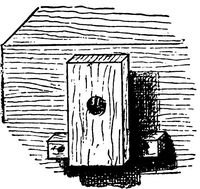

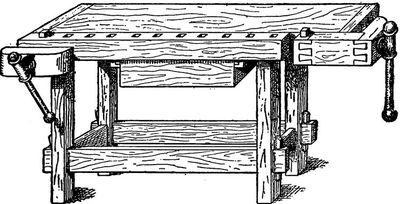

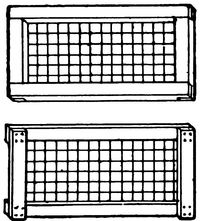

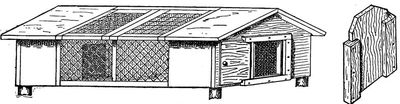

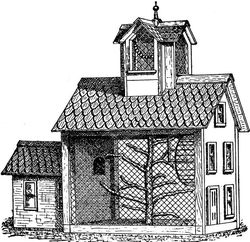

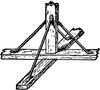

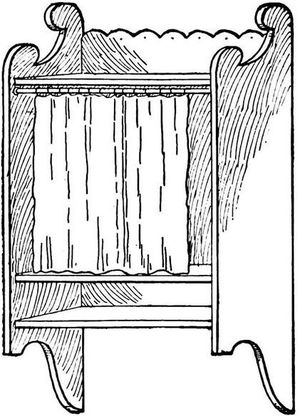

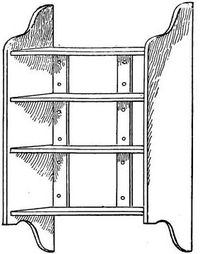

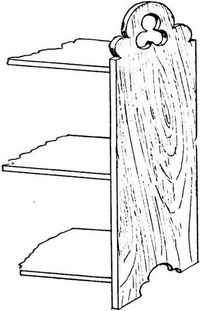

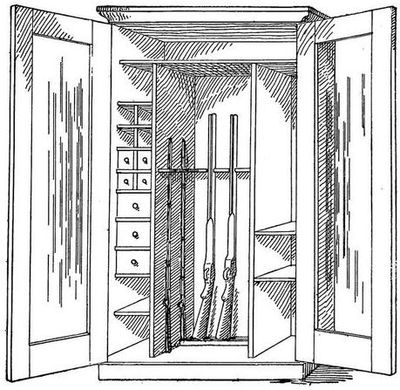

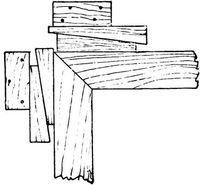

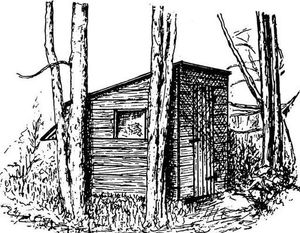

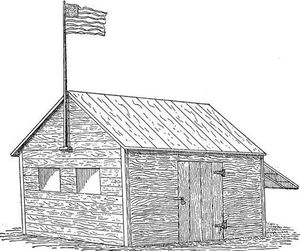

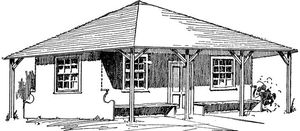

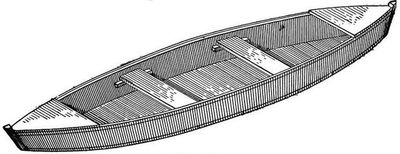

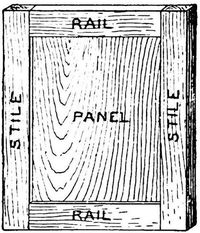

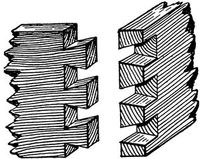

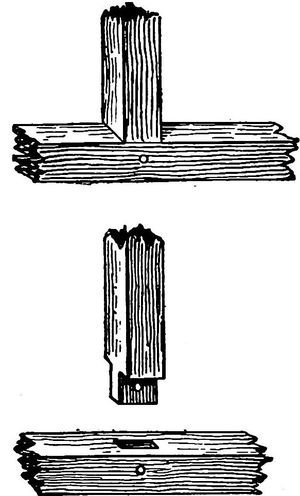

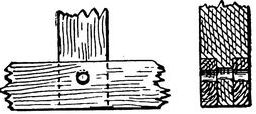

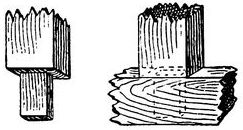

Fig. 1.

Title: Wood-working for Beginners: A Manual for Amateurs

Author: Charles G. Wheeler

Release date: August 30, 2013 [eBook #43604]

Most recently updated: October 23, 2024

Language: English

Credits: Produced by Albert László, Mark Young, P. G. Máté and the

Online Distributed Proofreading Team at http://www.pgdp.net

(This file was produced from images generously made

available by The Internet Archive)

Transcriber's Note

The cover image was created by the transcriber and is placed in the public domain.

A Manual for Amateurs

BY

CHARLES G. WHEELER, B.S.

"Know what thou canst work at and work at it like a Hercules."

Carlyle.

WITH OVER 700 ILLUSTRATIONS

G.P. Putnam's Sons

New York and London

The Knickerbocker Press

1900

Copyright, 1899

by

CHARLES G. WHEELER

The Knickerbocker Press, New York

TO THE

YOUTHFUL FOUNDERS

OF

"TOTLET TOWN"

WITHOUT WHOSE INSPIRATION THIS BOOK WOULD NOT

HAVE BEEN UNDERTAKEN

The aim of this book is to suggest to amateurs of all ages many things which they can profitably make of wood, and to start them in the way to work successfully. It is hoped that, in the case of boys, it may show them pleasant and useful ways to work off some of their surplus energy, and at the same time contribute toward their harmonious all-round development.

It is not an attempt to teach the arts of architecture, carpentry, cabinet-making, or boat-building. Although not intended primarily to impart skill in the use of tools (something which can only be acquired from experience and observation and cannot be taught by any book), still no one can go through the processes indicated without gaining at least some slight degree of manual skill as well as a fund of practical information and experience.

Many books which give directions for mechanical work (particularly those addressed to boys) have several serious faults, and can be grouped in three classes. Some seem to be written by practical workmen, who, however well fitted to do the work themselves, lack the pedagogical training or the psychological insight necessary to lay out such work with due regard to the mental and physical capacity, experience, and development of youth, or to the amateur's lack of experience in the rudiments of the subject. Others are written by teachers or amateurs who lack the trained mechanic's practical and varied knowledge and experience in serious work. Others (and this last class is, perhaps, the worst of the three) seem to be made by compilers who have apparently been satisfied to sweep together, without requisite[vi] knowledge or sufficient moral purpose, whatever they may have found that would be interesting or attractive, without due regard to its real value. All these writers are constantly falling into errors and making omissions harmful alike to the moral and the manual progress of the readers.[1]

Effort has been made in the preparation of this book to avoid these evils, to keep in line with the advanced educational ideas of the time, and to look at the subject from the standpoints of the teacher, the mechanic, the boy, and the amateur workman. The treatment is neither general nor superficial, but elementary, and no claim is made that it will carry anyone very far in the various subjects; but it aims to be thorough and specific as far as it goes and to teach nothing which will have to be unlearned.

Great care (based upon an extended experience with boys and amateurs) has been taken to include only what can be profitably done by an intelligent boy of from ten to eighteen or by the average untrained worker of more mature years. It is hoped that from the variety of subjects treated he may find much of the information for which he may seek—if not in the exact form desired, perhaps in some typical form or something sufficiently similar to suggest to him what he needs to know.

It is hoped and confidently believed that a work so comprehensive in scope and giving such a variety of designs, with detailed and practical directions for their execution, will be not merely novel, but may serve as a vade-mecum and ready-reference book for the amateur of constructive tastes.

Charles G. Wheeler.

Boston, June, 1899.

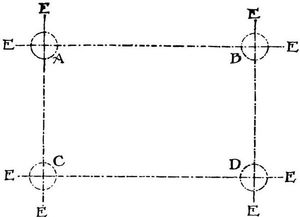

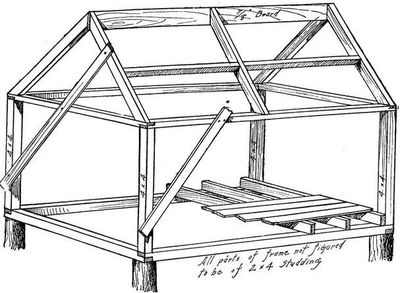

| PART I—A WORKSHOP FOR AMATEURS | ||

| CHAPTER | PAGE | |

| I— | Introductory | 1 |

| II— | Tools | 9 |

| III— | Wood | 29 |

| IV— | Working Drawings, Laying out the Work and Estimating | 49 |

| V— | The Workshop | 56 |

| PART II—ARTICLES TO BE MADE IN THE WORKSHOP | ||

| VI— | Introductory | 103 |

| VII— | A Few Toys | 106 |

| VIII— | Houses for Animals | 126 |

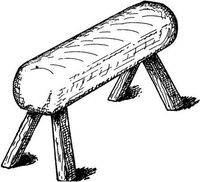

| IX— | Implements for Outdoor Sports and Athletics | 141 |

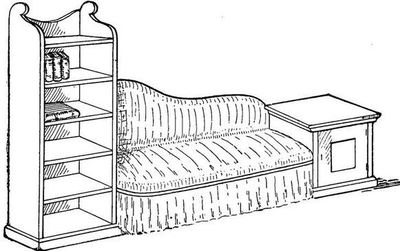

| X— | Furniture | 175 |

| XI— | A Few Miscellaneous Operations | 218 |

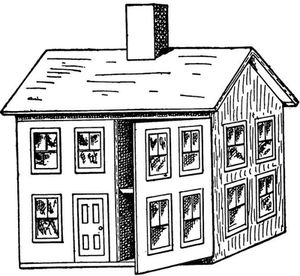

| PART III—HOUSE-BUILDING FOR BEGINNERS | ||

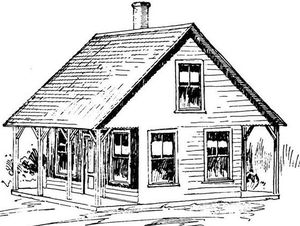

| XII— | Some Elementary Principles | 238 |

| XIII— | Simple Summer Cottages | 271 |

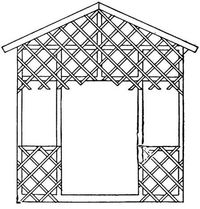

| XIV— | A Few Simple Structures | 291 |

| [viii] PART IV—BOAT-BUILDING FOR BEGINNERS | ||

| XV— | A Few Simple Boats | 298 |

| PART V—TOOLS AND OPERATIONS | ||

| XVI— | The Common Hand-tools, and Some Every-day Operations, Alphabetically Arranged for Ready Reference | 344 |

| Appendix— | Matters Relating to Wood, Suggestions about Working Drawings, etc. | 507 |

| Index | 539 | |

It has seemed best to address parts of this book particularly to boys, because the majority of beginners are boys, because boys need more suggestions than men, and because a man can easily pick what he needs from a talk to boys (and perhaps be interested also), while it is usually unprofitable to expect a boy to take hold of a technical subject in the right spirit if it is treated in a style much in advance of his degree of maturity. It is hoped, however, that the older reader also will find enough of those fundamental principles of successful work (many of which do not readily occur to the untrained amateur except as the result of much costly experience) to be a material help to him.

Homer, Iliad.

WOOD-WORKING FOR BEGINNERS

When one has made up his mind to make something, he usually wants to begin work at once; so, as I wish you to read this chapter, I will make it quite short. There is a great deal in getting started right, and there are some things to bear in mind if you wish to do good work, as of course you do.

One thing is not to be in too much of a hurry to begin the actual sawing and pounding. The old Latin phrase, "Festina lente" (make haste slowly), is a capital motto for the beginner. Do not wait until your enthusiasm has oozed away, of course, but do stop long enough to think how you are going to make a thing before you begin to saw.

The workman who thinks first and acts afterwards is the one who usually turns out good work, while the one who begins to work without any reflection (as boys, and even[2] men, have been known to do) is apt to spend much of his time in undoing his work, and usually does not get through till after the one who laid it out properly in the first place.[2]

If Homer, in the quotation at the head of this chapter, had been writing about the way boys' work is sometimes done, he might, perhaps, have reversed the positions of some of the words and made "swiftness" and "numerous strokes" the subjects of his emphasis. He has expressed well enough, however, the way that your work should be done, and it is one aim of this book to give you useful hints to that end.

Do not spend your time in working out a lot of set exercises, like joints and odd pieces that do not belong to any[3]thing in particular, merely for practice. You will be much more apt to put the right spirit into your work when you make complete and useful articles, and you will get the same practice and experience in the end. There is no need, however, to go through a deal of toilsome experience just to learn a number of simple little things that you might just as well be told in the first place. Begin the process of learning by experience after you have learned what you can from the experience of others. Begin, so far as you can, where others have left off.

Before you begin work it may be interesting to look for a moment at the way boys did their work from fifty to one hundred years ago. Have you read the books by Elijah Kellogg? The reason for speaking of these old-fashioned books is because of the picture they give of the time, not so very long ago, when boys and their elders made all sorts of things which they buy to-day, and also because of the good idea they give of how boys got along generally when they had to shift more for themselves than they do nowadays.

