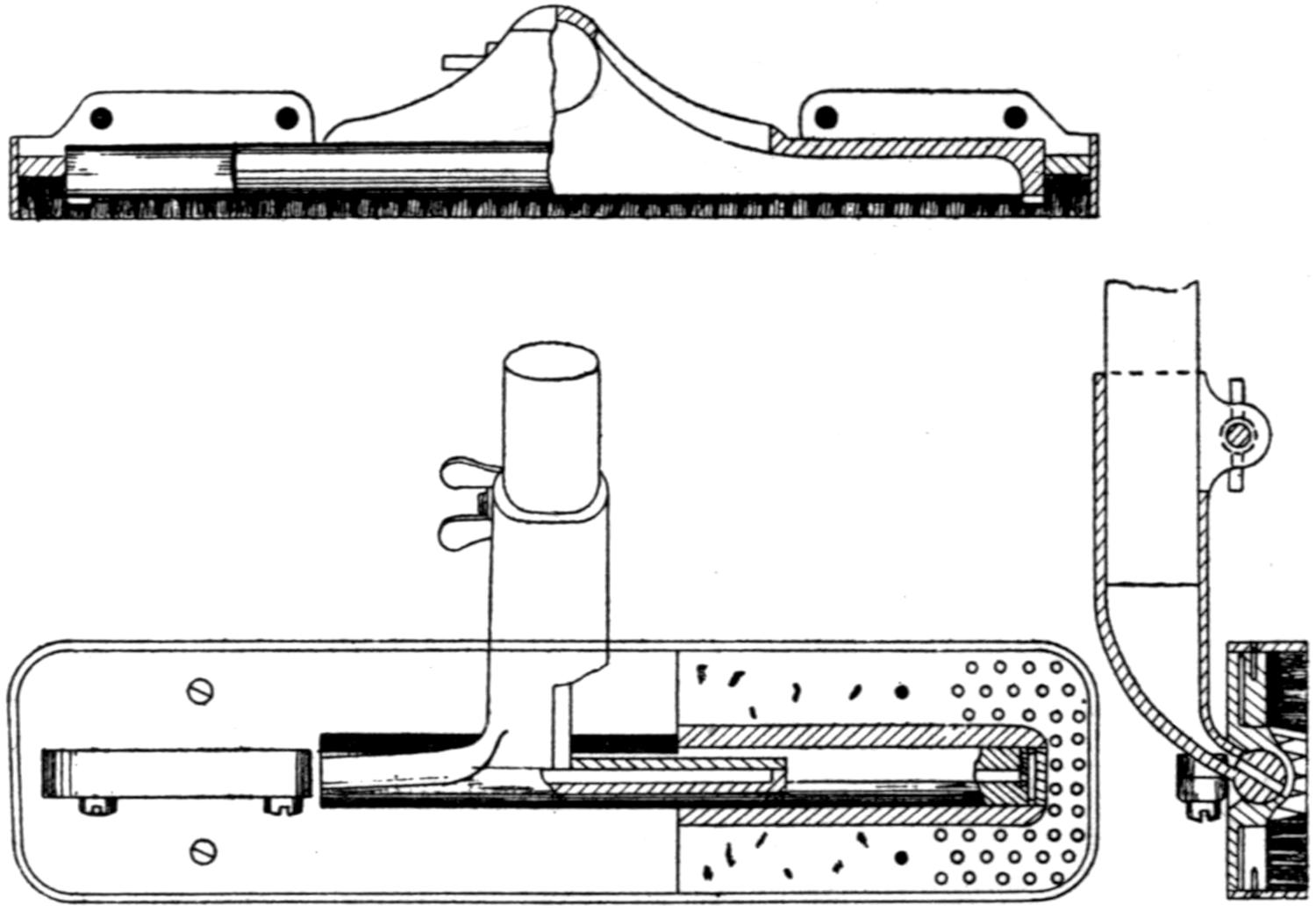

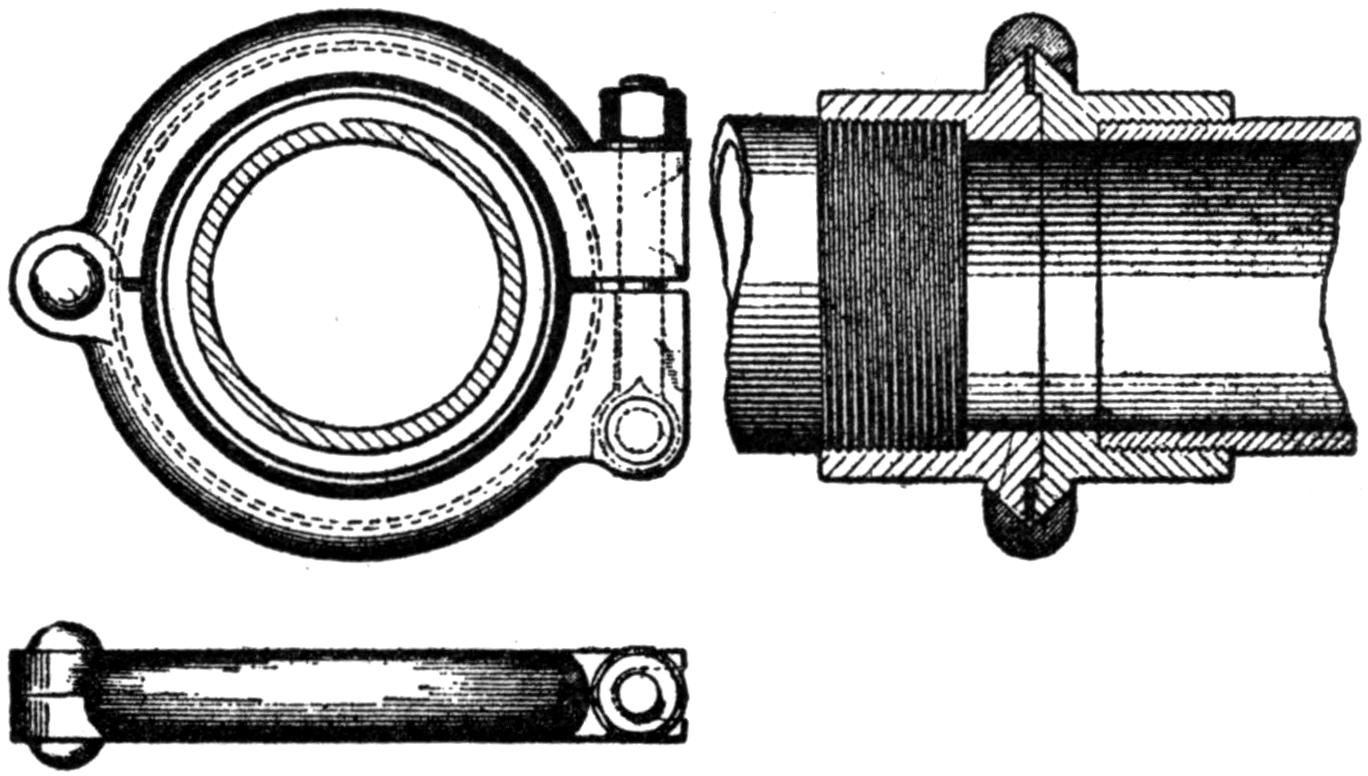

| 37. | Form of Swivel Joint Connecting Stem to Renovator | 72 |

| 38. | Swivel Joint Arranged to Prevent Dust Lodging Between the Wearing Surfaces | 73 |

| 39. | Swivel Joint in Use | 74 |

| 40. | Another Use of Swivel Joint, Showing Possibilities of this Form | 75 |

| 41. | Operator Cleaning Trim of Door with Swivel Joint | 76 |

| 42. | Swivel Joint, with Screwed Union | 76 |

| 43. | Swivel Joint Having Ball Bearings | 76 |

| 44. | Action of Ball-Bearing Swivel Joint | 77 |

| 45. | Illustration of Defects of Plug Cocks | 78 |

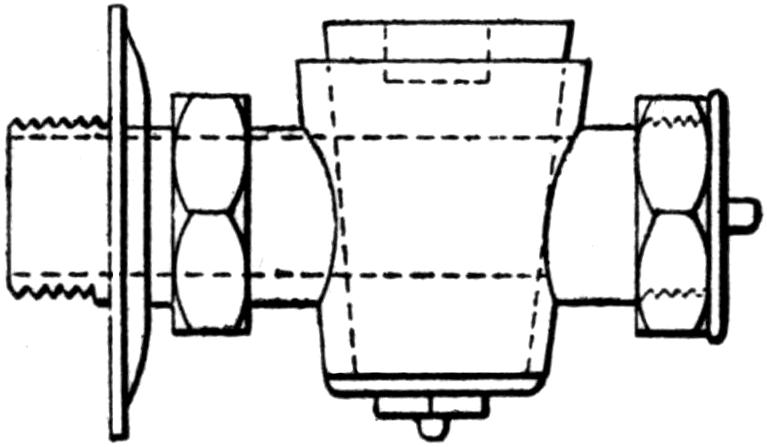

| 46. | Bayonet Type of Hose Coupling, Introduced by the American Air Cleaning Company | 82 |

| 47. | All Rubber Hose Coupling Used by the Spencer Turbine Cleaner Company | 83 |

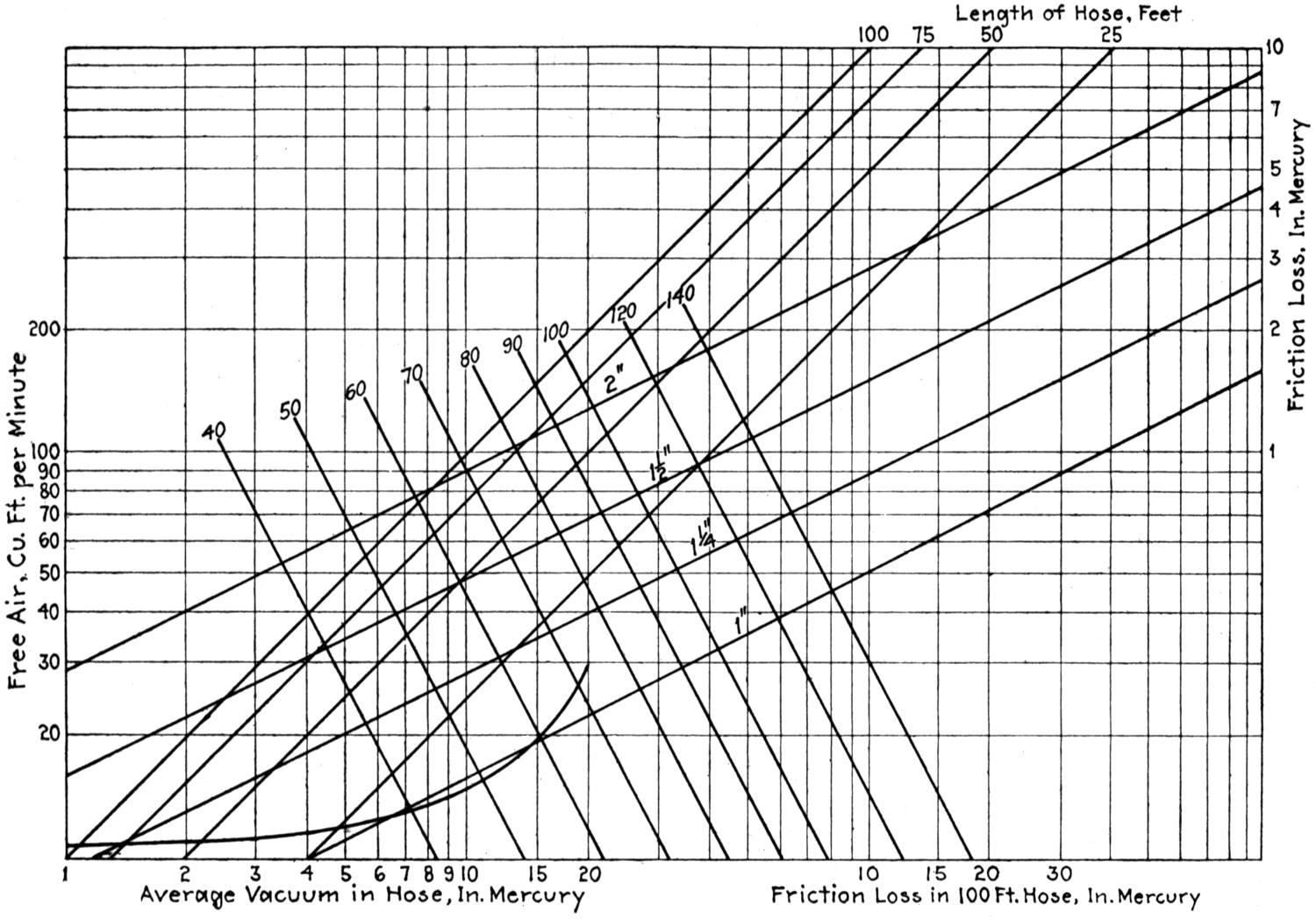

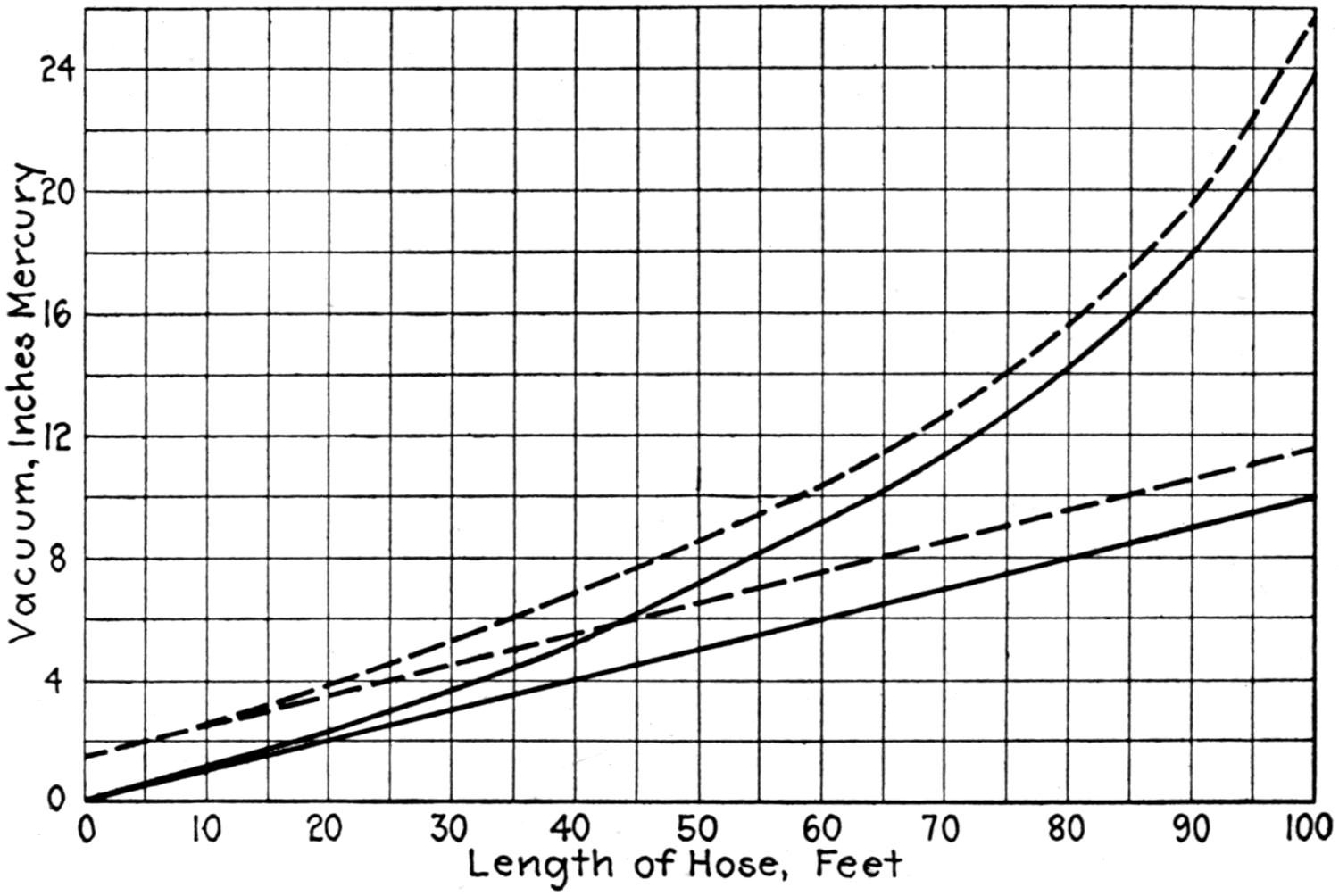

| 48. | Chart for Determining Hose Friction | 86 |

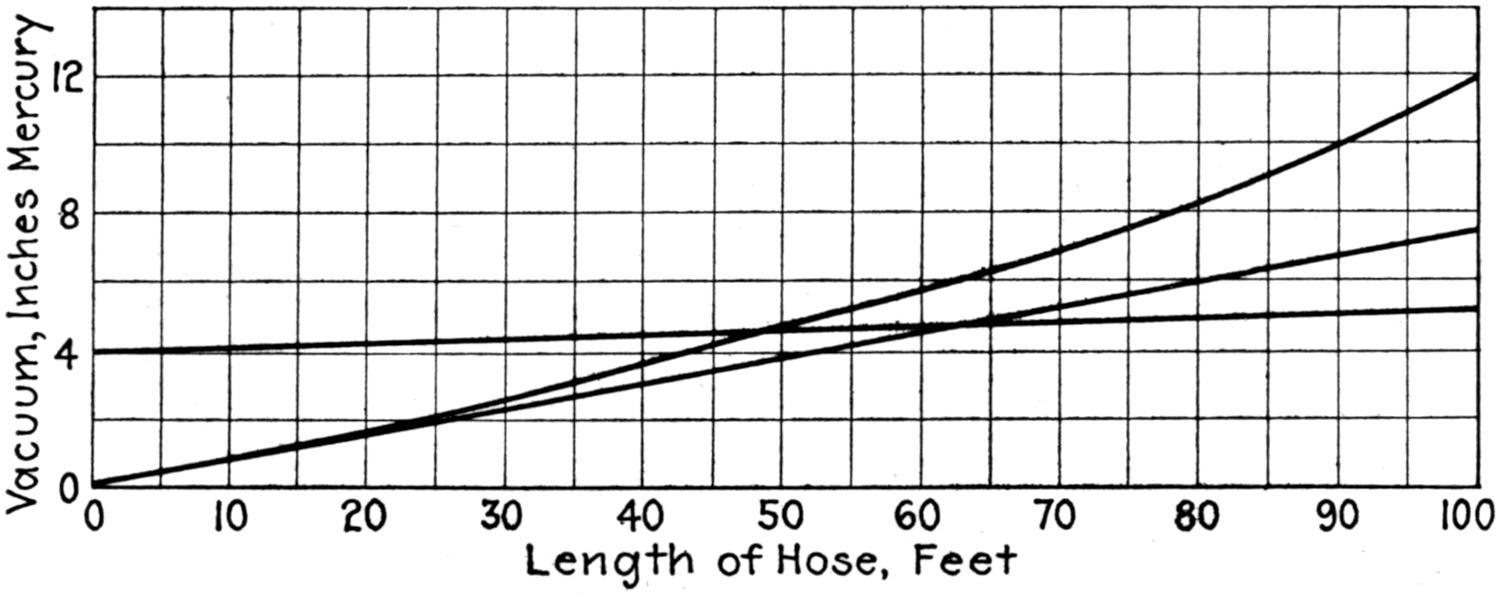

| 49. | Effect of Increase of Velocity on the Friction Loss | 88 |

| 50. | Another Test Showing Friction Loss Due to Velocity | 89 |

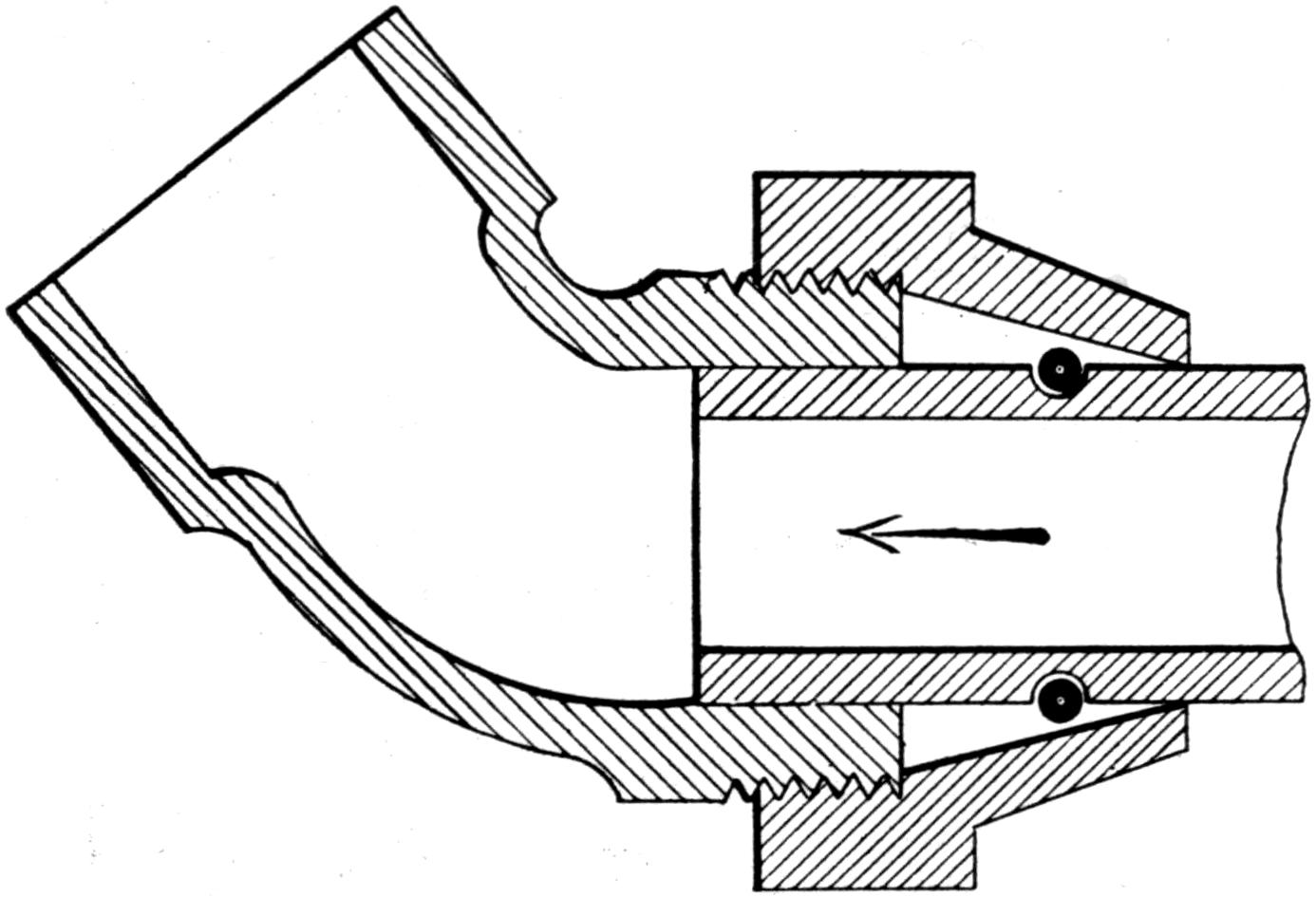

| 51. | Inlet Cock to Prevent Air Leakage when Not in Use | 101 |

| 52. | Type of Automatic Self-Closing Inlet Cock | 102 |

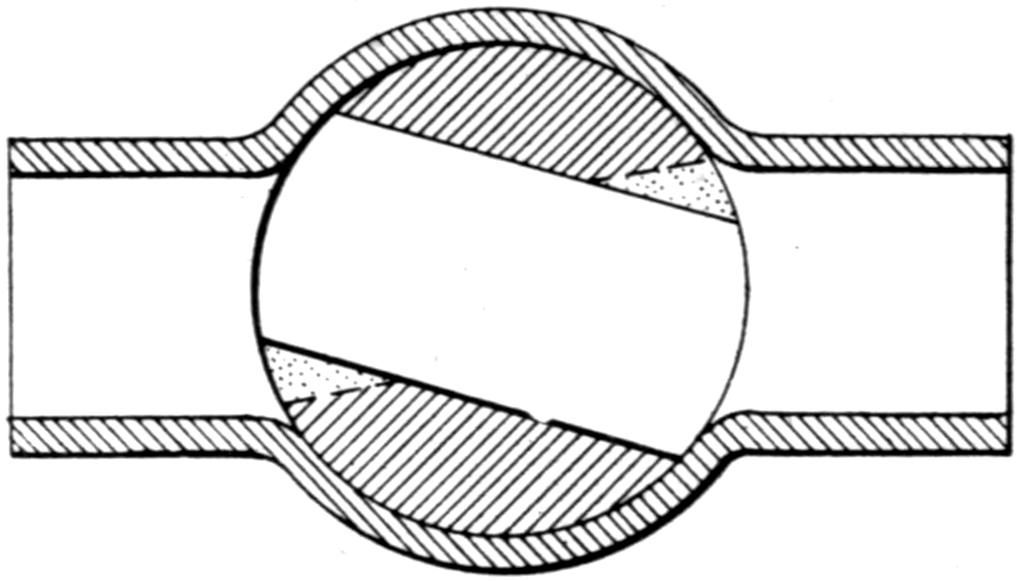

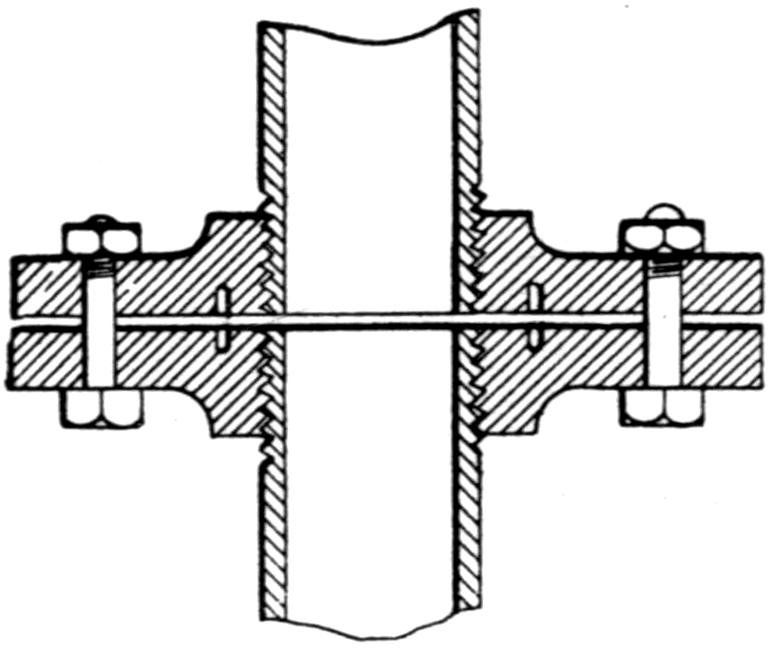

| 53. | “Smooth Bore” Pipe Coupling | 103 |

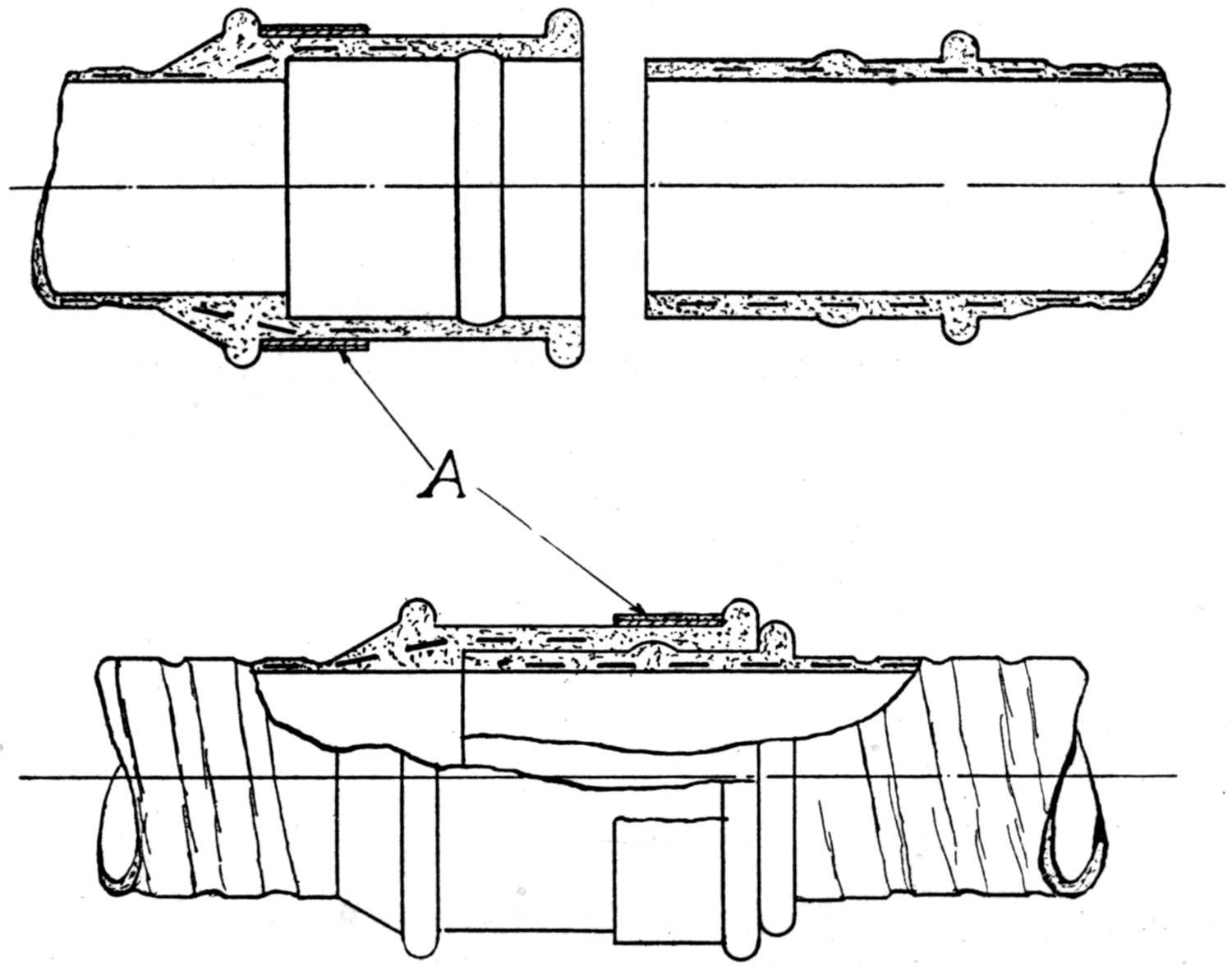

| 54. | Joint Made of Standard Pipe Flanges | 104 |

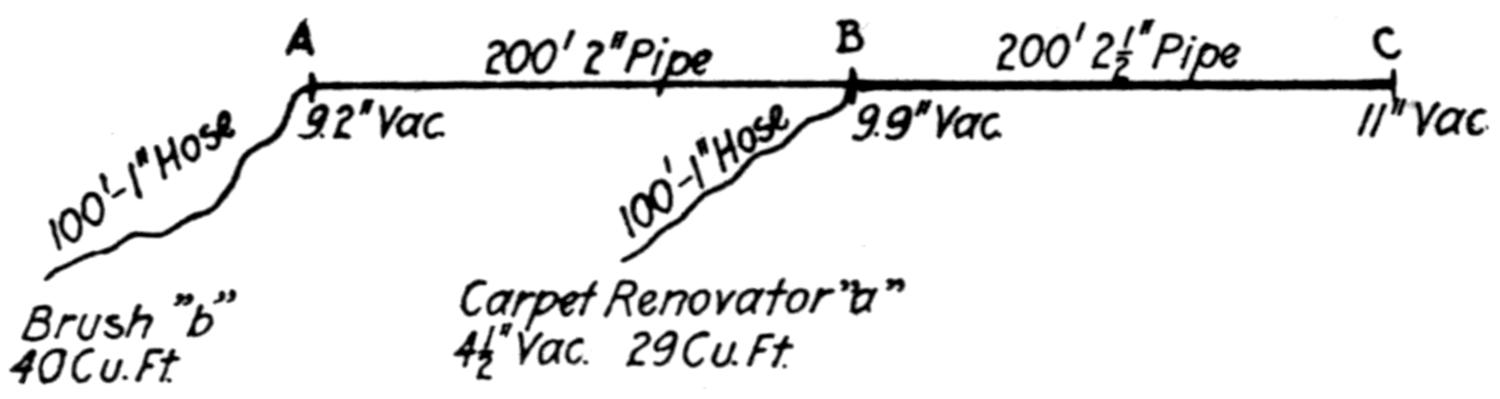

| 55. | Standard Durham Recessed Drainage Fittings Generally Used in Vacuum Cleaning Installations | 105 |

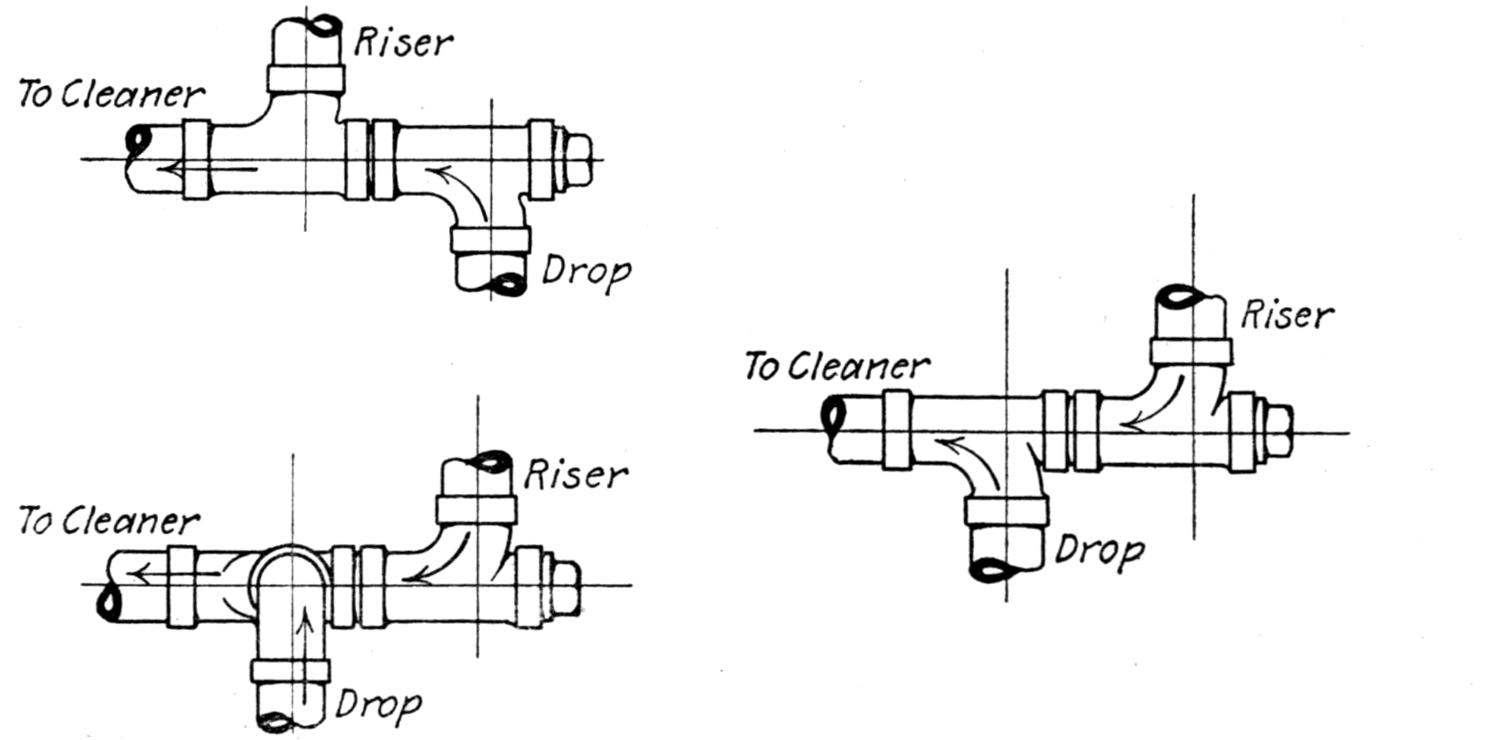

| 56. | Friction Loss in Pipe Lines | 106 |

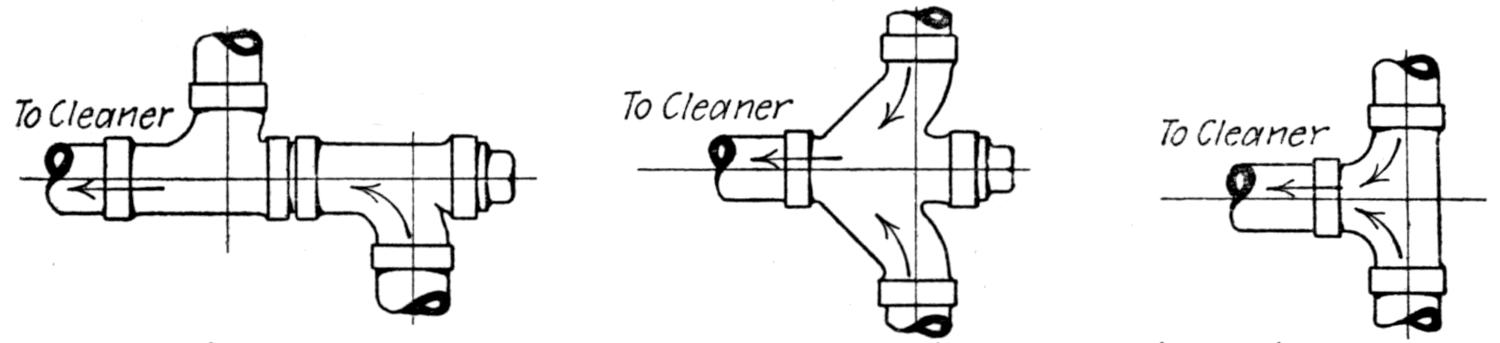

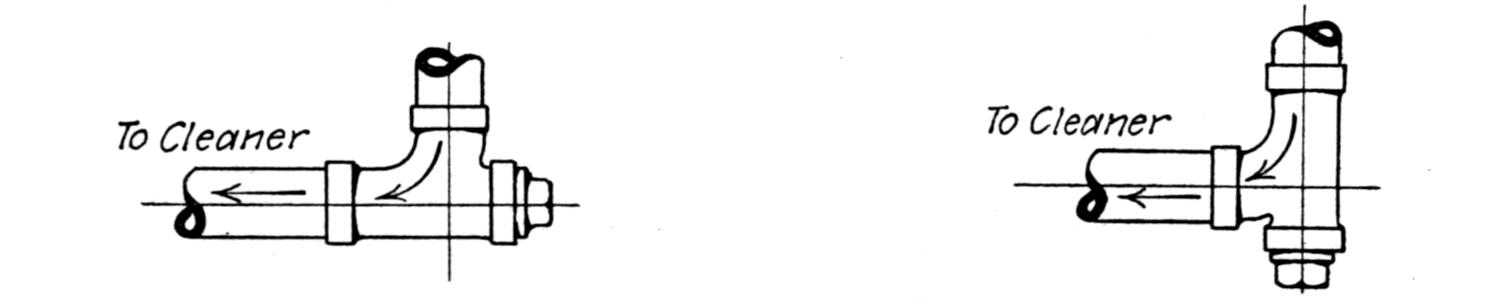

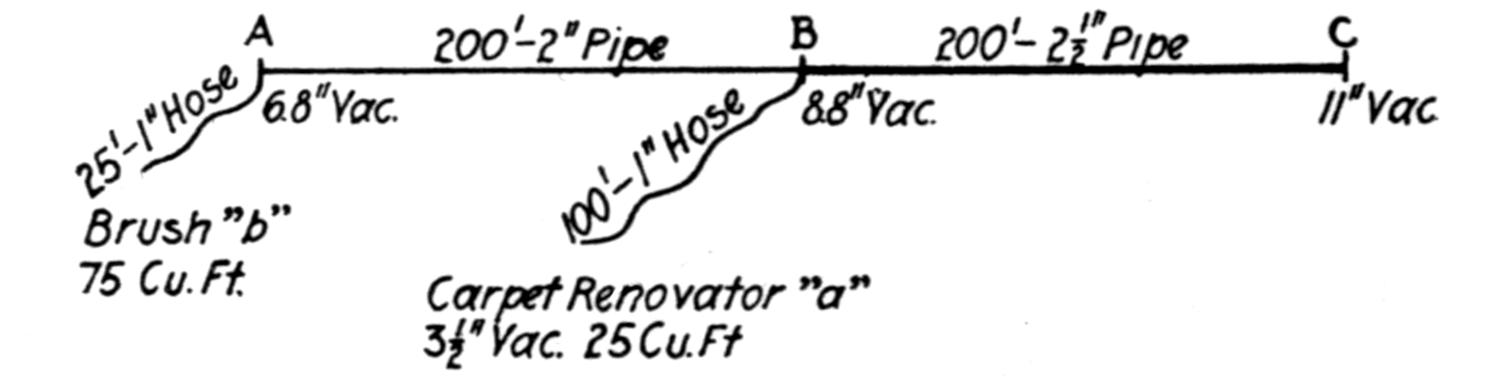

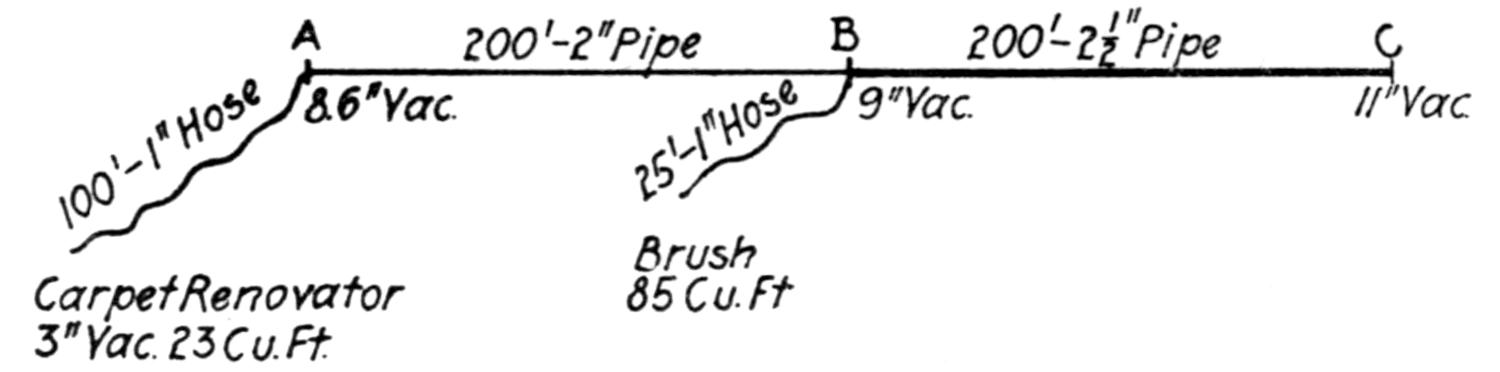

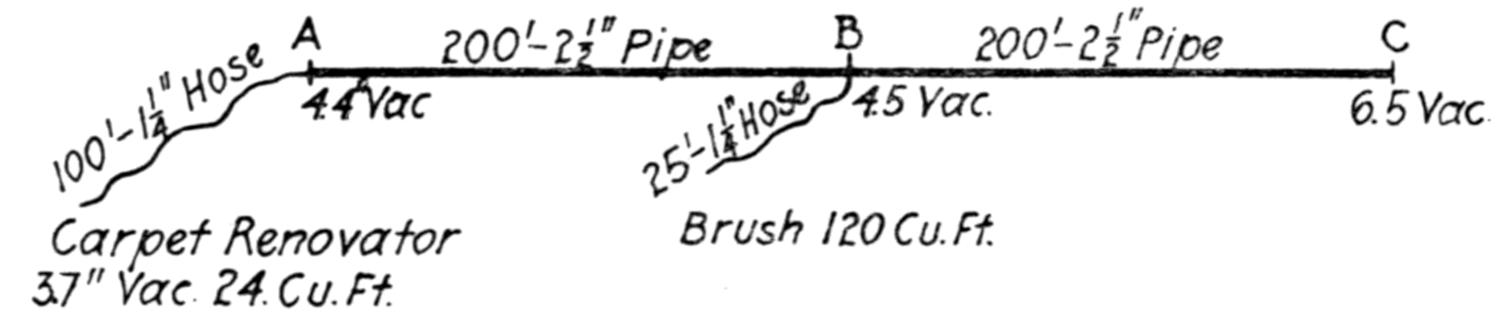

| 57-60. | Diagrams Showing Operation of Brush and Carpet Renovators Under Different Conditions | 110 |

