Title: Scientific American Supplement, No. 488, May 9, 1885

Author: Various

Release date: December 30, 2008 [eBook #27662]

Most recently updated: January 4, 2021

Language: English

Credits: Produced by Simon Gardner, Juliet Sutherland and the Online

Distributed Proofreading Team at https://www.pgdp.net

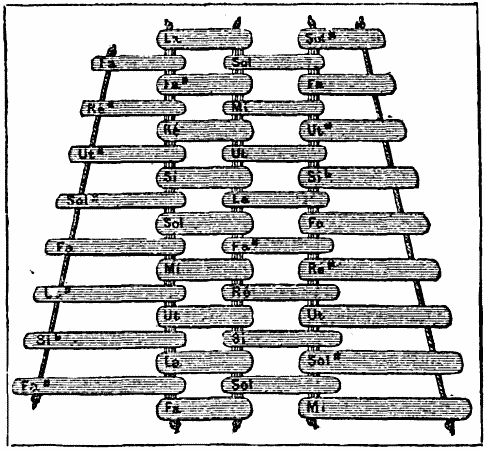

We give in this number of our Supplement several articles with illustrations, for which we are indebted to La Nature. They are entitled Electric Light Apparatus for Military Purposes, The Otoscope, A New Seismograph, Dinocrates' Project, The Xylophone, Plan of an Elevated Railway for Paris.

Here we are at the great forge (Fig. 1), that wonderful creation which has not its like in France, that gigantic construction which iron has wholly paid for, and which covers a space of twenty-four acres. We first remark two puddling halls, each of which contains 50 furnaces and 9 steam hammers. It is in these furnaces that the iron is puddled. The ball or bloom thus obtained is afterward taken to the hammer, which crushes it and expels the scoriæ.

The puddler's trade, which is without doubt the most laborious one in metallurgy, will surely soon be lightened through the use of steam. Two rotary furnaces actuated by this agent have been in operation for a few years at Creusot, and each is yielding 20 tons of iron per day.

We have but a court of 130 feet in width to cross in order to reach the rolling mill. At the entrance to this we enjoy one of the most beautiful sights that the immense works can offer. For a length of 1,240 feet we perceive on one side a series of rolling machines, and on the other a row of reverberatory furnaces that occasionally give out a dazzling light. In the intervals are fiery blocks that are being taken to the rolling machines, in order to be given the most diverse forms, according to the requirements of commerce.

The iron obtained by puddling is not as yet in its definite state, but the rolling mill completes what the puddling hall does in the rough. Five hundred and fifty thousand tons of iron, all shaped, are taken from the forge every day. To reach such a result it requires no less than 3,000 workmen and a motive power of 7,000 horses.

But do not be appalled at the cost of the coal, for, thanks to ingenious processes, the heat lost from the furnaces nearly suffices to run the boilers. If we remark that a power of one horse does in one hour the equivalent of a man's labor per day, we conclude that these machines (which run night and day) represent an army of 160,000 men that lends its gratuitous aid to the workmen of the forge. This is what is called progress in industry.

We have just seen that iron is obtained in small masses. These can be welded upon heating them to 1,500 or 2,000 degrees. It is impossible to manufacture a large piece exempt from danger from the weldings. Cast iron always has defects that are inherent to its nature, and these are all the more dangerous in that they are hidden. Steel is exempt from these defects, and, moreover, whatever be the size of the ingot, its homogeneousness is perfect. This is what has given the idea of manufacturing from it enormous marine engines and those gigantic guns that the genius of destruction has long coveted.

Ah, if the good sense of men does not suffice to put a limit to their increasing progress, bridges, viaducts, and tunnels will take it upon themselves, if need be, to bar their passage. But, in order to forge large ingots, it became necessary before all to increase the power of the steam hammer. The Creusot establishment, which endowed metallurgy with this valuable machine, had allowed itself to be eclipsed, not by the number (for it had 57), but by the dimensions of the largest one. In 1875, the Krupp works constructed one of 50 tons, and their example was followed at Perm, St. Petersburg, and Woolwich. It was then that Mr. Henry Schneider put in execution a bold project that he had studied with his father, that of constructing a 100 ton steam hammer, along with the gigantic accessories necessary (Fig. 2). It became necessary to erect a building apart for its reception. This structure covers a surface of one and three-quarter roods, and reaches a height of 98 feet in the center. As for the hammer, imagine uprights 25 feet in height, having the shape of the letter A, surmounted with a cylinder 19½ feet in length and of a section of 3½ square yards.