The majority of the boys of that time, not merely on Casco Bay, where Mr. Kellogg places the scenes of his stories, but in hundreds of other places, had to make many things themselves or go without. Of course there was a smaller number in the cities and larger towns who had no good opportunity to make things and were obliged to buy what they could afford (out of what we should call a quite limited variety), or to get the carpenter or other mechanic to make what they needed. But the majority of the boys of that time made things well and had a good time making them. The life they led made them capital "all-round" boys. They could turn their hands, and their heads too, to almost any kind of work, and do it pretty well.[4]

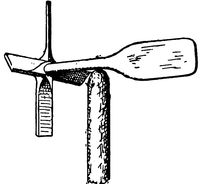

Boys did a good deal of whittling then. This habit, as you doubtless know, still clung to them after they grew up, and opening a jack-knife and beginning to whittle was a common diversion whenever the men rested, whether at the country-store or in the barn or dooryard or at their own firesides. You can see the same habit to-day in some places. The boys whittled splint-brooms of birch in Colonial days in almost every household.[3] Among some of the minor articles made by boys and young men were axe-helves and handles of all sorts, wooden rakes, wooden troughs for bread and for pigs, trays, trenchers, flails, rounds for ladders, bobbins, reels, cheese-boxes, butter-spats or-paddles, wooden traps, and dozens of other articles, not to speak of their handiwork in other materials than wood.

For that matter much of the same life can be found to-day in the remoter regions, and I have known young men brought up to this kind of life, who (within my recollection) have, as a matter of course, done all the farm work of good-sized cultivated farms with live stock, cut and hauled wood from their wood-lots, done a good deal of sea-fishing and salting down and drying of fish, tended and mended their[5] fish-nets, weirs, and lobster-traps, and sailed or rowed twenty-five miles to market with their produce and back again with their supplies. They also built their sheds, barns, and houses, and part of their furniture, their dories, big scows, and capital sailboats; made their own oars and rigged their boats; made many of their farm tools and implements; built their waggons and "ironed" them, their ox-sleds and small sleds, and shod them; made some of their tools; did their own blacksmithing, mason-work, brick-laying, and painting; made their own shoes, and did I do not know how many other odd jobs—all with but a limited supply of common hand-tools. This work did not interfere with their going to school through the winter months until they were twenty-one years old, and they still found time for the usual recreations of the period.

Now a young man must have been pretty well developed after going through all that, even if he did not know much about Greek or calculus or was lacking in superficial polish. And it is only the truth to say that quite a number used to tackle the higher branches of study too, with success made all the more assured by their development in other ways, and many, in addition to all this, paid their way through college by teaching or other work. How did they do so much? Partly, I suppose, because their life was so much simpler and less complex than ours. They did not have so many wants and there were not so many interests to distract their minds. Partly because when they wanted something they knew they must make it or go without. They did not draw so much as we do now, but they did a great deal of observing. They examined things like what they were to make and asked questions, and, knowing that where they had so much to do they could not afford to keep trying things again and again, they learned from their relatives[6] and neighbours what was considered the best way to do their work, and having thought it out carefully they went at it with great energy.

To-day we have only to go to a large factory to see a man standing before some machine and doing some simple piece of work, requiring but little thought—the same thing over and over again, hour after hour, day after day, year after year, until he seems to become almost a part of the machine itself, and is not fitted for doing much else. That is the other extreme. Of course we get things cheaper (even if they do not last so long) because of the factory; but how about the workman? Which of these two types is the better-developed man? First you want to be well-developed all-round boys, so that you will not become machines or badly one-sided men. After that—each to his special bent, of course.

Now because we no longer cut down trees ourselves, haul them to the mill to be sawed, or rive or saw or hew them ourselves, leave the wood to season, and then laboriously work it up into whatever we have to make—because we no longer do that, but go instead to a lumber-yard and a mill and have a large part of the work done for us—it is a good thing for us to pause a moment before we begin our work to take in the fact that all the advantage is not with us now, and to think what a capital gymnasium that former life was for strengthening a boy's muscle and mind, not to speak of his morals.

You could not go back to those days now if you wished to, of course (except, perhaps, when you go to some of the remoter regions in vacation), and you are doubtless better off for all the advantages you have now and for all our time-saving contrivances, but the advantage depends partly on how you use the time saved from their laborious tasks, does[7] it not? You can, however, get inspiration from the example of those older boys and from some of their methods, and can put their self-reliant, manly zeal, grit, and perseverance into your work, and have a capital time making the things and more sport and satisfaction afterwards for having made them.

This book does not try to show you a royal road or a short cut to proficiency in architecture, carpentry, cabinet-making, boat-building, toy-making, or any other art or science. It does not aim to cram you with facts, but merely to start you in the right way. It is for those of you who want to take off your coats, roll up your sleeves, and really make things, rather than sit down in the house and be amused and perhaps deluded by reading enthusiastic accounts of all the wonders you can easily do—or which somebody thinks you would like to be told that you can do. It is for those of you who do not wish to have your ardour dampened by finding that things will not come out as the book said they would, or that the very things you do not know and cannot be expected to know are left out.

It does not aim to stir up your enthusiasm at first and then perhaps leave you in the lurch at the most important points. I take it for granted that if you have any mechanical bent or interest in making things, as most boys have, and are any kind of a real live boy, you have the enthusiasm to start with without stirring up. In fact, I have even known boys, and possibly you may have, who, strange as it may seem, have had so much enthusiasm to make something or other that they have actually had to be held back lest they should spoil all the lumber within reach in the effort to get started!

What you want is to be told how to go to work in the right way—how to make things successfully and like a work[8]man—is it not? Then, if you mean business, as I feel sure you do, and really want to make things, read the whole book through carefully, even if it is not bristling with interesting yarns and paragraphs of no practical application to your work. You will not find everything in it, but you cannot help learning something, and I hope you will find that it attends strictly to the business in hand and will give you a start in the right direction,—which is half the battle.

"Man is a Tool-using Animal.... He can use Tools, can devise Tools; with these the granite mountain melts into light dust before him; he kneads glowing iron as if it were soft paste; seas are his smooth highway, winds and fire his unwearying steeds. Nowhere do you find him without Tools; without Tools he is nothing—with Tools he is all."—Carlyle, Sartor Resartus.

You can do a great deal with very few tools. The bearing of this observation lies in "the application on it," as Jack Bunsby would say.

Look at the complicated and ingenious curiosities whittled with a jack-knife by sailors, prisoners, and other people who have time to kill in that way! Have you ever seen the Chinese artisans turning out their wonderful work with only a few of the most primitive tools? But of course we cannot spend time so lavishly on our work as they do, even if we had their machine-like patience and deftness acquired through so many generations.

We cannot hold work with our feet and draw saws towards us or do turning out on the lawn with a few sticks and a bit of rope for a lathe; carve a set of wonderful open-work hollow spheres, each within the other, out of one solid ball of ivory; and the rest of the queer things the Orientals do: but it is merely a matter of national individuality—the training of hundreds of generations. We could learn to do such things after a long time doubtless, but with no such wonderful adaptability as the Japanese, for instance, are showing, in learning our ways in one generation.