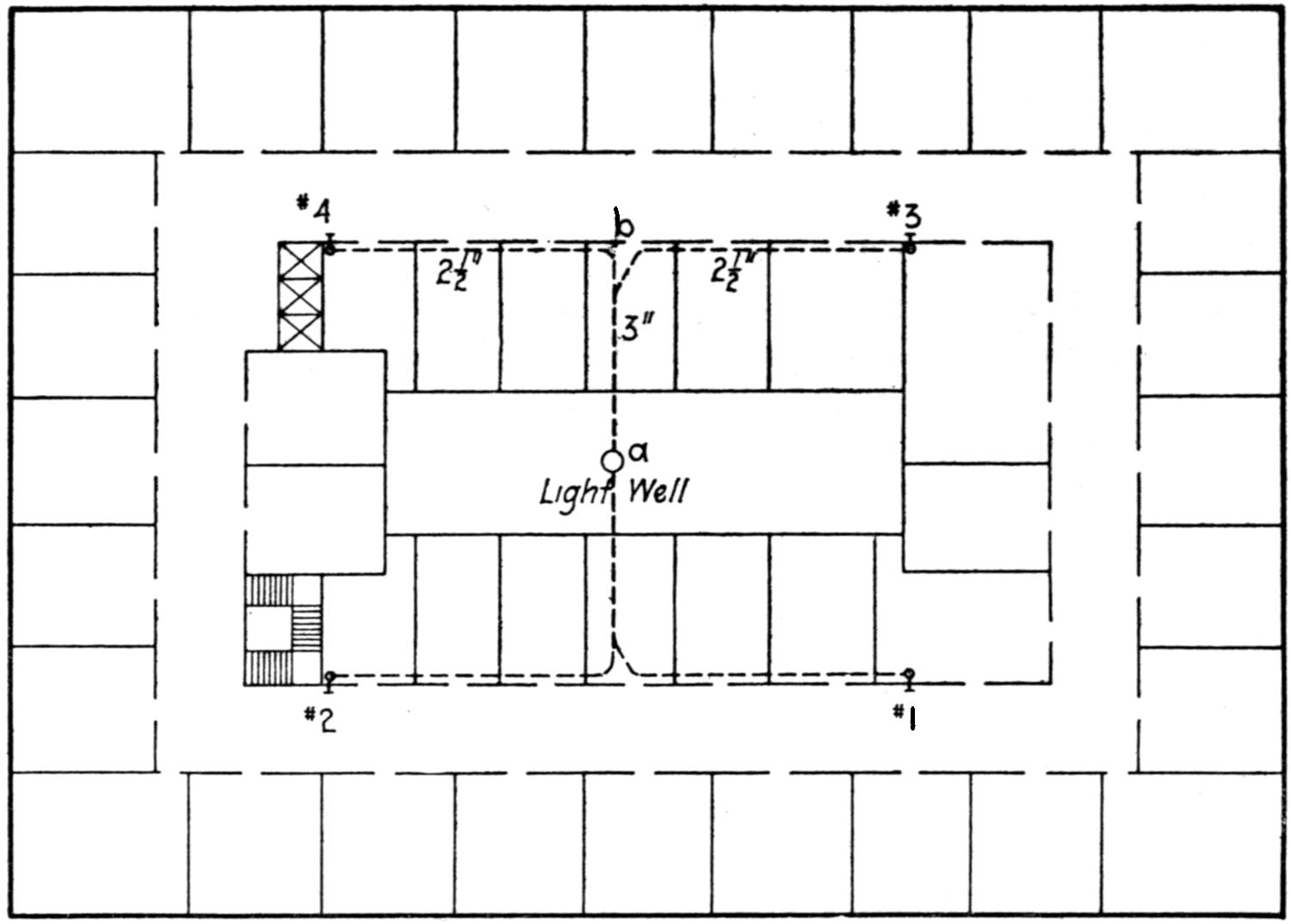

| 61. | Typical Floor Plan of Office Building Illustrating Number of Sweepers Required | 114 |

| 62. | Plan of Layout for Office Building Showing Best Location (at d) for Vacuum Producer | 118 |

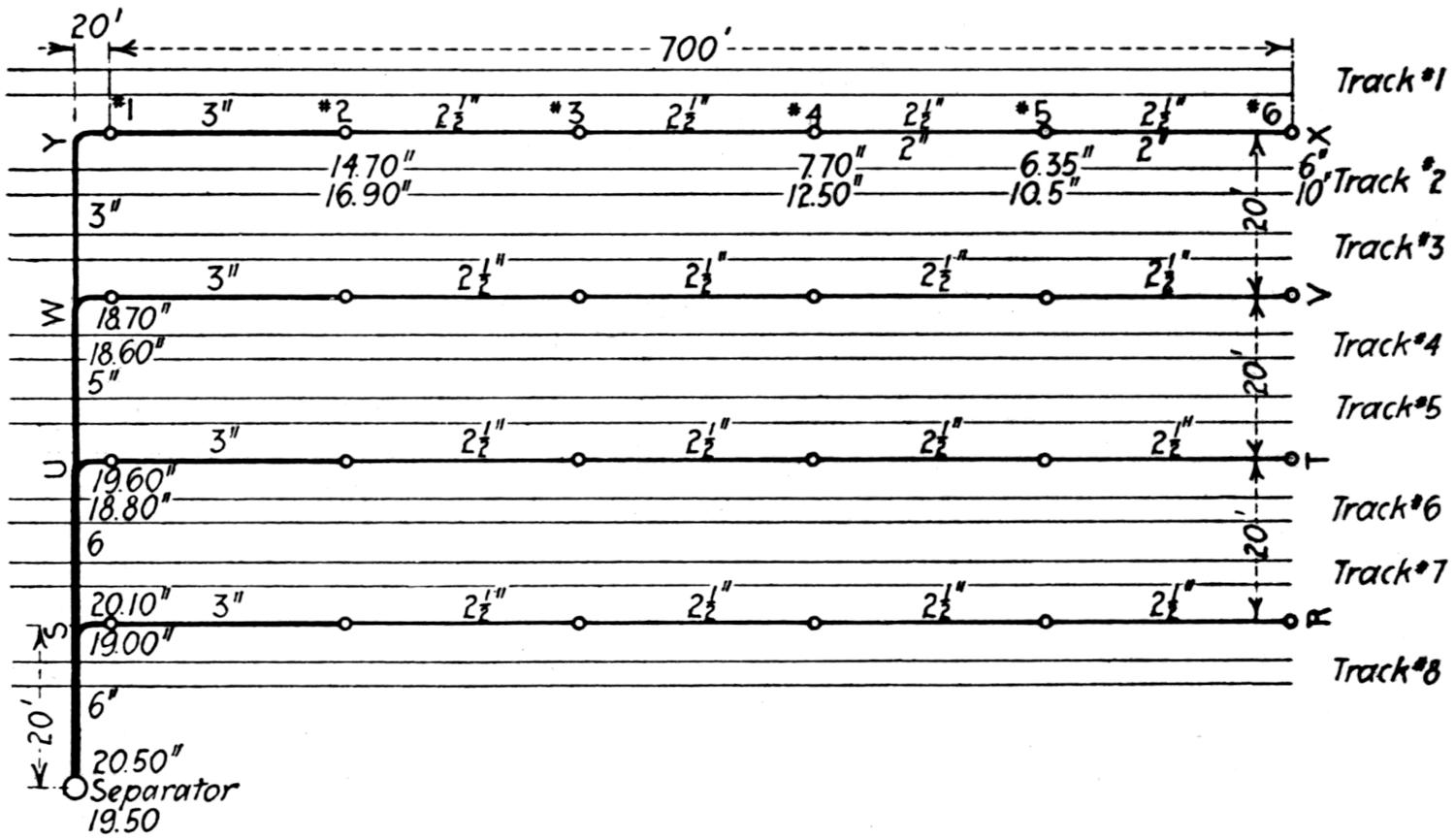

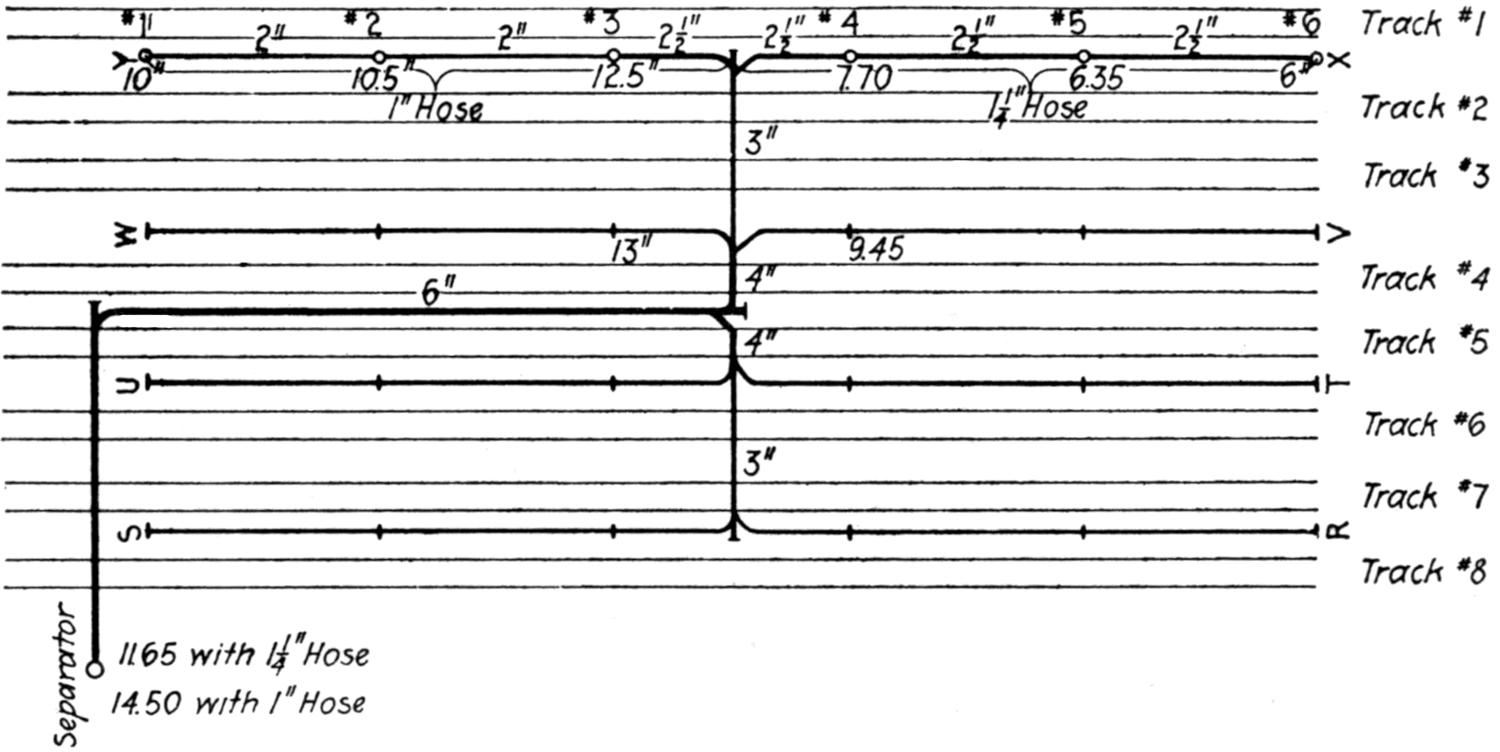

| 63. | Vacuum Cleaning Layout for a Passenger Car Storage Yard | 122 |

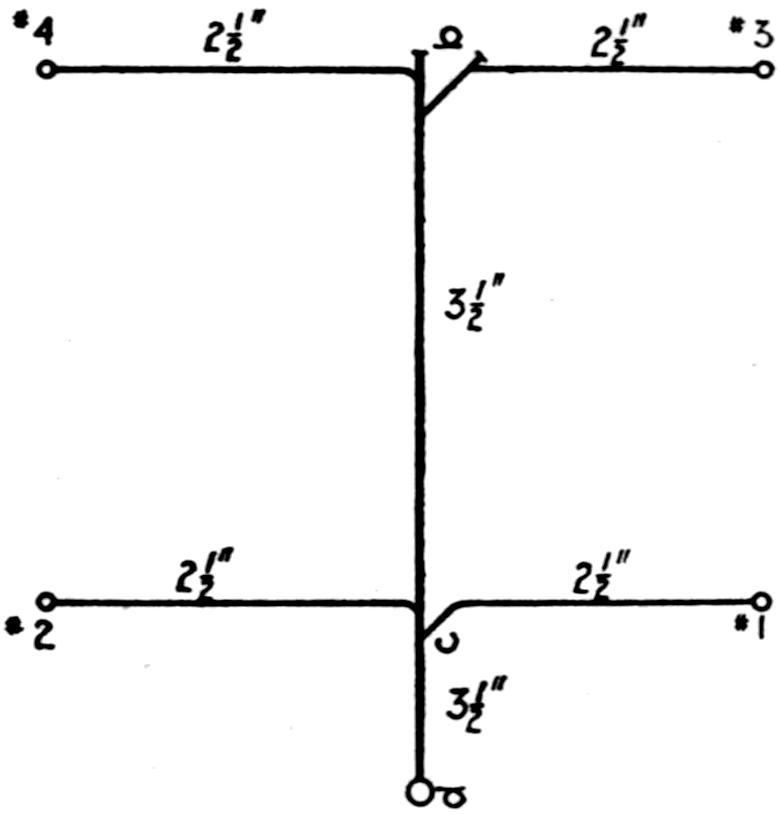

| 64. | Arrangement of Piping Recommended as Best for Passenger Car Storage Yard | 123 |

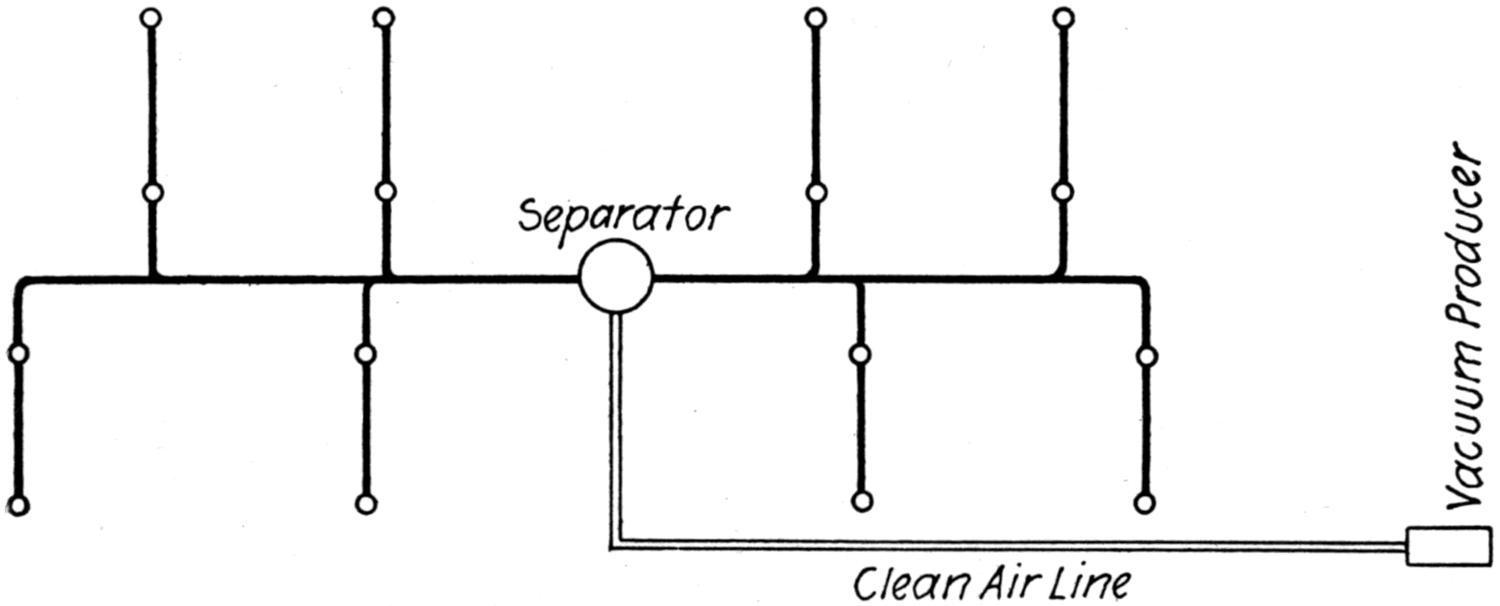

| 65. | Good Location for Dust Separator Where Large Areas Are Served by One Cleaning System | 125 |

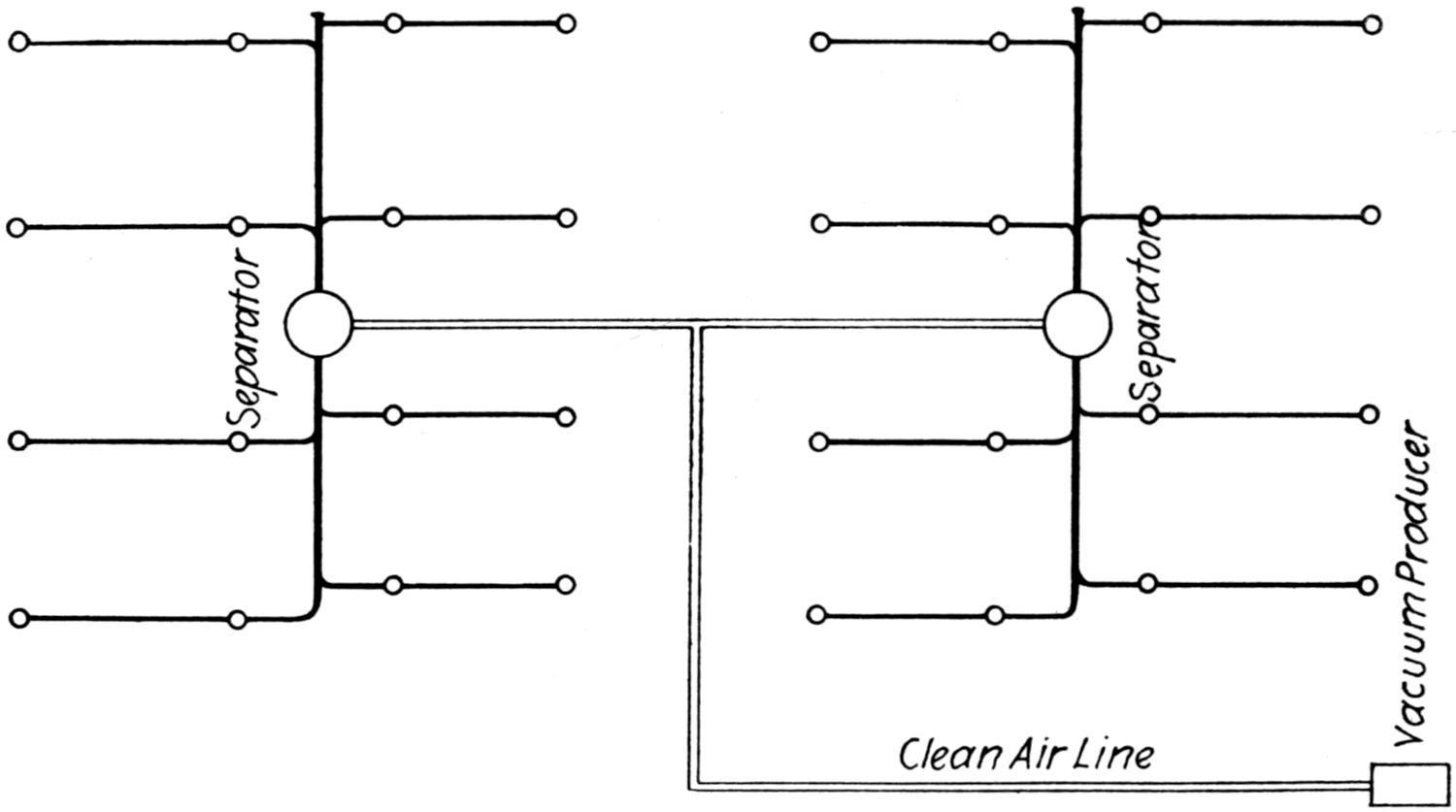

| 66. | Location of Separators at Centers of Groups of Risers for Large Systems[xiii] | 126 |

| 67. | Early Type of Primary Separator, Used by Vacuum Cleaner Company | 128 |

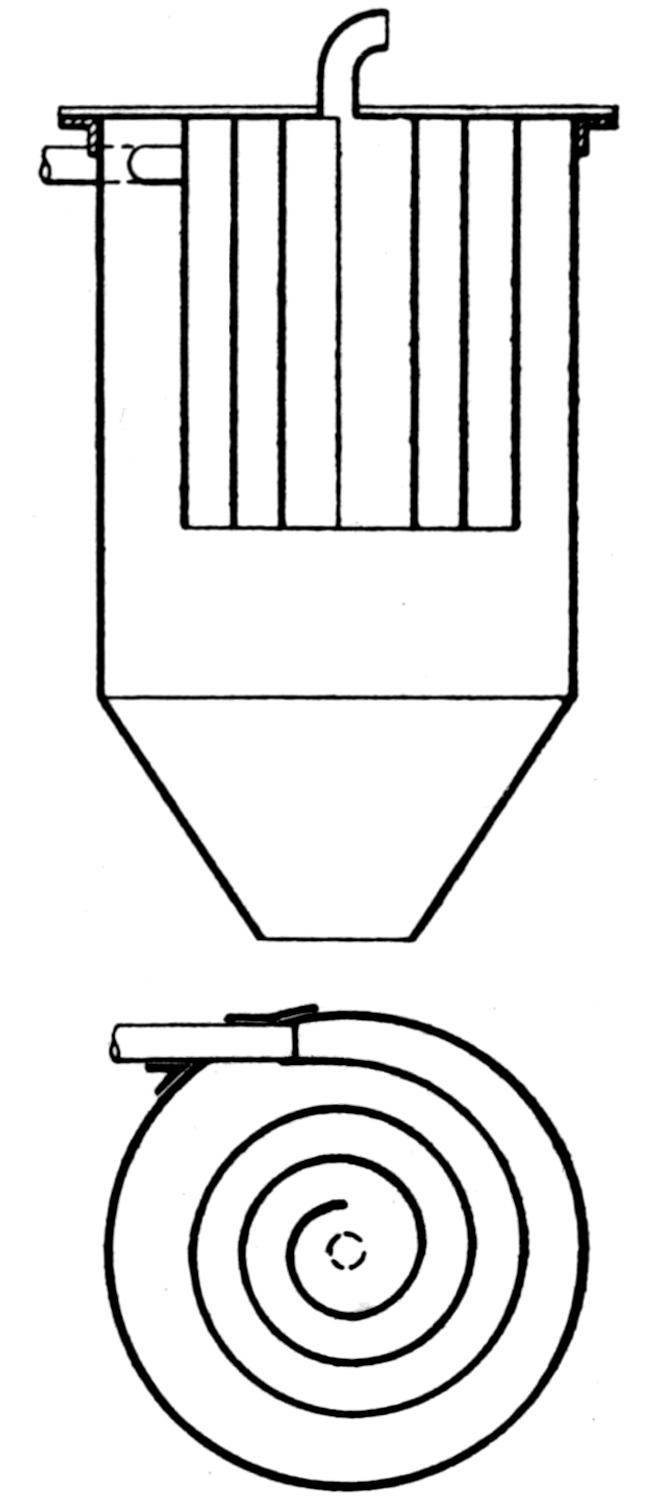

| 68. | Primary Separator Used by the Sanitary Devices Manufacturing Company | 128 |

| 69. | Primary Separator Used by the General Compressed Air and Vacuum Cleaning Company | 129 |

| 70. | Primary Separator Made by the Blaisdell Engineering Co. | 129 |

| 71. | Secondary Separator Used by the Vacuum Cleaner Company | 131 |

| 72. | Secondary Separator Used by the General Compressed Air and Vacuum Cleaning Company | 131 |

| 73. | Secondary Separator Used by the Sanitary Devices Manufacturing Company | 132 |

| 74. | Type of Dry Separator Used as Secondary Separator | 134 |

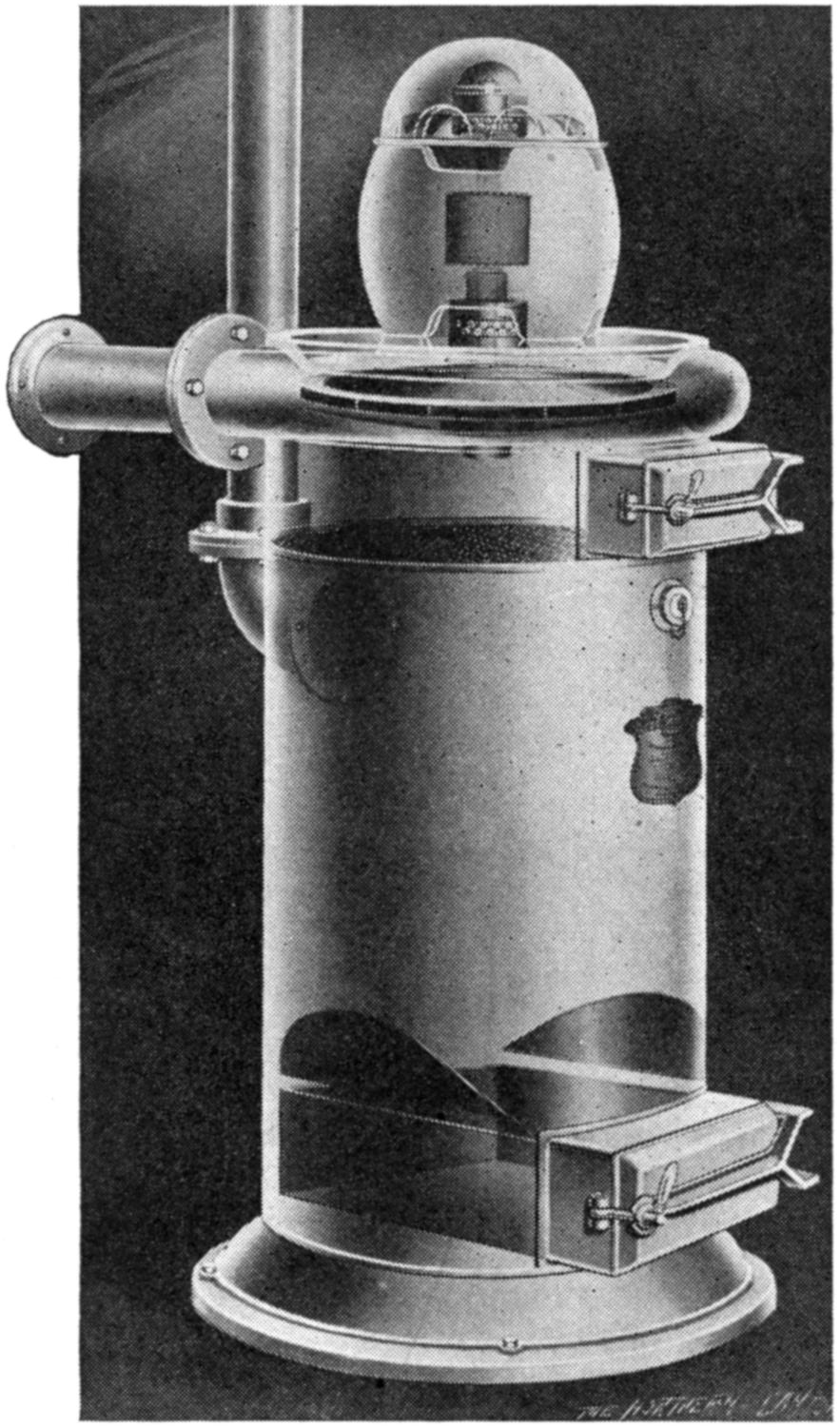

| 75. | Form of Complete Separator Used by the Vacuum Cleaner Company | 135 |

| 76. | Complete Separator Brought Out by the Electric Renovator Manufacturing Company | 136 |

| 77. | Complete Separator Made by the American Radiator Company | 137 |

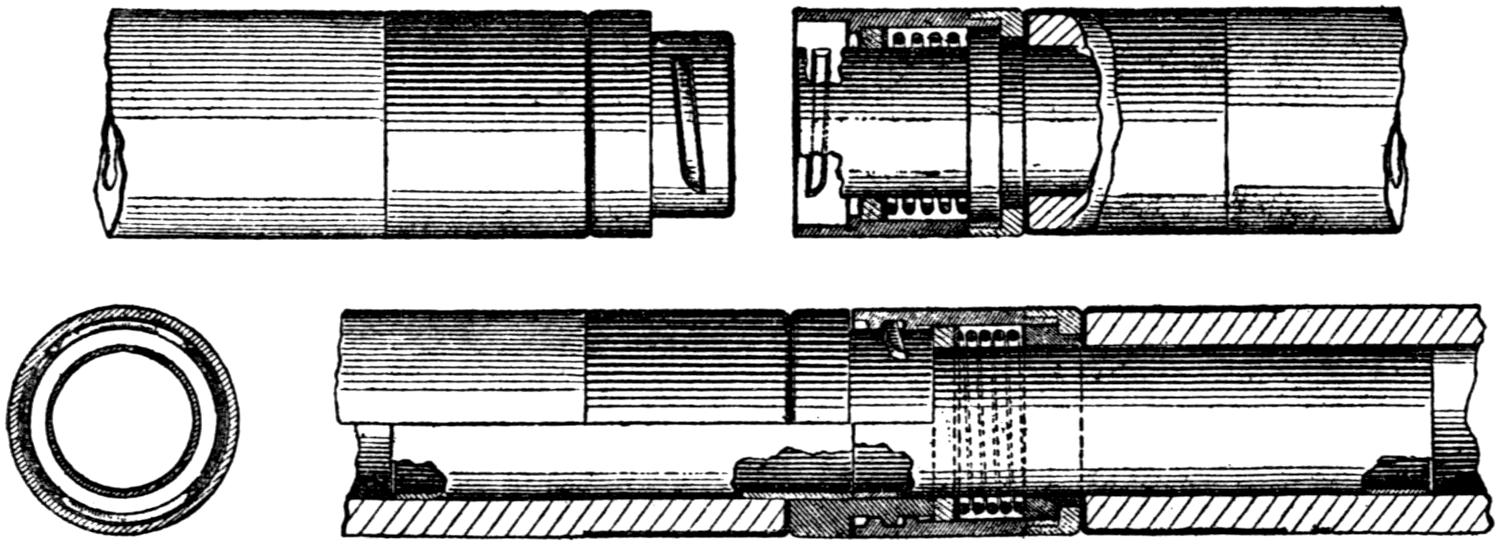

| 77a. | Interior Construction of Dunn Vacuum Cleaning Machine | 140 |

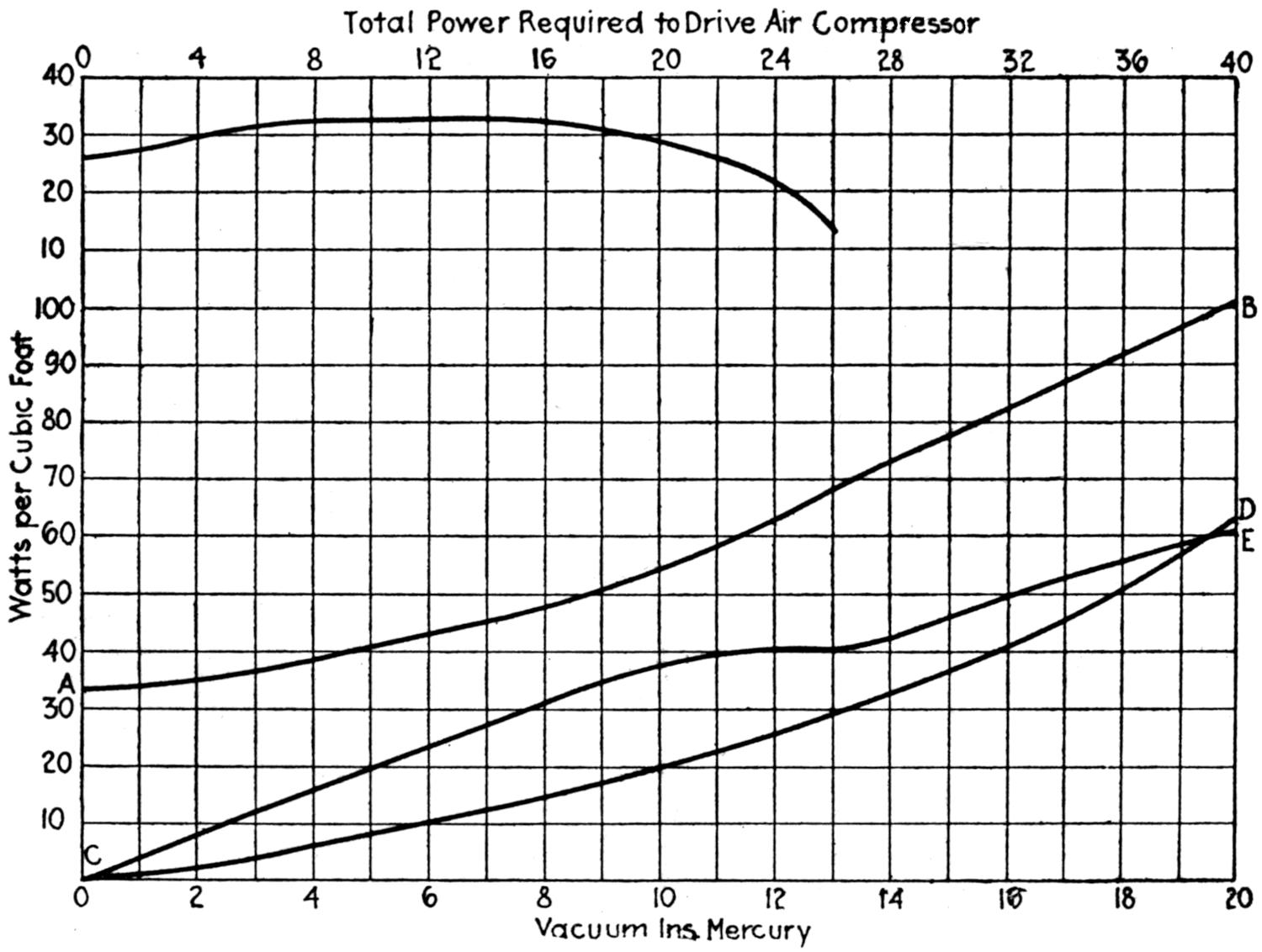

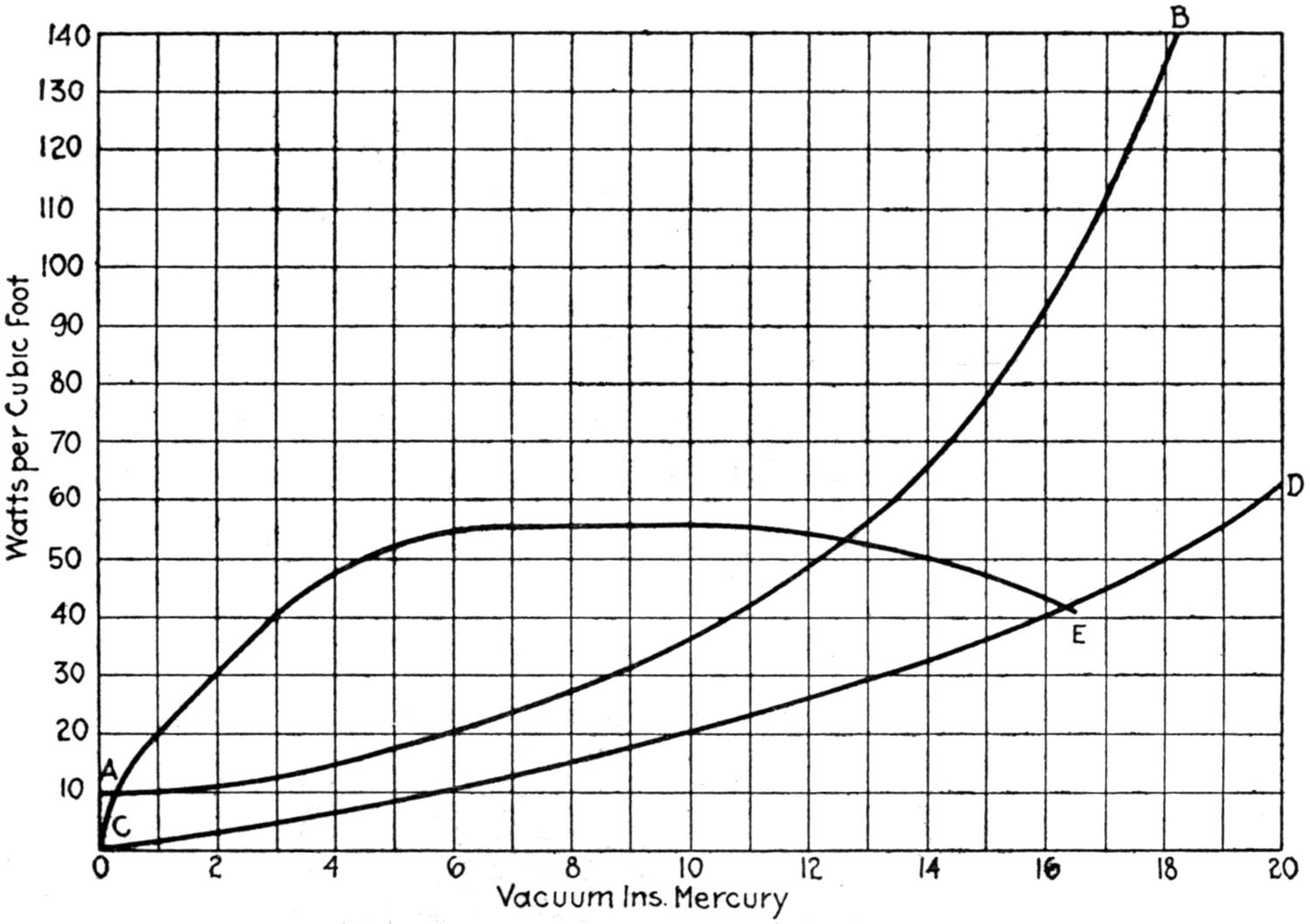

| 78. | Power Consumption and Efficiency of Air Compressor Used as a Vacuum Pump | 143 |