The piston which moves in this cylinder, under a pressure of 5 atmospheres, is capable of lifting a weight of 100 tons. The hammer, which is fixed to this piston by a rod, has therefore an ascensional force of 88,000 pounds. It can be raised 16 feet above the anvil, and this gives it a power three and a third times greater than that of the Prussian hammer. Large guns can therefore be made in France just as well as in Germany.

This enormous mass is balanced in space at the will of one man, who, by means of a lever, opens and closes two valves without the least effort. This colossal hammer required an anvil worthy of it. This weighs 720 tons, and rests upon granite in the center of 196 feet of masonry.

The hammer is surrounded with four furnaces heated by gas, and duty is done for each of these by steam cranes capable of lifting 350,000 pounds. These cranes take the glowing block from the furnace, place it upon the anvil, and turn it over on every side at the will of the foreman. Under this hammer a cannon is forged as if it were a mere bolt. The piece is merely rough-shaped upon the anvil, and a metallic car running upon a 36 foot track carries it to the adjusting shop. There the cannon is turned, bored, and rifled, and nothing remains but to temper it, that is to say, to plunge it into a bath after it has been heated white hot. For this purpose an enormous ditch has been dug in which there is a cylindrical furnace, and alongside of it there is a well of oil. The car brings the cannon to the edge of the ditch, and a steam crane performs the operation of tempering with as much ease as we would temper a knife blade.

In the presence of such engines of attack it was necessary to think of defense. The hammer that forges the cannon also gives us the armor plate to brave it. This time the ingot is flattened under the blows of the hammer, and even takes the rounded form of the stern, if it be so desired. Thus is obtained the wall of steel that we wish.

Will it be possible to keep up the fight long? In order that one may get some idea of this for himself, let us rapidly describe an entirely peaceful contest that took place recently upon the coast of Italy. Two rival plates, one of them English and the other French, were placed in the presence of the Spezia gun, which weighs 100 tons. These plates were strongly braced with planks and old armor plate. Three shots were to be fired at each of the plates.

In the first shot the ball was of hardened cast iron, and weighed 1,990 pounds. The English plate was filled with fissures, while the Creusot did not show a single one. The ball penetrated it about seven inches, and was broken into small pieces.

In the second shot the projectile was the same, but the charge was greater. The shot may be calculated from the velocity, which was 1,530 feet. It was equal to what the great hammer would give were it to fall from a height of a hundred yards. The English plate was completely shivered, while the French exhibited but six very fine fissures radiating from the point struck. The ball entered 8 inches, and was broken as in the first experiment.

The third shot fired was with a steel ball, against the French plate, the English being hors de combat. The penetration was the same; the ball was not broken, but was flattened at the point like the head of a bolt.

We should like to speak of those magnificent workshops in which the immense naval pieces are adjusted, where the shafts of helixes 60 feet in length are turned, and of the boiler works, where one may see generators that have a heating surface exceeding 2,000 square feet, for it requires no less than that to supply 8,000 H.P., and thus triumph over the force of inertia and those colossal iron-clads. But how describe in a magazine article what the eye cannot take in in a day?

Despite all our regrets, we have to pass over some things, but our duty will not have been performed if we omit the history of the works.

Creusot, which to-day is a regularly-built city with a population of 28,000 souls, was in 1782 but a poor hamlet called Charbonniere. The existence there of a coal bed had long been known, and iron ore had been found not far off. But how establish works in a locality deprived of a water course, and distant from the large ways of communication?

In 1782 the steam engine, which Watt had just finally improved, removed the first difficulty, and the second was soon to disappear, thanks to a projected canal. An iron foundry was then established there under the patronage of Louis XIV., while the Queen had glassworks erected.