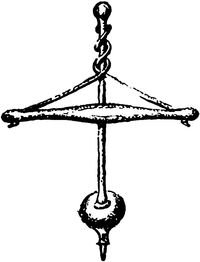

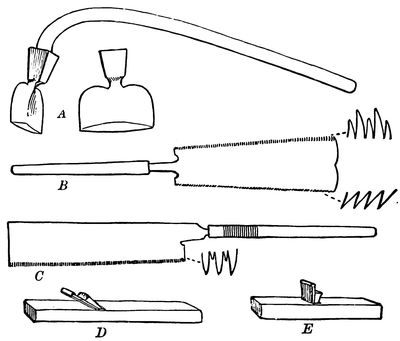

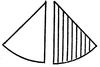

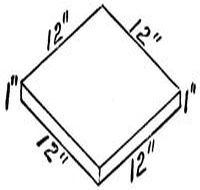

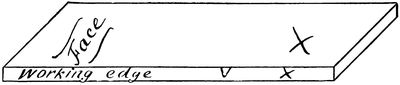

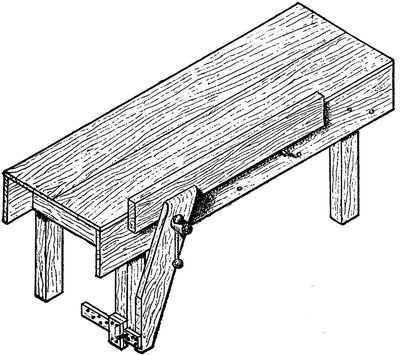

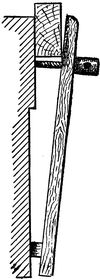

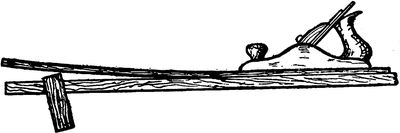

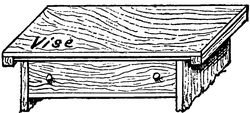

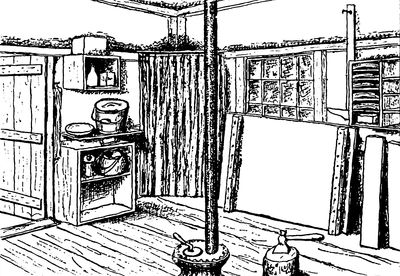

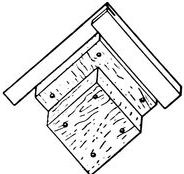

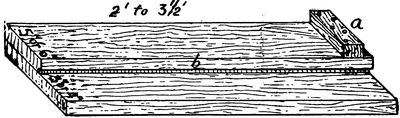

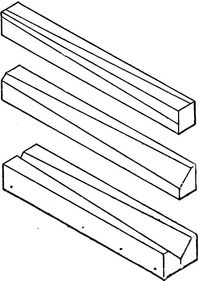

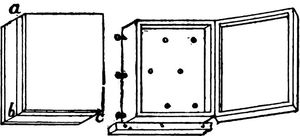

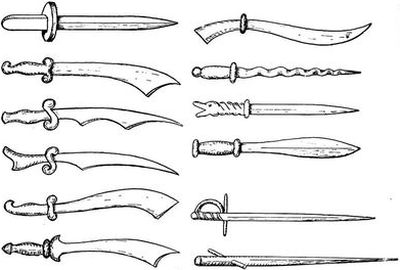

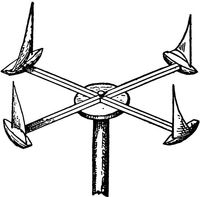

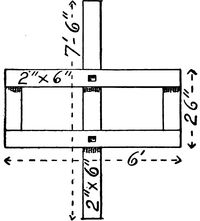

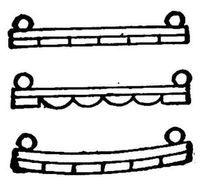

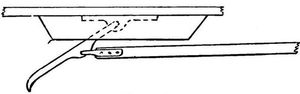

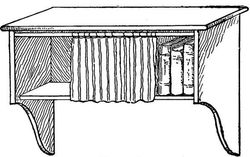

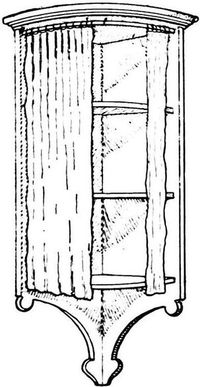

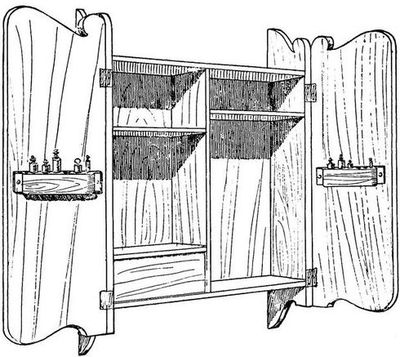

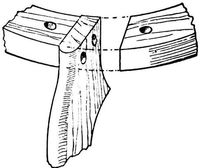

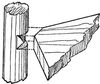

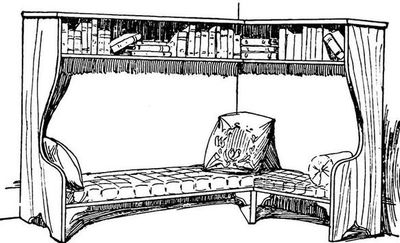

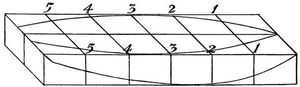

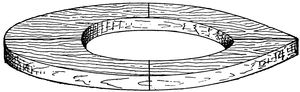

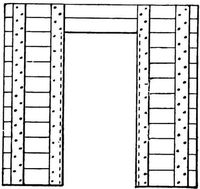

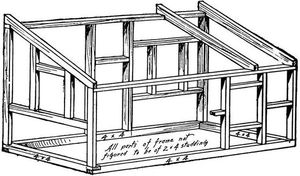

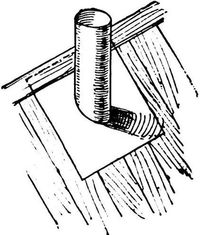

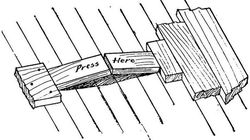

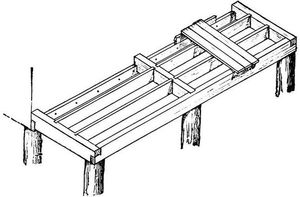

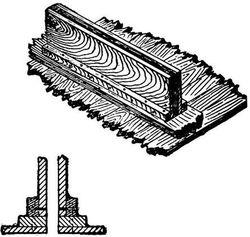

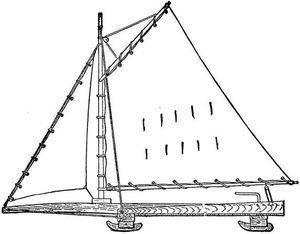

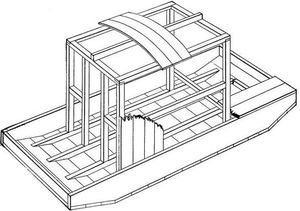

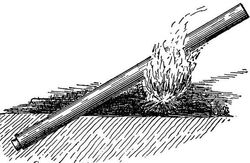

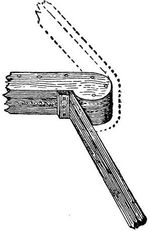

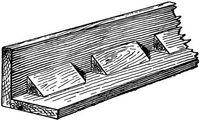

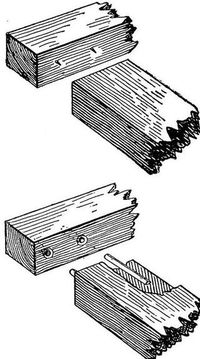

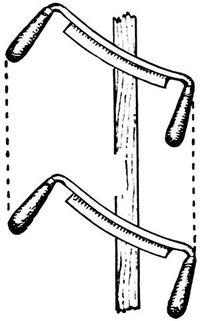

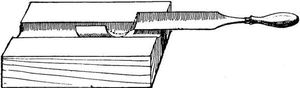

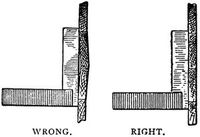

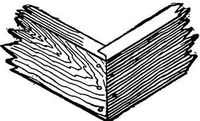

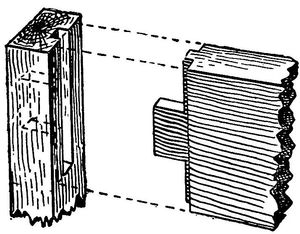

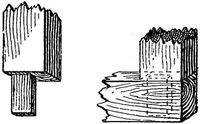

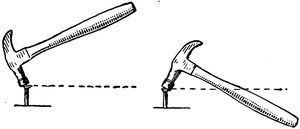

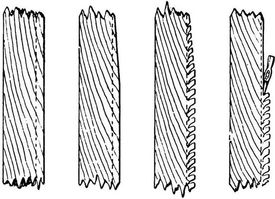

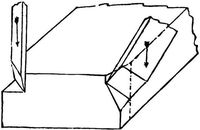

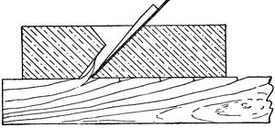

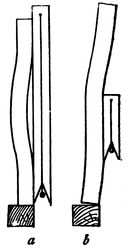

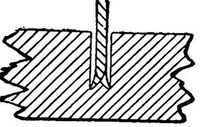

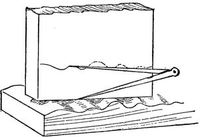

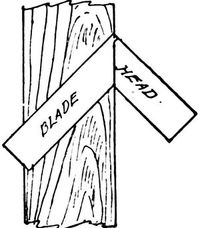

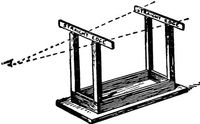

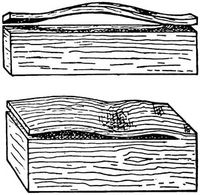

Fig. 1.

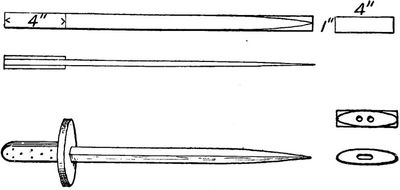

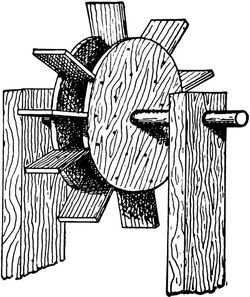

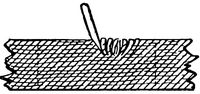

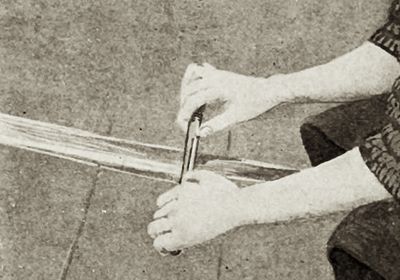

Examine some of the exquisite work which the Orientals sell so cheaply and think whether you know anyone with skill enough to do it if he had a whole hardware-shop full[10] of tools, and then see with what few simple and rude tools (like those shown in the following illustrations, or the simple drill, Fig. 1, still in use) the work has been done. Mr. Holtzapffel describes the primitive apparatus in use among the natives of India as follows[4]:

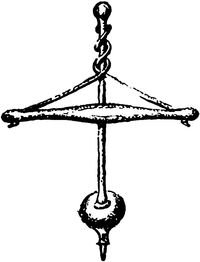

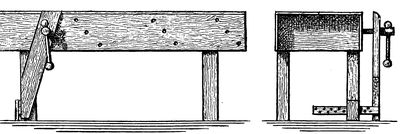

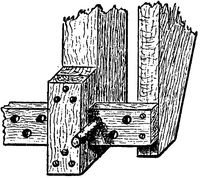

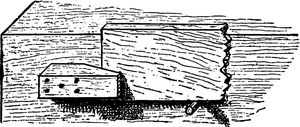

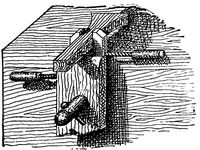

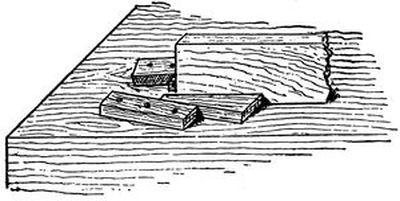

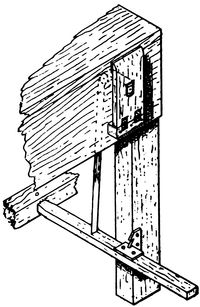

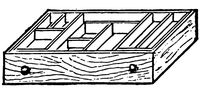

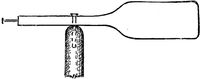

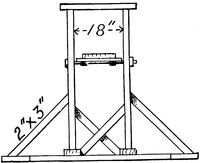

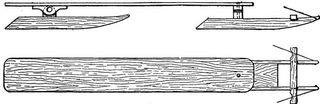

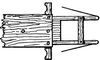

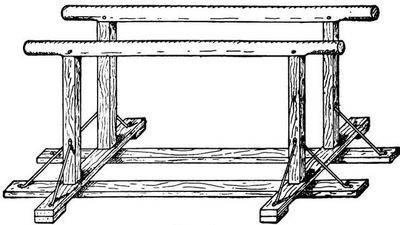

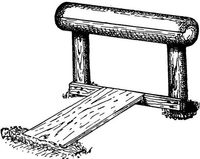

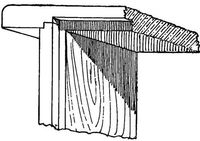

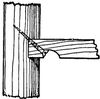

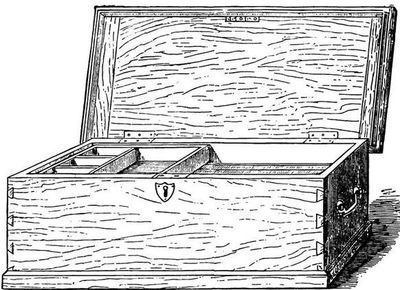

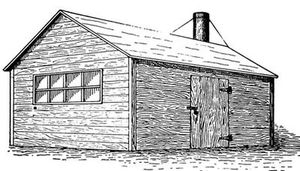

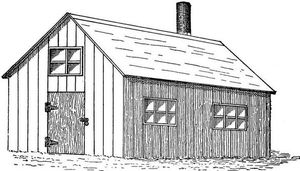

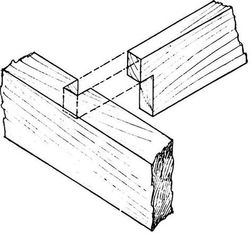

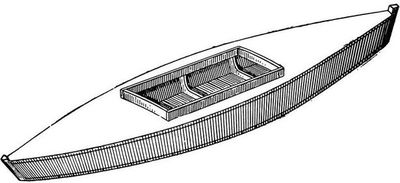

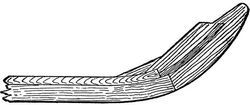

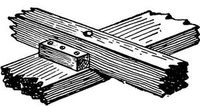

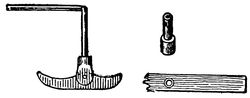

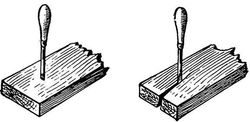

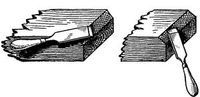

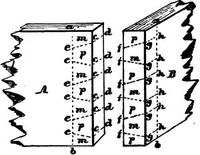

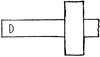

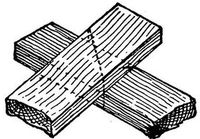

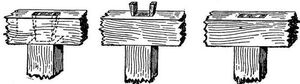

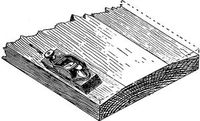

Fig. 2.

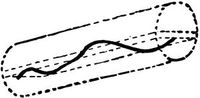

"When any portion of household furniture has to be turned, the wood-turner is sent for; he comes with all his outfit and establishes himself for the occasion at the very door of his employer. He commences by digging two holes in the ground at a distance suitable to the length of the work, and in these he fixes two short wooden posts, securing them as strongly as he can by ramming the earth and driving in wedges and stones around them. The centres, scarcely more than round nails or spikes, are driven through the posts at about eight inches from the ground, and a wooden rod, for the support of the tools, is either nailed to the posts or tied to them by a piece of coir or cocoanut rope. The bar, if long, is additionally supported, as represented, by being tied to one or two vertical sticks driven into the ground. During most of his mechanical operations the Indian workman is seated on the ground, hence the small elevation of the axes of his lathe. The boy who gives motion to the work sits or kneels on the other side of it, holding the ends of the cord wrapped around it in his hands, pulling them alternately; the cutting being restricted to one half of the motion, that of the work towards the tool. The turning tools of the Indian are almost confined to the chisel and gouge, and their handles are long enough to suit his distant position, while he guides their cutting edges by his toes. He grasps the bar or tool-rest with the smaller toes and places [11] the tool between the large toe and its neighbour, generally out of contact with the bar. The Indian and all other turners using the Eastern method attain a high degree of prehensile power with the toes, and when seated at their work not only always use them to guide the tool, but will select indifferently the hand or the foot, whichever may happen to be the nearer, to pick up or replace any small tool or other object. The limited supply of tools the Indian uses for working in wood is also remarkable; they are of the most simple kind and hardly exceed those represented in Fig. 2; the most essential in constructing and setting up his lathe being the small, single-handed adze, the bassōōlăh. With this he shapes his posts and digs the holes; it serves on all occasions as a hammer and also as an anvil when the edge is for a time fixed in a block of wood. The outer side of the cutting edge is perfectly flat, and with it the workman will square or face a beam or board with almost as much precision as if it had been planed;[12] in using the bassōōlăh for this latter purpose the work is generally placed in the forked stem of a tree, driven into the ground as shown in the illustration."