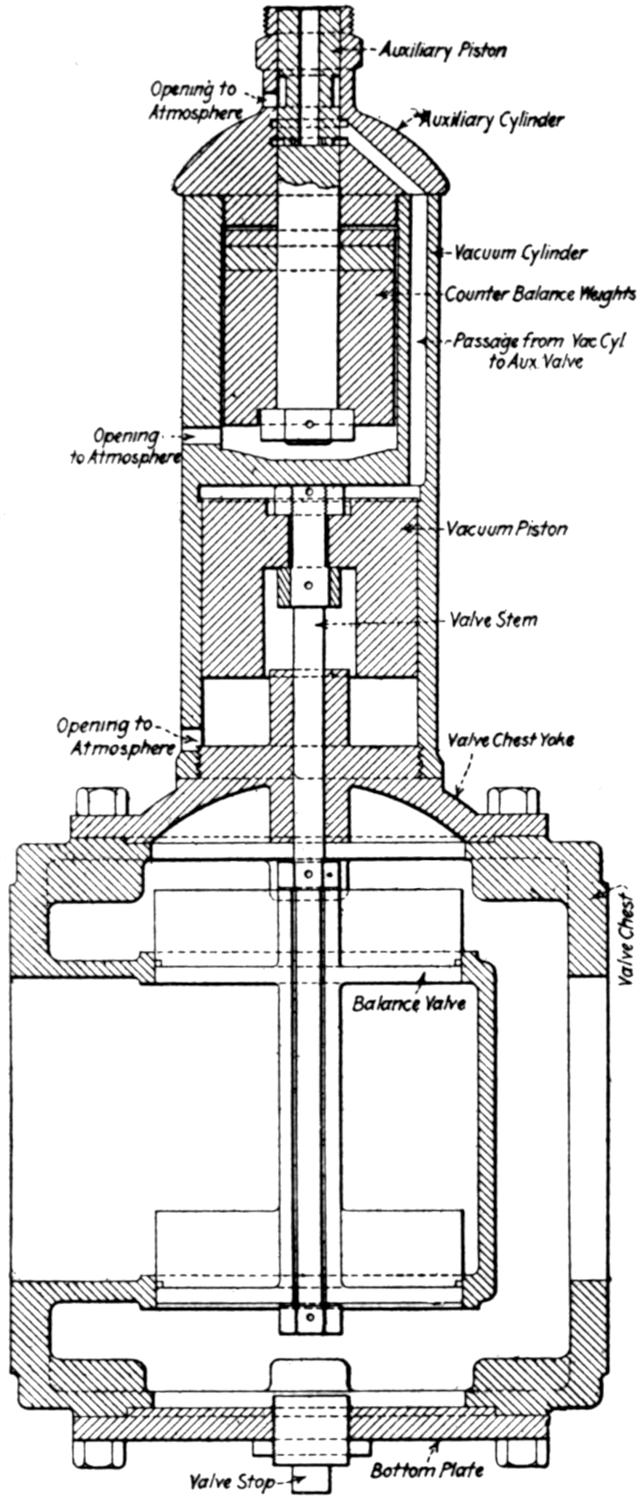

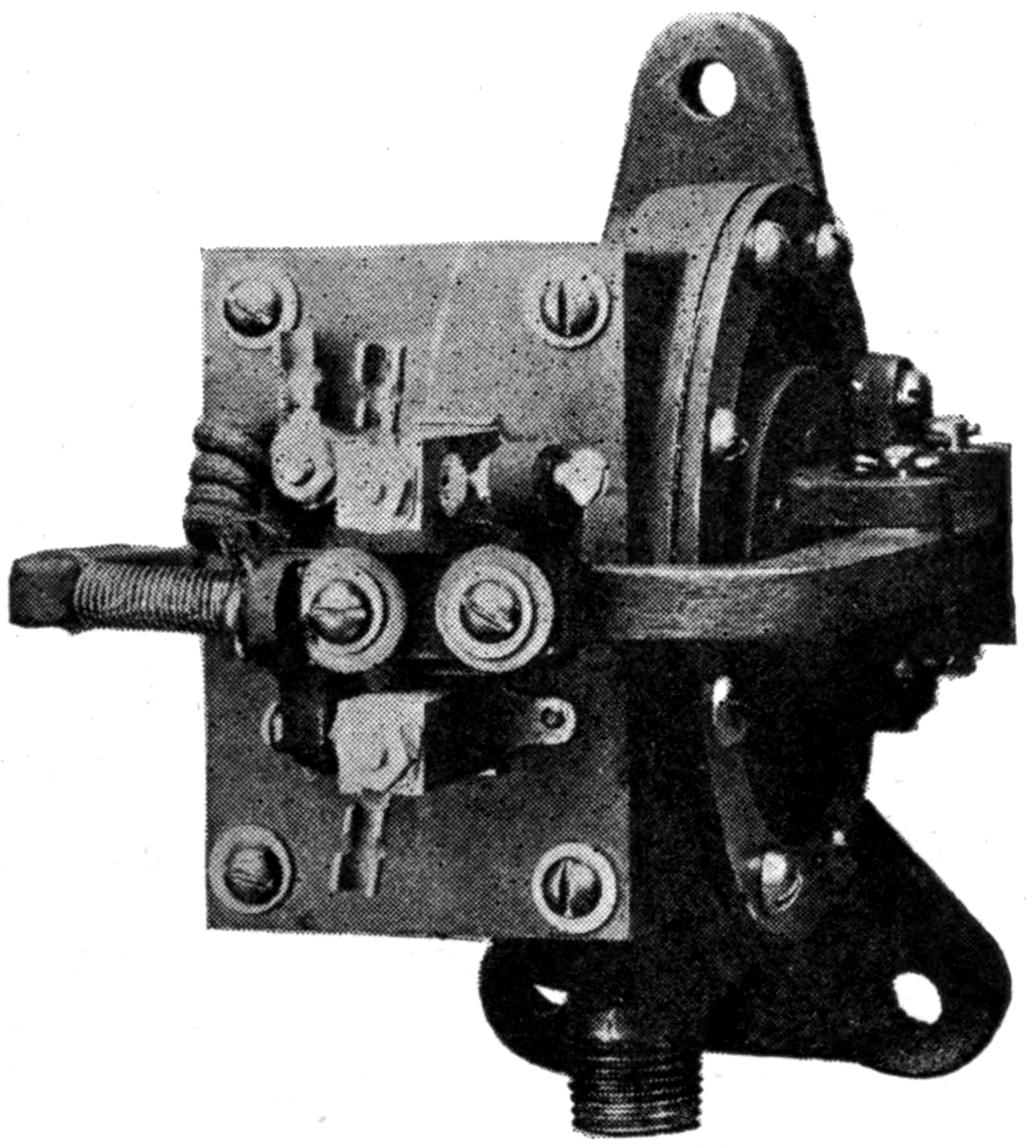

| 79. | Modification of Reciprocating Pump Made by the Sanitary Devices Manufacturing Company | 144 |

| 80. | Power Consumption and Efficiency of Modified Reciprocating Pump | 145 |

| 81 and 82. | Indicator Cards for Clayton and Modified Pumps | 146 |

| 83. | One of the Pumps Installed in Connection with the Vacuum Cleaning System in the New York Post Office, the Largest Reciprocating Pump Used for this Purpose up to the Present | 148 |

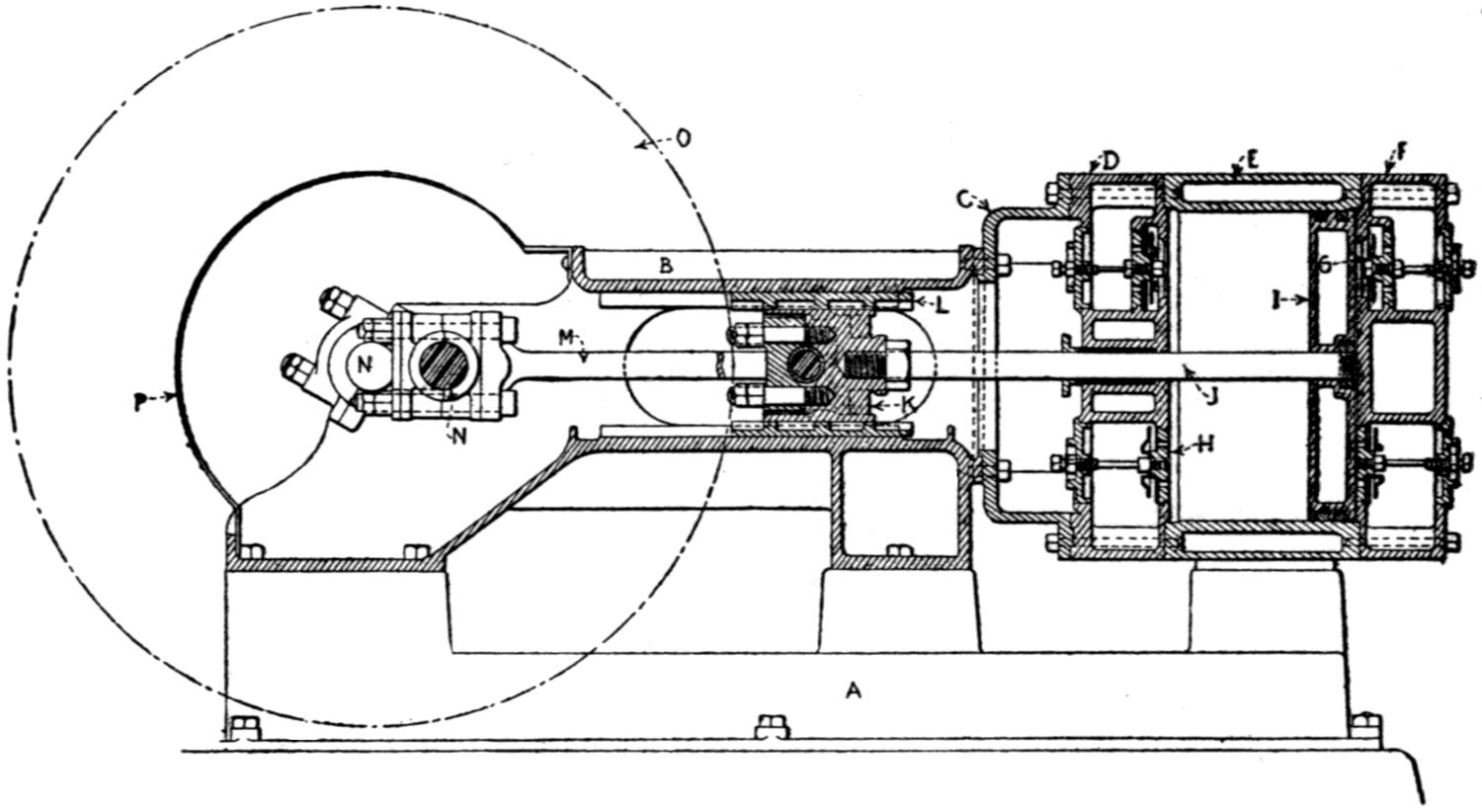

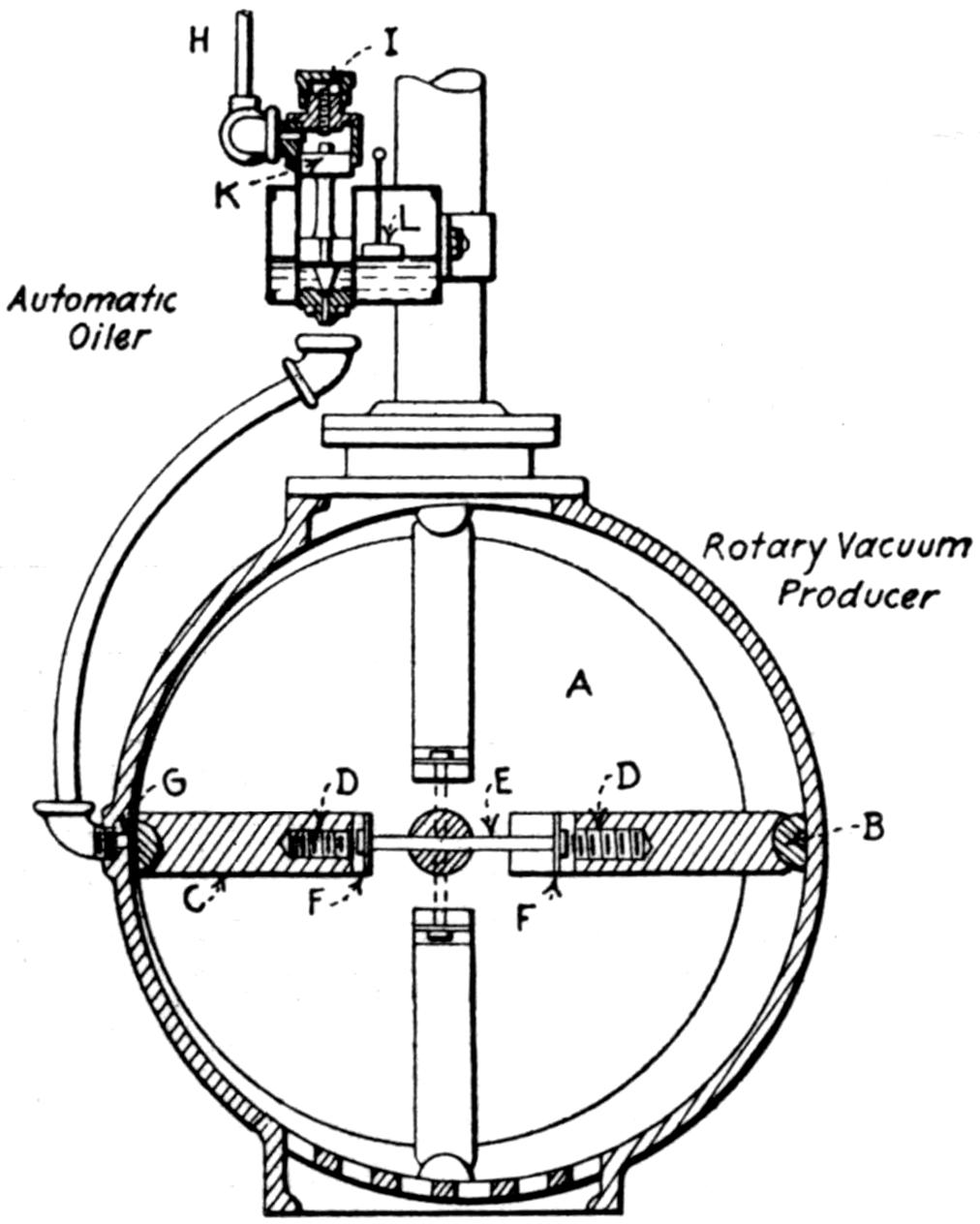

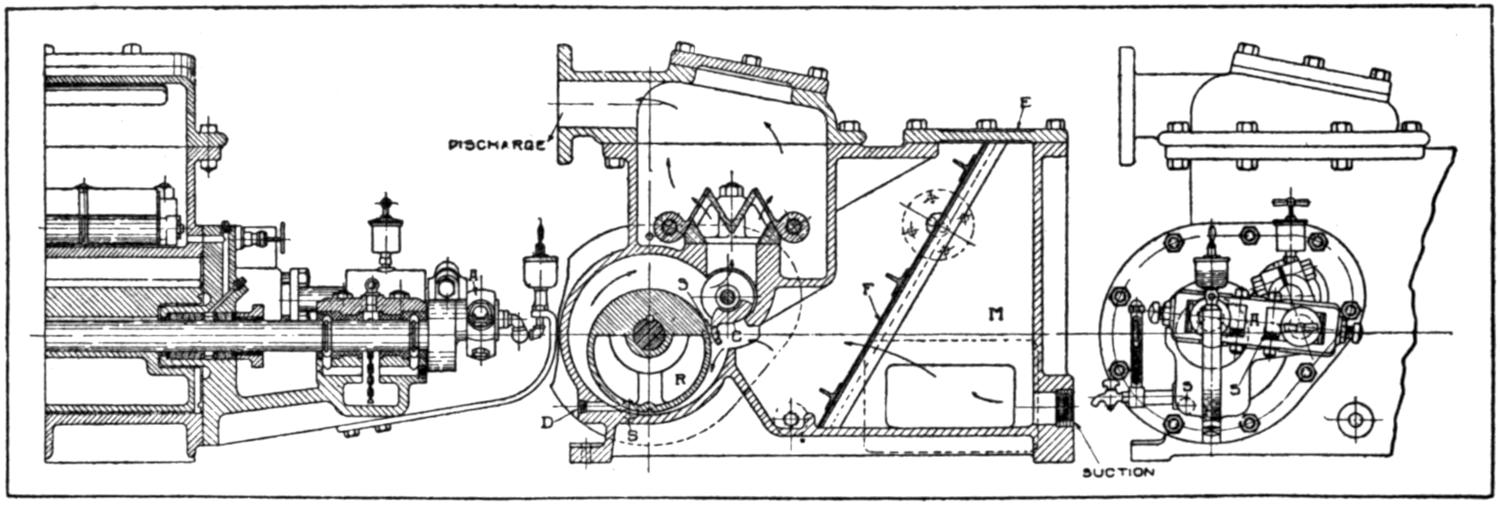

| 84. | Interior Arrangement of the Garden City Rotary Pump | 149 |

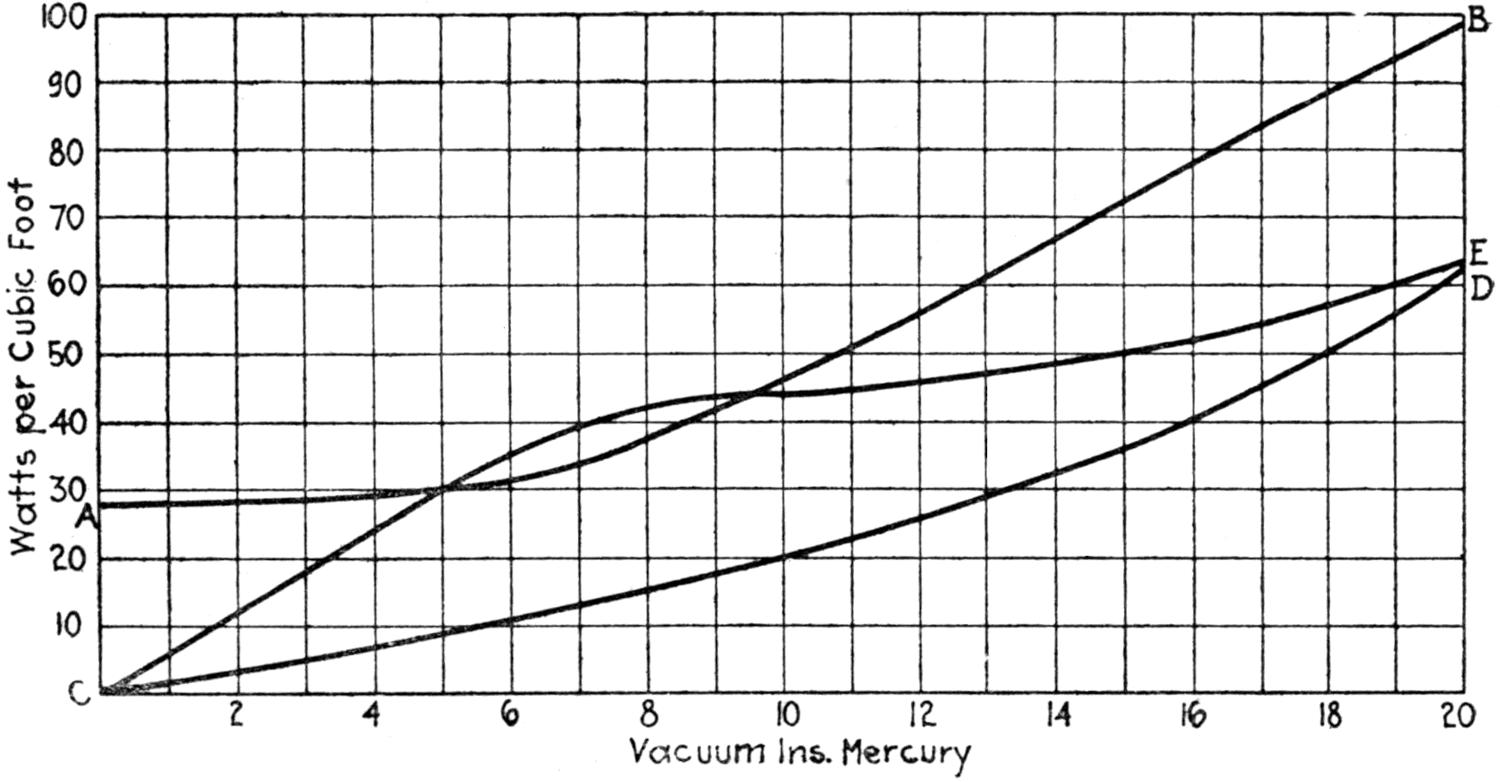

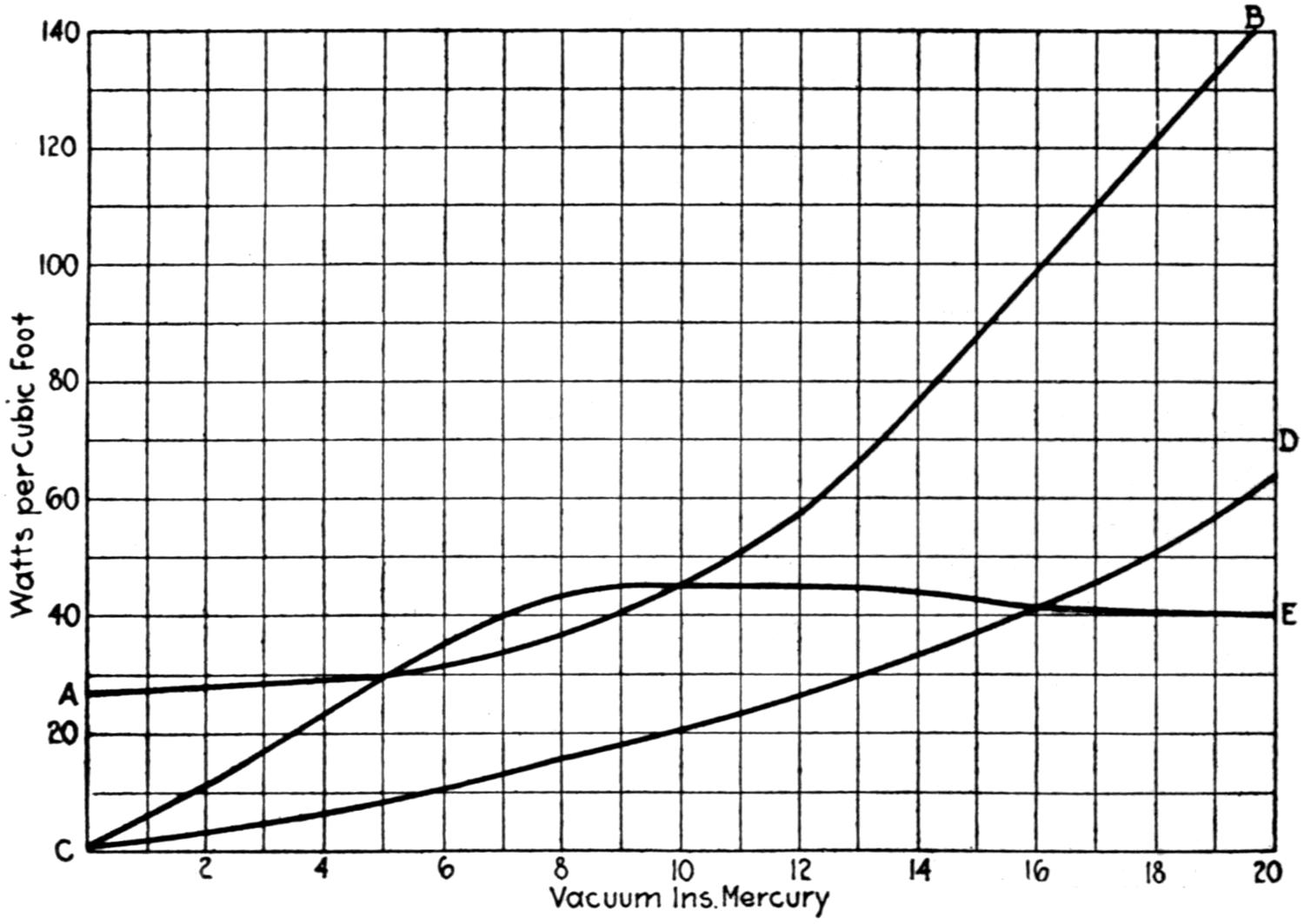

| 85. | Power Required to Operate Garden City Type of Rotary Pump | 150 |

| 86. | Arrangement of Double-Impeller Root Type Rotary Pump for Vacuum Cleaning Work | 151 |