As long as the war lasted the foundry supported itself through casting cannons and balls, but after the year 1815 it became necessary either to transform the works or sell them. It was decided to do the latter. The Messrs. Chagot, who became purchasers in the sum of $180,000, were in turn obliged to sell out in 1826. Creusot was then ceded to Messrs. Manby & Wilson, who already had works at Charenton. At the end of seven years of efforts this firm made a failure, and, finally, in 1836, after six million dollars had been swallowed up, Creusot was bought for $536,000, by Messrs. Adolphe & Eugene Schneider & Co. The period of reverses was at an end, and one of continued success was begun.

The new managers had seen that carriage by steam was soon to follow, and open up to metallurgy an entirely new horizon. The works were quickly transformed and enlarged, and in 1838, the first French locomotive was turned out of them. After locomotives came steamboats. It was then that the necessity of forging large pieces gave the idea of a steam hammer.

By a coincidence that can only be explained by the needs of the epoch, the English came upon the same discovery almost at the same time, and the Creusot patent antedated the English one by only two months.

Two years afterward, frigates such as the Labrador, Orenoque, Albatros, etc., of 450 H.P., were rivaling English vessels on the ocean.

After the death of Mr. Adolphe Schneider, on the 3d of August, 1845, his brother Eugene, left sole manager, displayed an activity that it would be difficult to exceed. He made himself familiar with the resources and productions of foreign countries and of France, and then made up his mind what to do. He desired to make his works the finest in the world, and it has been seen from what precedes that, after twenty years of effort, his aim has been attained. What a rapid progress for so short a time! In 1838, the first locomotive that was not of English origin appeared to us like a true phenomenon; a few years afterward the Creusot locomotives were crossing the Channel in order to roll proudly over the railways of a rival nation.

A general, no matter how skillful, could not conquer with an undisciplined army, so the education of the workmen's children was one of the things that the founder of this great industrial center had constantly in mind. Mr. H. Schneider has continued the work of his father, and has considerably extended it, at Creusot as well as in the annexed establishments. The number of pupils who frequent the schools exceeded 6,000 in 1878.

The work is not confined to educating the children, but a retreat is afforded the parents, without putting them under any restraint.

After twenty-five years' service a workman receives an income of $100 if he is a bachelor, and $150 if married, but upon one condition, however, and that is that he is a Frenchman. For $1.20 a month he is lodged in a pretty little house surrounded with a garden, and, if he is sick, he is attended gratuitously.

These benefits are not addressed to ingrates, as was proved by the profound sorrow that reigned in the little city when the death of the benefactor of Creusot was learned.—Science et Nature.

The members of the American Gun Foundry Board visited these works in 1883, and give the following in their report: The most important steel works in France are situated at Le Creusot, and bear the name of the location in which they are situated. These works have advanced year by year in importance and in magnitude since their purchase by Mr. Eugene Schneider.

This gentleman's death, in 1875, was a source of mourning to the whole town, the inhabitants of which looked up to him as a father. The grateful people have erected to his memory a monument in the market square.

Under the administration of his son, Mr. Henry Schneider, the fame of the products of the works has been enhanced, and the proportions of the establishment have been much increased. The whole number of workmen now employed here and at other points amounts to 15,000; and it is the great center of industry of the adjoining region. At no other place in the world is steel handled in such masses.

It would be foreign to the purpose of this report to dwell on the many objects of commerce which are supplied from these works, but it is safe to say that no proposed work can be of such magnitude as to exceed the resources of the establishment.

For the preparation of metal for cannon and armor-plates Le Creusot is thoroughly equipped. The iron is produced on the premises from the purest imported ores, and the manufacture of the steel is carried on by the most approved application of the open-hearth system with the Siemens furnace; the chemical and mechanical tests are such as to satisfy the most exacting demands of careful government officials; and the executive ability apparent in all the departments and the evident condition of discipline that pervades the whole establishment inspire confidence in the productions of the labor.