If we are inclined to feel proud of the kind of wood-work turned out by the average wood-worker of this country or England with his great variety of tools and appliances and facilities, we might compare his work with that done by the Orientals without our appliances. Read what Professor Morse tells us of the Japanese carpenter[5]:

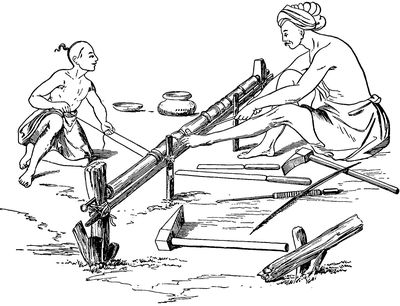

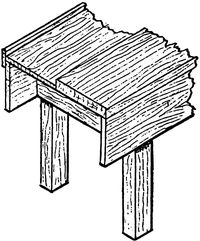

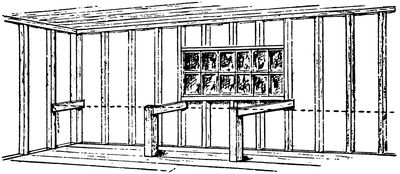

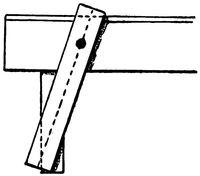

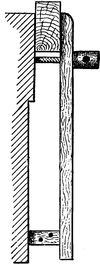

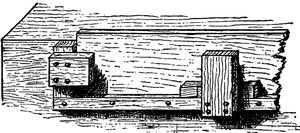

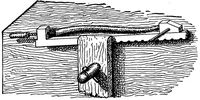

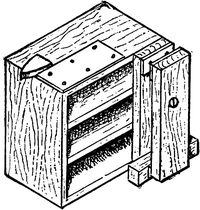

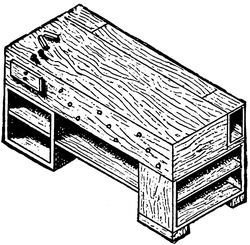

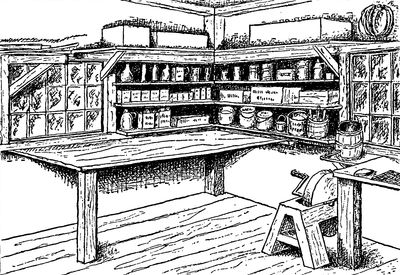

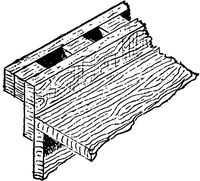

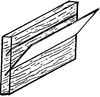

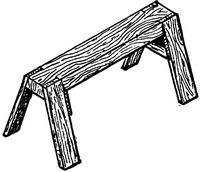

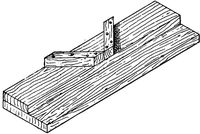

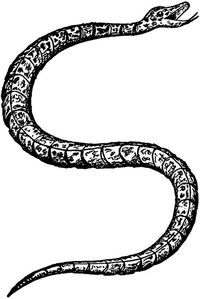

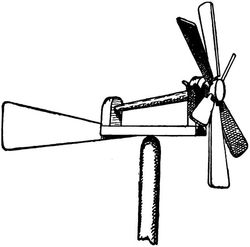

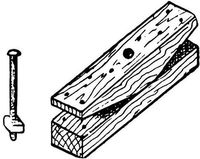

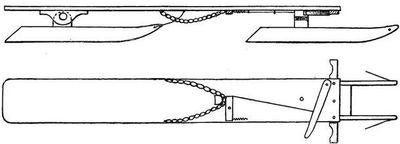

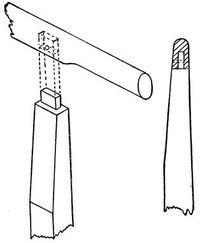

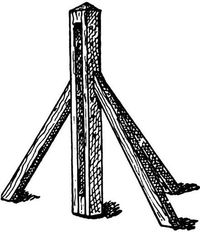

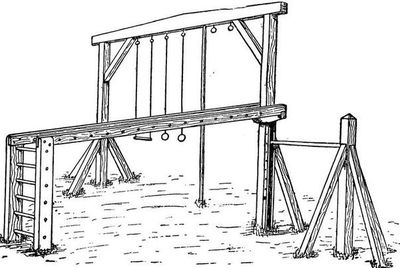

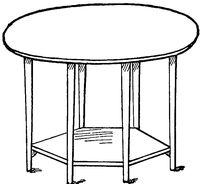

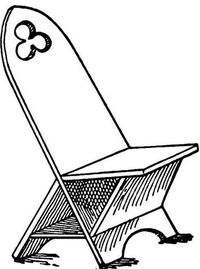

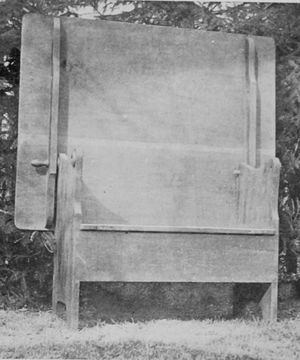

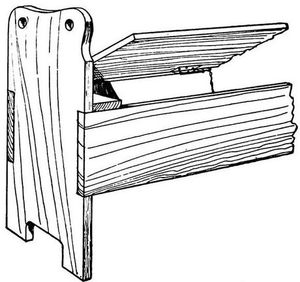

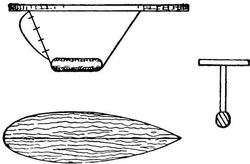

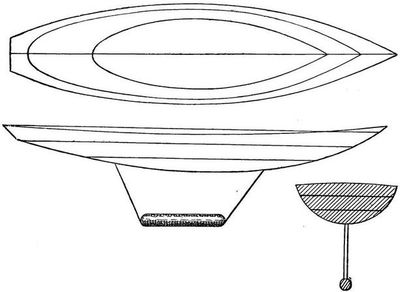

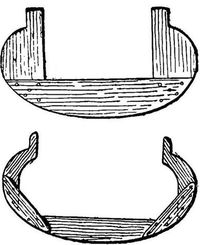

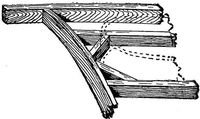

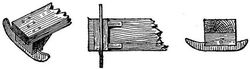

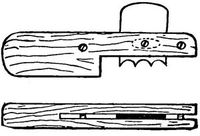

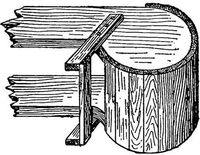

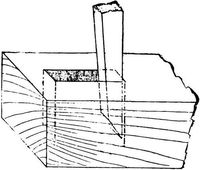

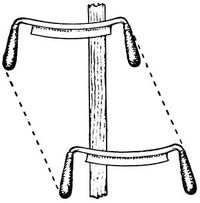

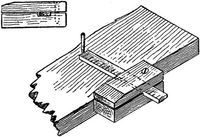

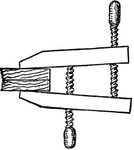

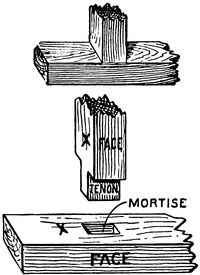

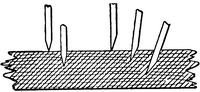

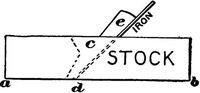

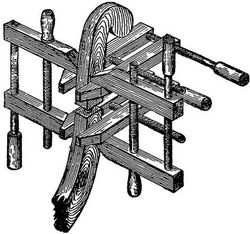

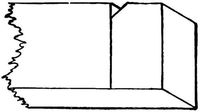

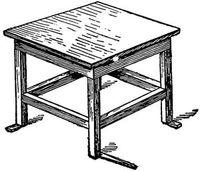

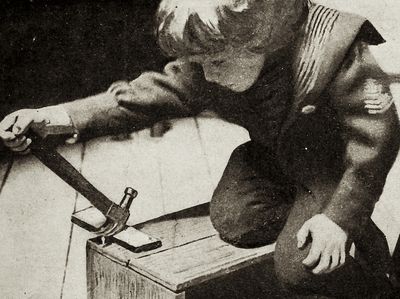

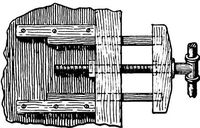

"His trade, as well as other trades, has been perpetuated through generations of families. The little children have been brought up amidst the odour of fragrant shavings,—have with childish hands performed the duties of an adjustable vise or clamp; and with the same tools which when children they have handed to their fathers, they have in later days earned their daily rice. When I see one of our carpenters' ponderous tool-chests, made of polished woods, inlaid with brass decorations, and filled to repletion with several hundred dollars' worth of highly polished and elaborate machine-made implements, and contemplate the work often done with them,—with everything binding that should go loose, and everything rattling that should be tight, and much work that has to be done twice over, with an indication everywhere of a poverty of ideas,—and then recall the Japanese carpenter with his ridiculously light and flimsy tool-box containing a meagre assortment of rude and primitive tools,—considering the carpentry of the two people, I am forced to the conviction that civilisation and modern appliances count as nothing unless accompanied with a moiety of brains and some little taste and wit.... After having seen the good and serviceable carpentry, the perfect joints and complex mortises, done by good Japanese workmen, one is astonished to find that they do their[13] work without the aid of certain appliances considered indispensable by similar craftsmen in our country. They have no bench, no vise, no spirit-level, and no bit-stock; and as for labour-saving machinery, they have absolutely nothing. With many places which could be utilised for water-power, the old country sawmill has not occurred to them. Their tools appear to be roughly made and of primitive design, though evidently of the best-tempered steel. The only substitute for the carpenter's bench is a plank on the floor, or on two horses; a square, firm, upright post is the nearest approach to a bench and vise, for to this beam a block of wood to be sawed into pieces is firmly held (Fig. 3). A big wooden wedge is bound firmly to the post with a stout rope, and this driven down with vigorous blows till it pinches the block which is to be cut into the desired proportions.

Fig.3.—A JAPANESE CARPENTER'S VISE.

From Morse's Japanese Homes.

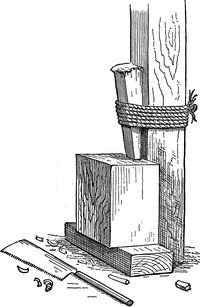

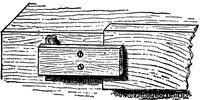

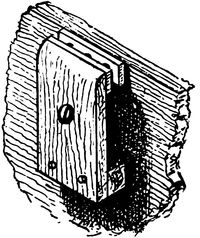

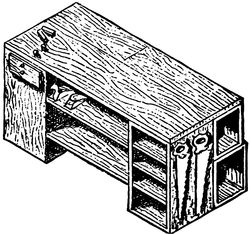

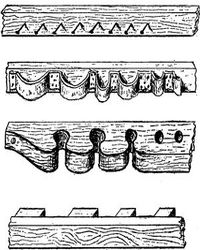

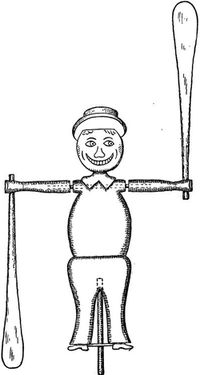

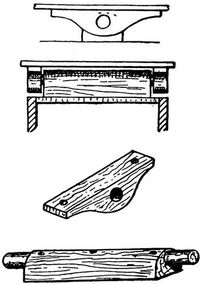

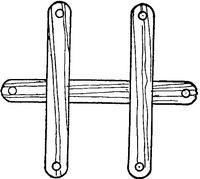

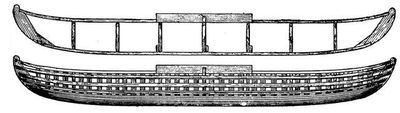

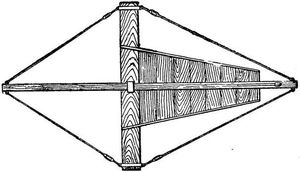

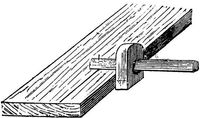

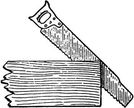

"In using many of the tools, the Japanese carpenter handles them quite differently from our workman; for instance, he draws the plane towards him instead of pushing it from him. The planes are very rude-looking implements. Their bodies, instead of being thick blocks of wood, are quite wide and thin (Fig. 4, D, E), and the blades are inclined at a greater angle than the blade in our plane. In some planes, however, the blade stands vertical;[14] this is used in lieu of the steel scrapers in giving wood a smooth finish, and might be used with advantage by our carpenters as a substitute for the piece of glass or thin plate of steel with which they usually scrape the surface of the wood. A huge plane is often seen, five or six feet long. This plane, however, is fixed in an inclined position, upside down; that is, with the blade uppermost. The board, or piece to be planed, is moved back and forth upon it. Draw-shaves are in common use. The saws are of various kinds, with teeth much longer than those of our saws, and cut in different ways.... Some saws have teeth on the back as well as on the front, one edge being used as a cross-cut saw (Fig. 4, B, C). The hand-saw, instead of having the curious loop-shaped handle made to accommodate only one hand, as with us, has a simple straight cylindrical handle as long[15] as the saw itself, and sometimes longer. Our carpenters engage one hand in holding the stick to be sawed while driving the saw with the other hand; the Japanese carpenter, on the contrary, holds the piece with his foot, and stooping over, with his two hands drives the saw by quick and rapid cuts through the wood. This style of working and doing many other things could never be adopted in this country without an importation of Japanese backs.... The adze is provided with a rough handle bending considerably at the lower end, not unlike a hockey-stick (Fig. 4, A).... For drilling holes a very long-handled awl is used. The carpenter seizing the handle at the end, between the palms of his hands, and moving his hands rapidly back and forth, pushing down at the same time, the awl is made rapidly to rotate back and forth; as his hands gradually slip down on the handle he quickly seizes it at the upper end again, continuing the motion as before. One is astonished to see how rapidly holes are drilled in this simple yet effective way. For large holes, augers similar to ours are used."

Fig. 4.—CARPENTERS' TOOLS IN COMMON USE.

From Morse's Japanese Homes.

When you are obliged to work some day with few and insufficient tools (as most workmen are at times), you will quickly realise how much you can do with very few in case of necessity, and will more fully appreciate the skill of those Eastern people who do so much with so little. We do not need so many hand-tools for wood-work as our grandfathers and our great-grandfathers, although we make a greater variety of things, because machinery now does so much of the work for us. Wood-workers of fifty years ago had, for instance, dozens of planes for cutting all sorts of grooves, mouldings, and the like, which are now worked by machine at the nearest mill.

Suggestions about Buying.—Do not start in by buying a chest of tools, certainly not one of the small cheap sets. They are not necessarily poor, but are very apt to be. Get[16] a few tools at a time as you need them. In that way you will get all you need in the most satisfactory way.

Besides the fact that you can do good work with few tools there are various reasons which make it better to begin with but few. You will probably take better care of a few than of many. If you have thirty chisels on the rack before you and you make a nick in the end of the one you are using, there is a strong chance that instead of stopping to sharpen it you will lay it aside and take one of the remaining twenty-nine that will answer your purpose, and before you realise it have a whole rack full of dull tools. If you have but few chisels, you will be compelled to sharpen them, and so get into the habit of taking proper care of them—not to speak of the time which is often wasted in putting away one tool and selecting another unnecessarily.