| 87. | Rotary Pump Arranged with Double-Throw Switch for Reversing Pump | 152 |

| 88. | Power Consumption and Efficiency of Root Type of Pump | 153 |

| 89. | The Rotrex Vacuum Pump, Used by the Vacuum Engineering Company | 153 |

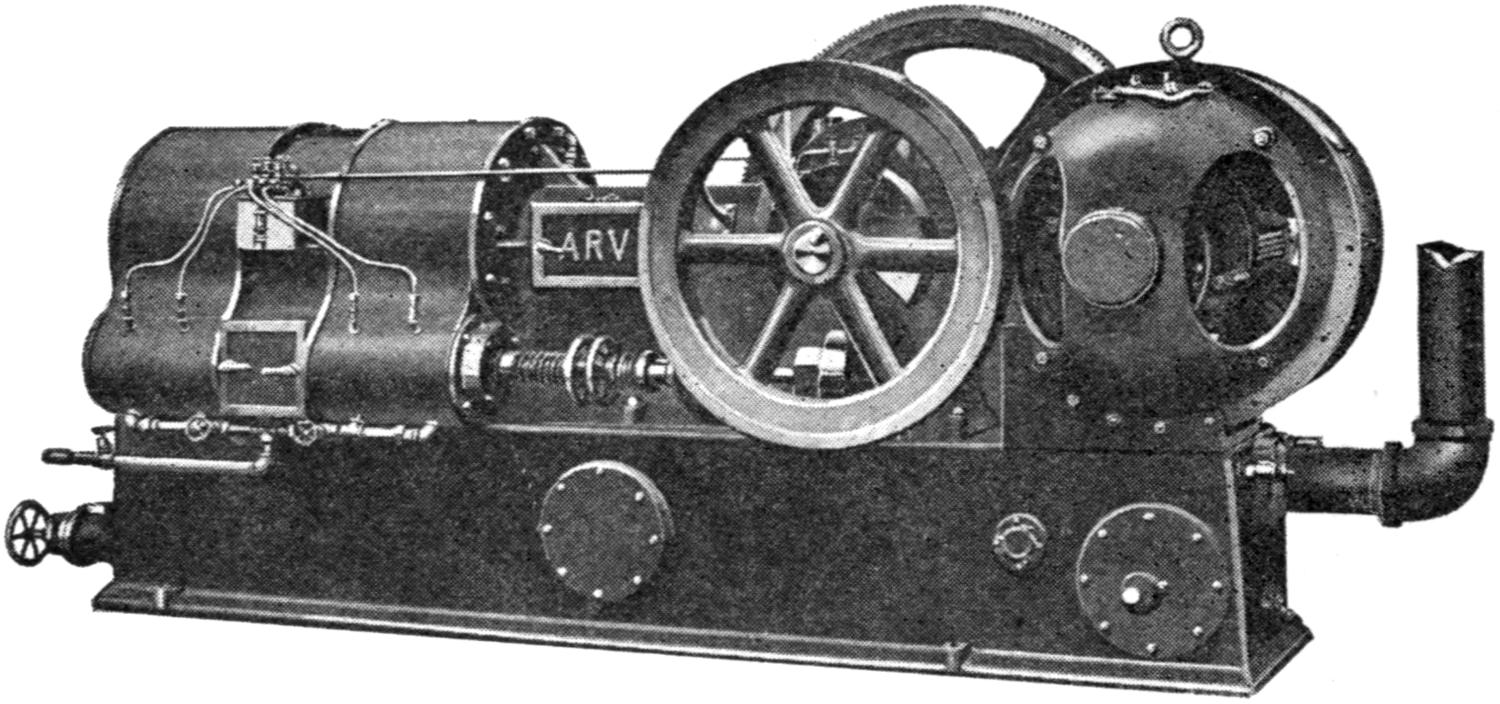

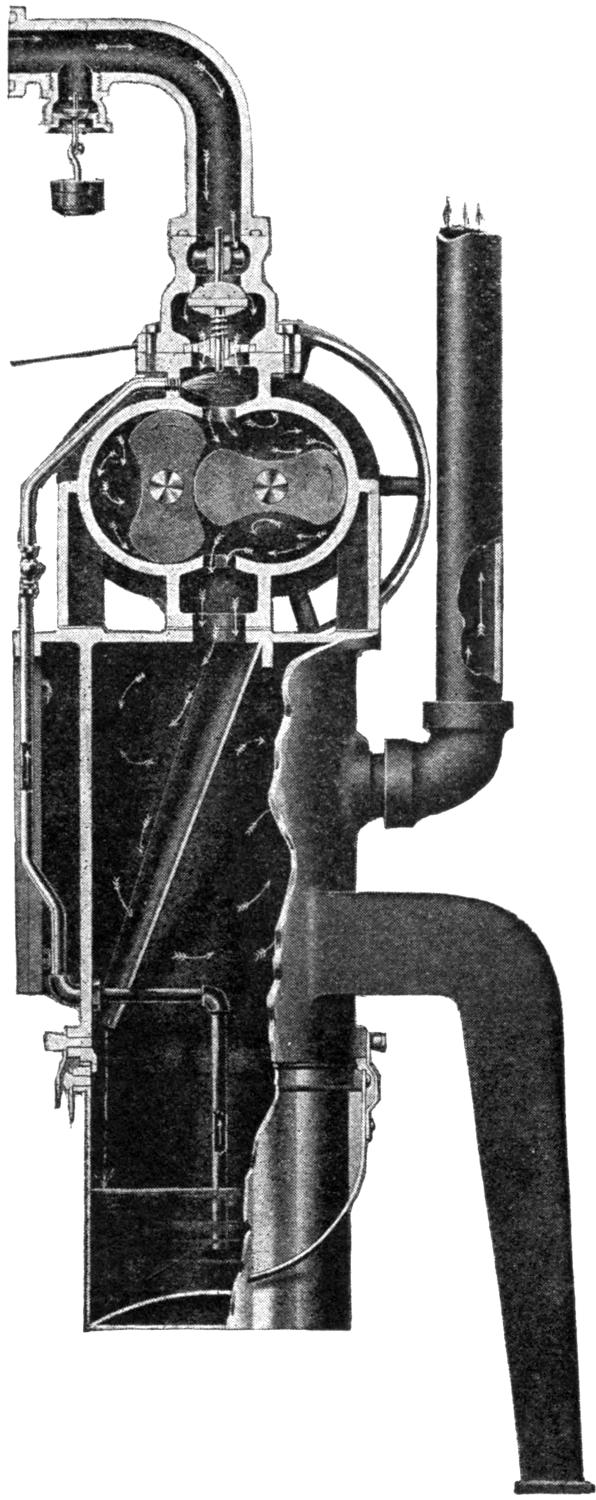

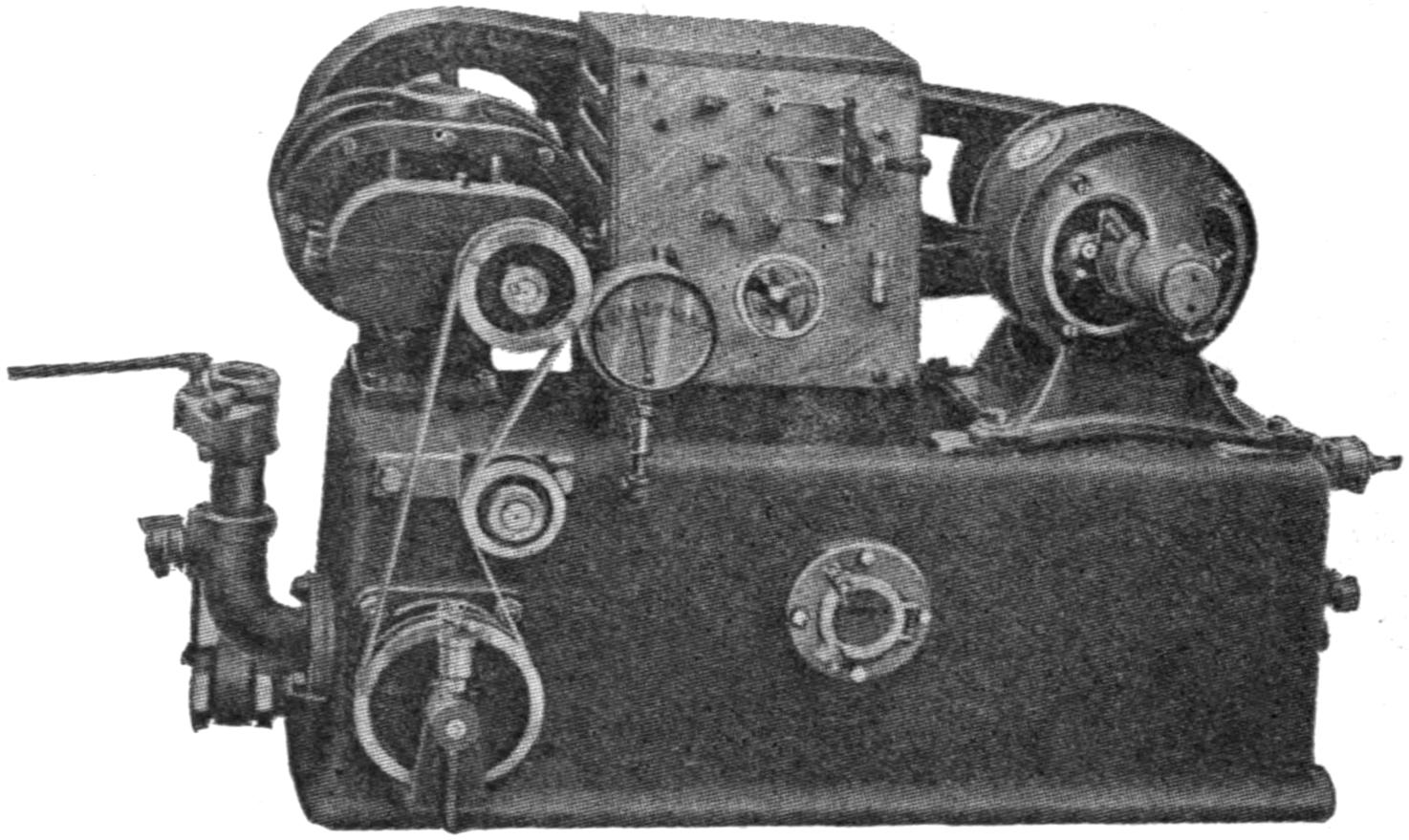

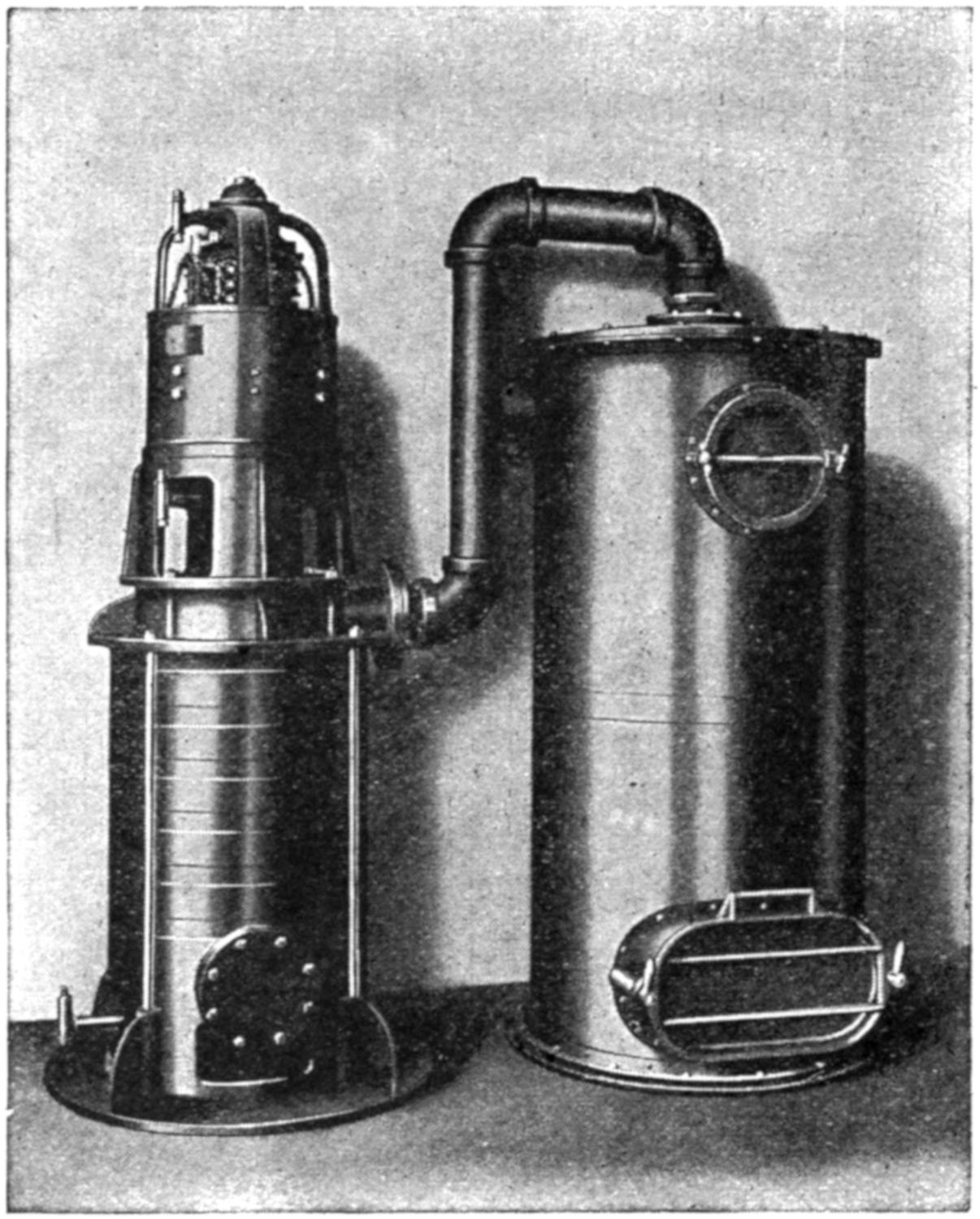

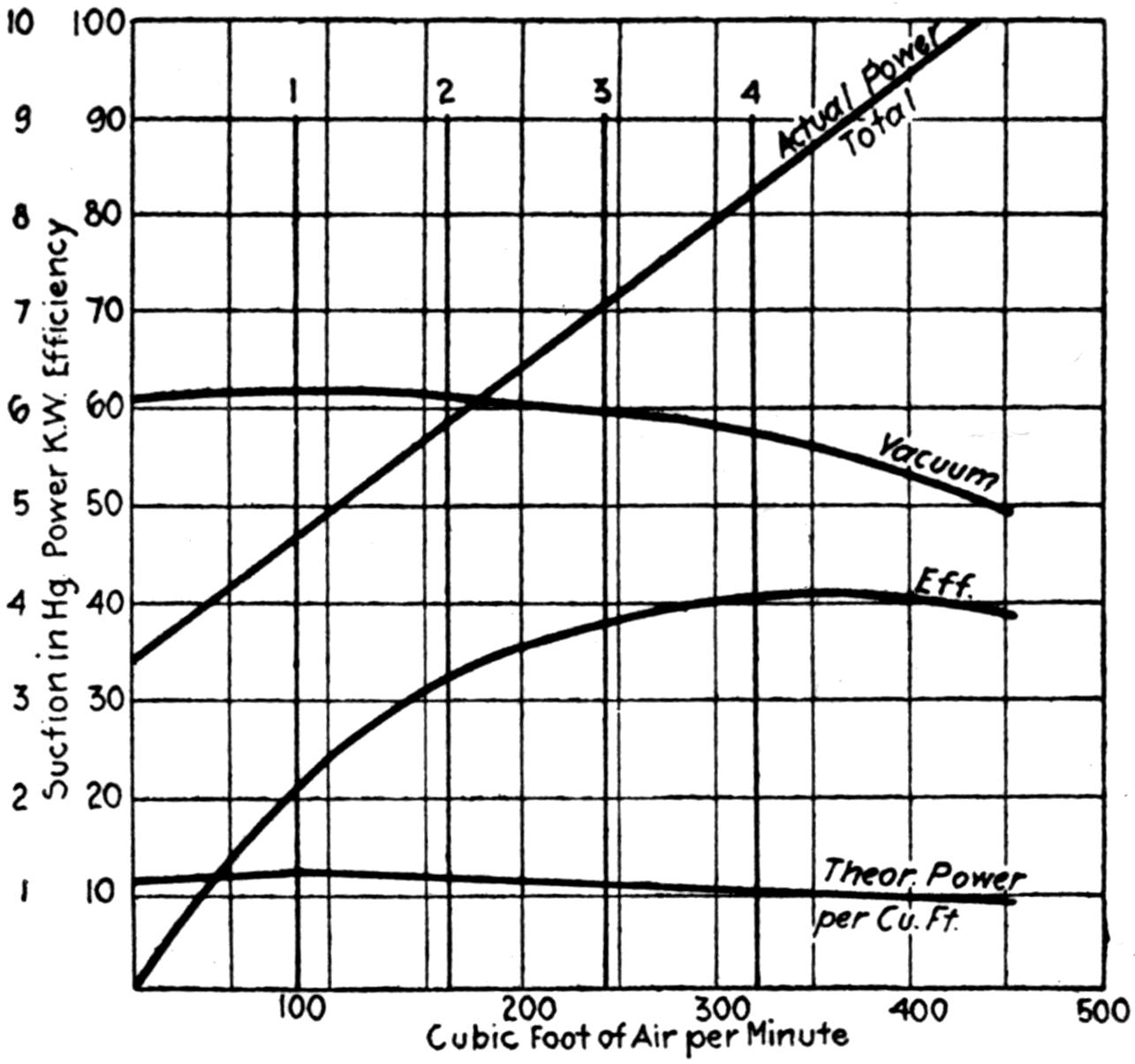

| 90. | Late Type of Centrifugal Exhauster Made by the Spencer Turbine Cleaner Company | 154 |

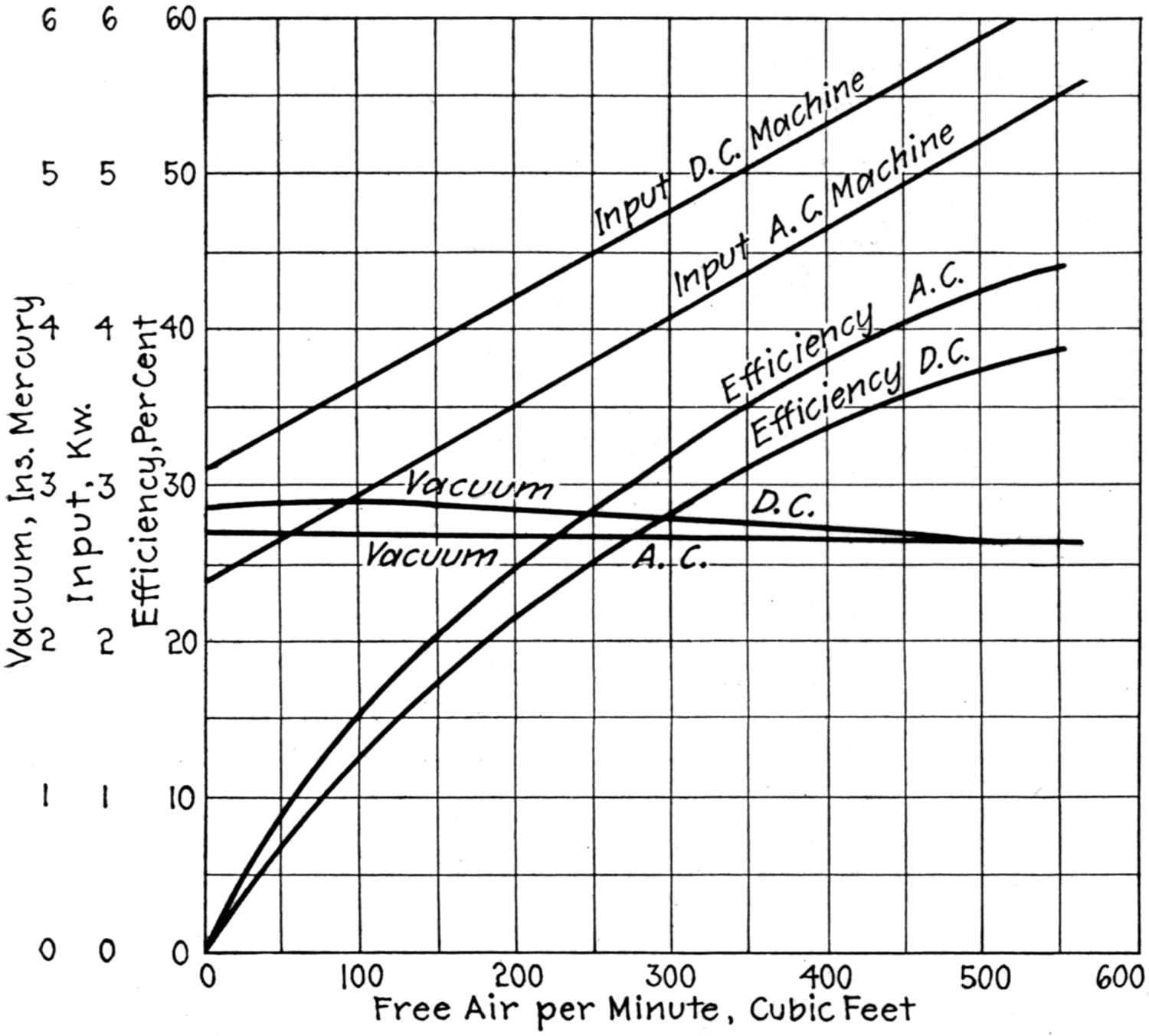

| 91. | Power and Efficiency Curves for the Spencer Machine | 155 |

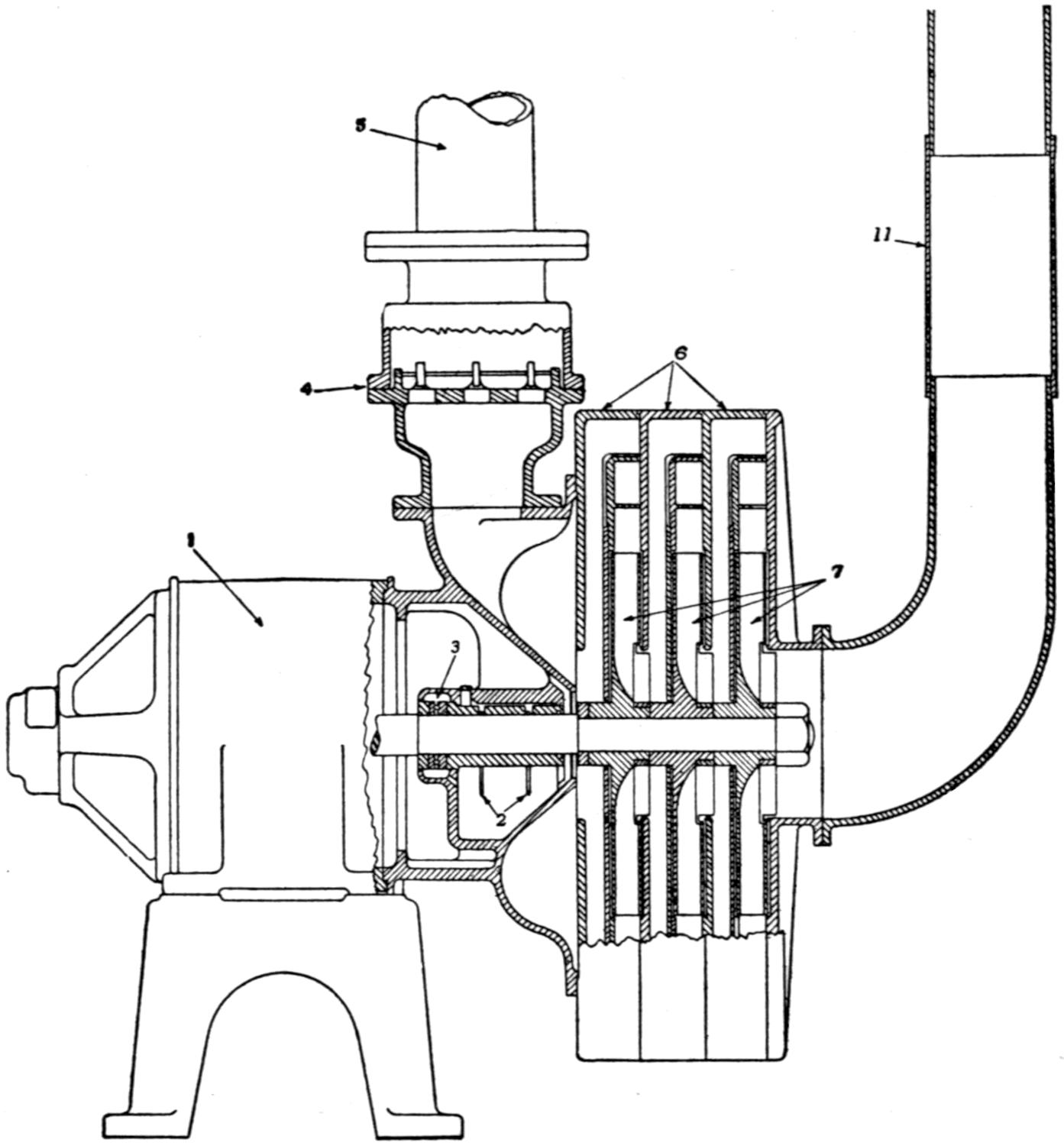

| 92. | Interior Arrangement of Invincible Machine, Manufactured by the Electric Renovator Manufacturing Company[xiv] | 156 |

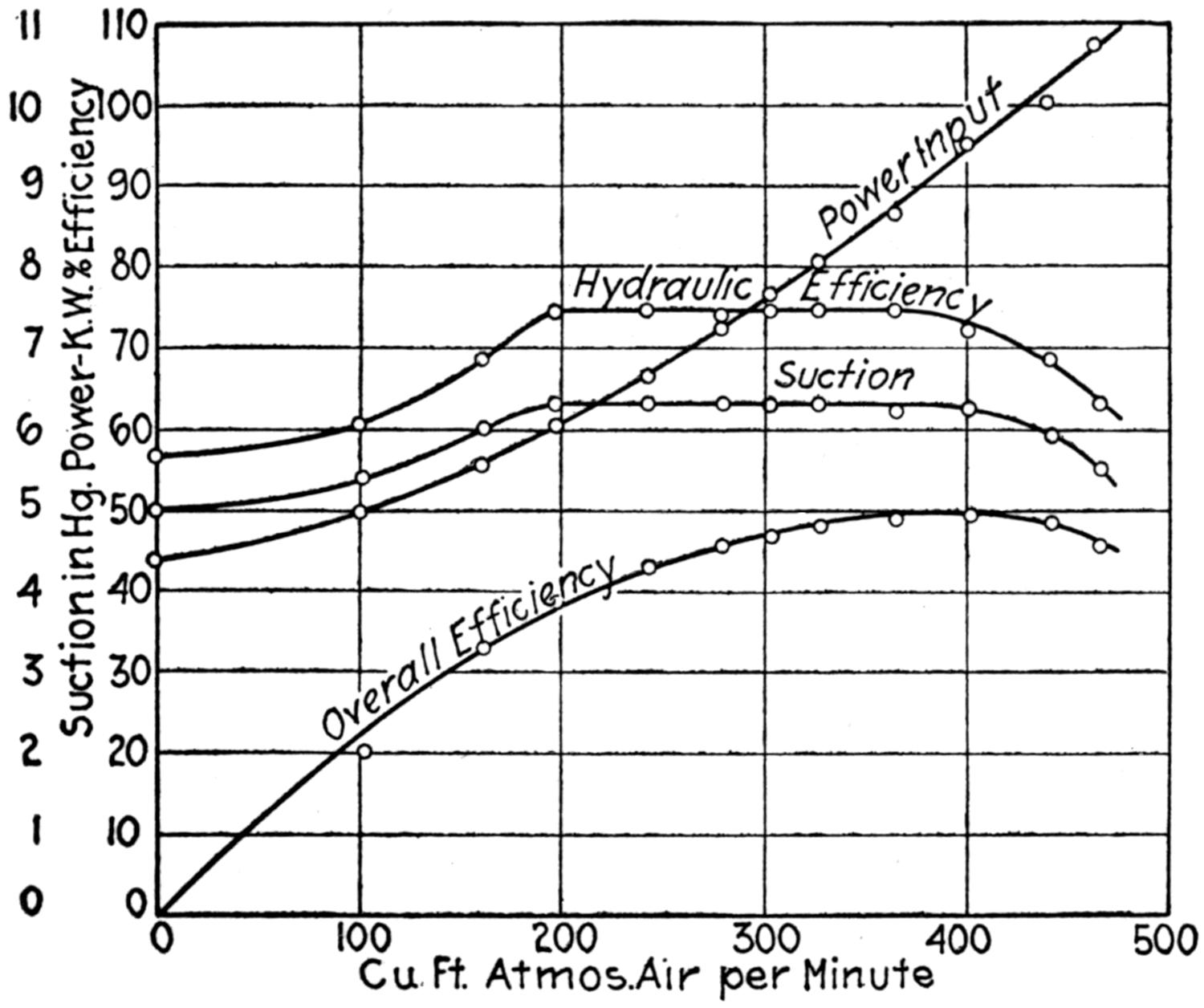

| 93. | Power Consumption, Vacuum and Efficiency of First Types of Invincible Machine | 157 |

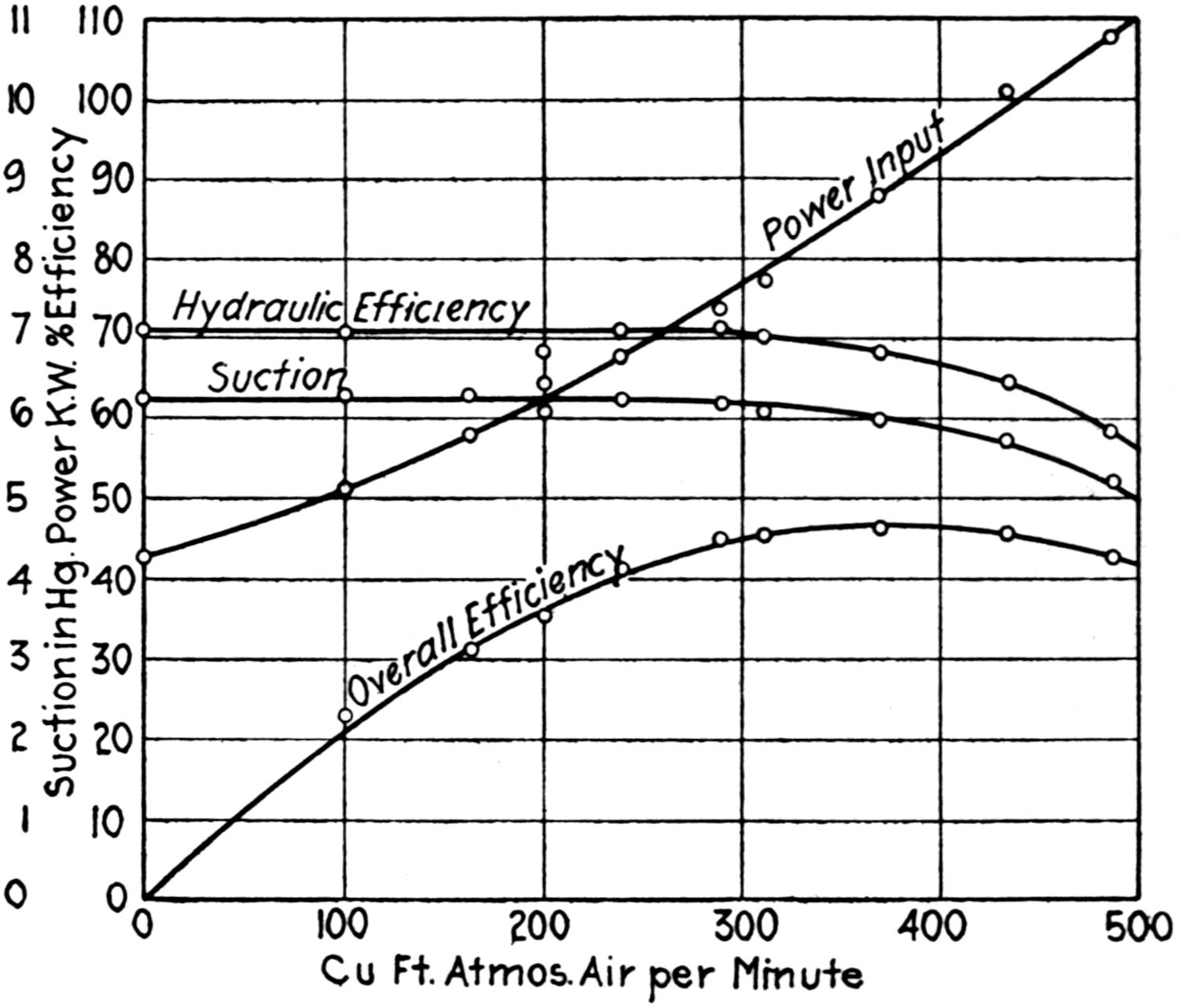

| 94. | Power Consumption, Vacuum and Efficiency of Invincible Machine After Valve Was Fitted to Discharge | 158 |

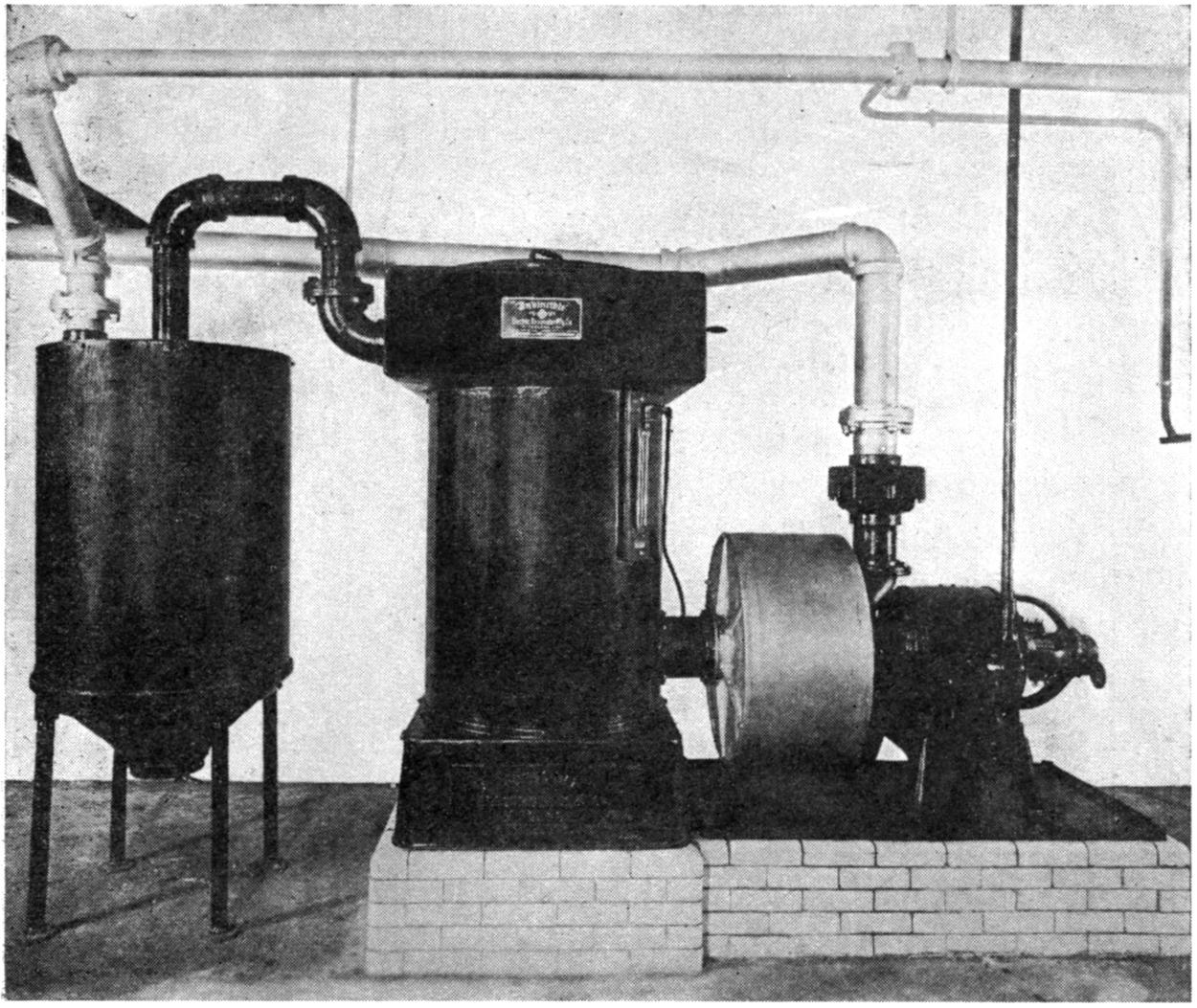

| 95. | Four-Sweeper Invincible Plant Installed in the United States Post Office at Los Angeles, Cal. | 159 |

| 96. | Centrifugal Pump with Single Impeller, Manufactured by The United Electric Company | 161 |

| 96a. | Test of Centrifugal Pump with Single Impeller | 162 |

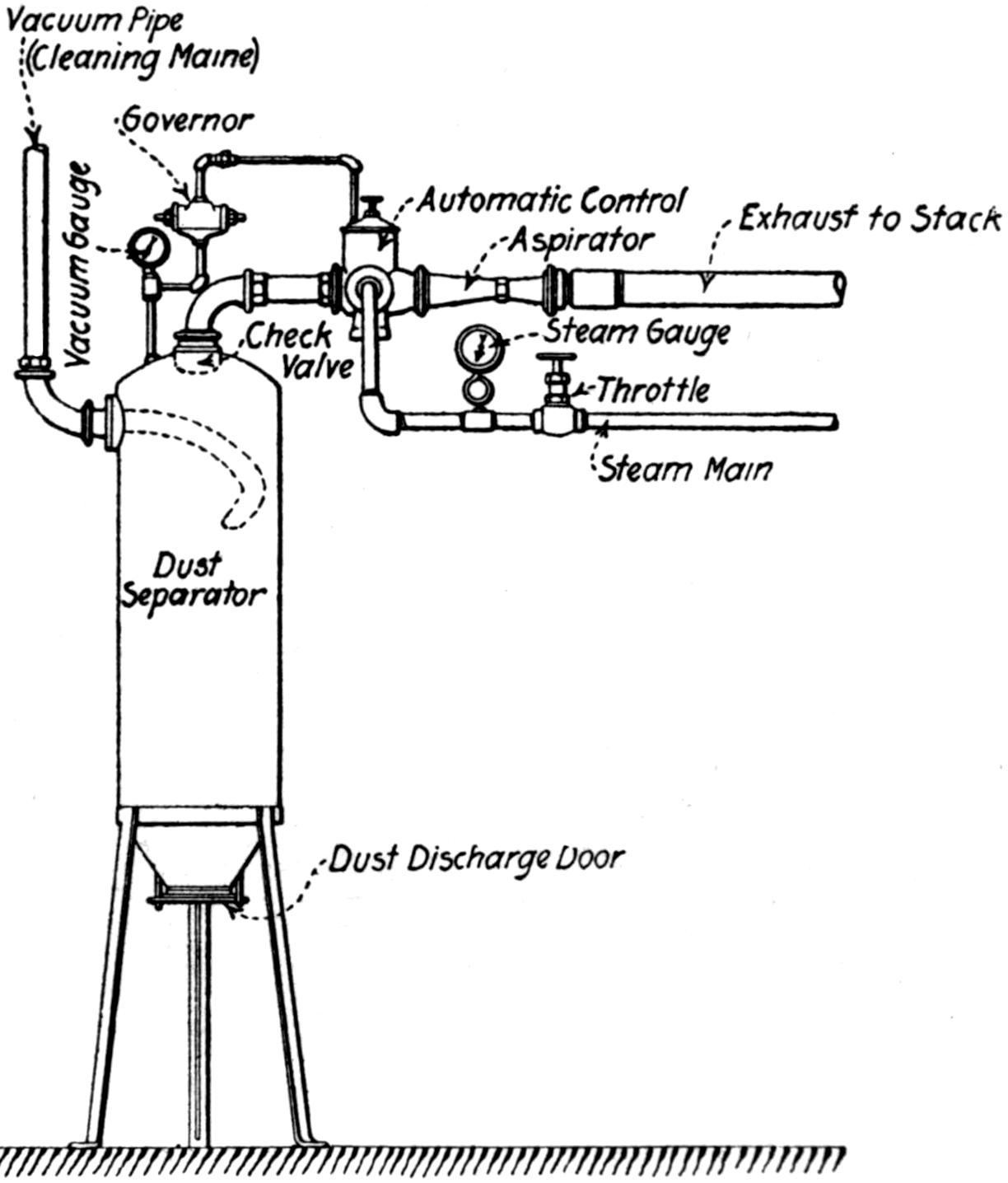

| 97. | Steam Aspirator Used by the American Air Cleaning Company | 163 |

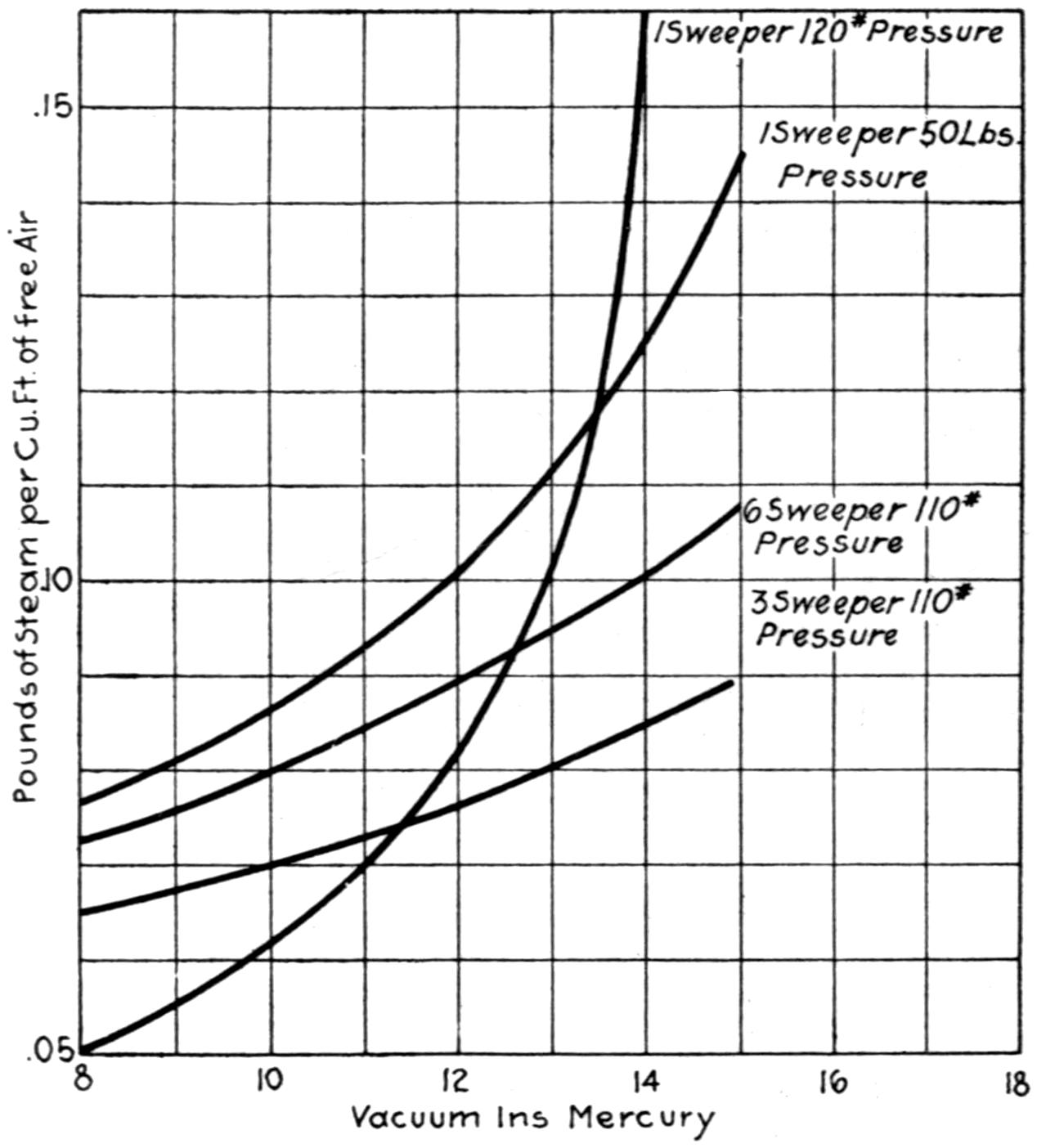

| 98. | Steam Consumption of Steam Aspirator | 164 |

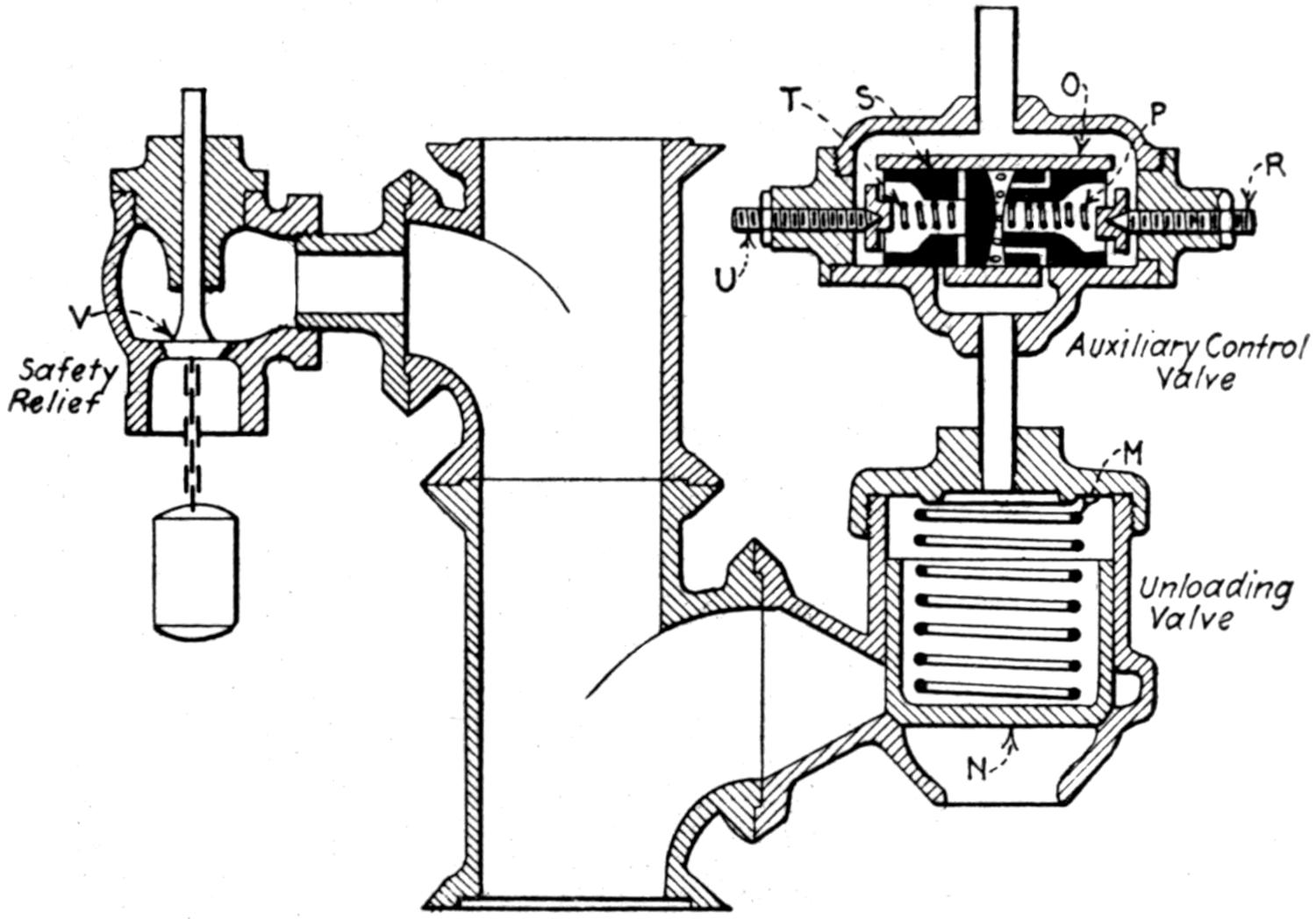

| 99. | First Type of Controller Introduced by the Sanitary Devices Manufacturing Company, known as the “Unloading Valve” | 167 |