The capacity for casting steel is represented by seven open-hearth furnaces of 18 tons each, equal to 126 tons; and the process of casting large ingots is a model of order and security. Ladles capable of holding the contents of one furnace, mounted upon platform cars, are successively filled at a previously determined interval of time and run on railways to a convenient position over the mould; before the first ladle is exhausted the supply from the succeeding one has commenced to run, and so on to the completion of the casting, the supply to the mould being uninterrupted during the entire process. The precision with which the several ladles are brought into position in succession makes it entirely unnecessary to provide a common reservoir into which all the furnaces may discharge. By this process the casting of a 45 ton ingot, which was witnessed by the Board, was effected in 23 minutes.

The process of tempering the gun-tubes was also witnessed by the Board. The excavation of the pit is, as at St. Chamond, 15 meters deep, with the furnace at one end and the oil tank (100 tons) at the other. One side of the upright furnace is constructed in the form of a door, which, by a convenient arrangement for swinging, is made to turn on its hinges. Thus, when the tube is raised to the right temperature, it is seized by the traveling crane, the door of the furnace swung open, and the tube at once advanced to the tank in which it is immersed.

All tubes are immersed in oil the second time, but at a temperature much below that to which they are raised at the first immersion. This process constitutes the annealing after tempering.

The manufacture of steel-armor plates is a specialty of Le Creusot, which is engaged in an active competition with the manufacturers of compound armor. Plates up to 60 centimeters in thickness and 3 meters wide are forged here; they are tempered after forging, but what subsequent treatment they receive was not explained.

The tempering pit for the plates consists of an excavation of convenient size, in the center of which is placed a tank containing 180 tons of oil. At the four corners of the pit are furnaces in which the plates are raised to a proper temperature. When sufficiently heated, a plate is seized by a walking crane and immersed in the oil.

Hoops for cannon are manufactured here in large quantities. They are cut from solid ingots, and those for guns up to 24 centimeters are rolled like railway tires; those for larger calibers are forged on a mandrel. Jackets of large size are also manufactured; these are made from solid ingots, which, after being forged, are bored out.

At Le Creusot a remarkable test of hoops was witnessed, which exemplifies not only the excellence of the manufacture of the steel but also the exacting character of the French requirements. The hoops for naval guns are made with the interior surface slightly conical. When forged, turned, and brought under a hammer, a standard mandrel of steel, conically shaped to suit the form of the cone in the hoop, but of a slightly increased diameter, is introduced, the smaller end of the mandrel being able to enter the larger end of the hoop. The mandrel is then forced in by the hammer until its lower edge has passed through the hoop. The blows are then made to operate on the upper edge, detaching it from the mandrel. Careful measurements are taken of the diameter of the hoop before and after this test, and it is required that the measurement subsequent to the operation shall show that the hoop has partially, but not entirely, returned to the diameter that it had before the entrance of the mandrel. This would show that there is left to the metal a small margin within its elastic limit. A system of manufacture which can comply with such a refinement of exactitude must be very precise.

Perhaps the most striking feature at Le Creusot is the forge, where is assembled an array of steam hammers not equaled in the world, viz.:

One 100 ton hammer with a fall of 5 meters.

One 40 ton hammer with a fall of 3 meters.

One 15 ton hammer with a fall of 3 meters.

Two 10 ton hammers with a fall of 2½ meters.

One 8 ton hammer with a fall of 2½ meters.

As the 100 ton hammer at these works is the largest in the world, some particulars concerning it will be appropriate.

The foundations are composed of a mass of masonry laid in cement resting on bed rock, which occurs at a depth of 11 meters, an anvil block of cast iron, and a filling-in of oak timber designed to diminish by its elasticity the vibrations resulting from the blows of the hammer. The masonry foundation presents a cube of 600 meters. Its upper surface is covered with a layer of oak about one meter in thickness, placed horizontally, on which rests the anvil block.

At the Perm foundry in Russia the anvil block for the 50 ton hammer is made in one piece, moulded and cast on the spot it was intended to occupy. Its weight is 622 tons. At Le Creusot, however, this idea was not approved, and it was determined to construct the block in six horizontal courses, each bedded upon plane surfaces. Each course is formed of two castings, except the upper one, a single block, which weighs 120 tons and supports the anvil. Thus formed in 11 pieces, it is 5.6 meters high, 33 square meters at the base, and 7 square meters at the top. Its entire weight is 720 tons.