The longer you work the more you will get to rely on a small number of tools only, however many you may have at hand for occasional use. After you have worked for some time you will be very likely to have your favourite tools, and find that certain tools do better work in your hands than certain others which perhaps someone else would use for the purpose, and you will naturally favour the use of those particular implements, which is another less important reason for not starting in with too great a variety. I do not mean that you will imagine you can do better with one tool than another, but that you really can do so. That is where individuality comes in—the "personal equation."

Watch a skilful carver at a piece of ordinary work. See how few tools he spreads before him, and how much he does with the one in his hand before he lays it down for another. You would think it would take twenty-five tools, perhaps, to cut such a design, but the carver may have only about half a dozen before him. He gets right into the spirit[17] of what he is doing, and somehow or other he does ever so many things with the tool in his hand in less time and carries out his idea better than if he kept breaking off to select others.

This shows that confidence in the use of a tool goes a long way toward the execution of good work, which is one reason for learning to use a few tools well and making them serve for all the uses to which they can advantageously be put. In short, if you have but few tools at first you get the most you can out of each tool and in the way best for yourself.

Now I do not mean by all this that it is not a good thing to have a large kit of tools, or that you should not have the proper tools for the various operations, and use them. I mean that you should get your tools gradually as you find that you need them to do your work as it should be done, and not get a lot in advance of needing them just because they seem to be fine things to have, or because some carpenter has them in his chest.

Do not place too much reliance on the lists of tools which you find in books and magazines—the "tools necessary for beginners," "a list of tools for boys," etc. Such lists are necessarily arbitrary. To make a short list that would be thoroughly satisfactory for such varied work as a boy or amateur may turn his hand to is about as impracticable as the attempts you sometimes see to name the twenty-five greatest or best men or the one hundred best books. When you can find half a dozen independent lists which agree it will be time enough to begin to pin your faith to them. The most experienced or learned people cannot agree exactly in such matters. It depends somewhat, for one thing, on what kind of work you begin with, and, of course, somewhat upon yourself also.[18]

Now while, as we have seen, most wonderful work can be done with the most primitive tools, the fact remains that you are neither Chinese nor Japanese, but Americans and English, and you cannot work to the best advantage without certain tools. "Well, what are they? Why don't you give us a list to begin with? That's what we are looking for." Simply because a quite varied experience has taught me to think it better to give you suggestions to help you make the selection for yourselves.

Just as the great majority of boys would agree upon Robinson Crusoe, for instance, as belonging in the front rank of boys' books, but would make very different selections of second-rate or third-rate books, so there are a few "universal" tools, upon the importance of which all agree, such as the saw, hammer, hatchet or axe, and a few others; but beyond these few you can have as many "lists" as you can find people to make them, up to the point of including all you are likely to want. So let your list make itself as you go along, according to your own needs.

It is safe to say, however, that if your work is to be at all varied, such as is given in this book, for instance, you cannot get along to good advantage for any length of time without a rule, a try-square, a straight-edge, a knife, two or three chisels, a hatchet, a gouge, a smoothing-plane, a spoke-shave, a panel-saw, a hammer and nail-set, a bit-brace and three or four bits (twist-drills are good for the smaller sizes), a countersink, a few bradawls and gimlets, a screw-driver, a rasp and half-round file for wood, a three-cornered file for metal, an oil-stone, a glue-pot. An excellent and cheap combination tool for such work as you will do can be bought almost anywhere under the name of "odd jobs." Of course you will need nails, screws, sandpaper, glue, oil, and such supplies, which you can buy as you need them. A[19] section (18 inches or 20 inches high) from the trunk of a tree is very useful for a chopping-block, or any big junk of timber can be used.

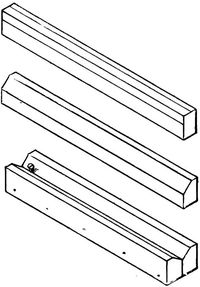

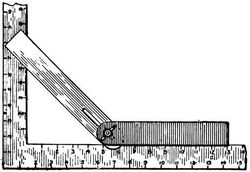

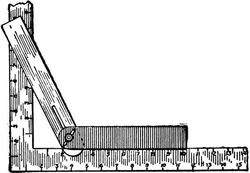

You will, however, quickly feel the need of a few more tools to do your work to better advantage, and according to the kind of work you are doing you will add some of the following: a fore-plane, a splitting-saw, a mallet, a back-saw, compasses, one or more firmer chisels, one or more framing-chisels, a block-plane, pincers, a gauge or two, one or more gouges, a steel square, a draw-knife, a large screw-driver, a scraper, a few hand-screws (or iron clamps), a few more bits, gimlets, bradawls, or drills, cutting-pliers or nippers, a bevel, a jointer (plane), a wrench. An iron mitre-box is useful but rather expensive, and you can get along with the wooden one described further on. A grindstone is, of course, essential when you get to the point of sharpening your tools yourself, but you can have your tools ground or get the use of a stone without having to buy one for a long time.

The following list makes a fair outfit for nearly and sometimes all the work the average amateur is likely to do, excepting the bench appliances and such contrivances as you will make yourselves and the occasional addition of a bit or chisel or gouge or file, etc., of some other size or shape when needed. This is not a list to start with, of course, unless you can afford it, for you can get along for a good while with only a part, nor is it a complete list, but merely one with which a great amount of useful work can be done to good advantage. You can always add to it for special purposes.

For further remarks about these tools and others and their uses, see Part V., where they will be found alphabetically arranged.[20]

| 1 two-foot rule. | 1 compass and keyhole saw (combined). |

| 1 try-square (metal-bound). | 1 bit-brace. |

| 1 pair of wing compasses. | 3 auger-bits (½", ¾", 1"). |

| 1 marking-gauge. | 3 twist-drills (1/8", 3/16", ¼"). |

| 1 mortise-gauge. | A few bradawls and gimlets. |

| 1 steel square (carpenter's framing-square). | 1 screw-driver for bit-brace. |

| 1 bevel. | 1 countersink. |

| 1 "odd jobs." | 1 hammer and 2 nail-sets. |

| 1 chalk-line and chalk. | 2 screw-drivers (different sizes). |

| 1 knife. | Files of several kinds (flat, |

| 5 firmer chisels (1/8", ¼", ½", 7/8", 1¼"). | three-cornered, and round |

| 2 framing- or mortising-chisels (1", 1½"). | for metal, and half-round |

| 3 gouges (¼", ½", 1"). | and round for wood). |

| 1 iron spoke-shave (adjustable). | 1 large half-round rasp. |

| 1 draw-knife. | 1 cabinet scraper and burnisher. |

| 1 hatchet. | 1 mallet. |

| 1 block-plane. | 1 pair cutting-pliers. |

| 1 smoothing-plane. | 1 pair of pincers. |

| 1 long fore-plane (or a jointer). | 1 wrench. |

| 1 jack-plane. | 1 oil-stone and oiler. |

| 1 rabbet-plane (¾" or 7/8" square). | 2 or 3 oil-stone slips (different |

| 1 cutting-off saw (panel-saw, 24"). | shapes). |

| 1 splitting-saw (26"). | 1 glue-pot. |

| 1 back-saw (12"). | 2 or more iron clamps. |

| 1 turning-saw (14"). | 2 or more wooden hand-screws. |

| 2 or more cabinet clamps (2' to 4'). |

An adjustable iron mitre-box will be a valuable addition to this list, and a grindstone is of use even when you get most of your grinding done.

A few carver's tools are also convenient at times if you can afford them, as a skew-chisel (½"), a parting-tool (¼"), and a small veining-tool.

General supplies, such as nails, screws, glue, etc., specified in Part V., will of course be required.

There are still more tools than those given above, as you[21] doubtless know, but by the time you have become workman enough to need more you will know what you need. Ploughs, matching-planes, and all such implements are omitted, because it is better and usually as cheap to get such work as they do done by machine at a mill. I also assume that all your heavy sawing and planing will be done at some mill. It is not worth while for the amateur to undertake the sawing and planing of large pieces, the hewing and splitting of the rougher branches of wood-work, for such work can be done almost anywhere by machine at very slight expense, and stock can be bought already got out and planed for but a trifle more than the cost of the wood alone.[6]

Be sure to get good tools. There is a saying that a good workman is known by his tools, and another that a poor workman is always complaining of his tools, that is, excusing his own incompetence by throwing the blame upon his tools. There is also another saying to the effect that a good workman can work with poor tools; but it is simply because he is a skilled and ingenious workman that he can if necessary often do good work in spite of inferior tools, and of course he could do the same work more easily and quickly, if not better, with good ones.

So do not think that because you sometimes see a skilled workman making shift with poor tools that you are justified in beginning in that way, for a beginner should use only good[22] tools and in good condition or he may never become a good workman at all, so make your tools and their care a matter of pride. If your tools are of good quality, and proper care is taken of them, they will last a lifetime and longer; so good tools prove the cheapest in the end.[7]

There are some cases, however, in which it is as well not to buy the most expensive tools at first, as a cheap rule will do as well as an expensive one, considering how likely you are to break or lose it, and a cheap gauge will answer quite well for a good while; but this does not affect the truth of the general statement that you should get only the best tools. There are also quite a number of tools, appliances, and makeshifts which you can make for yourselves, some of which will be described. I advise you not to pick up tools at second-hand shops, auctions, or junk shops, except with the assistance of some competent workman.

Care of Tools.—Keep your tools in good order. You cannot do nice, fine, clean work with a dull tool. A sharp tool will make a clean cut, but a dull edge will tear or crush the fibres and not leave a clean-cut surface. You can work so much more easily and quickly as well as satisfactorily with sharp tools that the time it takes to keep them in order is much less than you lose in working with dull ones, not to speak of the waste of strength and temper.

I assume that you will not attempt to sharpen your tools yourselves until you have had considerable experience in[23] using them; for sharpening tools (particularly saws and planes) is very hard for boys and amateurs, and not easy to learn from a book. So, until then, be sure to have them sharpened whenever they become dull. The expense is but slight, and it is much better to have fewer tools kept sharp than to spend the money for more tools and have them dull. When you get to the point of sharpening your tools, one lesson from a practical workman or even a little time spent in watching the operations (which you can do easily) will help you more than reading many pages from any book. So I advise you to get instruction in sharpening from some practical workman,—not at first, but after you have got quite handy with the tools. You can easily do this at little or no expense. For further points, see Sharpening, in Part V.

It is a good plan to soak tool handles, mallets, and wooden planes, when new, for a week or so in raw linseed oil and then rub them with a soft rag every day or two for a while. If you use wooden planes give them a good soaking. They will absorb much oil and work more freely and smoothly. You can save tool handles from being split by pounding, by sawing the ends off square and fastening on two round disks of sole-leather in the way adopted by shoe-makers. If there is any tendency to dampness in your shop the steel and iron parts of the tools should be greased with a little fat,—tallow, lard, wax, vaseline,—or some anti-rust preparation.

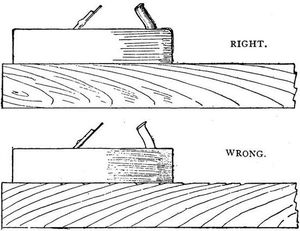

Use of Tools.—It is very important to get started right in using tools. If your first idea of what the tool is for and how it should be used is correct you will get along nicely afterwards, but if you start with a wrong impression you will have to unlearn, which is always hard, and start afresh.[24]

If you can go to a good wood-working school you will of course learn much, and if you know a good-natured carpenter or cabinet-maker or any wood-worker of the old-fashioned kind, cultivate his acquaintance. If he is willing to let you watch his work and to answer your questions you can add much to your knowledge of the uses of the different tools. In fact, so far as instruction goes that is about all the teaching the average apprentice gets. He learns by observing and by practice. Do not be afraid or ashamed to ask questions. Very few men will refuse to answer an amateur's questions unless they are unreasonably frequent. There will be problems enough to exercise all the ingenuity you have after you have learned what you can from others.

But the day for the all-round workman seems to be rapidly passing away and the tendency nowadays is for each workman, instead of spending years in learning the various branches and details of his trade, to be expert in only one very limited branch—or, as sometimes happens, a general botch in all the branches; so unless you find a real mechanic for a friend (such as an old or middle-aged village carpenter, or cabinet-maker, or wheelwright, or boat-builder, or carver), be a little guarded about believing all he tells or shows you; and beware of relying implicitly on the teachings of the man who "knows it all" and whom a season's work at nailing up studding and boarding has turned into a full-fledged "carpenter."

If you can learn to use your tools with either hand you will often find it a decided advantage, as in getting out crooked work, or particularly in carving, where you have such an endless variety of cuts to be made in almost every possible direction, but "that is another story." A bad habit and one to guard against is that of carrying with you the tool you may be using whenever you leave your work temporarily,[25] instead of laying it down where you are working. Edge-tools are dangerous things to carry around in the hand and there is also much chance of their being mislaid.

For directions for using the different tools see Part V.

Edge-Tools.—Bear in mind that all cutting tools work more or less on the principle of the wedge. So far as the mere cutting is concerned a keen edge is all that is required and your knife or other cutting tool might be as thin as a sheet of paper. But of course such a tool would break, so it must be made thicker for strength and wedge-shaped so that it may be pushed through the wood as easily as possible.

You know that you can safely use a very thin knife to cut butter because the butter yields so easily that there is not much strain on the blade, but that when you cut wood the blade must be thicker to stand the strain of being pushed through. Soft wood cuts more easily than hard, because it is more easily pushed aside or compressed by the wedge-shaped tool, and it does not matter how keen the edge may be if the resistance of the wood is so great that you cannot force the thicker part of the tool through it.