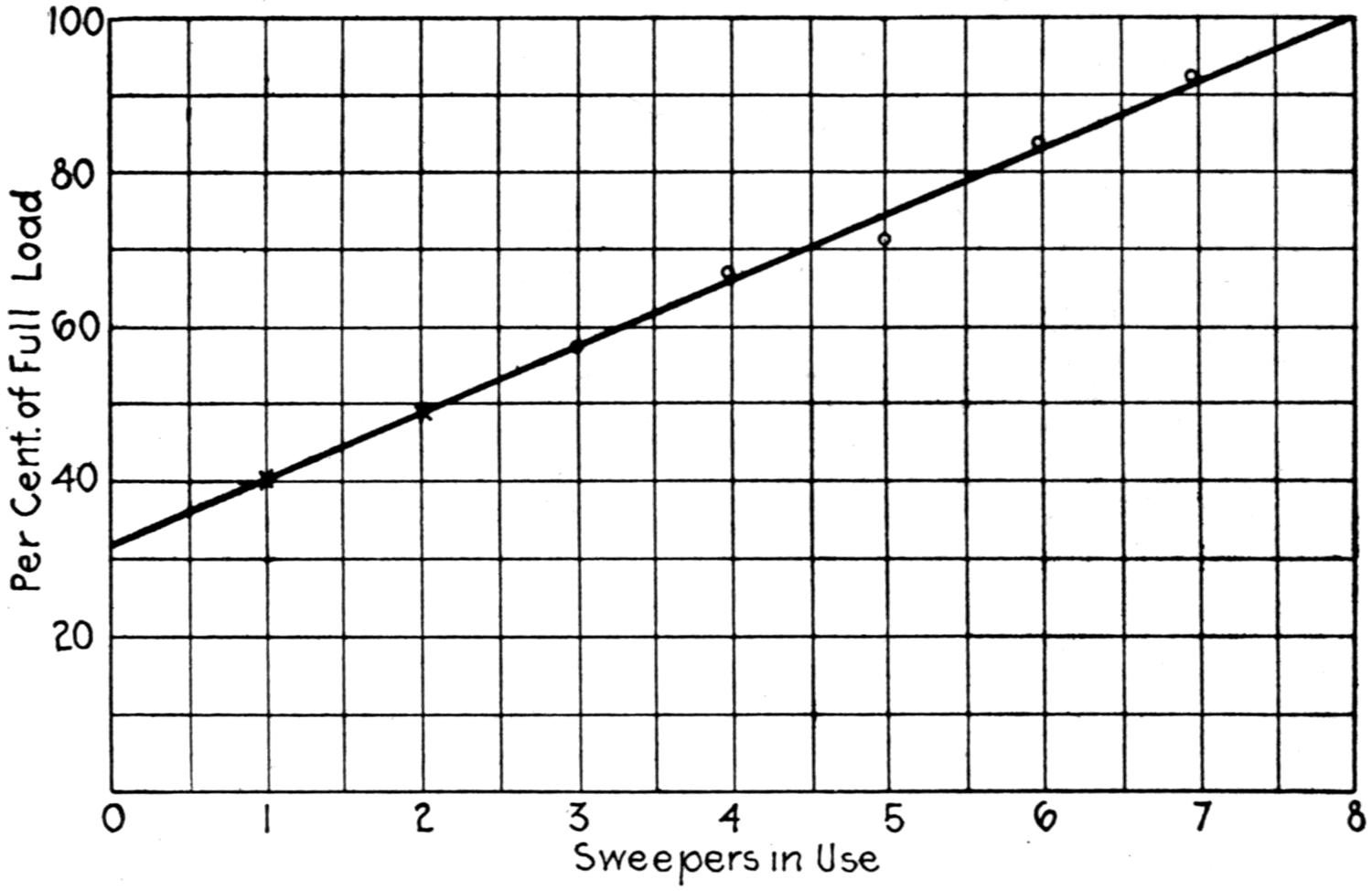

| 100. | Test of Controller Connected to Suction of 8-Sweeper Piston Pump | 168 |

| 101. | Type of Controller for Use on Pumps Without Valves | 169 |

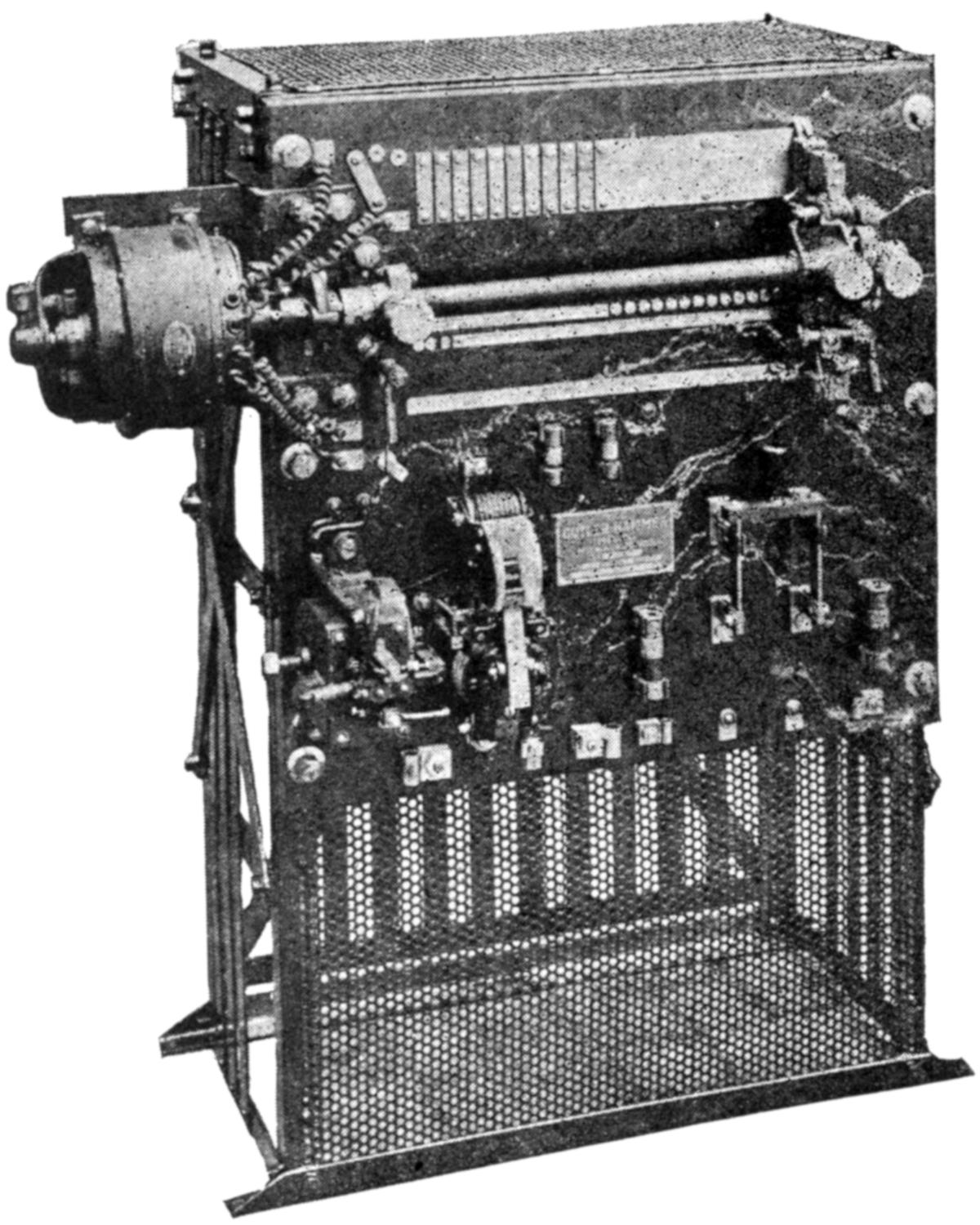

| 102. | Regulator for Motor-Driven Vacuum Pump, Manufactured by the Cutler-Hammer Manufacturing Company | 170 |

| 103. | Inspirator Type Vacuum Contactor, Used to Control Pilot Motor of Cutler-Hammer Controller | 171 |

| 104. | Vacometer for Use in Testing Vacuum Cleaning Systems | 190 |

[1]

The contents of this work are compiled from the observations of the author through the seven years during which he has been engaged in the preparation of specifications for, and the testing of, complete plants installed in the buildings under the control of the Treasury Department.

During this time it has become necessary to alter no less than five times the stock form of specifications for stationary vacuum cleaning plants which were adopted by the Government, with the intent of obtaining the widest competition possible with efficient and economical operation, in order to keep pace with the variation and improvement in the apparatus manufactured. As each new type of system has come on the market a personal investigation at the factory, together with tests, has been made. An exhaustive test of carpet renovators was also conducted, using one of the Government plants. In addition the vacometers recommended for use in capacity tests were carefully calibrated, using the machine at the Department of Agriculture.

The writer wishes to acknowledge the aid received from the various manufacturers in furnishing illustrations and data on their machines, to Messrs. Ewing & Ewing and Prof. Sidney A. Reeve for data on tests made by Prof. Reeve and used in defending the Kenney basic patent.

In analyzing the results of his tests and observations, the writer has endeavored to put his own conclusions into concrete form for the use of the consulting engineer and has not entered into the problems to be encountered in the design and manufacture of the various forms of apparatus.

—Whenever machinery has been introduced to assist or replace manual labor, the earlier attempts have been in imitating the tools formerly used by man. As the earliest mechanically-propelled carriages were mechanical walking machines, the earliest steamboats mechanical rowing machines, and the earliest flying machines mechanical birds, so were the earliest mechanical cleaners in the form of mechanical brooms.

These mechanical brooms were introduced about 1880 and took the form of the well-known street sweeper, with a large circular brush mounted on a four-wheeled cart and rotated by means of gearing driven from the wheels, the propelling power being the horses which drew the machine.

This machine at once made itself unpopular with the residents of the streets cleaned on account of its great activity in stirring up dust, because the streets were swept dry. This trouble was later overcome to a considerable extent by sprinkling the streets before sweeping, but only at a sacrifice in efficiency of cleaning, especially where such uneven surfaces as cobble or medina stone blocks formed the surface of the roadway. Various attachments were added to reduce this dust nuisance, but none has apparently been successful, as we see these machines in their original form in use today.

Almost simultaneously with the introduction of the street sweeper came its counterpart, the carpet sweeper, with a similar but smaller brush, enclosed in a wood and metal case, the brush being driven by friction from the wheels supporting the box and the power for operation being derived from the person who pushed the machine along the floor.

This machine has not been modified to any great extent during the thirty odd years of its existence. It is today in practically[4] its original form, and is doing no better work than when first introduced. This form of mechanical cleaner occupied the field of household cleaning for nearly twenty years without a rival, during which time it won its way into the hearts and hands of many housekeepers in this and other countries.

—This device, with its light brush and equally light pressure on the surface cleaned and its limited capacity for carrying the material picked up, has never been a thorough cleaner in any sense of the word, and has been and is now used only to take up that portion of the usual litter and light dust which is located directly on the surface, and is, therefore, most annoying to the housekeeper, owing to its being visible to the eye. Because of its generous proportions, made necessary to accommodate the material picked up, and its centrally-pivoted handle, made necessary by its mechanical construction, it is impossible to operate it under low furniture. Like the lawn mower, it must be in motion in order to operate its revolving brush, on which its cleaning action is dependent. It is impossible to make use of same in corners, along walls, or close to heavy furniture, its use being limited to a literal slicking up of those portions of the carpet in the most conspicuous portions of the apartment. In spite of these serious defects it came into, and is still in, nearly universal use, even in households equipped with the latest approved types of mechanical cleaners. Its use on bare floors has never been even a moderate success and in no case has it superseded the broom and dust pan of our grandmothers.

—Compressed air has been in use for many years in foundries and machine shops, for cleaning castings and producing certain finishes on metal. With the introduction of modern electrical machinery it was rapidly adapted to the cleaning of windings and other inaccessible parts of this machinery. Its first use in cleaning buildings was undoubtedly in the form of an open jet for dislodging dust from carvings and relief work, for which purpose it is very efficient as a remover of the dust from the parts to be cleaned and also as a distributor of this same dust over the widest possible area for subsequent removal by other means. It has a draw-back in that the expansion of air both cools the same and reduces[5] its ability to retain moisture, resulting in the deposit of moisture on the surfaces cleaned.

About 1898, attempts to overcome the objections to the open air jet and to produce a commercially successful compressed air carpet cleaner were undertaken almost simultaneously by two companies, the American Air Cleaning Company, of Milwaukee, operating under the Christensen patents, and the General Compressed Air Cleaning Company, of St. Louis, operating under the Thurman patents.

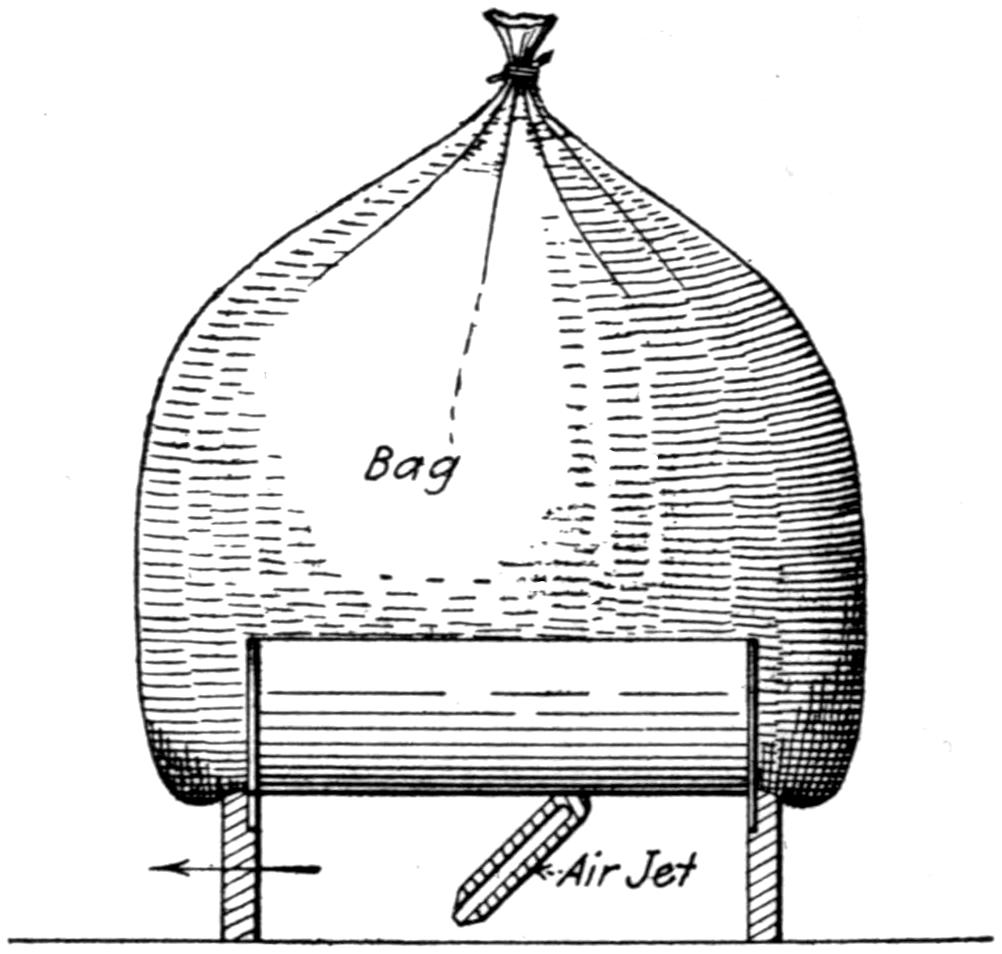

The renovator used by the American Air Cleaning Company consisted of a heavy metal frame, about 18 in. long and 12 in. wide, having mounted on its longer axis a wedge-like nozzle extending the entire length of the frame, with a very narrow slit, ¹⁄₆₄ in. wide, extending the entire length of its lower edge. This nozzle was pivoted and so connected to the operating handle, by which the renovator was moved over the floor, that when the renovator was alternately pushed and pulled over the surface to be cleaned, the slot was always inclined in the direction in which the renovator was being moved. The top of the renovator was closed by a canvas bag, smaller at the neck than in its center, which was supported by a wire hook.

Air was introduced into the nozzle, at a pressure of from 45 to 55 lbs. per square inch, and issued from the slot in a thin sheet which impinged on the carpet at an angle. The frame was held close to the carpet by its weight, preventing the escape of the air under its lower edge. The air striking the carpet at an angle was deflected up into the bag, inflating same like a miniature balloon. The dust loosened from the carpet by the impact of the air was carried up into the bag where it lodged, the air escaping through the fabric of the canvas into the apartment.

The renovator used by the General Compressed Air Cleaning Company differed from the above-described renovator in that it contained two nozzles, with slots inclined at fixed angles to the carpet. A pair of hand-operated valves were provided in the handle to introduce air into the nozzle which was inclined in the direction in which the renovator was moving; otherwise[6] the renovator was identical with that used by the Milwaukee company.

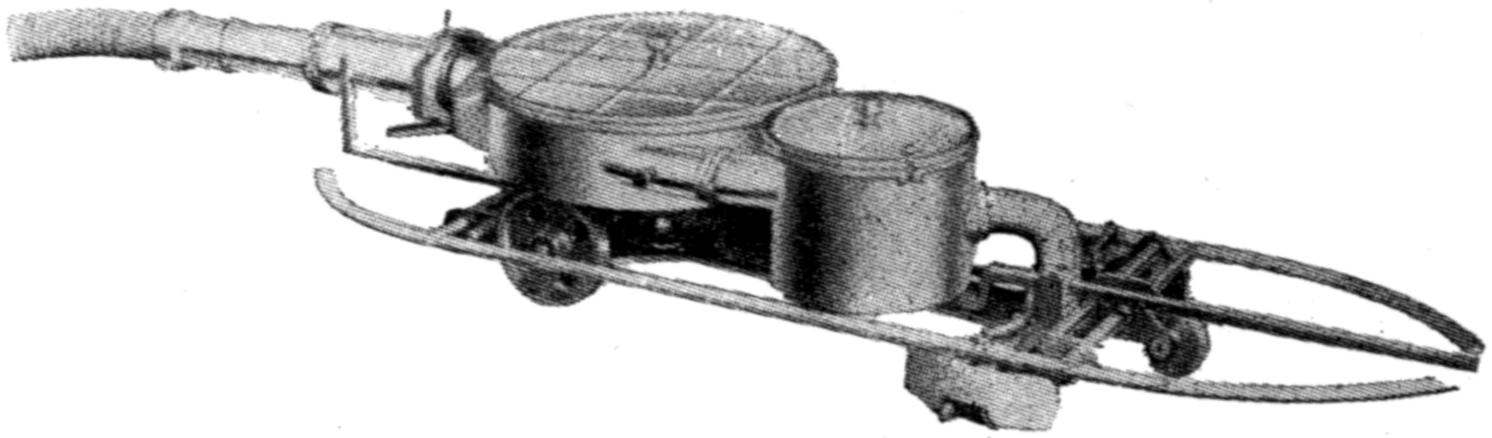

These renovators were generally supplied with air from a portable unit, consisting of an air compressor, driven by a gasoline engine mounted with the necessary gasoline and air storage tanks on a small truck. One of these machines was in use in Washington last year, but its use at that time was very limited and it is not to be seen this year.

These trucks were drawn up in front of the building to be cleaned and a large-size hose, usually 1¹⁄₄ in. in diameter, was carried into the house and attached to an auxiliary tank from which ¹⁄₂-in. diameter hose lines were carried to two or more renovators.

A few buildings were equipped with air compressors and pipe lines, with outlets throughout the building for use with this type of renovator, among which was the Hotel Astor in New York City.

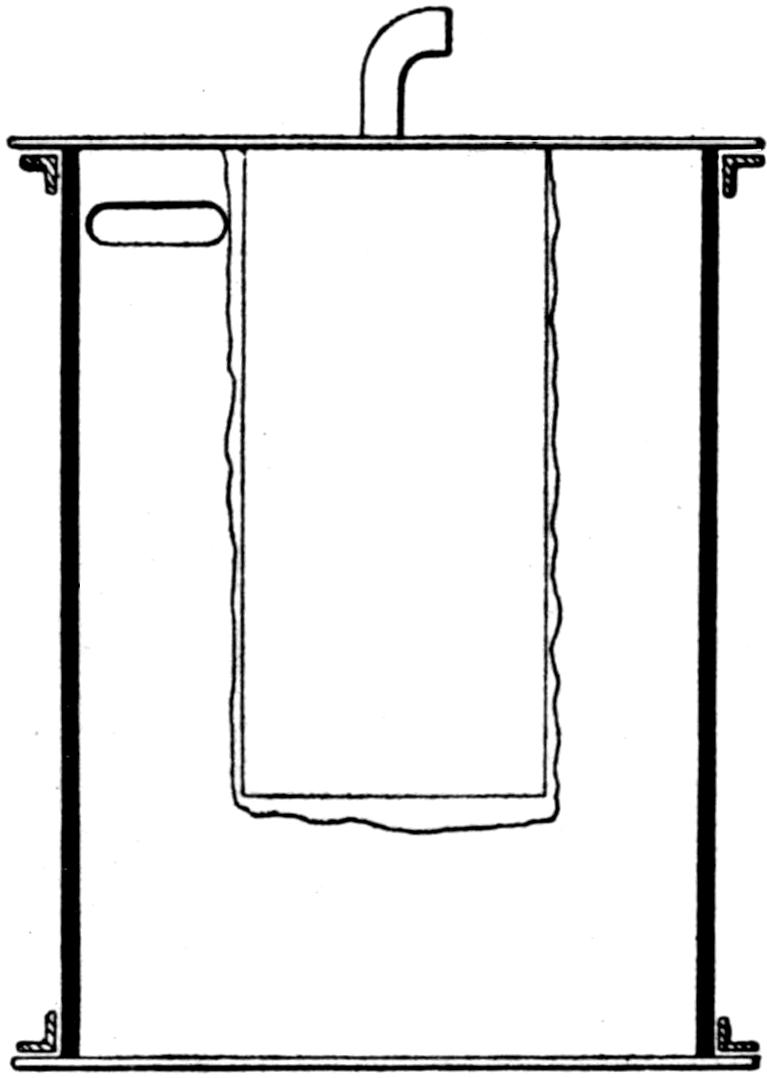

These renovators, the construction of which is shown diagrammatically in Fig. 1, required approximately 35 cu. ft. of free air per minute at a pressure of from 45 to 55 lbs. per square inch and were usually driven by a 15 H. P. engine.

FIG. 1. EARLY TYPE OF MECHANICAL CLEANING NOZZLE USING COMPRESSED AIR.

The renovators were very heavy to carry about, although their operation with the air pressure under them was not difficult. However, their operation was complicated, requiring[7] skilled operators. Owing to their generous proportions it was impossible to clean around furniture, making its removal from the apartment necessary, and limiting their use to the cleaning of carpets at the time of general house cleaning. The cooling effect of the expansion of the air in the nozzle often caused condensation of moisture on the carpets when the relative humidity was high. They were also at a disadvantage in that all the heavy dust collected in the canvas bag had to be carried from the apartment by hand. Owing to the constant agitation of the dust in the bag by the entering air currents, much of the finer particles of dust and all the disease germs liberated by the renovator were blown through the bag back into the apartment. They were not, therefore, by any means sanitary devices.

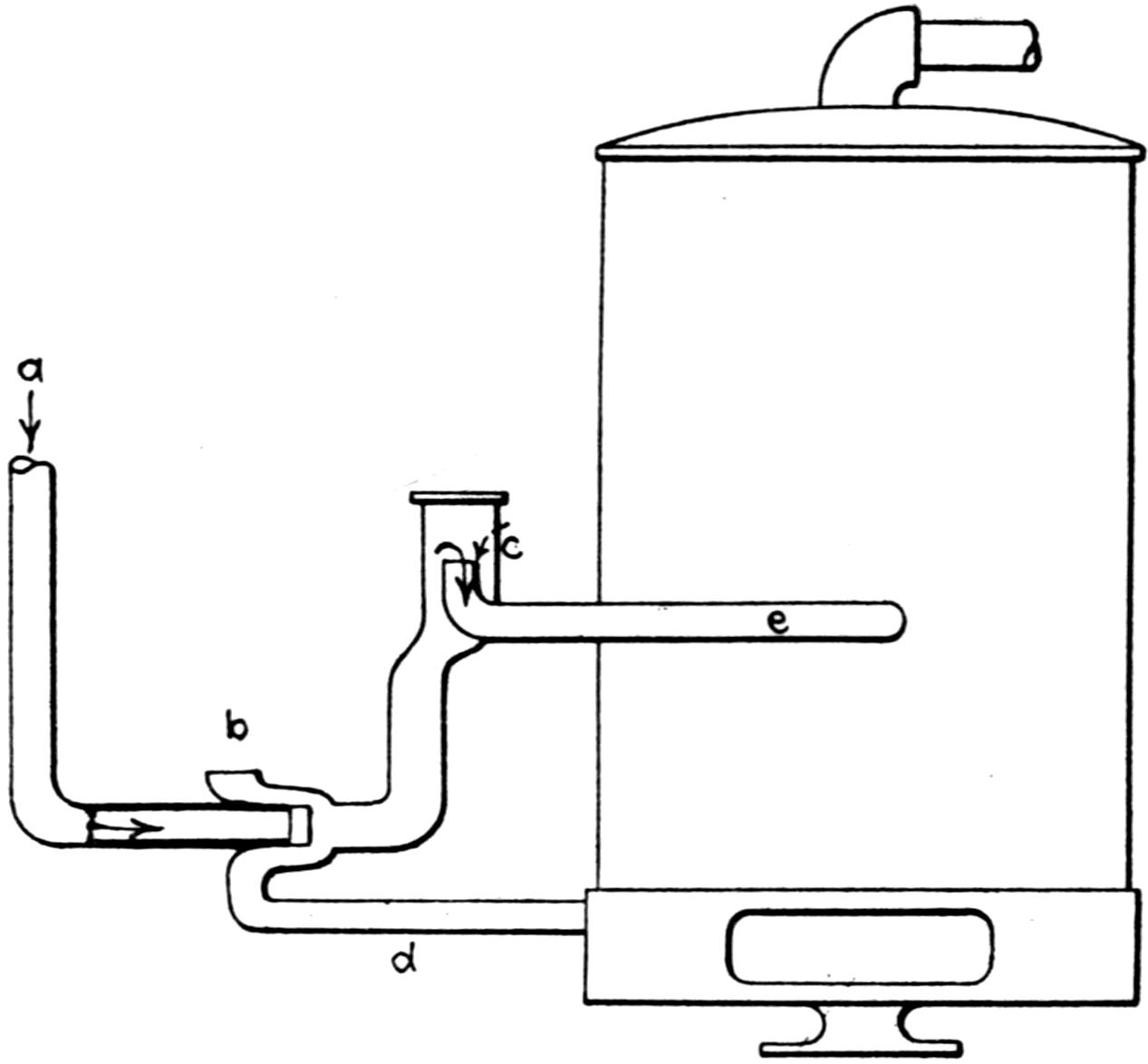

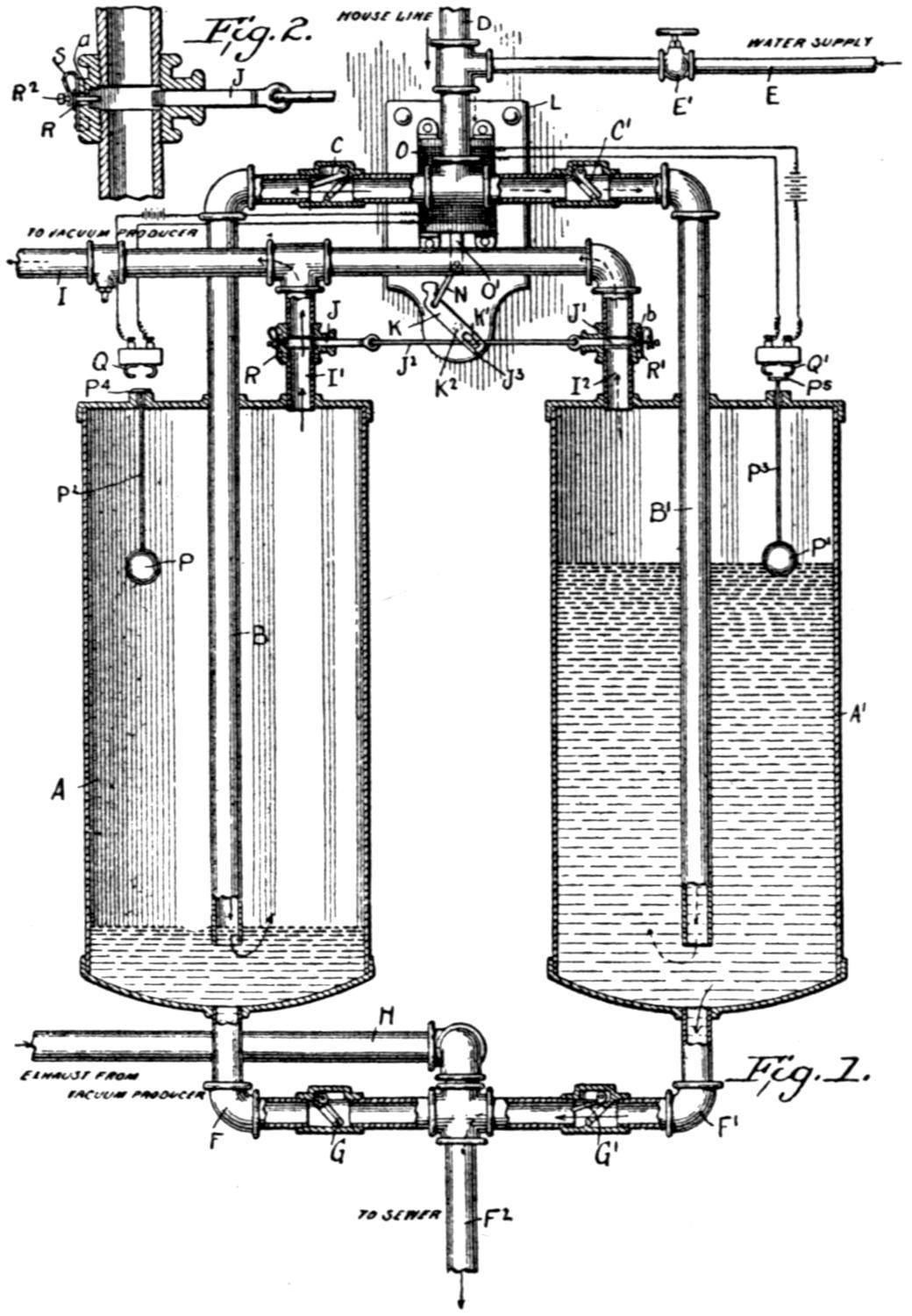

—The General Compressed Air Cleaning Company also introduced another form of renovator for use with their compressed air plants. This was composed of an ejector operated by compressed air, with a short hose attached to a carpet renovator of the straight narrow-slot type, such as was used later in vacuum cleaning systems. The outlet from this ejector was connected by another short hose to a metal box containing a canvas bag, woven backwards and forwards over metal frames to give a large surface for the passage of air. The dust picked up by the suction of the ejector was carried with the air into the box and there separated from the air, which escaped through the canvas into the apartment.

This form of renovator overcame some of the objections to the former type in that there was no condensation of moisture on the carpets, and it was possible to operate the renovator under and around furniture, and even on portieres and other hangings. However, the apparatus was rendered inefficient by the resistance of the bag, causing a back pressure on the injector which greatly reduced its air-drawing capacity.

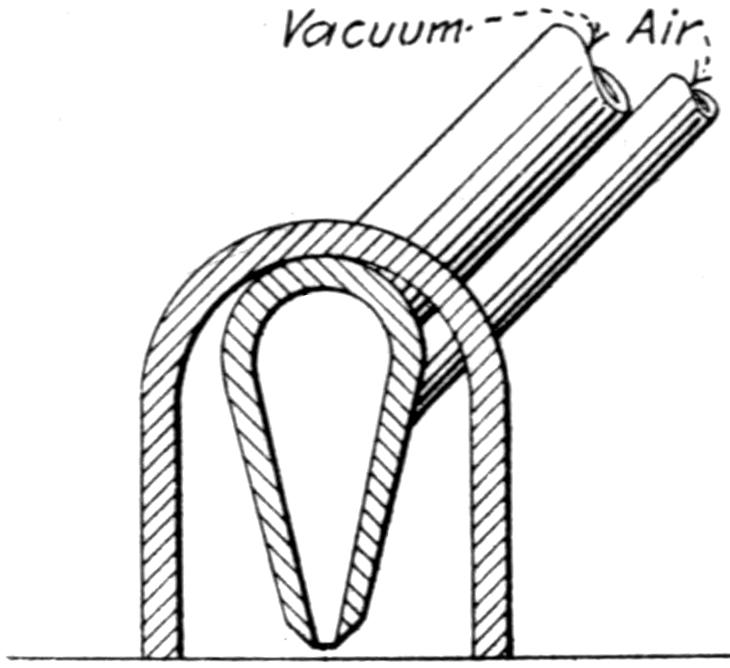

—Shortly after these two companies began operation, the Sanitary Devices Manufacturing Company, of San Francisco, introduced a new system of mechanical cleaning under the Lotz patents. This[8] system used a renovator having a compressed air nozzle terminating in a narrow slot, similar to the nozzles of the American and Thurman systems, but differing from them in that the slot was fixed vertically, pointing downward. This nozzle was surrounded by an annular chamber having an opening at the bottom of considerable width. The whole formed a renovator about 14 in. long and not over 2 in. wide at its base. In addition to the compressed air connection to its nozzle, a second hose, 1 in. in diameter, was connected to the annular space surrounding the nozzle and led to a vacuum pump by which the air liberated through the nozzle, together with the dust which was liberated from the carpet, was carried from the apartment. The construction of this renovator is shown diagrammatically in Fig. 2.

FIG. 2. ANOTHER TYPE OF COMPRESSED AIR CLEANING NOZZLE, SUPPLEMENTED WITH VACUUM PIPE.