The space between the block and the sides of the masonry in which it rests is filled in solidly with oak. The block is thus independent of the frame of the superstructure.

The legs of the frame, inclining toward each other in the form of an A, are secured at their bases to a foundation plate embedded in the masonry. They are hollow, of cast iron, and of rectangular cross section, each leg in two pieces joined midway of their length by flanges and bolts. The legs are also bound together by four plates of wrought iron, which, at the same time, holds the guides. The height of the legs is 10.25 meters, and their weight, with the guides, 250 tons. The binding plates weigh together about 25 tons, and the foundation plates 90 tons.

The entablature of the frame work weighs 30 tons; on it is placed the steam cylinder, single acting, made in two pieces, each 3 meters long united by flanges and bolts. The diameter of the cylinder is 1.9 meters, giving a surface of 27,345 square centimeters (deducting the section of the rod, which is 36 centimeters in diameter); which, for 5 atmospheres, gives a pressure under the piston of about 140 tons. As the weight of the hammer is 100 tons, it is evident that it can be raised with great velocity.

The stroke of the piston in the cylinder is 5 meters. This height of fall, multiplied by the 100,000 kilogrammes of the mass, gives a working force of 500,000 kilogrammeters, or about 1,640 foot tons. The width between the legs is 7.5 meters, and the free height under the cross ties 3 meters, thus providing ample space for maneuvering large masses of metal.

The entire height of this colossal structure from the base of the masonry foundation to the upper part of the steam cylinder is 31 meters (102 feet), but notwithstanding this unfavorable condition for stability and the enormous effect resulting from a shock of 500,000 kilogrammeters, everything is so well proportioned that there is but slight vibration.

The workman who maneuvers the hammer is placed on a platform on one of the legs, about 3 meters above the floor. He is here protected from the heat reflected from the mass of metal during the operation of forging.

Elevated railways have been in operation for a long time in New York, Berlin, and Vienna, and the city of Paris has decided to have recourse to this mode of carriage, so indispensable to large cities. The question of establishing a line of railways in our capital has been open, as well known, since 1871. During this period of nearly fourteen years this grave subject has at various times given rise to serious discussions, in which the most competent engineers have taken part, and numerous projects relating to the solution that it calls for have been put forth.

The problem to be solved is of the most complex nature, and the engineers who have studied it have not been able to come to an agreement except as regards a small number of points. It may even be said that unanimity exists upon but a single point, and that is that the means of locomotion in Paris do not answer the requirements of the public, and that there is an urgent necessity for new ones. The capital question, that of knowing whether the railway to be built shall be beneath or above ground, is not yet settled; for, up to the present, no project has been prescribed in one direction or the other.

While some extol the underground solution as being the only one that, without interfering with circulation in the streets, permits of establishing a double-track railway capable of giving passage to ordinary rolling stock and of connecting directly with the large lines, others, objecting that such a road could not give satisfaction to the taste of Parisians, and that it would necessitate work out of proportion to the advantages gained, conclude upon the adoption of an open air railway.

Preferences generally are evidently for this latter solution.

We have received from a learned engineer, Mr. Jules Garnier, a project for an elevated railway, which appears to us to be very ably conceived, very well studied out, and which we hasten to make known.

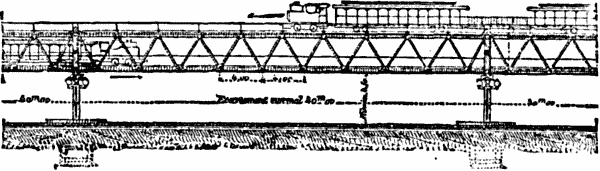

(1.) The system is characterized by the following fundamental points: The up and down tracks, instead of being laid alongside of each other, as in an ordinary railway, are superposed upon two distinct platforms forming a viaduct, which is consequently so arranged as to permit of the laying of one of the tracks at its lower part and of the other at its upper.