You will understand from all this that the more acute the angle of the cutting edge the more easily it will do its work, provided always that the angle is obtuse or blunt enough to give the proper strength to the end of the tool; and also that as the end of the tool encounters more resistance in hard than soft wood, the angle should be more obtuse or blunter for the former than for the latter. Theoretically, therefore, the angle of the cutting edge, to obtain the greatest possible advantage, would need to be changed with every piece of wood and every kind of cut, but practically all that can be done is to have a longer bevel on the tools for soft wood than for hard. Experience and observation will teach these angles. See Sharpening in Part V.[26]

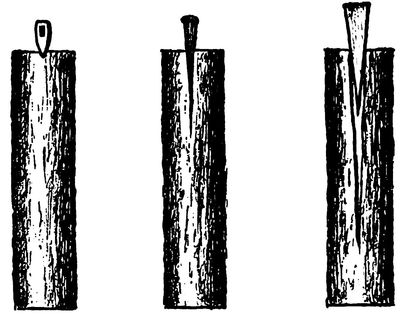

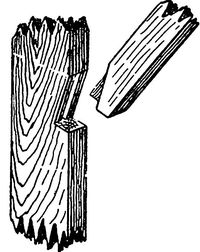

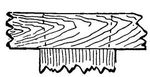

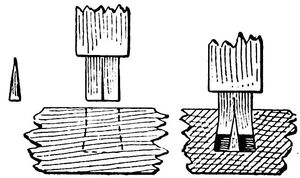

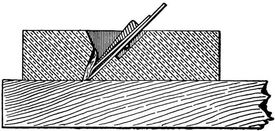

When you cut off a stout stick, as the branch of a tree, you do not try to force your knife straight across with one cut. You cut a small notch and then widen and deepen it by cutting first on one side and then on the other (Fig. 5). The wood yields easily to the wedge on the side towards the notch, so that the edge can easily cut deeper, and thus the notch is gradually cut through the stick. The same principle is seen in cutting down a tree with an axe. You have only to look at the structure of a piece of wood when magnified, as roughly indicated in Fig. 6, to see why it is easier to cut with the grain than across it.

Fig. 5.

Fig. 6.

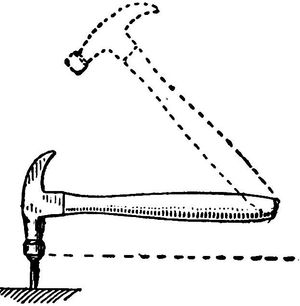

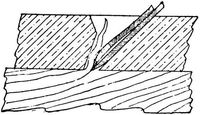

Fig. 7.

You can often cut better with a draw-stroke, i.e., not merely pushing the tool straight ahead, but drawing it across sideways at the same time (Fig. 7). You[27] can press the sharp edge of a knife or razor against your hand without cutting, but draw the edge across and you will be cut at once. Even a blade of grass will cut if you draw the edge quickly through your hand, as you doubtless know.

If you try to push a saw down into a piece of wood, as you push a knife down through a lump of butter, or as in chopping with a hatchet, that is, without pushing and pulling the saw back and forth, it will not enter the wood to any extent, but when you begin to work it back and forth it cuts (or tears) its way into the wood at once. You know how much better you can cut a slice of fresh bread when you saw the knife back and forth than when you merely push it straight down through the loaf. You may have noticed (and you may not) how much better your knife will cut, and that the cut will be cleaner, in doing some kinds of whittling, when you draw it through the wood from handle to point (Fig. 7), instead of pushing it straight through in the common way, and you will discover, if you try cutting various substances, that as a general rule the softer the material the greater the advantage in the draw-stroke.

Now put the sharpest edge-tool you can find under a powerful microscope, and you will see that the edge, instead of being so very smooth, is really quite ragged,—a sort of saw-like edge. Then look at the structure of a piece of wood as roughly indicated in Fig. 6, and you will understand at once just what we do when we cut wood with an edge-tool. You see the microscopically small sticks or tubes or bundles of woody fibre of which the big stick is composed, and you also see the microscopically fine saw to cut them. Now if the edge of the tool is fine you can often do the work satisfactorily by simply pushing the tool straight through the wood, but do you not see that if you can draw or slide[28] the tool either back or forth the edge, being saw-like, will do its work better?

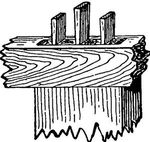

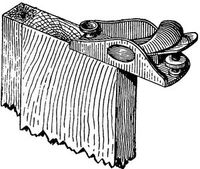

This stroke cannot be used of course in chopping with the axe or hatchet, splitting kindling-wood, or splitting a stick with the grain with a knife or chisel. In these operations the main principle is that of the wedge, pure and simple, driven through by force, the keen edge merely starting the cut, after which the wedge does the rest of the work by bearing so hard against the wood at the sides of the cut that it forces it to split in advance of the cutting edge, as in riving a log by the use first of an axe, then of an iron wedge, and finally a large wooden wedge (Fig. 8).

Fig. 8.

Practical directions and suggestions about the different Tools and their Uses and the various Operations will be found alphabetically arranged in Part V.

Before you can make anything successfully, you must have not merely wood, but the right kind of wood for the purpose. There are, also, "choice cuts" in lumber, as the butcher says of meat, and judicious selection of the stock often makes all the difference between a good job and a poor one; so let us examine a log and follow it through the sawmill.

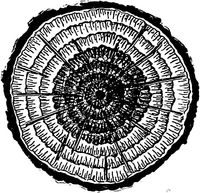

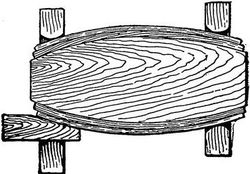

Fig. 9.

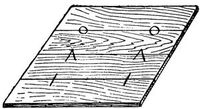

You have, of course, seen the rings, or circular lines, on the ends of pieces of wood (Fig. 9). These are called the annual rings,[8] and each ring marks a new layer of wood added to the tree, for, as perhaps you may have learned, the trees we use for wood-working grow by adding new layers of wood on the outside. Examine the ends of pieces of wood of various kinds. In some pieces these rings will be very plain. In others they will be quite indistinct.

Notice that the wood nearest the bark, known as the sapwood, usually looks different from the inner wood, which is called the heart (Fig. 9).

In some trees you will see rays, or lines, radiating from the centre, and known as the medullary rays (Figs. 9 and[30] 10), because they spring from the pith (Latin medulla). Sometimes these lines are too fine to be noticed.

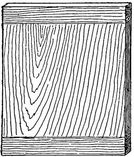

You will see from Fig. 10 that the layers of wood are also shown in the lines of what we call the "grain" on the surface of a piece of wood cut lengthways, and that the lines of the grain are continuations of the annual rings. You will also notice at the ends of timber, after the seasoning has begun, cracks radiating from the centre, showing the natural lines of cleavage or separation.

Fig. 10.

Fig. 11.

The way the log is sawed is important, though you might naturally think that the only thing is to saw it any way that will give pieces of the required size and shape.

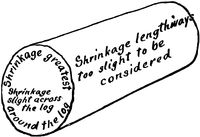

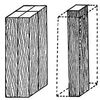

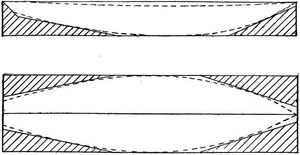

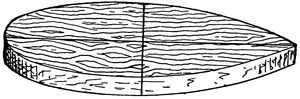

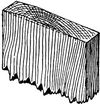

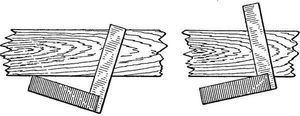

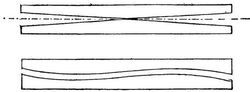

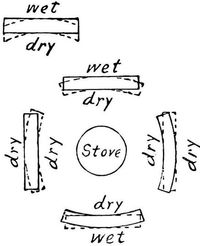

Why is green wood heavier and softer than dry wood, and the sapwood of green timber softer than the heart? Because of the sap or water contained. The amount of water is sometimes even as much as fifty per cent. of the weight of the wood, but the quantity depends upon the kind of tree, the season, etc. Now the more water the green log contains, the more it will shrink. It begins to dry and[31] shrink as soon as the tree has been cut down. The sapwood shrinks more than the heart because it contains more water, and faster because, being on the outside, it is more exposed. The log shrinks most in the line of the annual rings, that is, around the tree. It shrinks much less in the line of the medullary rays, that is, across the tree. Shrinkage lengthways is too slight to be considered[9] (Fig. 11).

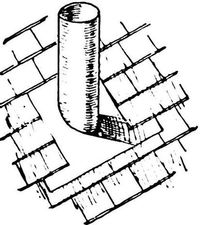

The result of all this unequal shrinking is that the log tends to split, or crack open, at the circumference (Fig. 12), the cracks running in toward the centre, in the line of the medullary rays. If the log is halved or quartered, so that the inner parts are exposed, the drying goes on more uniformly throughout, the cracking is not so bad, and the parts of the log will shrink somewhat as shown in Figs. 13 and 14.

Fig. 12.

Fig. 13.

Fig. 14.

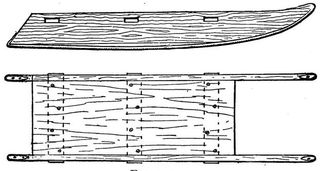

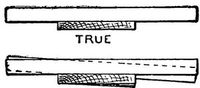

The beams, joists, planks, or boards cut from a log have[32] the same tendency to shrink unevenly that is found in the log itself. This causes them to be irregular in shape and to curl or warp more or less, according to the part of the log from which they are taken. A piece cut from the centre of a log will thus hold its shape better than if cut from one side (Fig. 15).

Fig. 15.

Fig. 16.

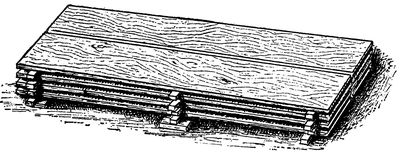

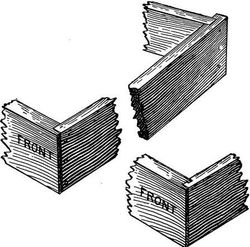

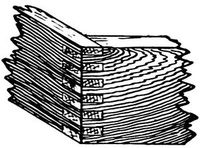

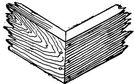

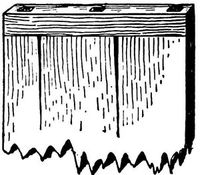

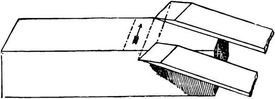

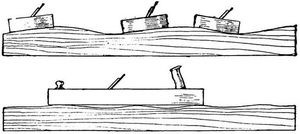

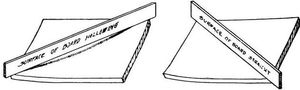

When a log is sawed into boards or planks (Fig. 16) the middle board shrinks but little in width and in thickness at the centre, but becomes thinner towards the edges. It does not curl, because it is cut through the centre of the log and has no more tendency to curl one way than the other. The outside board shrinks least in thickness and most in width, and all, except the middle one, shrink differently on one side from the other. They become convex toward the pith, or heart, and concave toward the outside. Different kinds[33] of wood shrink and warp to different degrees. You can learn something about these matters by examining the stock in any lumber-yard.

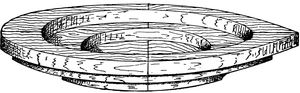

Now to come to the practical application of our brief study of the log and the sawing process: if you merely wish to get the most that you can from a log in the form of boards or plank, have the pieces sliced off in the simple way just shown (Fig. 17). This is the usual way of sawing for ordinary purposes. Boarding for the outside of a house, for instance, cut in this way answers every purpose. By this process the central boards will be good and the outer ones inferior,[10] as just shown (Fig. 16), but for common work all can generally be used.

Fig. 17.

Fig. 18.

Fig. 19.

If you wish the highly figured grain[11] often seen in oak, ash, chestnut, etc., you can get it by sawing the log as just shown in Fig. 17. The figure of the grain will be most marked in the outer boards (Fig. 18), because the annual rings are cut more[34] obliquely in them than in the boards at or near the centre. These boards (Fig. 17) will tend to change their shape, as just shown (Fig. 19), but if they are to be firmly fastened in some way, or confined (as in a panel), handsome grain effects can be obtained.

Fig. 20.

Fig. 21.

Fig. 22.

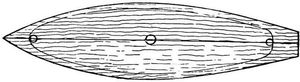

If you wish the beautiful figure formed when the medullary rays show on the surface of the board, as in "quartered" oak, the log should be cut in the direction of the radii, that is, along the lines of the medullary rays (Fig. 20). The more exactly the side of a board is cut on the radial line the more richly the figure of the medullary rays will be shown, as in Fig. 21. This method of sawing is more expensive than the first way, of course, as it requires more labour and wastes more of the wood. The wide board shown in Fig. 21 and either of those in Fig. 22 are examples.

If you wish boards that will shrink the least in width and remain as true as possible, then the log should be sawed on the radial lines as just shown, so that all the boards will be from the middle[35] of the log. Wood shrinks but little in the direction of the radii, as just shown, and middle boards will be alike on both sides as regards heart-and sapwood, etc., and, therefore, have the least tendency to change of shape. The middle board by the method of Fig. 17 will be a good board in these respects.

Fig. 23.

Fig. 24.