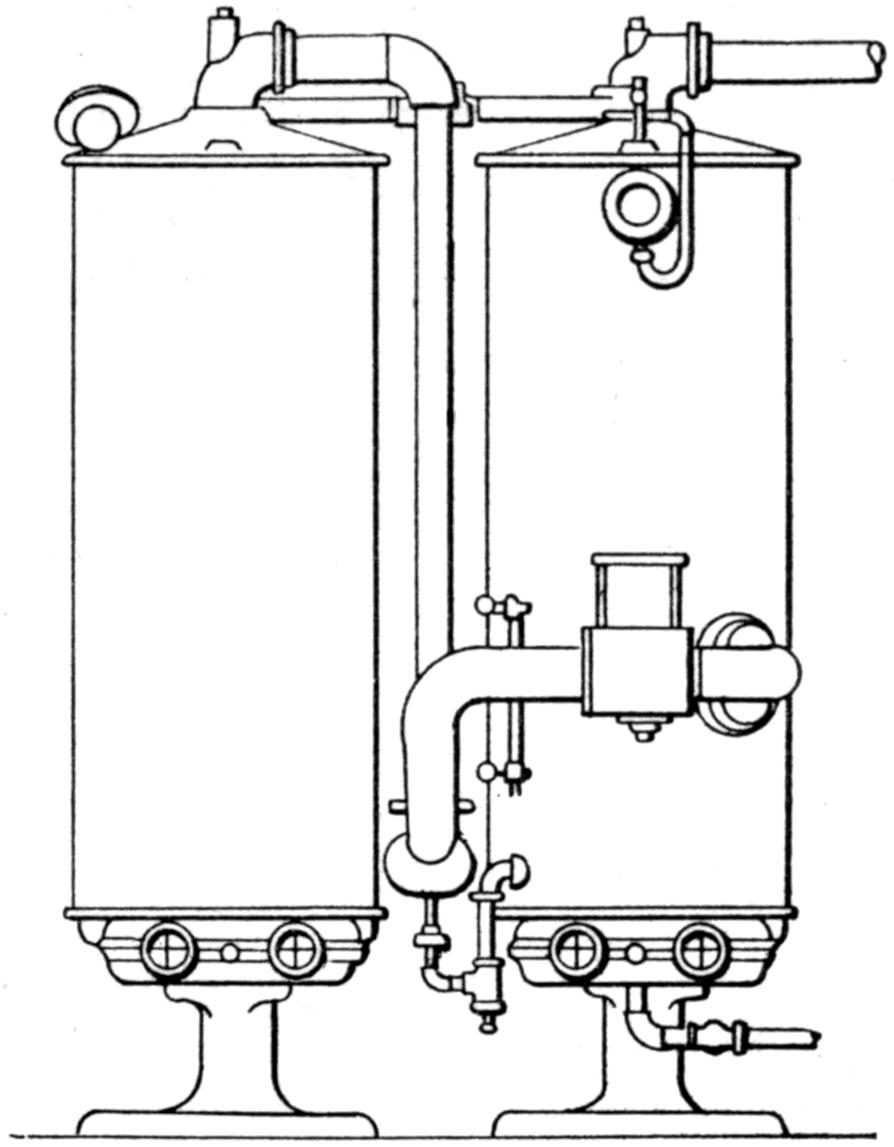

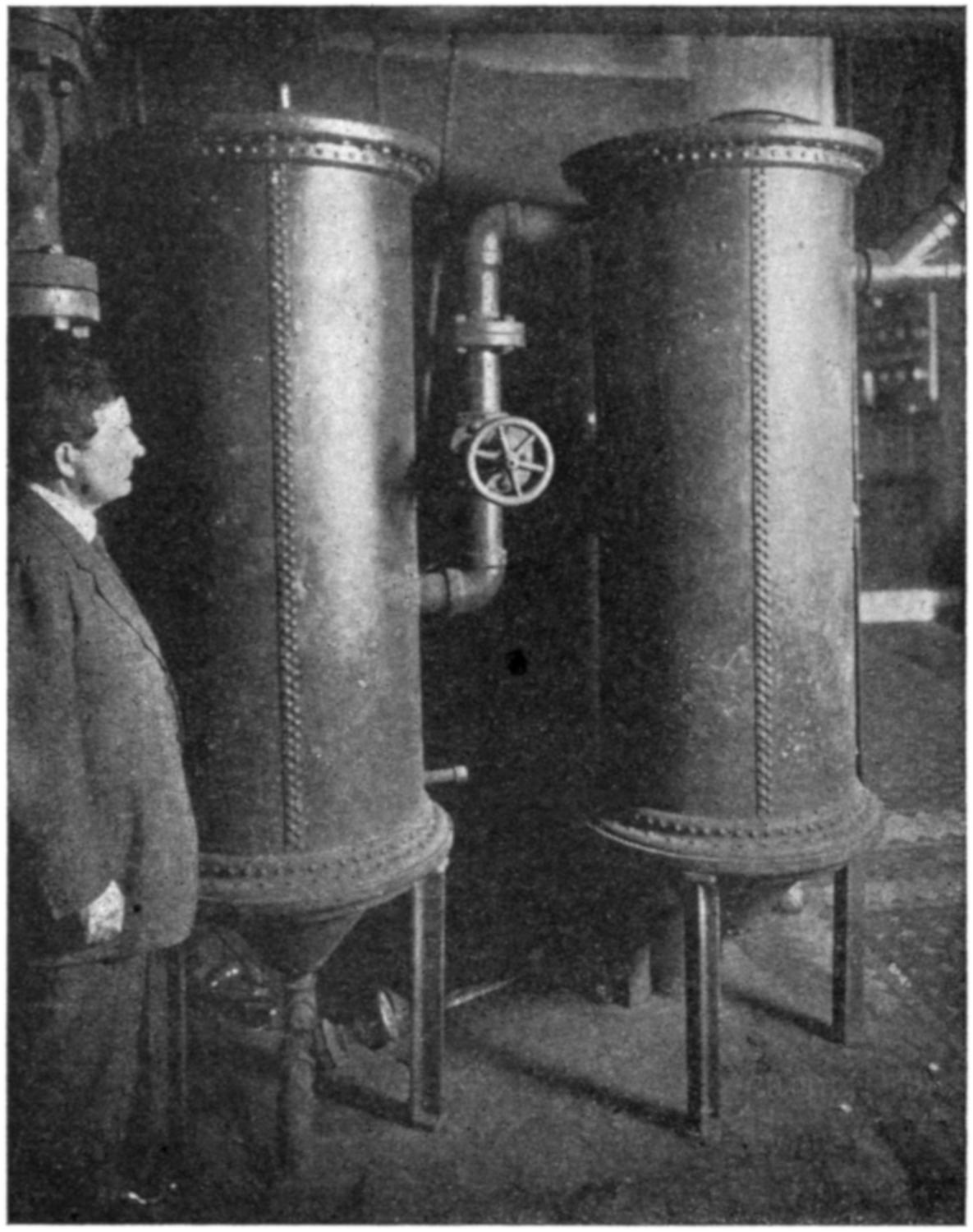

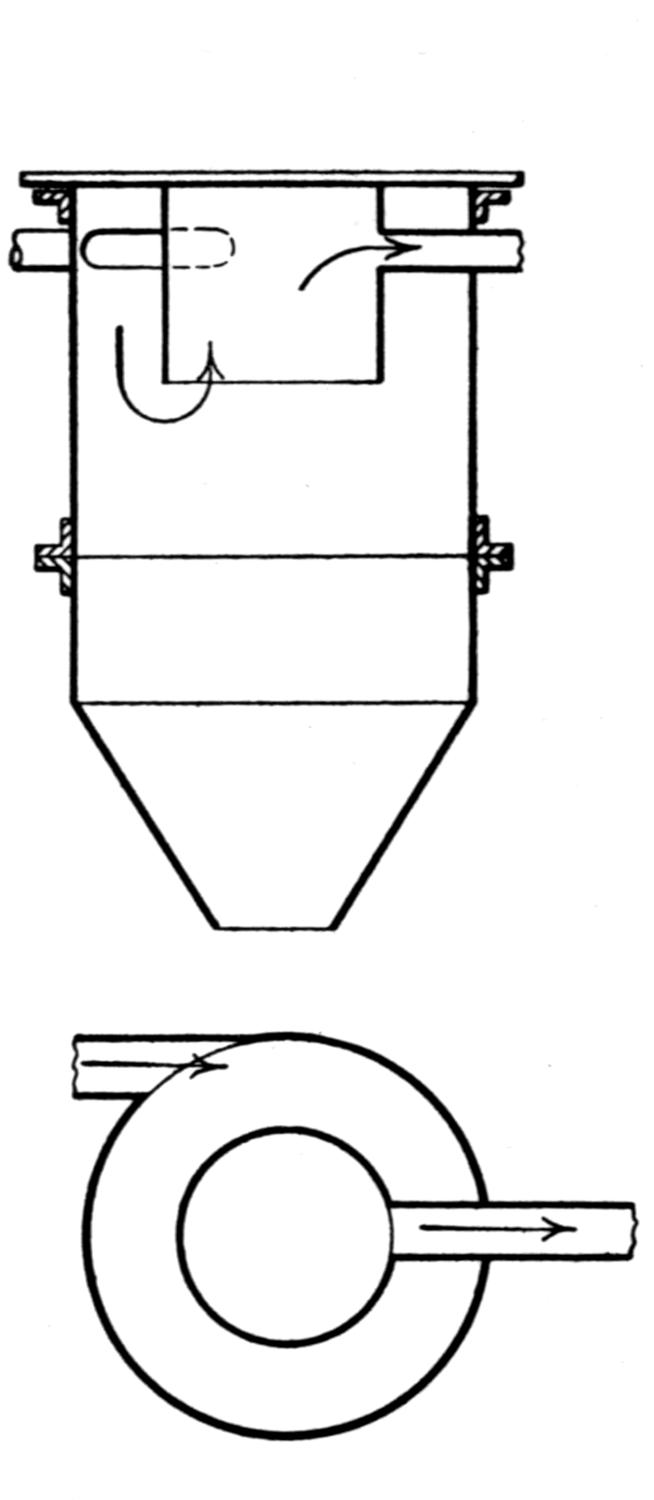

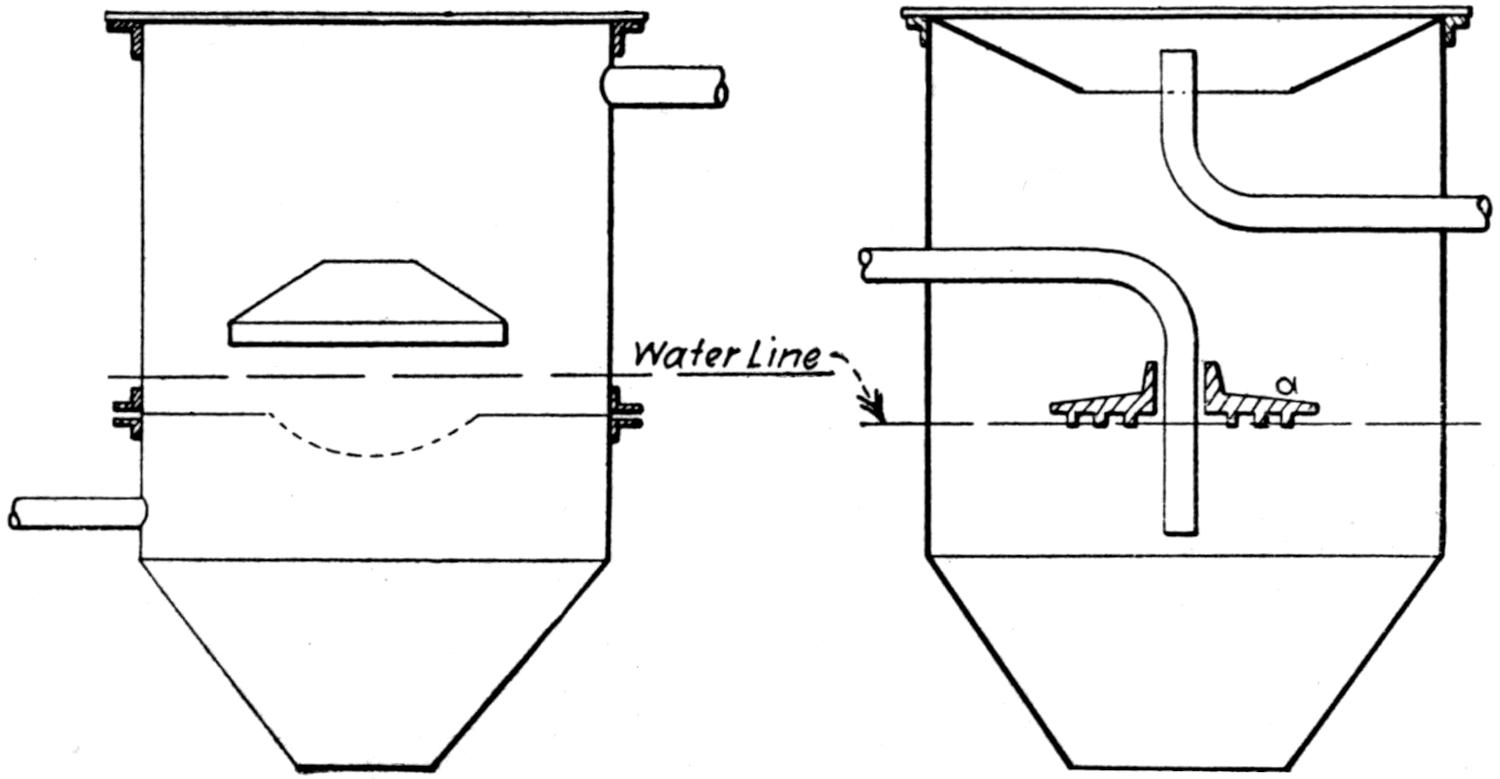

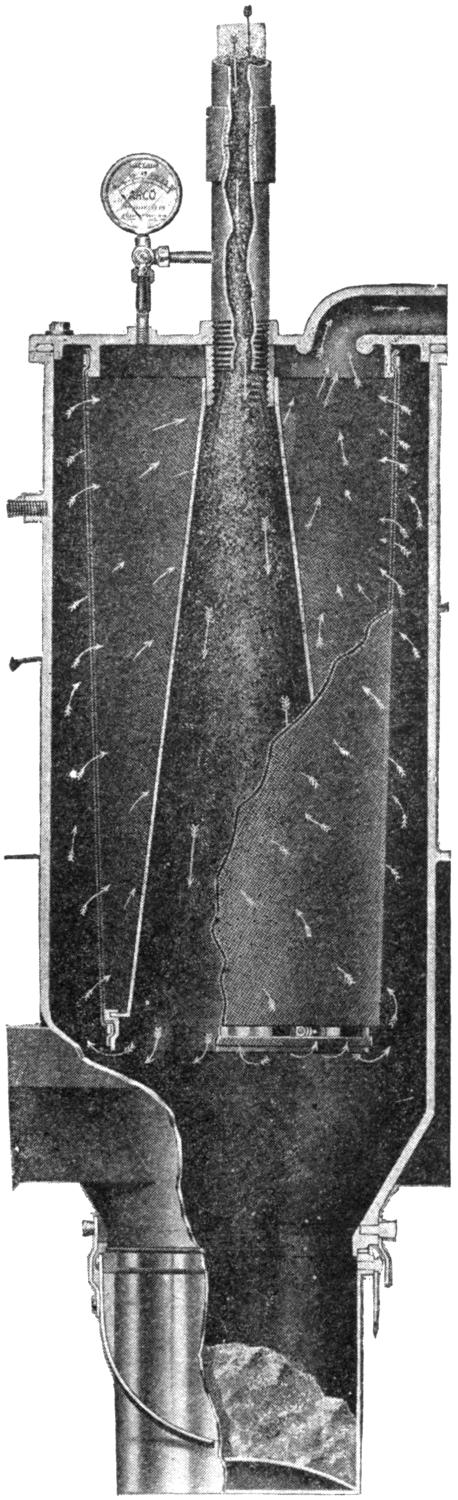

As dust-laden air was not suitable to be carried through the pump used as a vacuum producer, separators had to be provided to remove the dust from this air before it reached the pump. The separators used consisted of two cylindrical tanks. The air was introduced into the first tank in such a way that a whirling motion was imparted to it, thus separating the heavier particles of dust by centrifugal force. The second tank contained water which was brought into intimate contact with the air by means of an atomizer located in the pipe connection between the two tanks, thus washing the air in a manner somewhat similar to the familiar air washers used in connection with mechanical ventilating systems. The air and spray then entered the second tank, above the water line, where[9] the entrained water separated on the reduction of velocity and fell back into the water below, to be recirculated through the atomizer. The air passed on out of the top of the tank to the pump. An illustration of these separators is shown in Fig. 3.

FIG. 3. SEPARATORS USED WITH COMBINED COMPRESSED AIR AND VACUUM MACHINES.

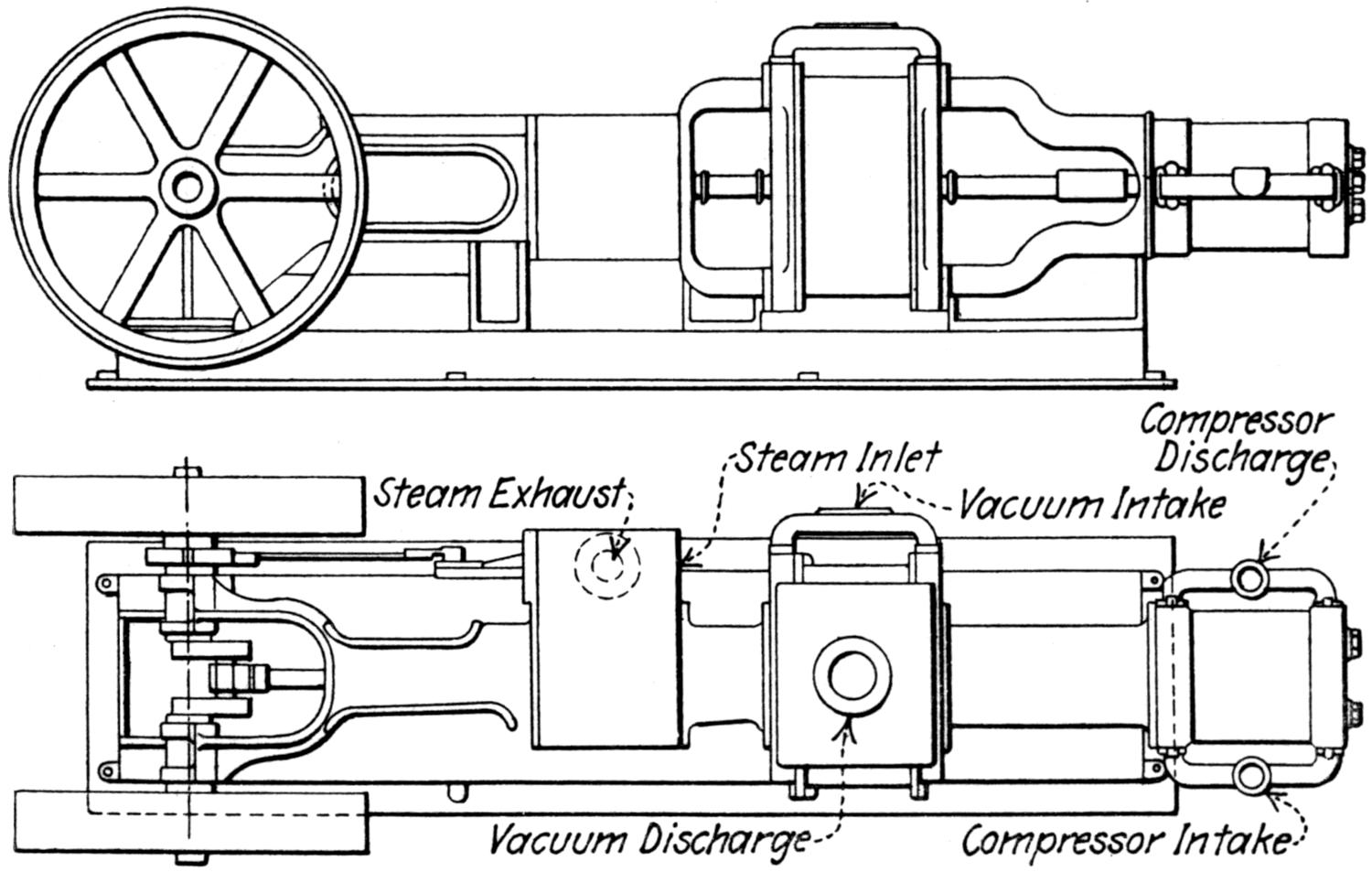

FIG. 4. PISTON TYPE OF VACUUM PUMP, MOUNTED TANDEM WITH AIR COMPRESSOR.

—Various types of apparatus were tried as vacuum producers, including an air ejector, such as was used with the Thurman[10] renovator, and found to be ineffective due to its inability to overcome the back-pressure necessary to discharge the air through the hose, which was placed on its outlet. A rotary pump was next tried, but, owing to the selection of an inefficient type, this was abandoned and, finally, a piston-type vacuum pump, with very light poppet valves and mounted tandem with the air compressor, was adapted and remained in use with this system until straight vacuum was adopted, when the air compression cylinder was omitted. This pump is illustrated in Fig. 4.

FIG. 5. MR. KENNEY’S FIRST RENOVATOR, VACUUM ALONE BEING USED AS CLEANING AGENT.

In this system we see the first sanitary device to be introduced into the field of mechanical cleaning, as the dust and germ-laden air were removed entirely from the apartment and purified before being discharged into the outside atmosphere. The foulness of the water in the separators clearly showed the amount of impurities removed from the air.

[11]

These machines were mounted on wagons, similar to their forerunners, and were also installed in many buildings as stationary plants, among which were the old Palace Hotel and the branch Mint, in San Francisco, and the old Fifth Avenue Hotel, in New York City.

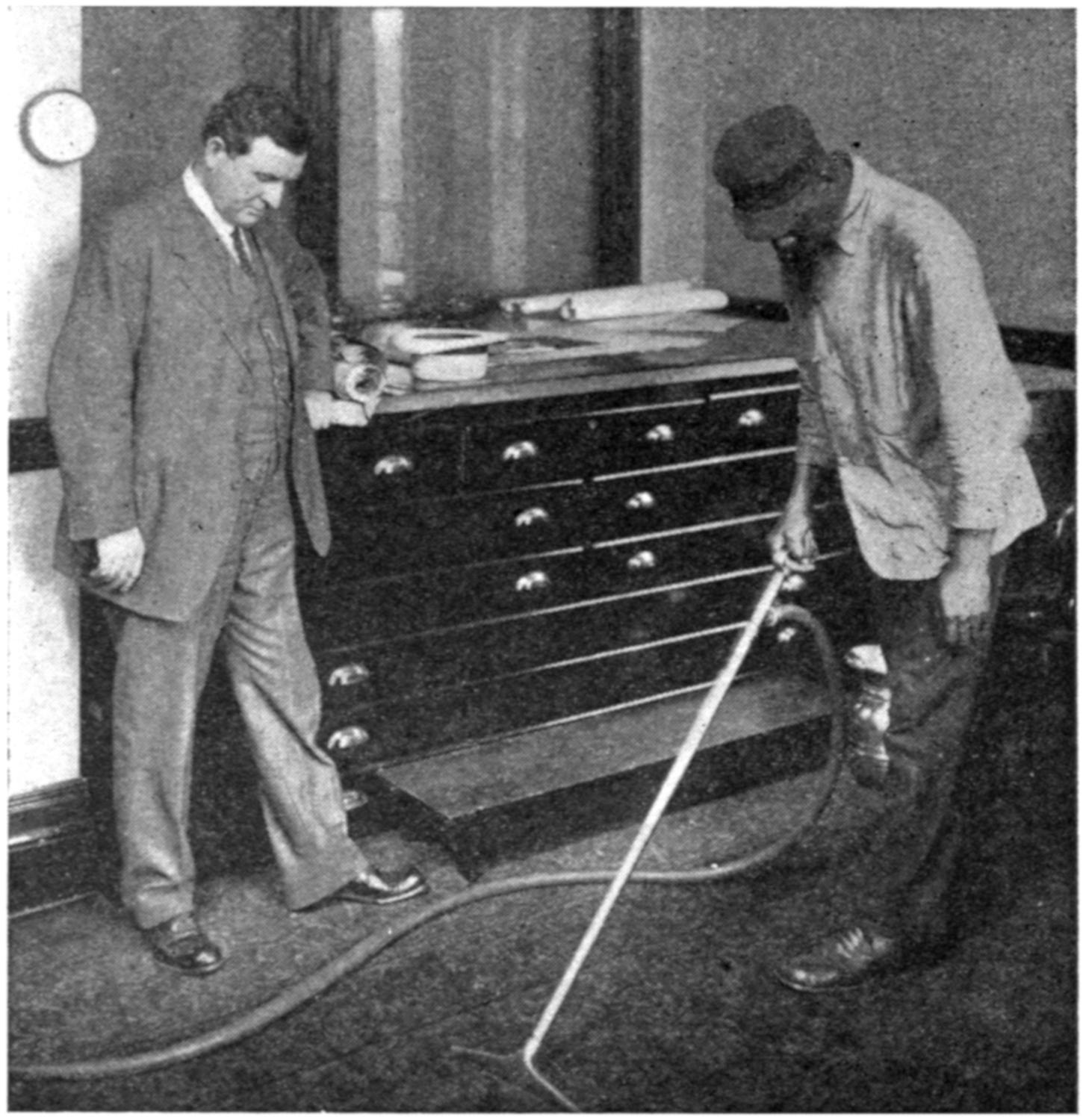

—In 1902 David T. Kenney, of New York, installed the first mechanical cleaning system in which vacuum alone was used as the cleaning agent. Mr. Kenney used a renovator with a slot about 12 in. long and ³⁄₁₆ in. wide, attached to a metal tube which served as a handle, and to a ³⁄₄-in. diameter hose and larger pipe line leading to separators and vacuum pump. Mr. Kenney’s first renovator is illustrated in Fig. 5.

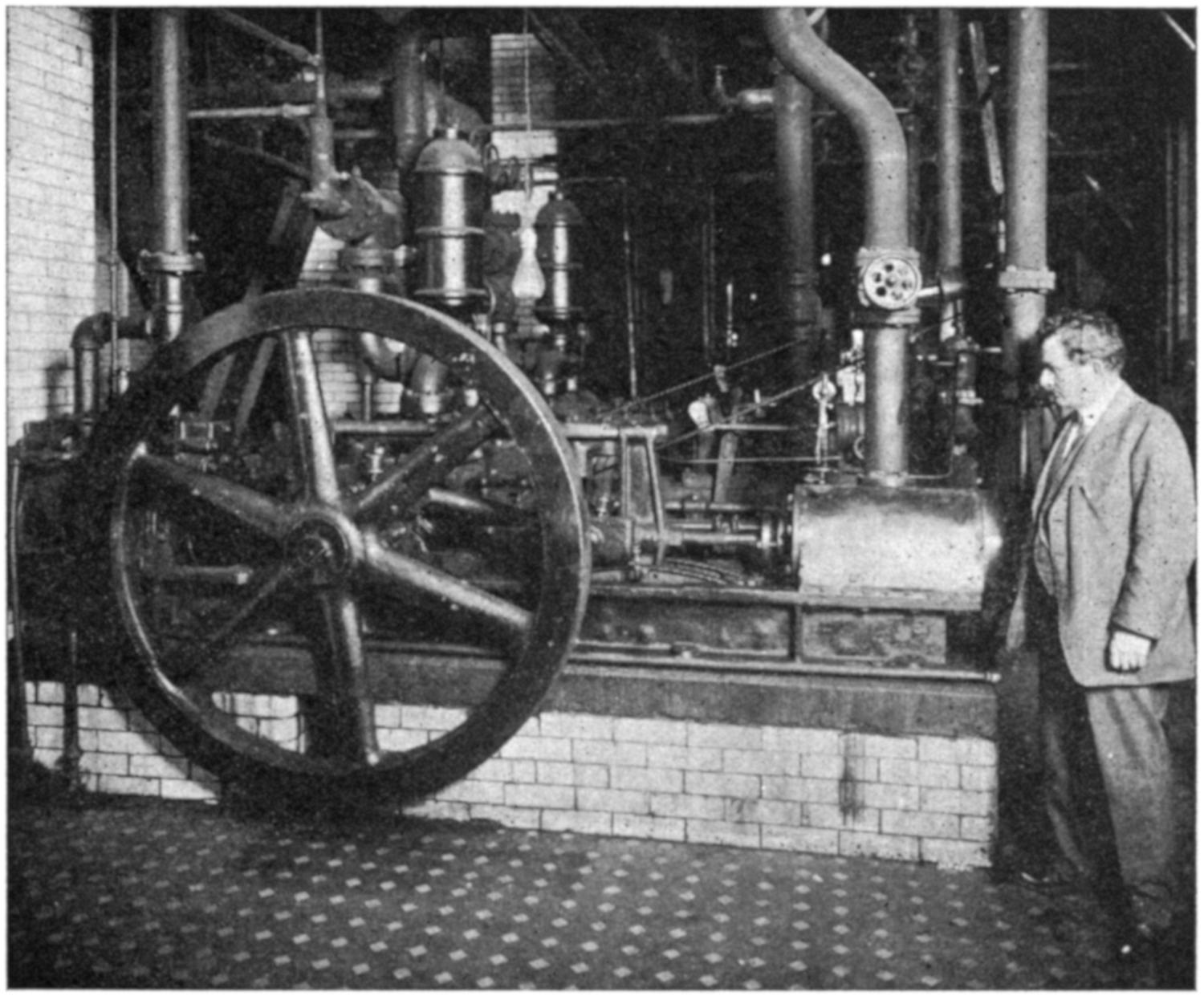

FIG. 6. AIR COMPRESSORS ARRANGED FOR OPERATION AS VACUUM PUMPS.

Mr. Kenney used as vacuum pumps commercial air compressors, the first of which was installed in the Frick Building in 1902 and is illustrated in Fig. 6. Later he adapted the Clayton[12] air compressor, with mechanically-operated induction and poppet eduction valves on larger sizes, and single mechanically-operated induction and eduction valves on the smaller sizes.

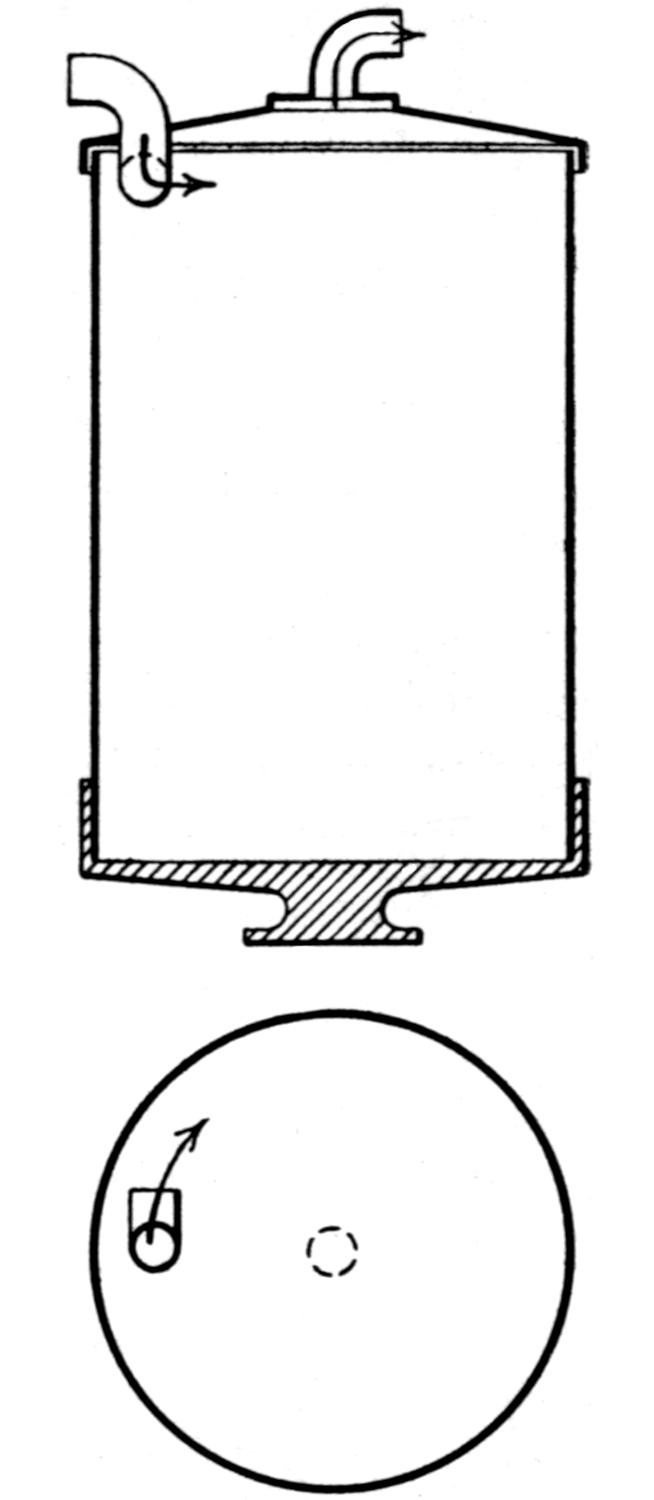

The separators used by Mr. Kenney differed from those used by the Sanitary Devices Manufacturing Company in that they contained several interior partitions, screens, and baffles, and the air was drawn directly through the body of water in the wet separator. The relative merits of these types of separators will be discussed in a later chapter.

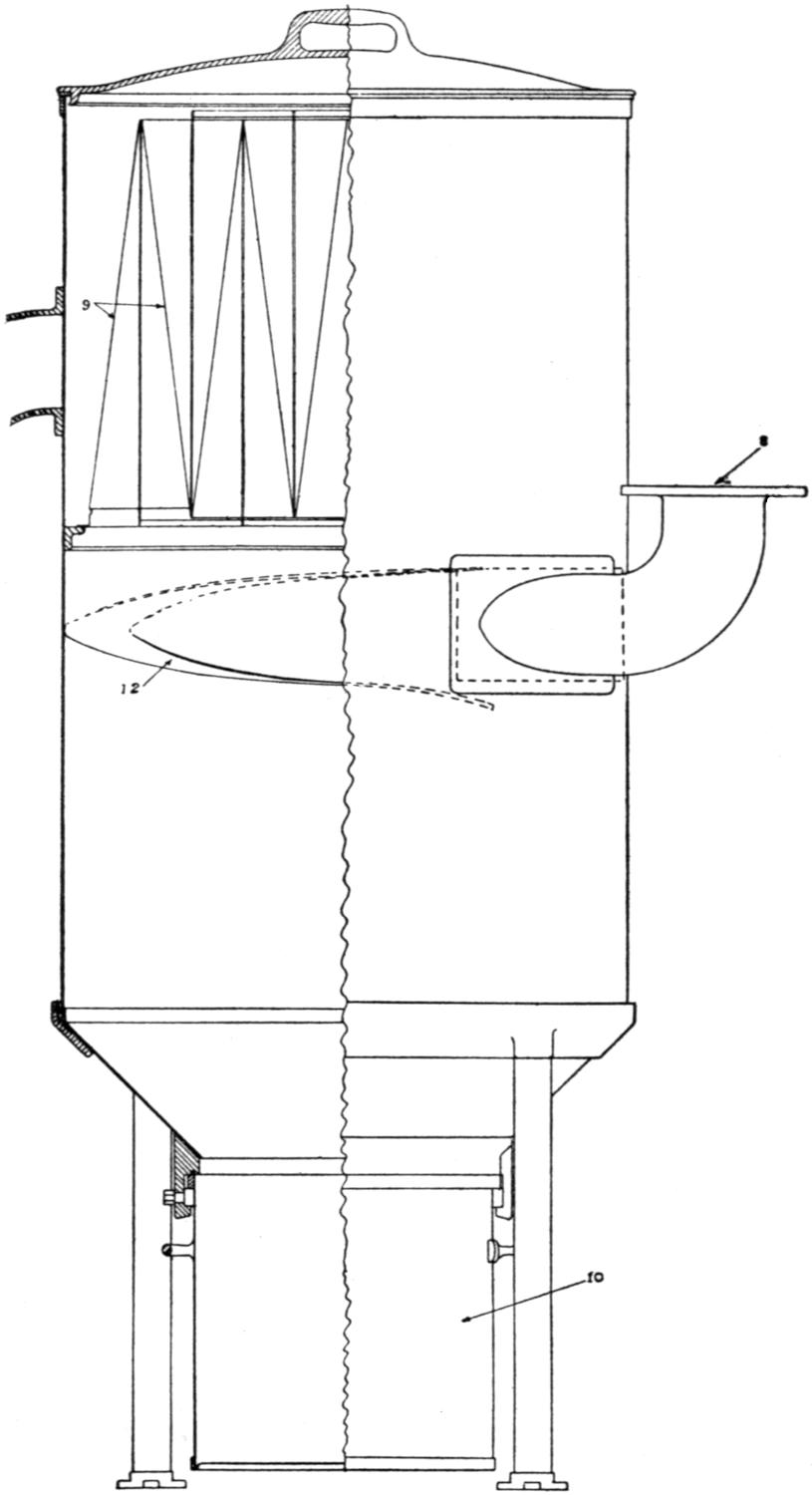

FIG. 7. SEPARATORS INSTALLED BY MR. KENNEY IN FRICK BUILDING.

The separators installed by Mr. Kenney in the Frick Building, and which are practically the same as were used by him[13] as long as he manufactured vacuum cleaning apparatus, are illustrated in Fig. 7.

After his application had been in the patent office for about six years he was granted a fundamental patent on a vacuum cleaning system.

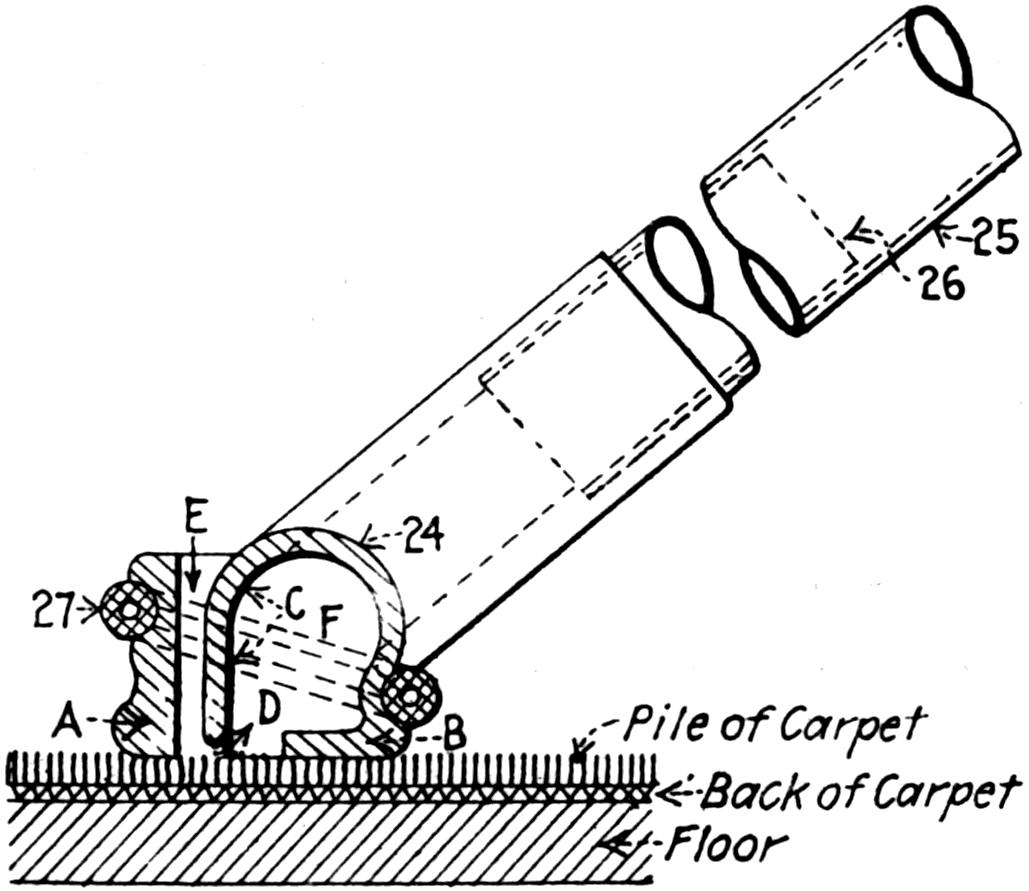

—The Sanitary Devices Manufacturing Company then produced a carpet renovator using vacuum only as a cleaning agent. This cleaner has a wider cleaning slot than the cleaners usually furnished by Mr. Kenney, about ⁵⁄₁₆ in. wide, with a supplemental slot or vacuum breaker opening out of the top of the renovator and separated from the cleaning slot by a narrow partition extending nearly to the carpet, as illustrated in Fig. 8. The relative merits of these types of renovators will be discussed in a later chapter.

FIG. 8. VACUUM RENOVATOR WITH INRUSH SLOT, INTRODUCED BY THE SANITARY DEVICES MANUFACTURING CO.

Shortly after the introduction of vacuum cleaning by Mr. Kenney and the Sanitary Devices Manufacturing Company, the American Air Cleaning Company published an interesting little booklet entitled, “Compressed Air Versus Vacuum,” which set forth in great detail the so-called advantages of compressed air over vacuum as a medium of mechanical carpet cleaning, and, apparently, proved that vacuum cleaners were much less efficient than cleaners operated by compressed air. A year or two later the American Air Cleaning Company evidently had a change of heart and began to manufacture these same “inefficient”[14] vacuum cleaners. Their previous treatise on vacuum cleaning, which apparently was not copyrighted, was republished by both the Sanitary Devices Manufacturing Company and by the Vacuum Cleaner Company, which had acquired Mr. Kenney’s patents, and freely distributed. Thus this little work of the Milwaukee company, instead of injuring their competitors, was turned into good advertising for them and required a lot of explanation from the Milwaukee company.

—The American Air Cleaning Company used a steam aspirator as its vacuum producer and, unlike its predecessor, the air-operated ejector, it made good and has also been used to a limited extent by the Sanitary Devices Manufacturing Company. It is now marketed by the Richmond Radiator Company, and its merits will be discussed in a later chapter. The American Air Cleaner Company also used as a vacuum producer the single-impeller type of rotary pump, made by the Garden City Engineering Company, which was also later adopted, to a limited extent, by the Vacuum Cleaner Company. This will be discussed further on.

The renovator used by this company was a single-slot type, with ¹⁄₈-in. by 10-in. cleaning slot. These systems at once became notable on account of the small size of the vacuum producers used, the low degree of vacuum carried, and the vigorous campaign of advertising which was conducted.

Several firms soon began to market vacuum cleaning systems almost identical with that of Mr. Kenney, among which were the Blaisdell Machinery Company, The Baldwin Engineering Company, and The General Compressed Air and Vacuum Machinery Company, the latter being the original Thurman company.

The Vacuum Cleaner Company then began a series of infringement suits against nearly every manufacturer of vacuum cleaning systems. In nearly every case the suit has resulted in the offending company paying license fees to the Vacuum Cleaner Company, and this concern has now abandoned the manufacture of vacuum cleaners and has become a licensing company. At this writing nearly twenty firms are paying[15] license fees to the Vacuum Cleaner Company and there is one suit now in the courts.

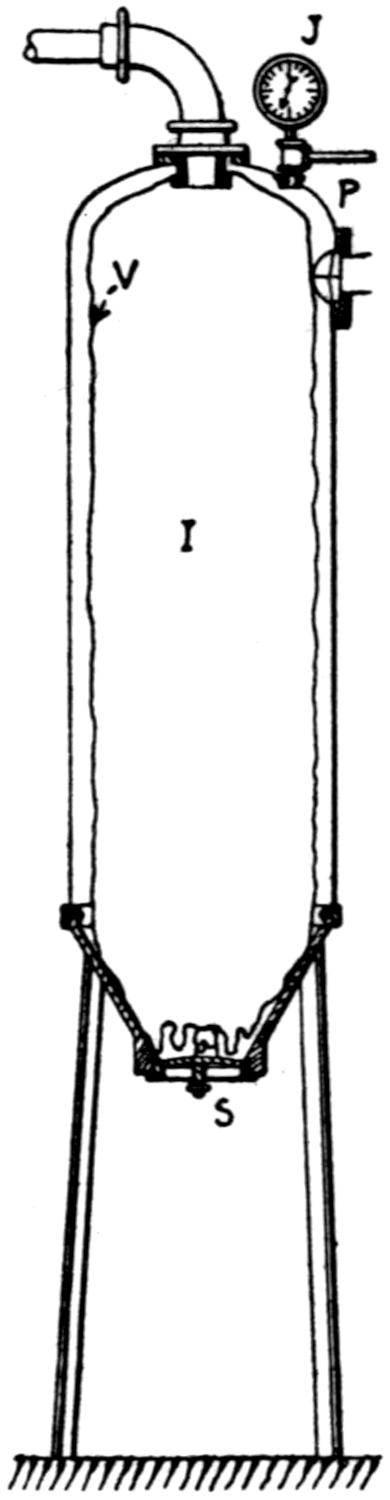

—A vacuum cleaning system of somewhat different design was produced by two former employees of the Vacuum Cleaner Company, Mr. Dunn, the once well-known “Farmer Dunn” of the weather bureau, afterward salesman for the Vacuum Cleaner Company, and Mr. Locke, at one time this firm’s engineer. This company was first known as the Vacuum Cleaning Company, and, shortly afterward, as the Dunn-Locke Vacuum Cleaning Company. No separators were used with this system, but the dust-laden air was led from the pipe lines directly into a chamber on the pump, known as the “saturation chamber,” and there mingled with a stream of water converting the dust into a thin mud. The air, water and mud then passed through the pump, the muddy water was discharged into the sewer, and the air into the atmosphere. The vacuum producer used was a piston pump without suction valves. With this system it was possible to handle water in almost unlimited quantities and with this feature a system of mechanical scrubbing was attempted for which great claims were made, none of which, however, were realized in a commercial way.

These gentlemen sold their patents to the E. H. Wheeler Company, which attempted to market the system in its original form. It was found, however, that the piston pump was not adapted to the handling of grit which was picked up by the renovators, and a rotary pump, with single impeller and a follower was substituted. This system is now marketed by the Vacuum Engineering Company, of New York, and is known as the Rotrex system.

Mr. Dunn again entered the field of vacuum cleaning and began marketing his machine a short time ago with a new form of automatic separator discharging to sewer.