(2.) The system of constructing the viaduct is so combined as to be capable of giving passage upon the road to the rolling stock of the large lines during the stoppage of the daily passenger trains.

(3.) The tracks are connected at the extremities by a curve that has the proper incline to compensate for the difference in level between the two, and which has a sufficiently large radius to allow the slope of the track to be kept within the limits admitted. The running of the trains is thus uninterrupted.

(4.) When two lines of different directions bisect one another, a special arrangement permits the passengers from one line to pass to the other by means of what is called a "tangent" station, without the trains of one line crossing the tracks of another, the purpose of which arrangement is to avoid those accidents that would inevitably occur through the crossing of a track by the trains of a transverse line.

(5.) The rolling stock is arranged in a manner that allows the entrance and exit of the passengers to be effected with great promptness.

In ordinary avenues, comprising a roadway and two sidewalks, the elevated railway is placed in the axis of the roadway at a sufficient height to prevent it interfering with the passage of carriages, say 14¾ feet above the surface, while in boulevards or avenues of great width, having contre-allees1 bordered by a double row of trees, it is installed in one of the contre-allees.

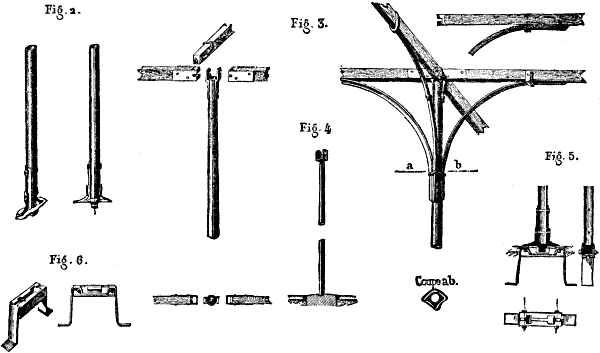

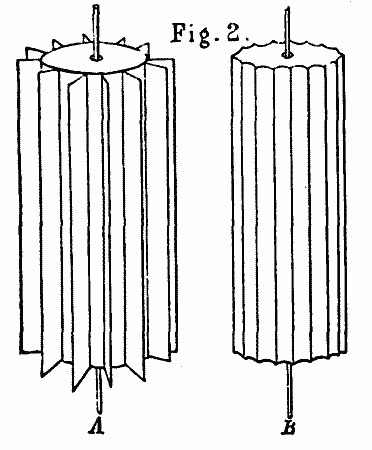

In the first case (Fig. 1), the viaduct is wholly metallic, while in the second it comprises masonry arches surmounted by a metallic superstructure. The viaduct is formed of independent spans supported by metallic piers that rest upon masonry foundations (Fig. 2).

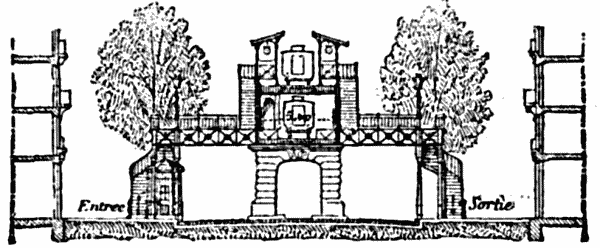

The line will have three kinds of stations, intermediate, "tangent," and terminal ones. It is at the latter that the two superposed lines are connected by the circular inclined plane.

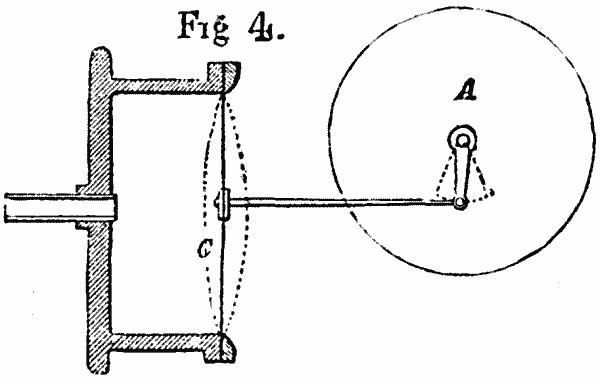

The waiting platforms of the intermediate stations will be formed simply by the widening of the span corresponding to the station. Access to these platforms will be had by stairs running up from the edge of the sidewalk. The passengers will make their exit by means of corresponding stairs on the opposite side. (Figs 3 and 4.)