Fig. 25.

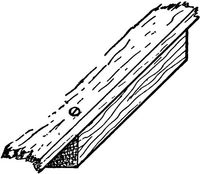

Various methods of radial sawing, or in which part of the boards are so cut, are shown in Figs. 20 and 26, Figs. 23, 24, 25, and 26 showing the log quartered and various ways of sawing into boards. Thus we see that the middle boards, those passing through or near the centre, are the best for most purposes.

Fig. 26.

Fig. 27.

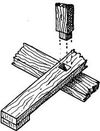

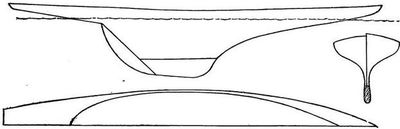

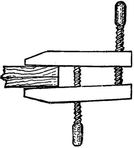

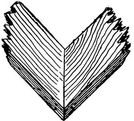

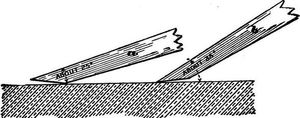

Split or rift stock is stronger than sawed. If you wish a piece especially tough and durable, as for an axe handle or[36] a stout pin, it should be split out rather than sawed, unless the wood is very straight-grained, because the splitting is sure to be in the line of the fibres, thus avoiding "cross-grain," which cannot well be entirely prevented in sawing. If the grain is straight, there may be no practical difference in the result between sawing and splitting, as in the so-called rift flooring, which is really sawed, but with crooked-grained pieces the difference is marked in such cases as the block shown in Fig. 27, from which four pins can be sawed, while but one can be split out. That one will be straight-grained, however, and stronger than the sawed ones, which will be cross-grained.

Try your best to get well-seasoned wood for your nice work. If it is not dry before you use it, it must of course dry afterwards, which is likely to cause cracks, warping, opened joints, and often the entire ruin of the article you have made. You will have to trust the dealer, or some friend, until you have had enough experience to judge for yourself, for it is no easy matter for an amateur to decide, except in case of very green stock, which is of course wet and soggy.

There are two ways of drying wood in common use. One is the old-fashioned way (commonly known as seasoning, weather-drying, or air-drying) in which the wood is gradually seasoned by the natural process of exposure to the air (but protected from the weather), that is, letting it dry of itself.

Do not believe the statements so common in books that it "takes lumber" some definite time, as one year or two years, "to season." It all depends on the kind of wood, its shape and size, the condition of the atmosphere, and various circumstances. For some rough work (a pig-pen, for instance) there is no advantage in seasoning at all, because the stock can just as well dry after the work is done as before. For many kinds of com[37]mon work one or two years is sufficient for some kinds and sizes of wood; for a nicer grade of work two or three years is none too much, while for very nice indoor work four years or more is not too long for the stock to season. There is very little danger of its being kept too long. It never will get perfectly dry (see Appendix). Whether it is dry enough or not depends on what you want it for.

To save time and money the artificial way (known as kiln-drying) of shutting it up in a room and drying it quickly by steam or other heat is now used, and, so far as drying the wood is concerned, this process can do the work well and much more quickly than the old way—sometimes too quickly. It is no exaggeration to say that in factories where cheap furniture and other common articles are made nowadays, a standing tree is felled on Monday, the log rolled into one end of the factory, and before Saturday night the finished articles made from it, all varnished and complete, are sent out from the other end of the shop—and some articles are turned out even quicker.

In the natural process of air-drying the moisture gradually and slowly works out to the surface and evaporates, until the wood is seasoned, though never absolutely dry, and the stock is firmer, more elastic, and less affected by heat and cold, moisture and dryness, than if kiln-dried. The latter process tends to dry the outside and ends of the lumber too fast for the inside. It certainly lessens the elasticity of the wood and weakens it. Making it so unnaturally dry (as if baked), as is often done, only makes it more susceptible to the atmosphere when taken from the kiln, and, unless it is at once protected from the air in some way, it will reabsorb moisture until it gets into a more natural condition; but that will not fully restore the loss of elasticity (see Appendix). The deterioration in the quality of the wood can be plainly[38] seen by any wood-worker, and is often a subject of remark in regard to oak.

The kiln-drying "takes the life out of the wood," as workmen express it, but just why this is so is not easy to explain, for the structure and properties of wood are very complex. I have seen too many illustrations in my own experience and that of others to have any doubt of the fact, however, and lumber left for years to season naturally, "stands," as the expression is, better than if kiln-dried—a fact which is, I think, generally conceded by wood-workers who have had experience with both kinds.

The gain by kiln-drying, in time and money, is, therefore, more or less offset by impairment of the quality of the wood, so if you can find stock that you know has been seasoning for years by the natural process, buy it by all means for your nice work, even if you have to pay more, regardless of what the dealers in kiln-dried stock or the makers of articles for sale may tell you about the advantages of kiln-dried wood.

On the other hand, if a dealer brags of his new patent "chain-lightning" dryer that will make green wood "dry as a bone" in two or three days, go elsewhere to buy your stock, for wood dried in a few days is not the kind to use for good work. You will probably have to use kiln-dried stock for most, or, perhaps, all of your work, but get it from a slow-drying kiln and keep it for further seasoning as long as you can.

Even if wood has been well seasoned, it is best, before putting it into nice work, to cut it up and dress it approximately to shape and leave it in a dry place for some time for a final seasoning, particularly in the case of thick stock. Do this with kiln-dried stock fresh from the dry-house. Let it have a little time to get into harmony with the atmos[39]phere. Whenever wood has been exposed to damp air, as in a wet shed or cellar, let it stand in the warm shop a while before using it for nice work.

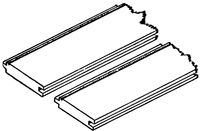

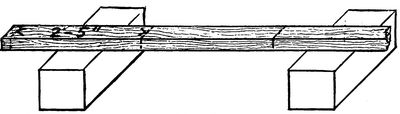

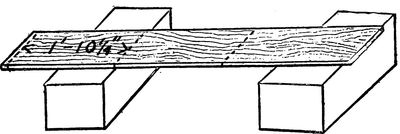

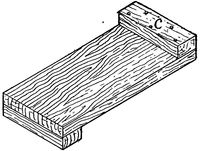

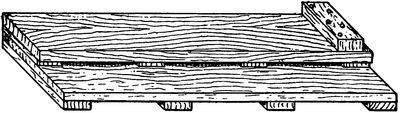

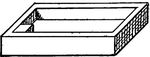

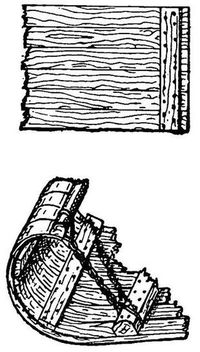

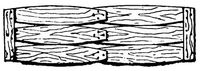

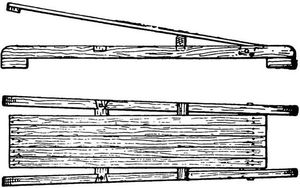

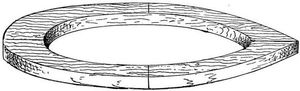

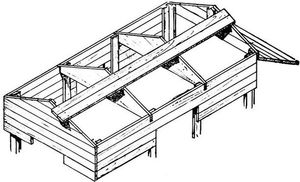

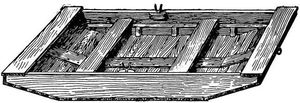

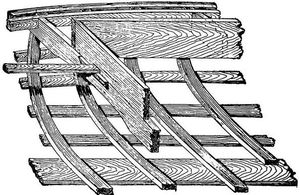

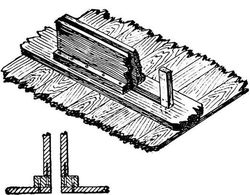

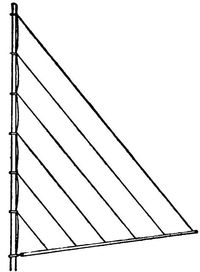

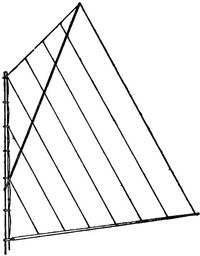

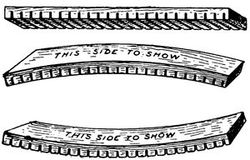

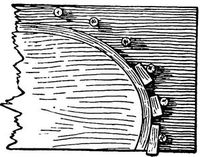

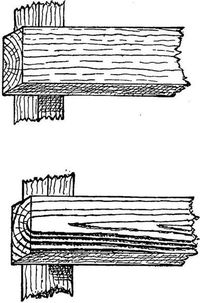

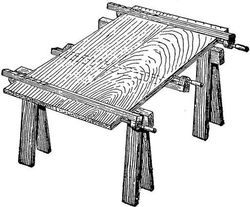

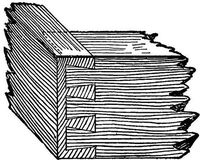

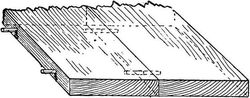

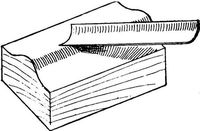

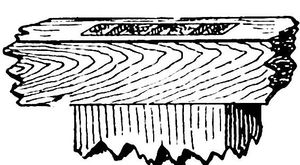

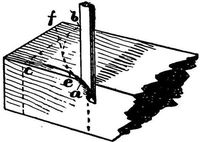

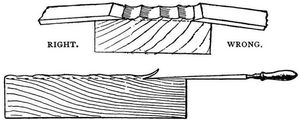

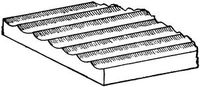

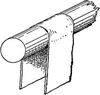

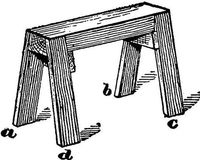

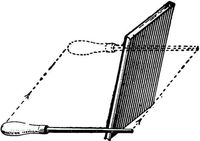

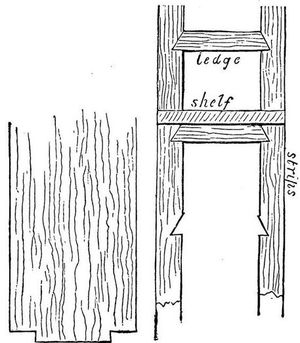

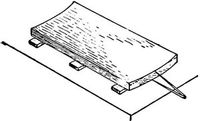

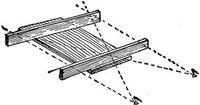

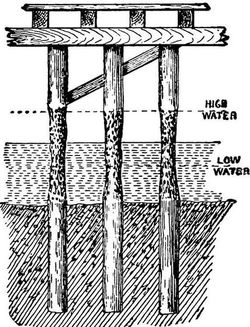

The stock is arranged for seasoning so as to allow the air to circulate around and between the pieces. A common way is simply to arrange them in piles, each piece being separated from those above and below by strips or sticks laid across (Fig. 28). These sticks should be placed directly over one another, and so that the lumber will lie straight, else the weight of the pile, which should tend to make the pieces dry straight, will have the opposite effect and make them permanently crooked. There are other ways of arranging wood for drying, but this method is common and illustrates the most important principles. Stock is sometimes stacked upright, and small pieces are occasionally hung up for such nice work as billiard cues and bows.

Fig. 28.

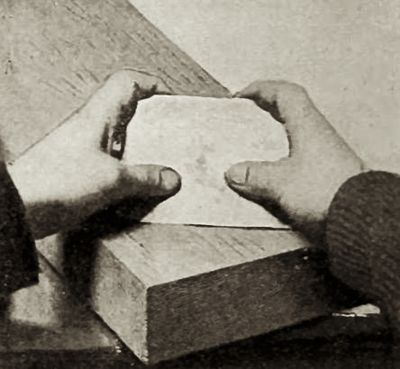

Seasoned wood is lighter in weight than green, dryer to the touch, usually has a different odour, cuts differently when you whittle it (and the piece you whittle off breaks differently), and it shows a difference when you saw it. It is impossible to define these differences and you will have to learn them by actual work. It is not always easy even for[40] an experienced person to tell with certainty about some pieces until he has "worked" them, so much do the characteristics of different pieces vary. One test is to rap the boards sharply with a hammer. A green board and a dry one of the same kind will "rap" differently,—that is, will have a different vibration and give out a different sound. Of course this cannot be described, but you can judge quite well in this way. It is one of the many things you can learn only by experience. You can ascertain much about the character and condition of lumber by sawing or planing or whittling a piece. This is a good test for dryness, toughness, and elasticity (which you can tell about by breaking the shavings).

Weather-dried timber is usually somewhat darkened from exposure, but kiln-drying lightens the colour of some woods.

Stock with a bright lustrous appearance and of dark hue is generally superior to that of a lighter colour and duller appearance, but such characteristics depend much upon the kind of wood. Green wood is tougher than seasoned wood, but the latter is more elastic. To subject seasoned wood to moisture and heat brings it back, to a certain extent, to its original condition, and renders it for the time being tougher, hence the process of bending wood by the application of steam or hot water (see Bending in Part V.).

Reject "wany" lumber, or that of which the edges or corners have not been squared (Fig. 18), and also boards and planks which have not been sawed to a uniform thickness. It is not uncommon for a board to be considerably thinner than it should be in some part of its length, due to irregularity in sawing.