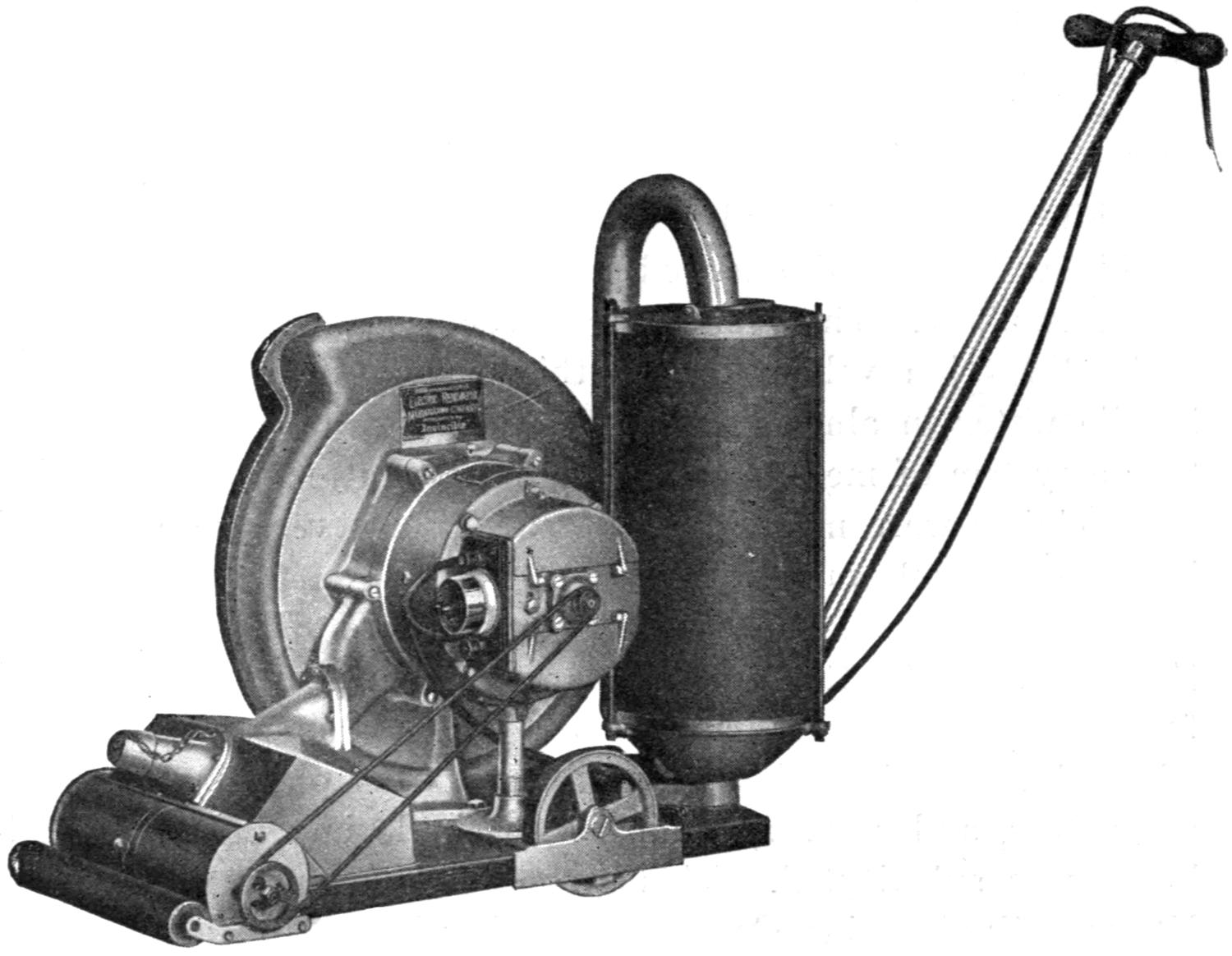

—About 1905, Dr. William Noe, of San Francisco, constructed the first portable vacuum cleaner. This machine contained a mechanically-driven rotary brush, similar to the brushes used in the familiar carpet sweeper, for loosening the dust from the carpet. This dust was sucked up by a two-stage turbine fan and discharged into a dust bag,[16] mounted on the handle, similar to the bags on the compressed air cleaners. The whole machine was mounted on wheels and provided with a small direct-connected motor. This machine is illustrated in Fig. 9 and is the original form of the well-known Invincible renovator manufactured by the Electric Renovator Company, of Pittsburgh. This company now produces a complete line of stationary and portable vacuum cleaners, all of which use multi-stage turbines. The sale of the product of this company, until recently, was controlled by the United States Radiator Corporation.

FIG. 9. FIRST PORTABLE VACUUM CLEANER, CONSTRUCTED BY DR. WILLIAM NOE, OF SAN FRANCISCO, IN 1905.

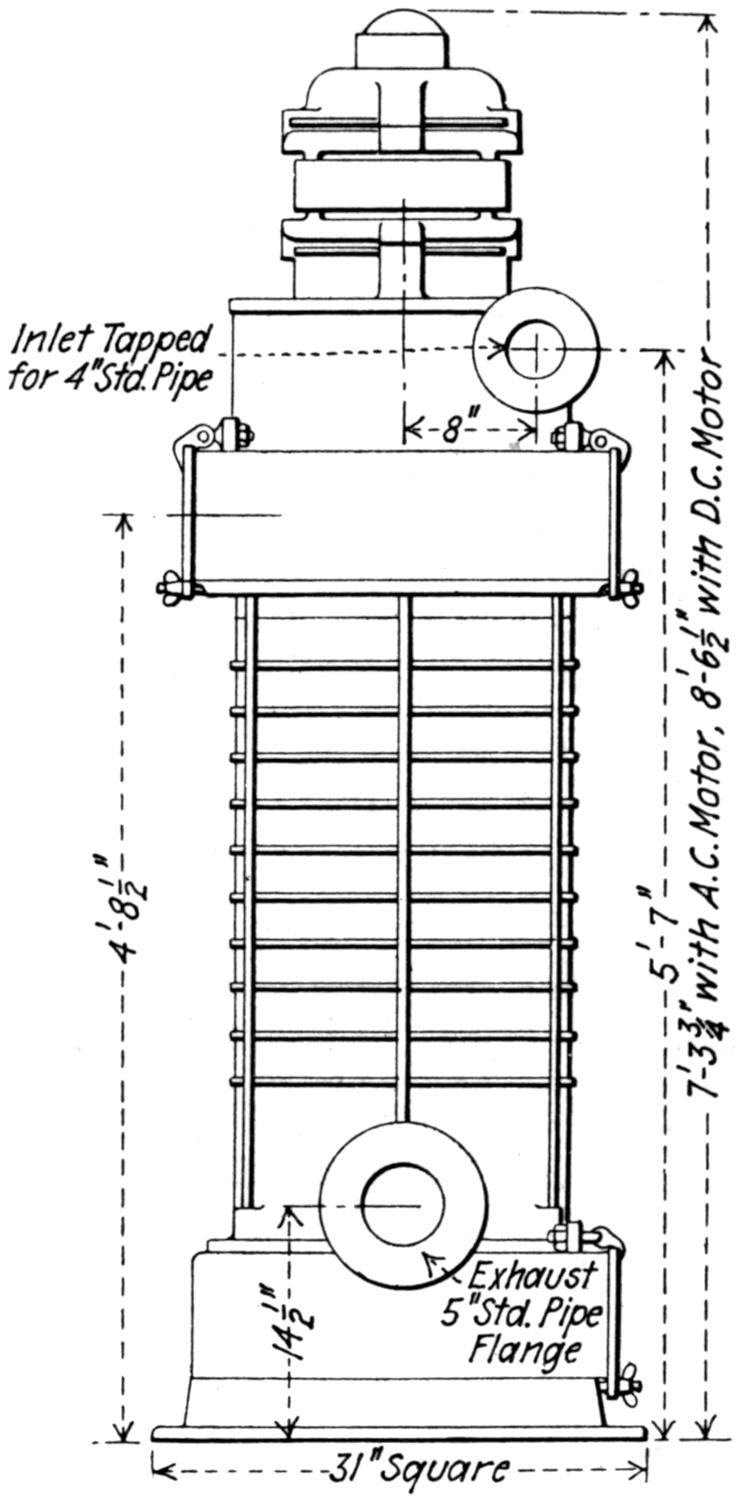

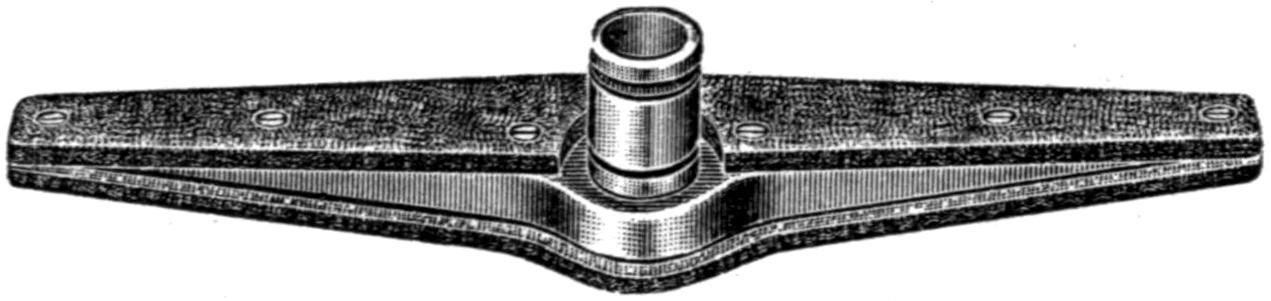

—About 1905 Mr. Ira Spencer, president and engineer of the Organ Power Company, which manufactured a multi-stage turbine blower for organs, known as the “Orgoblow,” organized the Spencer Turbine Cleaner Company and marketed a vacuum cleaning system, using a modification of the “Orgoblow” as a vacuum producer. These machines were first constructed with[17] sheet metal casings and had sheet steel fans, with wings riveted on and mounted on horizontal shafts. The separators were sheet metal receptacles with screens for catching litter. Light-weight hose, 2 in. in diameter, was used to connect the renovators to 4-in. sheet metal pipe lines. A variety of renovators was produced for use with this system. Carpet renovators having cleaning slots varying from 10 in. by ³⁄₄ in. to 20 in. by ¹⁄₄ in. were used, and a very complete line of swivel joints for connecting the renovators and the hose to the handles was developed. This system was operated at 5 in. vacuum, which was much lower than that used by any other system, 15 in. being standard at that time, and a much larger volume of air was[18] exhausted under certain conditions than was possible with any of the then existing systems. Owing to the large volume of air exhausted and to the large size of the renovators, hose and pipe lines, larger articles could be picked up than was possible with any of the existing systems. A great deal of weight was attached to this condition by the manufacturers, a favorite stunt being to pick up nails, washers, waste, small pieces of paper and even pea coal from a floor and finally to pick up a quantity of flour which had first been carefully arranged for the demonstration.

FIG. 10. LATE TYPE OF SPENCER VACUUM CLEANING MACHINE, OPERATED BY MULTI-STAGE TURBINE BLOWER.

This invasion of the vacuum cleaning field was considered by the established manufacturers as a freak and the apparatus was christened “the tin machine.” Whenever it was installed in competition with other forms of cleaning systems, the daily question asked by its competitors was, “Has the tin machine fallen apart?” However, the tin machine did not fall apart, but held its own with the other systems, even in its crude and inefficient state. Finding that the construction he had adopted was too flimsy and subject to abnormal leakage, Mr. Spencer developed a new form of machine, using cast-iron casing and welded fan wheels and adopted standard pipe and fittings. He also brought out a line of sheet metal tools and on the whole perfected a satisfactory cleaning system. One of his machines of a later type is illustrated in Fig. 10.

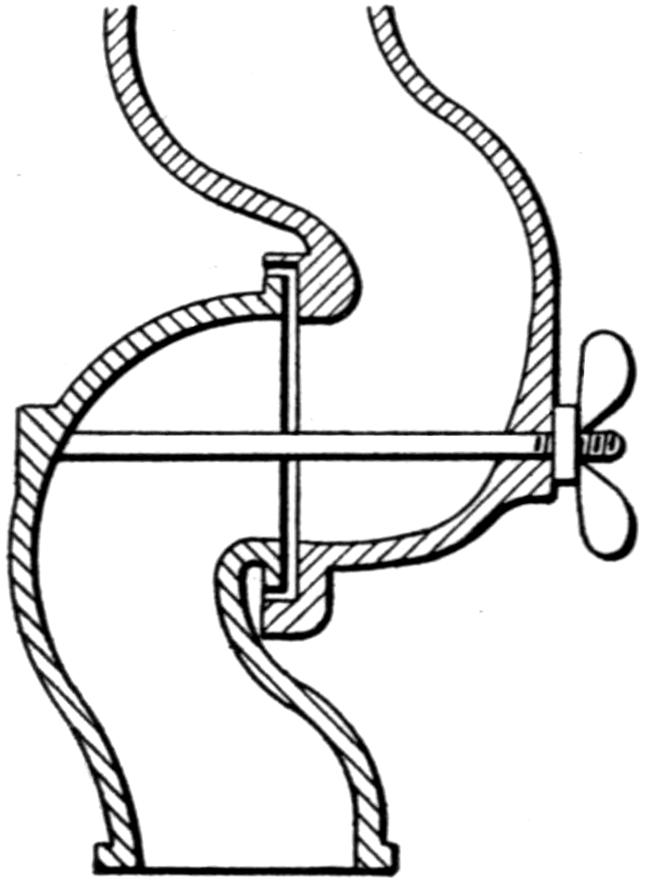

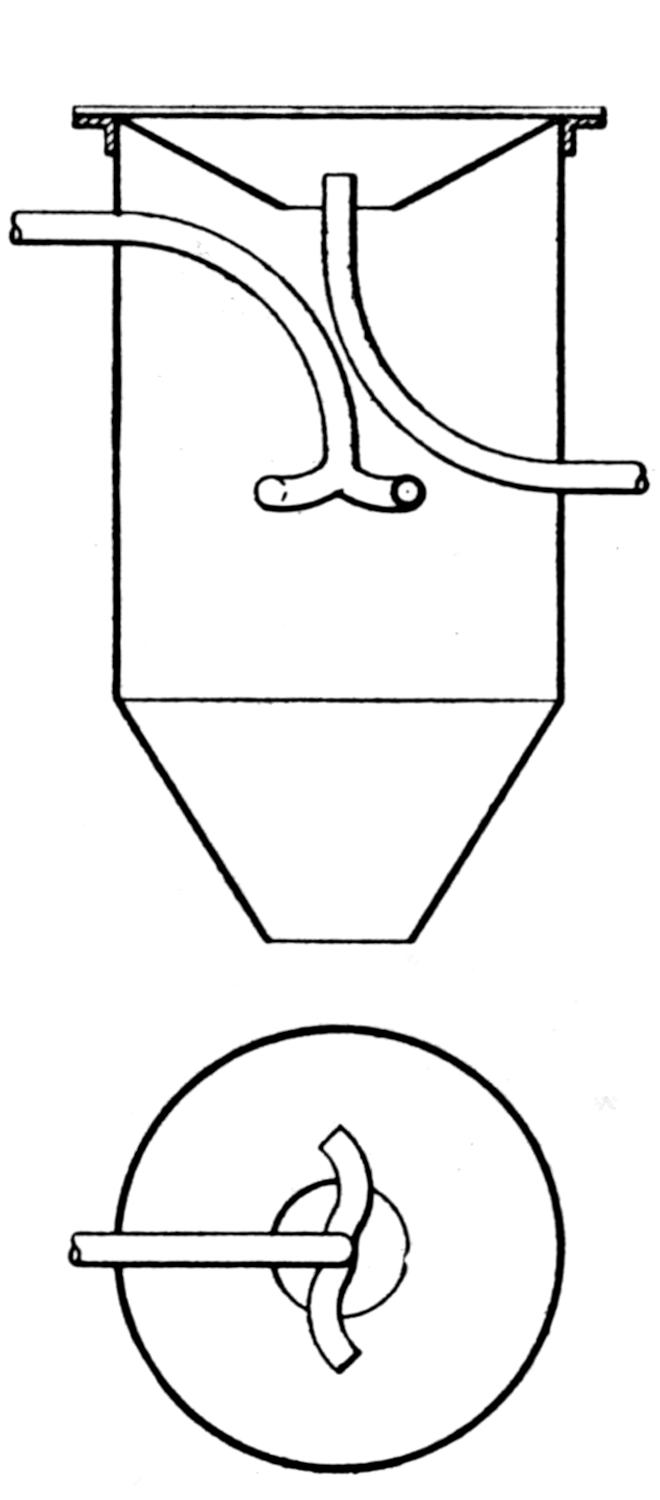

—A new form of vacuum cleaning system was introduced by Mr. Moorhead, of San Francisco, who used an inrush type of renovator having an inlet for air on each side of the cleaning slot.

The separator used with this system was a wet separator and contained a screen cleaned by a rotary brush into which all the dust contained in the air lodged. The pump used with this system was generally of the piston type, fitted with a single rotary valve, so connected to the valve stem that it could be rotated thereon and the machine changed from a vacuum pump to an air compressor in order that the contents of the separators might be discharged into the sewer by air pressure when it was desired to empty same.

This system was marketed by the Sanitary Dust Removal Company, of San Francisco, and, later, was taken over by the American Rotary Valve Company, of Chicago, which is now[19] marketing same. It eliminates the manual handling of the dust at any stage of its removal, a feature which is made much of by its manufacturers, but one which is likely to cause some trouble for the sewerage system if care is not exercised.

—The use of a Root type of rotary pump as a vacuum producer was first undertaken by the Foster and Glidden Engineering Company, of Buffalo, which marketed the Acme system about 1907, the same company having previously built a similar system for the removal of grain from steam barges. The other features of this system did not differ materially from those already on the market.

Being familiar with the various uses to which this type of vacuum pump had been adapted, the principal one being the operation of pneumatic tube systems, the author suggested the use of this type of vacuum producer about two years previous to its introduction and was advised by one manufacturer that such a type of pump was not suitable for vacuum cleaning. The fallacy of this statement will be brought out in detail in a later chapter.

The type of vacuum producer just described has been adopted in many makes of vacuum cleaners, including the Hope, Connellsville, Arco, and, lately, in the American Rotary Valve Company’s smaller systems.

During the past four years a score or more of new stationary vacuum cleaning systems have been introduced, among which are the Palm, a modification of the Dunn-Locke system; the Tuec, a turbine cleaner; the Water Witch, which uses a water-operated turbine as a vacuum producer, and the Hydraulic, with water-operated ejector. At the same time a hundred or more portable vacuum cleaners have been marketed. These are of almost every conceivable type and form and are operated by hand, electricity, and water power. Among them will be found machines which are good, bad and indifferent, the efficiency and economy of which will be discussed in a later chapter.

This nearly universal invasion of the vacuum cleaner field by anybody and everybody looking for a good selling article, establishes the fact that the vacuum cleaner is not a fad or fancy, but has become almost a household necessity and has led[20] large corporations to take it up as a branch of their business. First, the Sanitary Devices Manufacturing Company and the Vacuum Cleaner Company, the pioneers in the field, after a legal battle of years, consolidated with a view of driving their competitors from the field as infringers of the patents controlled by the two organizations. The result of this was the licensing of other companies. In an attempt to control the sale of their type of apparatus notice was served on all users of other types of vacuum cleaners that they were liable to prosecution for using infringing apparatus.

Later, the McCrum-Howell Company, a manufacturer of heating boilers and radiators, secured control of the products of the American Air Cleaning Company and the Vacuum Cleaner Company and sold these machines to the trade for installation by the plumbers and steam fitters. The McCrum-Howell Company has been succeeded by the Richmond Radiator Company, which is handling these vacuum cleaning machines.

Shortly afterwards, the United States Radiator Corporation secured control of the Invincible and the Connellsville systems, and, lastly, the American Radiator Company secured the Wand system.

Thus we see that vacuum cleaning seems to be virtually in the control of the manufacturers of heating apparatus, who are also among the largest corporations in this country and well able to control the future of this business to their liking.

As to the future of vacuum cleaning the author considers that it is at present, like the automobile, at the height of its career, and also, like the automobile, that it is a useful appliance to mankind and that it has its proper place as a part of the mechanical equipment of our modern buildings.

As to the type of vacuum cleaner of the future, the author believes that these appliances will become standardized, just as all other useful appliances have been, and that the form that it will then take will be a survival of the fittest. What that form may resemble the reader may more readily judge when he has completed the reading of this book.

[21]

Before a comparison of the relative merits of any line of appliances, used for any one purpose, can be intelligently made, one must have either some form of that apparatus which we consider as a standard for comparison that we may rate all others as inferior or superior thereto, or else an ideal of a perfect system must be assumed, and the measures with which each of the various appliances approaches the requirements of the ideal will establish their relative merits.

The author has elected to use the latter method in comparing the various systems of vacuum cleaning, and it is necessary, therefore, to first determine what are the requirements we shall impose on the ideal system.

An ideal vacuum cleaning system would be one which, when installed in any building, will displace all appliances used for dry cleaning in the semi-annual renovating or house cleaning, the weekly cleaning or Friday sweeping and the daily supplemental cleaning. If our system be truly an ideal one, the premises should never become so dirty as to require any semi-annual cleaning at all, and, if the daily cleaning be anyway thorough, there need be no weekly cleaning. This latter condition may be governed by the will of the housekeeper or janitor.

The compressed air cleaners first introduced were intended for use only at the semi-annual cleaning and they were in reality carpet renovators, which were assumed as imparting to the carpets all the beneficial results that could be obtained by taking them up and sending them to a carpet-cleaning establishment, with the advantage over this latter method, that the labor of removal and replacement of the carpets was rendered unnecessary, but with the disadvantage that all the germ-laden[22] air, used as a means of cleaning the carpets, was blown back into the apartment, leaving the germs in their former abode.

This disadvantage, however, is partly offset by the fact that while the majority of the germs in one’s own carpet are blown out at the carpet cleaners, a mixed company of germs from your neighbors’ and others’ carpets, which may be in the tumbling barrel at the same time with your own, are returned to you with your carpet.

Neither of these conditions is ideal and we will expect our ideal cleaner to completely remove from the premises, not only the dust and dirt, but also the germ-laden air which is used as a means of conveying this dirt.

For replacing the weekly and the daily cleaning, these earlier renovators were not suitable, as in order to use same the furniture must all be removed from the apartment.

To accomplish this daily and weekly cleaning, the ideal vacuum cleaner must replace the broom and dust pan, and their inseparable companion, the duster, and must also supersede that time-honored mechanical cleaner, the carpet sweeper.

The reader will doubtless consider that in making this statement the author is asking the vacuum cleaner to perform much more than it is usually called on to do. However, we are now discussing an ideal system, and the above requirements are not absolutely beyond what can be accomplished by some of the cleaning systems now on the market.

To accomplish this requirement the ideal cleaner must pick up everything likely to be found on the floor which cannot be readily picked up by hand. The character of this material will vary greatly according to the uses of the apartment cleaned. In residences and offices, where carpets or rugs are in use, cigar stumps and matches are usually deposited in cuspidors and small pieces of paper in waste baskets, consequently there should be nothing but dust to be removed from a residence and, perhaps, mud and sand from the shoes of the many visitors, in addition to the dust in an office.

However, there are special conditions likely to be met in many cases; sewing rooms will be littered with basting threads and scraps of cloth; department stores, with a great quantity of pins; banking rooms with bands and large-sized bank pins; all[23] of which increase the requirements of the ideal system. A cleaner which is perfectly adapted to one sort of apartment will be entirely unsuited for another, and the ideal cleaner will be one which can be readily adapted to all conditions likely to be met in the building in which it is installed.

The ideal cleaner must be able to accomplish the above stated requirements without the necessity of moving heavy pieces of furniture out of or about the apartment; that is, it must be capable of being efficiently operated under beds, tables and chairs, around the legs of other heavy furniture, behind bookcases, pianos, cabinets, etc., over curtains, draperies and hangings, over walls, behind pictures and over mouldings and carved ornaments, all without injury to any of the furniture or fittings of the apartment, and with the least expenditure of energy by the operator.

These conditions should be met with the fewest possible number of cleaning appliances, none of which should be provided with small attachments liable to be lost or misplaced, and all parts of the system, which must necessarily be moved about, either before, after or during the cleaning operation, should be of minimum weight and bulk, but of rugged and lasting construction.

The ideal vacuum cleaner should be of such proportions and provided with ample motive power to clean rapidly and effectively.

For use in an office building the cleaner should be able to thoroughly clean an average-sized office, including floor, walls, furniture and fittings in from 10 to 15 minutes, and for residence work, should be of sufficient capacity to clean an apartment, including floor, walls, curtains, draperies, pictures and furniture in not exceeding 30 minutes.

The ideal system should be so arranged that any apartment in the building can be cleaned with the least possible disturbance and without affecting the use of any other apartment, excepting perhaps, the corridors or hallways.

In large offices, drafting rooms and similar apartments, it may become necessary to clean same while they are occupied; therefore, our ideal system must be practically noiseless in operation and must offer the least possible obstruction to the proper use of the room by its regular occupants.

[24]

—To be of sufficient power to do rapid cleaning and in order to remove from the building all dust and germ-laden air, the cleaning system must necessarily contain some stationary parts. The motive power can generally be confined to these stationary parts, and must, in such cases, be located within the building to be cleaned. Therefore, it should operate with the minimum of noise and vibration.

Machines located in office or other large buildings, containing elevators or other complicated apparatus requiring skilled attendance, which are provided with complicated control and with other attachments, are not objectionable, and in such cases simplicity should give way to efficiency, but unnecessary complications should be avoided.

In residences and other small buildings, where the vacuum cleaner is likely to be the only machinery installed, the system must be one which requires the minimum attention and must be capable of being started and stopped by any person of average ability, without the necessity of going to the point where the machine is located.

The power consumption of the ideal system should be a minimum to accomplish satisfactory results and should be, as nearly as possible, directly proportioned to the amount of cleaning being done. This requirement is most important in hotels, where some cleaning is likely to be done at all hours, day and night. In other words, vacuum must be “on tap” and as readily attainable at any point in the building as your water or electric light. In office buildings, where a schedule of cleaning hours is fixed, and in residences where cleaning hours are few and the capacity of the plant is rarely more than could be attended to by one operator, this requirement is not of as great importance.

Lastly, our ideal system, from the standpoint of the purchaser, must be of such rugged construction, as will enable it to operate efficiently for, at least, ten years and its mechanical details such that it will operate continuously, without expert attention, and that the annual expense for repairs during the life of the machine will not exceed 5% of the first cost of the system.

[25]

In undertaking the comparison of a number of different makes of any appliance, in order to determine the good and bad points in each, where the apparatus is composed of a number of separate and distinct parts, each having its proper function, which they must perform in order to make the whole apparatus effective, as in a vacuum cleaning system, it becomes necessary to isolate temporarily each part and consider its action, first, as a unit working under the most favorable conditions, and, second, as a component part of the whole apparatus in order to determine where the weak points in any system occur and what modifications are necessary in the various parts of the apparatus to make some vital part of the whole more effective. It is further necessary to determine what are the vital parts of the system in order that the other parts may be accommodated to the effective action of that part.

—In analyzing a vacuum cleaning system it naturally divides itself into four parts, viz.: the cleaning tool or renovator, the air-conveying system or hose and pipe lines, the separators or other means of disposal of the material picked up, and the vacuum producer.

The author considers that the renovator is the most important part of the system and that the other parts should be made of such proportions and with such physical characteristics as will produce the proper conditions at the renovator to permit it to perform its functions in the most effective manner.

As the vacuum cleaning system must be capable of cleaning surfaces of a widely variable character many forms of renovators are necessary. Of the various surfaces cleaned the author considers that carpets and rugs comprise the most important,[26] as well as the most difficult to clean effectively, so that the carpet renovator will be considered first.

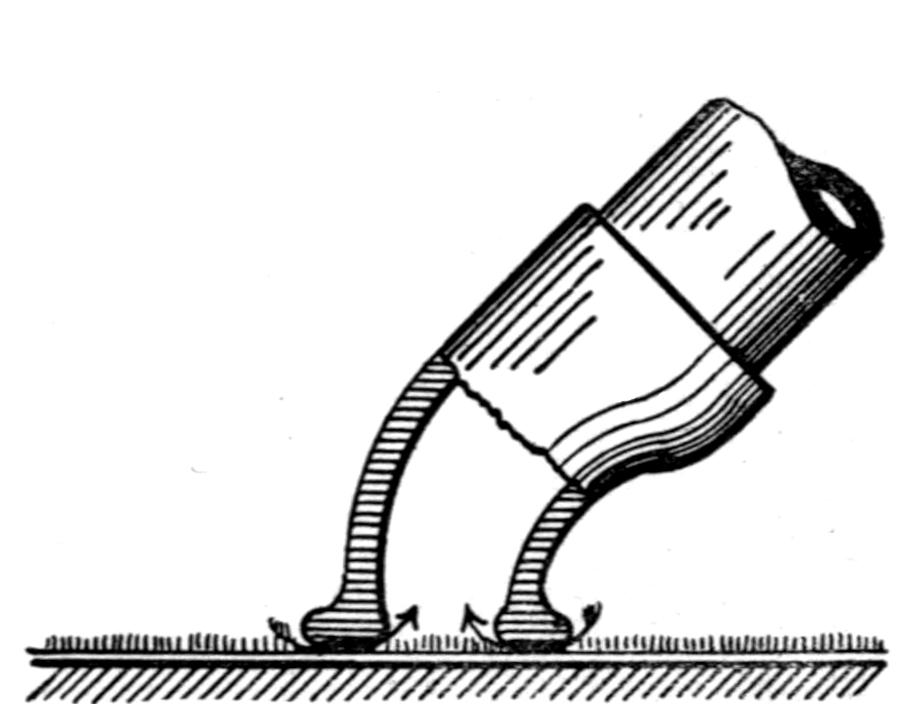

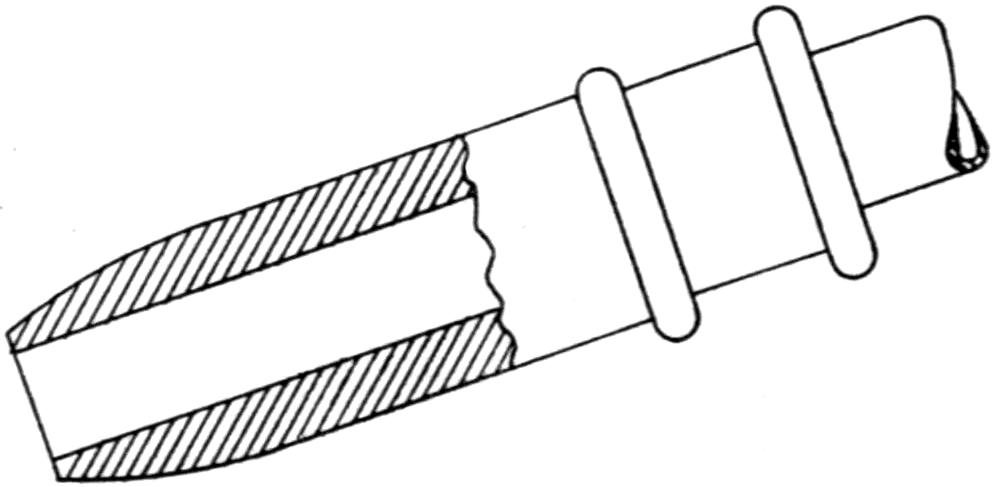

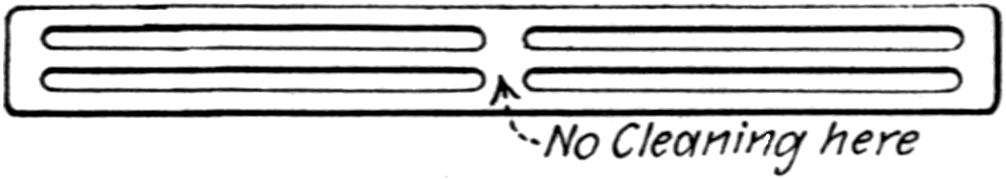

—Various forms of carpet renovators have been and are in use by manufacturers of vacuum cleaning systems. The first type of renovator to be considered is that having a cleaning slot not over 12 in. long, with its edges parallel throughout its length, and not over ³⁄₈ in. wide, with a face in contact with the carpet not over ³⁄₈ in. wide on each side of the slot. This form of renovator is illustrated in Fig. 11 and is designated by the writer as Type A. The first of these renovators was introduced by Mr. Kenney and, as finally adopted by him, was 12¹⁄₂ in. long, with ⁷⁄₈-in. face and with a cleaning slot 11¹⁄₂ in. long and ⁵⁄₃₂ in. wide. This form of cleaner was termed the “straight vacuum tool” and is used today by many manufacturers. Slight modifications in its form and dimensions were made in some cases, as in the one manufactured by the American Air Cleaning Company. In the one used in all tests by the writer on type A renovators, the slot was reduced to 10 in. long and ¹⁄₈ in. wide and the face of the renovator was slightly rounded at the outer edges, leaving very little surface in contact with the carpet.

FIG. 11. TYPE A, THE STRAIGHT VACUUM TOOL.

FIG. 12. TYPE B, WITH WIDE SLOT AND WIDE BEARING SURFACE.

A renovator of this type is easily operated over any carpet even when a considerable degree of vacuum exists within the renovator itself. It has met with favor when used with the piston type of vacuum pump without vacuum control, as was the case with the earlier systems. However, when a very high[27] degree of vacuum occurs within the renovator it has a tendency to pull the nap from the pile of the carpet.

Soon after the introduction of this form of renovator, some users of same, particularly in San Francisco, complained that while the renovator effectively removed the dust from carpets it failed to pick up matches and other small articles and preliminary or subsequent cleaning was necessary in order to remove such litter.

To overcome this difficulty Mr. Kenney increased the width of the cleaning slot to nearly ¹⁄₂ in., with the result that when a high degree of vacuum existed within the renovator, which often occurred where no vacuum control was used, it stuck to the carpet, rendering its operation difficult and, at the same time, doing great damage to the carpet. Hence, its use with the piston type of vacuum pumps was abandoned.

Mr. Kenney then modified this wide slot renovator by making the face of same much wider, thus having more surface in contact with the carpet on each side of the slot, preventing the renovator from sinking into the nap of the carpet. This type of renovator is illustrated in Fig. 12 and has been designated as Type B. While not as destructive to the carpets, when a high degree of vacuum existed under the same, it still pushed hard and was not as rapid a cleaner as the narrow-lipped Type A renovator.

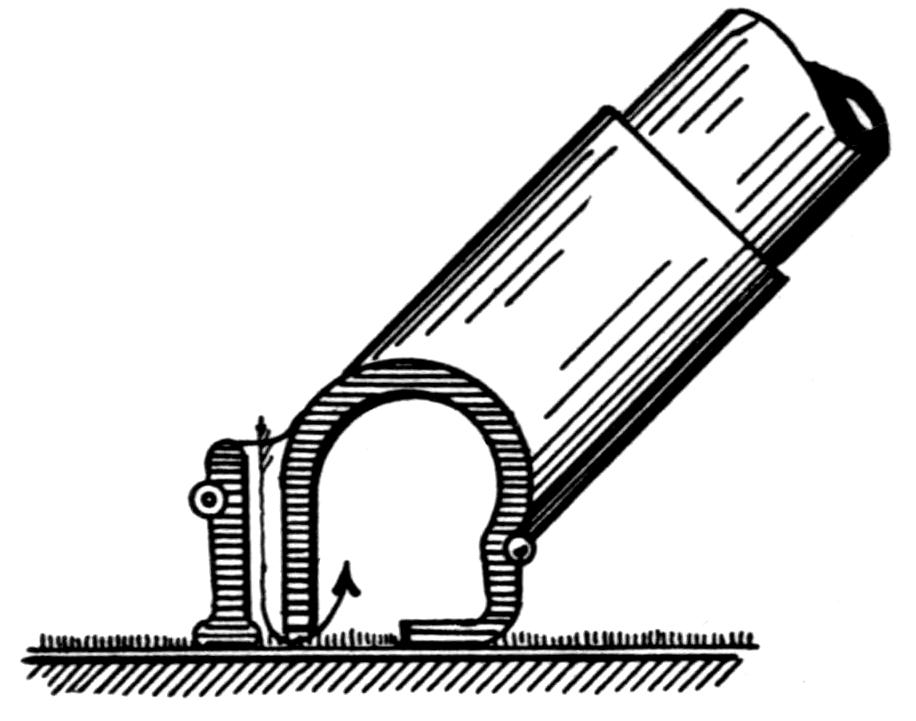

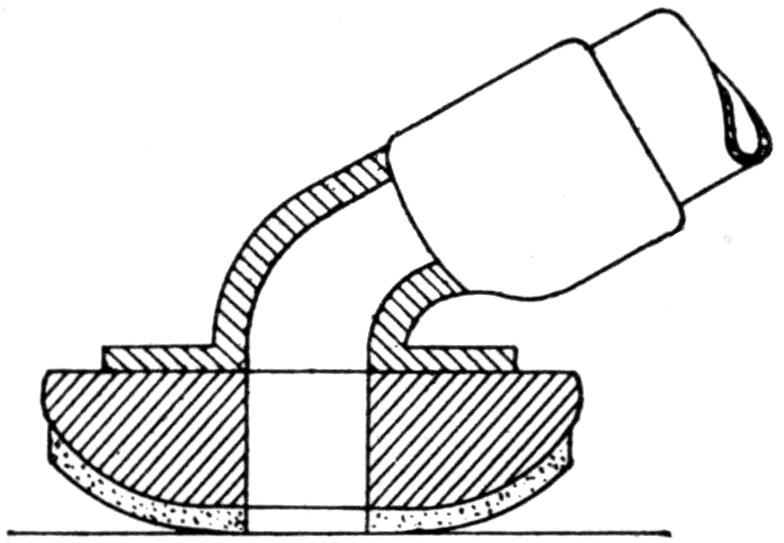

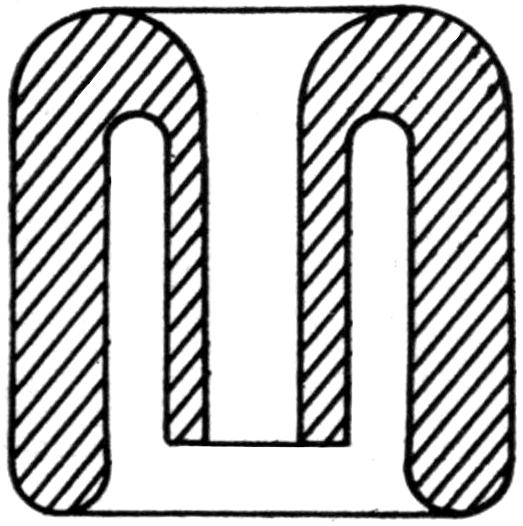

—The renovator introduced by the Sanitary Devices Manufacturing Company differed widely from the former types in that it was provided with an auxiliary slot, open to the atmosphere through the top of the renovator, which communicated with the slot open to the vacuum by a space of ¹⁄₃₂-in. under the partition separating the slots. The cleaning slot was made ⁵⁄₁₆-in. wide and the face of the renovator was made 2-in. wide, which gave a contact of ¹³⁄₃₂-in. in front of the inrush slot and ²¹⁄₃₂-in. in the rear of the cleaning slot. This form of renovator is illustrated in Fig. 13 and is designated as Type C.

The auxiliary slot or vacuum breaker permitted air to enter the cleaning slot even when the renovator was placed on a surface plate, and, owing to this feature, a high degree of vacuum never existed within the renovator. It was always[28] easy to operate and did not damage the carpet. Owing to the wide slot, articles of considerable size could be picked up, and there was always an abundance of air passing through the renovator to produce a velocity in the hose and pipe lines sufficient to carry any heavy articles picked up.

The vacuum producer, control apparatus and the proportions of the hose and piping used at that time made the degree of vacuum in the renovator a function of the quantity of air passing, with wide limits of variation under existing conditions, and this form of renovator is practically the only one which will do effective cleaning, including the picking up of litter, without undue wear on carpets, when used with a system having the above-stated characteristics. This renovator, however is not without its faults. Owing to the wide surface in contact with the carpet, a considerable degree of vacuum is necessary in order that any air shall enter the renovator under the faces of same and, as the air entering the inrush slot prevents the formation of such vacuum within the renovator, very little air enters the renovator between its face and the carpet. When the renovator is operated on a carpet having a glue-sized back, no air enters through the carpet, therefore all air entering the renovator must come through the inrush slot and under the partition separating same from the cleaning slot. Under these conditions only one side of the vacuum slot is effective and this effective side is raised above the surface of the carpet.