The tangent stations are placed at the meeting point of two lines, which, instead of crossing each other, are bent inward like an X, the two parts of which will be tangent to the central point. Through such arrangements the running of the trains will be continuous, and a traveler reaching one of these stations will be able, upon changing train, to take at his option any one of the three other directions.

As may be seen, Mr. Garnier's project presents conditions which are very favorable to the establishment of an elevated road in the interior of Paris. Far from injuring the aspect of the great arteries of our metropolis, the viaduct, as it has been conceived, will contribute toward giving them a still more imposing look. If the beautiful is, as has been said, the expression of the useful, an elevated railway, well conceived, may be beautiful. The project of a subterranean railway is attended with great drawbacks, not only as regards the great expense that it would necessitate, but also the difficulties of constructing it. And there is a still graver objection to it, and that is that it would oblige travelers to move like moles in dark, cold, and moist tunnels. At Paris, where we are accustomed to a pleasant climate and clear atmosphere, we like plenty of air and broad daylight.—La Nature.

[1] Paths parallel with the public walks.

I propose to devote the very limited time at my disposal to the consideration of some of the most important of those improvements which are obviously and immediately connected with civil engineering. I am aware of the danger there is of making a serious mistake, when one excludes any matter which at the moment appears to be of but a trivial character. For who knows how speedily some development may show that the judgment which had guided the selection was entirely erroneous, and that that which had been passed over was in truth the germ of a great improvement? Nevertheless, in the interests of time some risk must be run, and a selection must be made; I propose, therefore, to ask your attention while I consider certain of (following the full title of Division I.) "The apparatus, appliances, processes, and products invented or brought into use since 1862." In those matters which may be said to involve the principles of engineering construction, there must of necessity be but little progress to note.

Principles are generally very soon determined, and progress ensues, not by additions to the principles, but by improvement in the methods of giving to those principles a practical shape, or by combining in one structure principles of construction which had been hitherto used apart. Therefore, to avoid the necessity of having a pause, in referring to a work, by finding that one is overstepping the boundary of principle, and trenching within the domain of construction, I think it will be well to treat these two heads together.

If my record had gone back to just before 1851 (the date of the great exhibition), I might have described much progress in the principles of girder construction; for shortly prior to that date, the plain cast-iron beam, with the greater part of the metal in the web, and with but little in the top and bottom flange, was in common use; and even in the preparation of the building for that exhibition, it is recorded that one of the engineers connected therewith had great difficulty in understanding how it was that the form of open work girder, with double diagonals introduced therein (a form which was for years afterward known as the exhibition girder), was any stronger than a girder with open panels separated by uprights, and without any diagonals. But, long before 1862, the Warren and other truss-girders had come into use, and I am inclined to say that, so far as novelty in the principle of girder-construction is concerned, I must confine myself to that combination of principles which is represented by the suspended cantilever, of which the Forth Bridge, only now in course of construction, affords the most notable instance. It is difficult to see how a rigid bridge, with 1,700 foot spans, and with the necessity for so much clear headway below, could have been constructed without the application of this principle.