For plain work avoid "cross-grained" stock, as well as that having knots (which are sometimes "tight" and sometimes "loose"), as it is harder to work and to smooth, is not[41] as strong, and does not hold its shape as well, as a rule. Sometimes it is desirable, however, on account of the beautiful figure of the grain shown in many crooked-grained pieces, as in mahogany for furniture (see Appendix). Bear in mind that when especial strength is required rift stock is best.

Reject wood which smells musty, or has rusty-looking spots, which are signs of decay, or of the attack of fungi, which may spread and under favourable conditions attack other pieces which are sound (see Appendix).

Fig. 29.

Fig. 30.

Reject crooked stock. The worst form is winding or twisting. Of course no one would take such an extreme case as Fig. 29, unless for some very rough work, but even a very slight winding may make much trouble in your nice work. So look particularly for this defect, which you can often detect at once by the eye, but if your eye is not well trained use winding-sticks (see Part V.). Warped or curled stock, with the surface rounded or hollowed (Fig. 19), is also bad, but you will need no instructions to detect this defect by the eye or any straight stick. When boards are rounding on one side and hollowing on the other, it is due either to the way the log was sawed, as we have seen, or to one side having been more exposed and so having dried faster and shrunk faster than the other, causing that side to be concave, while the other became convex. Stock is sometimes crooked[42] lengthways,—either a simple bending in a curve or at an angle, or wavy (Fig. 30), or both,—often due to careless "sticking" (Fig. 28) while the wood was green. Sighting lengthways will of course show these defects.

Reject stock badly checked at the ends, or cracked. There is apt to be more or less of this in most lumber. In seasoning, the pieces dry faster on the outside than in the middle, which causes checks or cracks, usually worse at the ends of the pieces, where the drying takes place most rapidly. The ends of valuable boards and planks are sometimes painted or cleated, which in a measure prevents this result. Occasionally, when the cleat is removed a crack will suddenly extend and even split the board.

Do not take a cracked or partly split board, thinking that you can use the sound end from the point where the crack appears to stop. Possibly you can, but oftentimes and in some kinds of wood it is impossible to tell before the stock is cut where the cracks end. In mahogany, for example, they sometimes are found to extend, or develop, several feet beyond where they appear to stop. Sometimes you can buy wood with such defects at a discount. Unless you are sure, however, that there is enough sound, clear wood outside of the cracks or knots, and unless the discount is pretty large, it will usually be better to buy clear, sound stock for nice work, as the waste is very apt to offset the saving, not to speak of the extra time and labour it takes to work up such material. (See Shakes in Appendix.)

Reject sapwood as far as possible, because it is usually inferior to the heartwood.

In the case of elm and young ash the sapwood is, however, superior to the heart. The heartwood is usually harder and more durable than the sapwood, heavier, of better texture, and commonly of better colour.[43]

"The sapwood is, as a rule, darker in the whitewood class than the heartwood, whether seasoned or unseasoned, but is paler in colour in most hardwood trees which have had time to season. In some of the white, or softer woods, when fresh cut, the difference is scarcely perceptible; but exposure to the air quickly gives to the outer layers a greenish tinge, due to a species of mould fungi which attack them."—Laslett and Ward. (See also Appendix.)

When buying, do not take boards just as they happen to come from the pile. Select them yourself. Most good-natured dealers will let you do this if you do not expect them to unstack a whole pile just for one or two boards. It is better to do this for nice work even if a slight charge should be made for the privilege. When you come to pick out boards you will see the application of what has been said about the ways of cutting the log, and you can tell by the annual rings at the ends of the boards, by the sapwood (when visible), the grain, etc., from what part of the log the pieces were sawed.

Use good, clear stock for everything but rough work. Of course in rough or temporary work you can save expense by using wood from packing-cases, boxes, old fence-rails, or anything that will serve the purpose, but as a rule avoid trying to make nice, new things of wood taken from old work or boxes. The quality of the wood used for boxes nowadays is apt to be poor and hard to work. The wood taken from old cabinet-work is, however, often better than you are likely to buy, but you need to be very cautious about working over old material, for the dirt which has been ground into it is apt to dull your tools, and, moreover, the presence of concealed nails, etc. (which it is sometimes almost impossible to detect), will often injure your tools so much as to more than offset what you save in expense.[44]

Do not buy thick stock with the idea of sawing it into thinner pieces (unless necessary). Of course it can be sawed into thinner or smaller pieces, but you cannot always be sure that these will be as true as the original stock. Suddenly exposing the middle of a piece of wood to the air in this way sometimes plays queer pranks with the shape of the pieces (see Appendix). If you want to use boards for good work buy those which have seasoned as boards, instead of splitting up thicker lumber; and always try to treat both sides of a board alike so far as you can.

Bear this in mind: If you take an inch board to the mill to be planed down to three eighths of an inch, for instance, have it planed equally, as nearly as may be, from both sides. Ignorant hands often simply smooth off, or "surface," one side, and then plane the board down on the other side, when it will sometimes warp badly at once and be useless, perhaps, for the purpose intended.

If you carefully pile and "stick" the stock you have bought (Fig. 28), it will tend to keep the pieces straight and true. Never lay good boards down flat directly upon one another unless they are thoroughly seasoned. It is the best of all ways, however, to keep a pile of thoroughly seasoned stock, but not the way to season it. The top board will warp. Never lay a single board of nice stock flat on its side. Keep short pieces of nice stock standing on end where they will be equally exposed on both sides to heat and cold, moisture and dryness.

The best way to learn about any kind of wood is from the wood itself. It is a capital idea to make a collection of specimens of as many kinds as you can.[12] You will be sur[45]prised to see how varied, interesting, and handsome a collection you can make at little or no expense. (See Appendix.)

The kinds of wood which you are likely to use are commonly known as either hard or soft, the former class from trees with broad leaves, as the oak, the latter from the coniferous or needle-leaved trees, as the white pine. This distinction between hard and soft wood you may find somewhat puzzling at first, for the common whitewood of the hardwood class you will find softer and easier to work than hard pine of the softwood class, but the distinction is based on botanical reasons. The hard woods are usually more durable as well as stronger than the soft. For various woods see Appendix.

Timber.—The word timber is applied in a general way to the log and to the material itself, and to the standing trees. It is also applied more specifically to the larger squared pieces, or "dimension" stock, such as sills, beams, etc.

Lumber.—As the term is used in the United States, lumber consists, according to Webster, of "timber sawed or split for use, as beams, joists, boards, planks, staves, hoops, and the like."

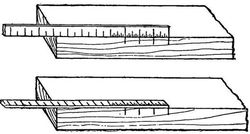

Lumber may be either undressed or dressed, that is, rough (as it comes from the saw) or planed. It is usually sawed in regular thicknesses, and for stock which is in steady demand, such as joists, floor timbers, etc., in regular widths, as 2" x 4", 4" x 6", etc. It is commonly sold in lengths varying from 10 feet to 20 feet. Twelve feet is a common length for boards. Planing (by machine) rough or undressed boards on both sides will usually reduce the thickness of an inch board to about seven eighths of an inch. Other thicknesses will of course be reduced correspondingly. Bear this in mind. The terms 1" board, 2" plank, etc., apply, as a rule, to the stock in the rough state as it comes from the saw. When you buy planed or dressed lumber it will be thinner—that is, the[46] "inch board" that you wish to get for a shelf will not be one inch thick (unless you get it unplaned), but seven eighths of an inch.

You must make allowance for this when you figure on dressed lumber. If for example the board must be one inch thick when planed, you will have to get a thin plank and have it planed down, or pull over the pile until you find a board which happens to be sawed as thick as one inch and one eighth. You can sometimes find boards planed one inch thick, but as a rule you will find the thickness seven eighths of an inch. A similar statement will apply to the various thicknesses of planks also. The sawing is often very irregular, however, and frequently some boards or planks will run thick enough in sawing to give the required thickness when planed, so it is well to look for such when you need pieces a little thicker than planed stock usually runs.

For such work as you are likely to do you will chiefly need boards, planks, and joists. Other forms will be referred to farther on.

Fig. 31.

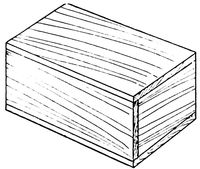

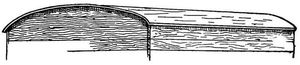

Boards.—These are one inch thick or less.

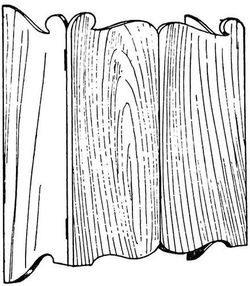

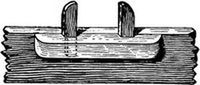

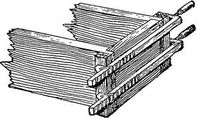

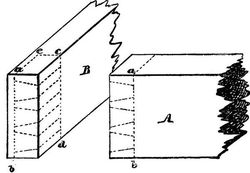

Matched-boards, or "sheathing," have a groove on one edge and a corresponding tongue on the other (Fig. 31.) Any number of boards can thus be joined to make a wide surface. The edges of these boards were formerly tongued and grooved by hand[47] with "matching-planes," but now this is done by machine, usually with some form of bead or moulding at one edge (and sometimes in the middle) to render the joint less noticeable.

Planks.—These are thick boards,—more than one inch in thickness. Both planks and boards can be of any width or length, the distinction being merely in thickness.

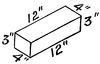

Joists.—These are the same as narrow planks, but of some fixed width, as 2" by 3", which is the same as a 3" strip sawed from the edge of a 2" plank.

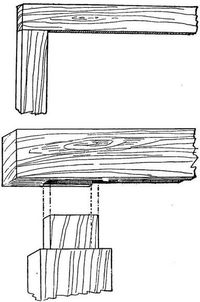

Fig. 32.

Fig. 33.

Fig. 34.

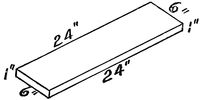

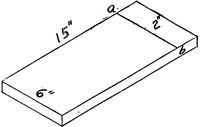

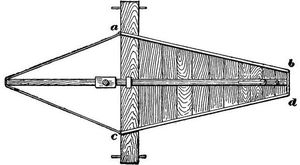

Most of the lumber you will require is sold by the square foot, at so much an M (1000 feet), or so much a foot. The square foot has an area of 144 square inches and is one inch thick, or contains 144 cubic inches, regardless of the shape or size of the piece. That is, Figs. 32, 33, and 34 each equal one square foot by board measure.

Thus a board 12' long, 12" wide, and 1" thick, contains 12 feet, board measure. A board 12' long, 6" wide, and 1" thick, contains 6 feet. A plank 12' long, 12" wide, and 2" thick, contains 24 feet. A plank 12' long, 6" wide, and 2" thick, contains 12 feet, or the same as the board first mentioned. You can bear in mind that in case of boards 12' long the contents in feet is indicated by the width in inches, as you will see from the examples[48] just given. A board 12' long and 7" wide contains 7 square feet. So all you have to do to measure 12' stock is to find the width in inches. If the board tapers in width, measure at the middle. The same is true of planks, only the width in inches must be multiplied by the thickness of the plank. A plank 12' long, 7" wide, and 3" thick, contains 21 square feet. Of course this principle can be quickly applied to pieces whose length is any convenient multiple or fraction of twelve. Thus a board 18' long, 8" wide, and 1" thick, contains 1½ times as many square feet as one 12' long, or 12 feet. A plank 9' long, 6" wide, and 2" thick, contains ¾ as many square feet as if 12' long, or 9 square feet.

Boards less than one inch thick are usually sold by the square foot of surface, regardless of thickness—the price varying according to the thickness, except in cases where an inch board is planed down, when, of course, inch thickness is charged for. There is no distinction made in measuring between a rough board 1" thick and a planed board 7/8" as, of course, they represent the same amount of lumber. The cost by the foot of the planed board is greater because of the expense of planing. In cities, and sometimes in the larger towns, you can find thin boards (½", 3/8", 3/16", 1/8" thick) already planed, and even scraped, for nice work.

Some of the rarer and less commonly used woods are often sold by the pound, as ebony, leopard wood, tulip wood, etc. Pieces turned out in quantities for special uses, as strips, mouldings, etc., are often sold by the "running foot," meaning simply the length, the price varying according to the amount of lumber and labour required. Certain regular sizes and shapes of lumber are sold by the hundred or by the piece. Shingles, clapboards, laths, and the like, are sold in bunches or bundles.

For other matters relating to wood, see Appendix.

Working Drawings.—A simple drawing will often give you a better idea of an object than you can get from any description in words, for drawing is not only a very ancient form of language but one readily understood by people of all countries and all times. It is one of the chief tools of a workman in these days, so of course the quicker you become familiar with it the better, for the day for "rule-of-thumb" work and feeling one's way along step by step is fast giving way to the guidance of the working drawing, which shows one not only exactly what is to be made but exactly how to make it.

When you wish to make some particular thing, you should begin by making rough sketches to express your idea, and from them an accurate working drawing in which every detail and measurement is clearly given. Make all your working drawings carefully to scale (see Appendix), and whenever you can, make them full size. Do not guess at the height, width, and length, but measure, and measure very carefully. Never mind if it takes time. Learn first to do it right, and practice will soon teach you to do it more quickly.

The time to make changes in your plans is when you are making the drawings—particularly the rough preparatory sketches. Making the drawings will, if you make them complete and accurate, show you what you know and what you[50] do not know about the subject. The working drawing should be complete and final.

Begin the making of sketches and detailed drawings with the first article you make, no matter how simple it may be. You can go about the work with confidence, which goes a long way toward success, when you know that you have thought it out to the end and have it all done on paper. For practical suggestions about working drawings, see Appendix.