FIG. 13. TYPE C, WITH AUXILIARY SLOT, OPEN TO ATMOSPHERE.

FIG. 14. TYPE D, WITH TWO CLEANING SLOTS.

When operated on an ingrain or other loose-fabric carpet, much air enters through the fabric of the carpet, due to the[29] wide cleaning and inrush slots, in addition to the quantity of air entering through the inrush slot, making this renovator, when operating under these conditions, use an unnecessary amount of air. Apparently, this renovator has been designed to prevent the formation of any great degree of vacuum under same and such a design has resulted in a greater volume of air at a lower vacuum passing through than through renovators of other types.

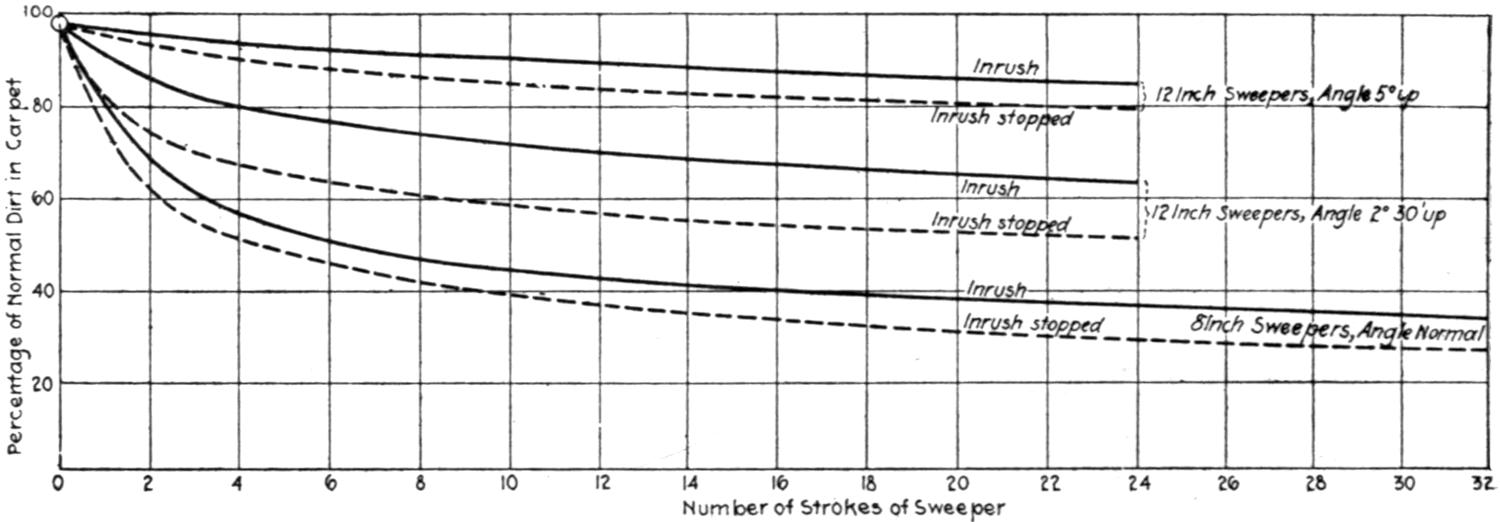

This property of the renovator raises the question whether the quantity of air or the degree of vacuum in the renovator is most essential for the removal of dirt from carpets. Tests made by Mr. S. A. Reeve, consulting engineer for the Vacuum Cleaner Company, with this type of renovator, with the inrush open and repeated with the inrush closed, disclose the fact that it does more effective cleaning with its inrush closed, while the volume of air passing is considerably less with the inrush closed. The degree of vacuum was greater, which tends to indicate that the vacuum within the renovator is the most important factor.

An extract from the affidavits of Mr. Reeve in one of the numerous patent suits will show his explanation of this phenomenon: “If we examine more closely into the actual process whereby such a sweeper succeeds in extracting dust from carpets, etc., it will appear that the actual cleaning is effected at the periphery of the slot in the lower surface of the sweeper. It is accomplished chiefly by the development of local changes of air pressure at the lips defining this slot, incidentally to the movement of the tool over the carpet. These changes cause the air occupying the interstices between the dust particles to expand suddenly, thus ‘raising the dust.’ To a lesser degree, the scouring is effected by highly localized air currents of considerable velocity, engendered where the tool comes in contact with the carpet. These air currents pick up the dust which has already been expanded or raised by pressure change. They will be of higher velocity, and therefore more effective, the better the contact of the tool with the carpet. The same is true of the pressure changes.

“All this action depends for its intensity, speed and effectiveness, not on the vacuum existing at the pump or in the[30] separators, but upon the vacuum prevailing within the sweeper head itself.”

—Another form of renovator was introduced by the Blaisdell Machinery Company which contained two cleaning slots each ³⁄₁₆-in. wide and 12-in. long, separated by a partition ¹⁄₄-in. wide in contact with the surface of the carpet, as indicated in Fig. 14 (Type D). While this form of renovator has a greater area of cleaning slot than Type A, its individual cleaning slots are no wider; therefore, it cannot pick up anything larger than can be picked up by Type A. As no air can enter under the partition it can do no more effective work as a dust remover when operated on a carpet with a glue-sized back and its only advantage over a cleaner of Type A is that when operated on a loose-fabric carpet more air can pass through the fabric into the cleaning slot, thus giving a greater variation in the quantity of air exhausted when operated on carpets of different texture, a condition which is undesirable when used with a system having characteristics previously described.

Tests of this type of renovator, made by Mr. Reeve, are given later in this chapter.

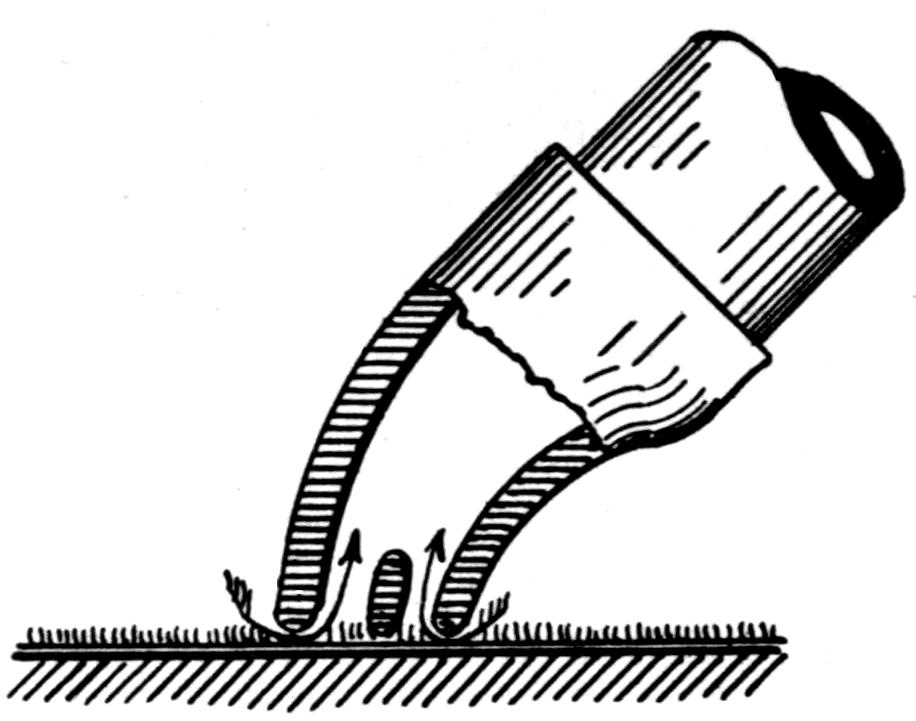

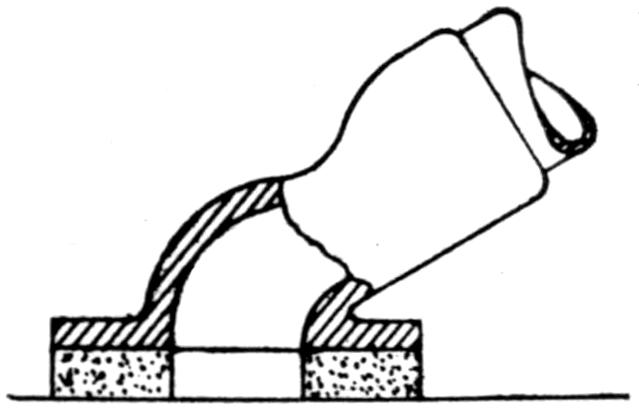

—Another form of renovator, introduced by Mr. Moorhead, is illustrated in Fig. 15 (Type E). This is a modification of Type A in that an inrush slot is provided on each side of the vacuum slot, these inrushes being hinged members which form the sides of the cleaning slot. This cleaner has the advantage over Type C renovator in that it can take air from either side, but in action it takes air from but one side at any time. Its inrush will not become entirely clogged, but its mechanically-moving parts in contact with the dust and lint picked up will easily become inoperative and are as like as not to become caught wide open when the air entering the cleaner will not come into intimate contact with the carpet. In that event, its cleaning efficiency will be greatly reduced. The author has not had an opportunity to make any comparative tests of this form of renovator.

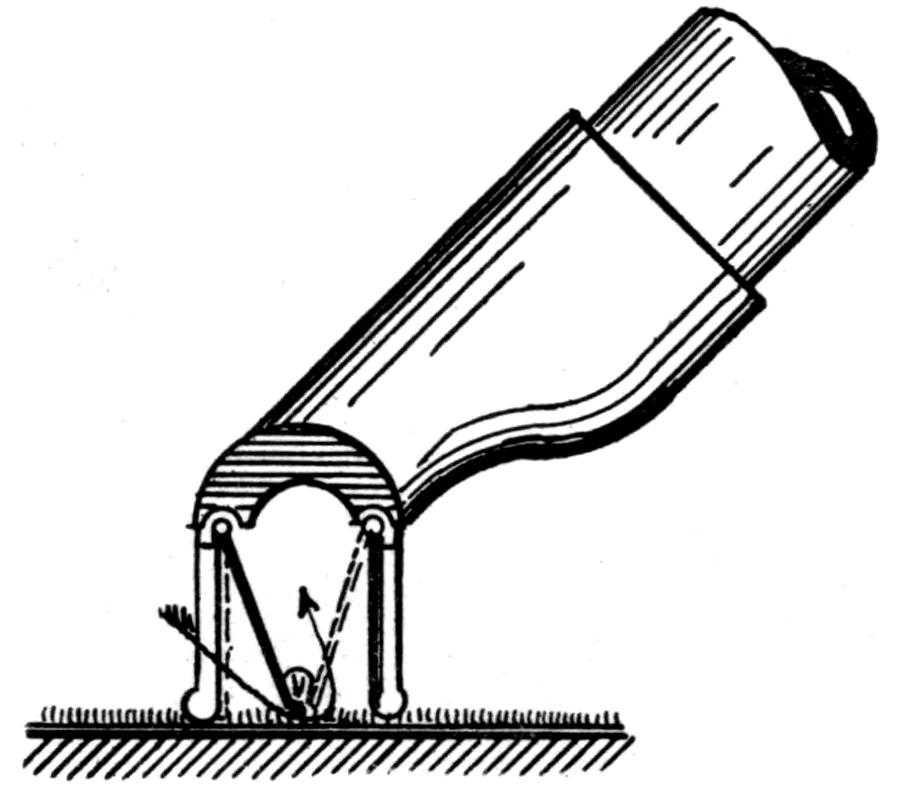

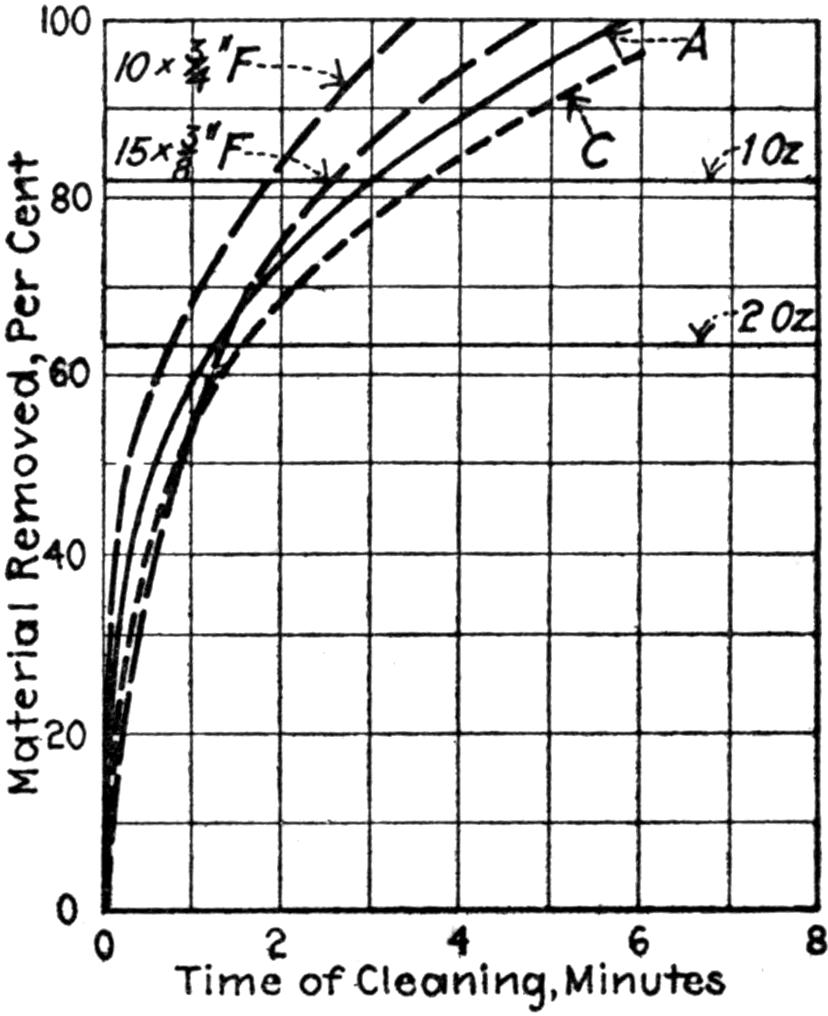

When Mr. Spencer introduced the centrifugal fan as a vacuum producer, he also brought out a series of carpet renovators[31] of various forms and sizes. One had a cleaning slot ³⁄₄-in. wide and 10-in. long, another a slot 15-in. long, ¹⁄₄-in. wide at its end, increasing to ³⁄₄-in. at the center. Another had a slot 20-in. long and ³⁄₈-in. wide, and finally he adopted a tool with a cleaning slot 15-in. long and ¹⁄₂-in. wide throughout its length. This is merely the re-entrance into the field of the wide-slot tool first used by Mr. Kenney and its successful operation depends on its use with a vacuum producer of such characteristics and a hose and pipe line of such proportions that practically a constant vacuum is maintained within the renovator, regardless of the quantity of air passing through the tool. The latest form of this renovator, as used by Mr. Spencer, is illustrated in Fig. 16. At the time that the writer made tests on renovators of this make, the majority of the tests were made with a renovator having a cleaning slot 10-in. long and ³⁄₄-in. wide. This renovator is designated as Type F, while the 15-in. × ¹⁄₄-in. to ³⁄₄-in. slot is designated as Type F¹.

FIG. 15. TYPE E, WITH INRUSH SLOT ON EACH SIDE OF VACUUM SLOT.

FIG. 16. TYPE F, AN EXAGGERATED FORM OF TYPE B.

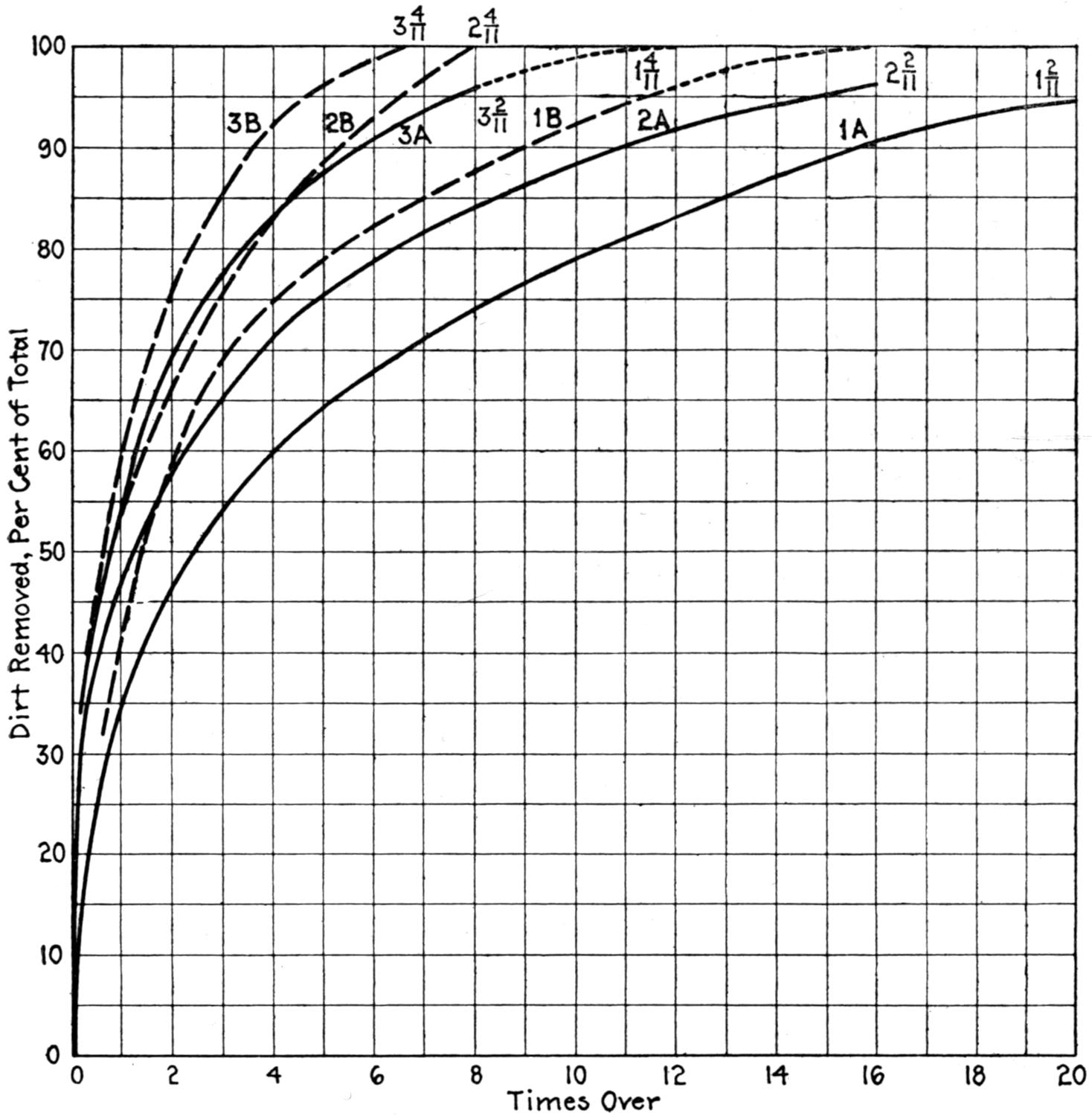

About seven years ago the Supervising Architect of the United States Treasury Department gave consideration to the use of a carpet cleaning test to determine the acceptability of any vacuum cleaning system which might be installed in any of the buildings under his control. The author was instructed to make a series of tests of carpet renovators, with a view of determining: (1) the feasibility of using a carpet cleaning test to determine the merits of a vacuum cleaning system; (2) to[32] fix the requirements to be incorporated in a specification where the acceptance of the system was dependent on a satisfactory carpet cleaning test, to be made at the building after the completion of the installation; (3) to determine what requirements, other than a cleaning test, would be necessary to obtain a first-class cleaning system.

The record of many such tests was shown to the author, shortly before he began making tests. These purported to have been made by Prof. Miller at the Massachusetts Institute of Technology, with a pump furnished by the Sanitary Devices Manufacturing Company, in which the efficiency of the inrush type of renovator (Type C) and the straight vacuum renovator (Type A) was compared. The results of these tests, as given in a brief resumé, which was distributed by the Sanitary Devices Manufacturing Co., indicated that the Type C renovator was the more rapid and efficient cleaner.

The author learned that these tests were made by the undergraduate students as a part of the regular laboratory work, and that later a series of tests was made as the basis of a thesis by Messrs. Paterson and Phelps in 1906, using the above-described apparatus. The following year another series of tests was made by Mr. Stewart R. Miller, as the basis of an undergraduate thesis, in which the efficiencies of the piston pump and inrush sweeper of the Sanitary Devices Manufacturing Co. were compared with those of the steam aspirator and straight vacuum renovator of the American Air Cleaner Company. A copy of this thesis was furnished the author by the Sanitary Devices Manufacturing Company shortly after the completion of the tests made by the author.

The relative efficiency of the two types of renovators reported by these tests differed widely in each case, an occurrence which is liable to happen where undergraduate students are engaged in such work. They were, therefore, considered as of doubtful reliability.

The author could find no record of any tests made by anyone of longer experience and, indeed, these were the only tests of which he could find any record.

As the author desired to specify a cleaning test which could be readily repeated at the building in which the cleaning system[33] was installed, which building was likely to be located in any part of the United States, no exhaustive laboratory methods were desired or attempted. As the building was likely to be located in a city where no other vacuum cleaning systems were then installed and in a new building in which no dirty carpets were available, and as it was not desirable to have the contractor furnish the material for the test, it was considered necessary to use some material in soiling carpets which would be readily obtainable anywhere, which could be readily brought to a standard, and which, when worked into the carpets in a reasonable length of time, would be as difficult to remove as the dirt found in the average dirty carpet.

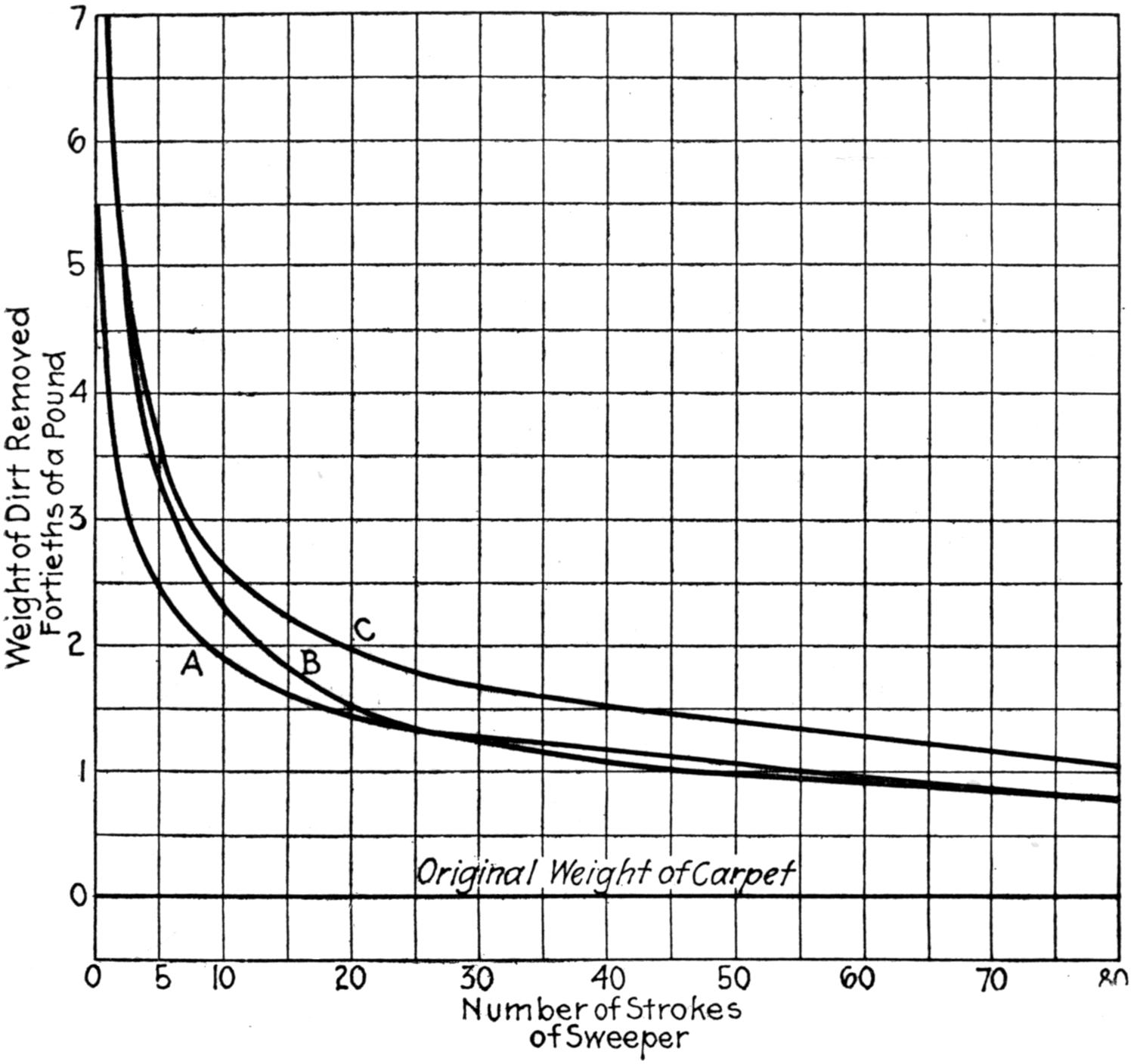

—As no tests of cleaning an actually dirty carpet were on record, quicksand having been used in the Institute of Technology tests, it was necessary to first clean some carpets that had been soiled in actual daily service in order to obtain a standard with which to compare the results in removing various substances, which it was intended to try as a substitute for dirt. A carpet which had been in actual use for a number of years on the floors of the old United States Mint building, in Philadelphia, and receiving the ordinary amount of cleaning, was procured. This was a Brussels carpet with a glue-sized back, containing about 20 sq. yds. It was divided into three approximately equal parts.

An indicator was attached to the vacuum pump for taking air measurements, and it was found that there was considerable leakage of air into the system through the connections to the separators and at other points, therefore the pump was operated with 22 in. of vacuum in the separator and a card taken with all outlets closed and the amount of leakage noted. During the tests this degree of vacuum was always maintained in the separators and pipe lines and the vacuum in the renovator was varied throughout the tests by throttling the hose cock. This manner of making tests gave a practically constant leakage which was deducted from the quantities shown by the indicator cards taken with the renovators in operation.

As the writer had already made many tests of the efficiency of various types of vacuum pumps as air movers under various degrees of vacuum, and as the capacity of the pump available[34] was far in excess of that required to operate one renovator, no attempt to obtain the efficiency of the plant as a unit was made. Instead, the vacuum at the hose cock was adjusted until the degree obtained was what the writer had found to be within the limit obtained in practice. The resulting vacuum at the renovator was then noted.

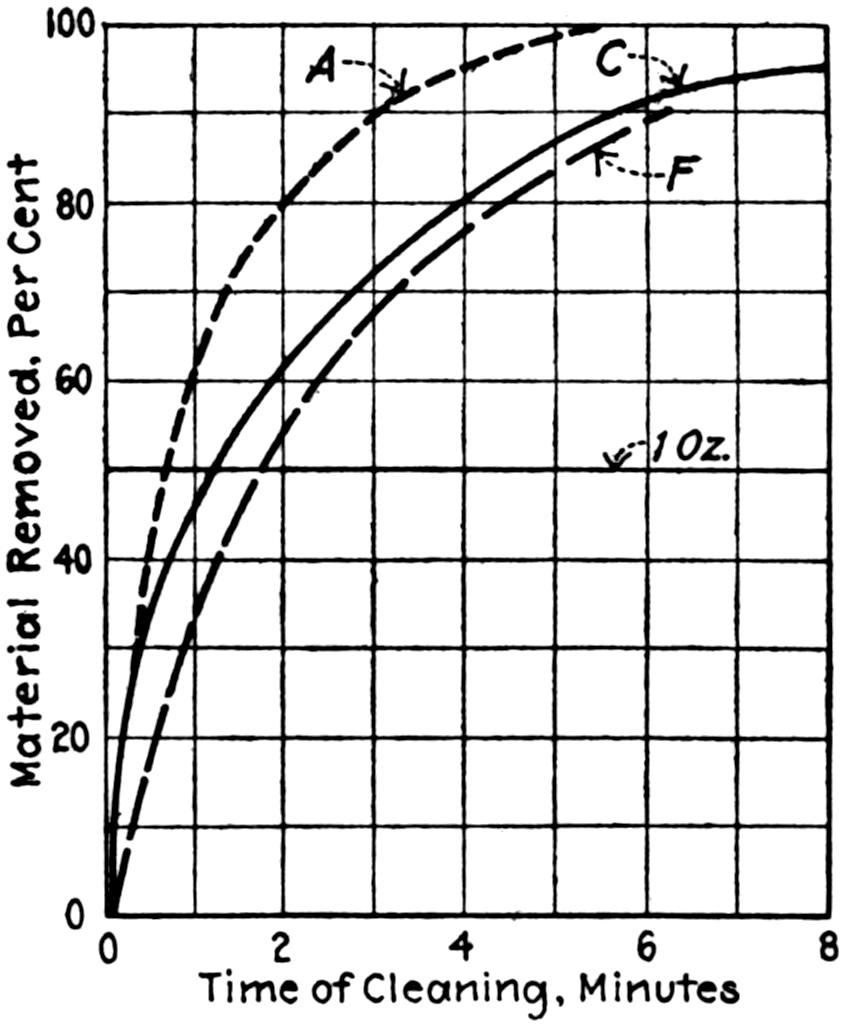

Each piece of carpet was cleaned during six periods of one minute each, using a different vacuum at the tool for each piece of carpet. The carpets were weighed at the beginning of the test and after each one-minute period. At the conclusion of these tests each carpet was cleaned until no change of weight occurred after two minutes’ cleaning. They were then considered as being 100% clean and this standard was made a basis for computing the percentage of dirt removal. A renovator of Type C was used in these tests.

Shortly afterward a similar test was made on a dirty carpet of 4.6 sq. yds. area, using a renovator of Type F. This carpet was also a Brussels, with glue-sized back, which had been in use in the shoe department of a large department store in Hartford. These carpets contained approximately 2 oz. of dust per square yard, none of which was visible on the surface, and they were probably as clean as the average carpet after being gone over with a carpet sweeper or after a light application of a broom.

TABLE 1.

Cleaning Tests of Dirty Carpets.

| Type of Renovator. | A | C | F | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vacuum in renovator, in. Hg | 2 | 4¹⁄₂ | 1 | 2¹⁄₂ | 4 | 3¹⁄₂ | ||||||

| Air exhausted, cu. ft. per min. | 16 | 27 | 24 | 37 | 44 | 59 | ||||||

| Material removed, per cent. of total, 1 min. | 50 | 60 | 37 | 39 | 47 | 35 | ||||||

| Material removed, per cent. of total, 2 min. | 72 | 81 | 52 | 59 | 63 | 55 | ||||||

| Material removed, per cent. of total, 3 min. | 85 | 90 | 59 | 66 | 71 | 69 | ||||||

| Material removed, per cent. of total, 4 min. | 90 | 95 | 61 | 72 | 83 | 77 | ||||||

| Material removed, per cent. of total, 5 min. | 93 | 98 | 66 | 75 | 87 | 84 | ||||||

| Material removed, per cent. of total, 6 min. | 95 | 100 | 67 | 82 | 90 | 89 | ||||||

| H. P. per ounce dust | 0. | 037 | 0. | 147 | 0. | 045 | 0. | 116 | 0. | 252 | 0. | 261 |

| Ounces dust per minute | 1. | 9 | 2. | 0 | 1. | 34 | 1. | 64 | 1. | 8 | 1. | 78 |

| H. P. at renovator | 0. | 07 | 0. | 29 | 0. | 06 | 0. | 19 | 0. | 45 | 0. | 475 |

[35]

As the sizes of the carpets used in making the tests were not always the same, allowance has been made for this variation by using, in the case of Type F renovator, instead of the true time, a calculated time which allows each renovator the same time for cleaning 1 sq. yd. of carpet. For instance, in the case of the small carpet cleaned with Type F renovator, an interval of 60 × 4.6 ÷ 6, or 46 seconds, was taken as equal to one minute’s cleaning of the carpet with types A and C renovators. Such interval is stated and plotted as one minute in the table opposite, which gives the results of cleaning dirty carpets with the three types of renovators.

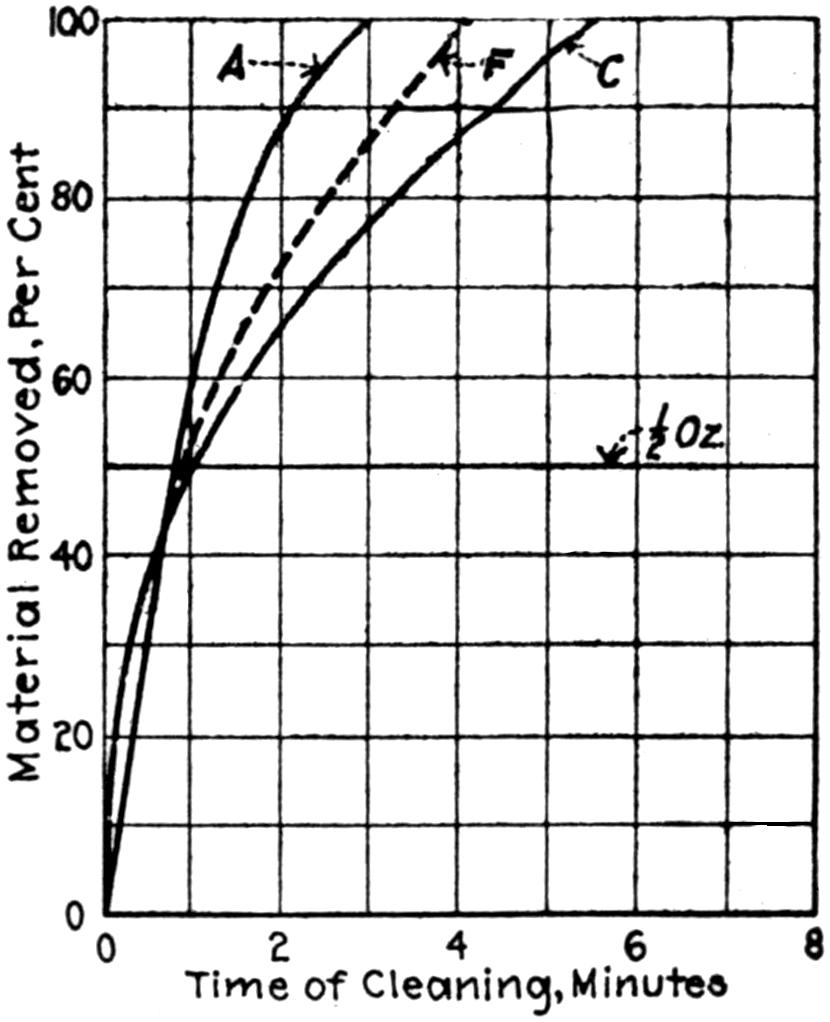

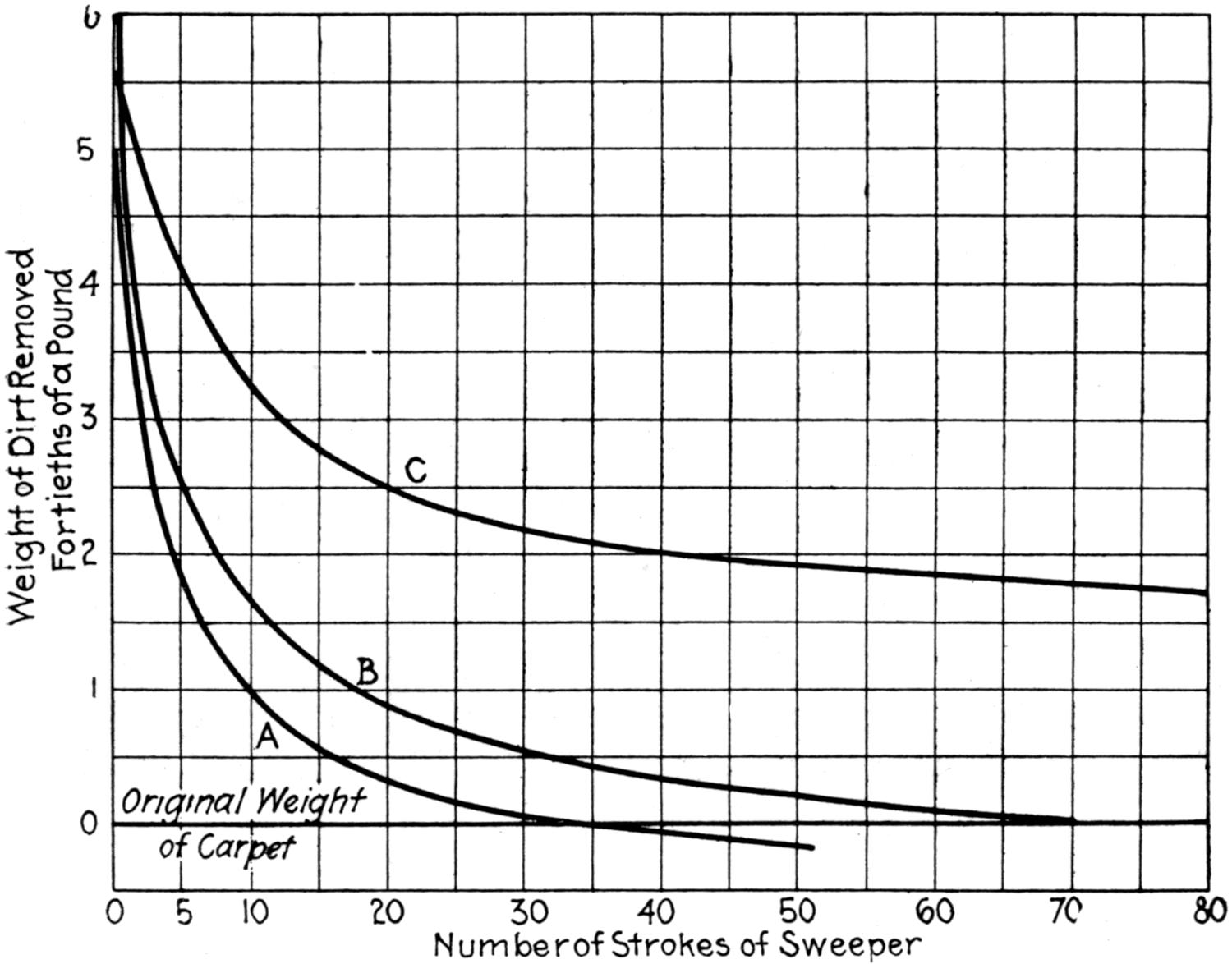

—The results of the tests of the three types of renovators, each when it was operated with the highest vacuum under the renovator, are plotted in Fig. 17 in order that a ready comparison may be made. This curve indicates that Type A renovator does more effective cleaning in less time than either of the other two types tested.

FIG. 17. TESTS OF THREE RENOVATORS ON DIRTY CARPETS.

Referring to the second line of the table, which gives the degree of vacuum obtained in the renovator during the tests, it will be noted that the highest vacuum attained with each type of renovator is practically the same. This degree of[36] vacuum was obtained with the average vacuum at the hose cock, using 100 ft. of hose in each case, and corresponds to that obtained in the commercial operation of each of the renovators with the vacuum producers ordinarily used, which was 15 in. in the case of Type C, 10 in. in case of Type A, and 5 in. in case of Type F, the hose being the size used by each of the systems as marketed.