Pursuing this subject of bridge work, the St. Louis Bridge of Mr. Eads may, I think, be fairly said to embody a principle of construction novel since 1862, that of employing for the arch-ribs tubes composed of steel staves hooped together. Further, in suspension bridges there has been introduced that which I think is fairly entitled to rank among principles of construction, the light upper chain, from which are suspended the linked truss-rods, doing the actual work of supporting the load, the rods being maintained in straight lines, and without the flexure at the joints due to their weight. In the East River Bridge, New York, there was also introduced that which I believe was a novelty in the mode of applying the wire cables. These were not made as untwisted cables and then hoisted into place, thereby imposing severe strains upon many of the wires composing the cable through their flexure over the saddles and elsewhere, but the individual wires were led over from side to side, each one having the length appropriate to its position, and all, therefore, when the bridge was erected, having the same initial strain and the same fair play. Within the period we are considering, the employment of testing-machines has come into the daily practice of the engineer; by the use of these he is made experimentally acquainted with the various physical properties of the materials he employs, and is also enabled in the largest of these machines to test the strength and usefulness of these materials, when assembled into forms, to resist strains, as columns or as girders. I of course do not for one moment mean to say that experimental machines were unknown or unused prior to 1862—chain cable testing-machines are of old date, and were employed by our past President, Mr. Barlow, and by others, in their early experiments upon steel; but I speak of it as a matter of congratulation that, in lieu of such machines being used by the few, and at rare intervals upon small specimens, for experimental purposes, they are now employed in daily practice and on a large scale.

In harbor work we have had the principle of construction employed by Mr. Stoney at Dublin, where cement masonry is moulded into the form of the wall for its whole height and thickness, and for such a length forward as can be admitted, having regard to the practical limit of the weight of the block, and then, the block being carried to its place, is lowered on to the bottom, which has been prepared to receive it, and is secured to the work already executed by groove and tongue.

It would not be right, even in this brief notice of such a mode of construction, to omit mention of the very carefully thought out apparatus by which the blocks are raised off the seats whereon they have been made, and are transported to their destination. It is no simple undertaking (even in these days) to raise (otherwise than hydraulically) a weight of 350 tons, which is the weight of the blocks with which Mr. Stoney deals. But he does this by means of pulley-blocks attached to shears built on the vessel which is to transport the block, and he contrives to lift the weight without putting upon his chains the extra strain due to the friction of the numerous pulleys over which they pass. The height of the lift is only the few inches needed to raise the block clear of the quay on which it has been formed, and this is obtained by winding up the chain by steam gear quite taut, so as to take a considerable strain, but not that equal to the weight of the block, and then water is pumped into the opposite end of the vessel to that upon which the shears are carried, this latter end rises, and the block is raised off the seat on which it was formed, without the chains being put to work to do the actual lifting at all. The vessel, with the block suspended to the shear legs and over the bows, is then ready to be removed to the place where the block has to be laid. A word must here be said about an extremely ingenious mode of dealing with the slack chain, to prevent its becoming fouled, and not paying out properly, when the block is being lowered. This is accomplished by reeving the slack of each chain over two fixed sets of multiple sheaves.

A donkey-engine works a little crab having a large drum, the chain from which is connected with the main chain, and draws it round the multiple sheaves so as to take up the slack as fast as the main crab gives it out. The steam is always on the donkey, which is of such limited dimensions that it can do no injury to the chain even when its full power is in vain endeavoring to draw it any further; directly, however, the main crab gives more slack, and the chain between it and the two sets of sheaves falls into a deeper catenary, and one which therefore puts less opposition to the motion of the donkey-engine, that engine goes to work and makes a further haul upon the slack, and in this way, and automatically, the slack is kept clear.

A noteworthy instance of the use of pneumatic appliances in cylinder sinking for foundations is that in progress at the Forth Bridge. The wrought-iron cylinders are 70 feet in diameter at the cutting-edge, and have a taper of about 1 in 46. They are, however, at a height of 1 foot above low water (that is, at the commencement of the masonry work of the pier) reduced to 60 feet in diameter; at their bottoms there is a roofed chamber, into which the air is pumped, and in which the men work when excavating, this roof being supported by ample main and cross lattice girders. Shafts with air-locks and pipes for admitting water and ejecting silt are provided. The air-locks are fitted with sliding doors, worked by hydraulic rams, or by hand, the doors being interlocked in a manner similar to that in which railway points and signals are interlocked, so that one door cannot be opened until the other is closed. The hoisting of the excavated material is done by a steam engine fixed outside the lock, this engine working a shaft on which there is a drum inside the lock, the shaft passing air-tight through a stuffing box. A separate air-lock, with doors, ladder, etc., complete, is provided to give ingress and egress for the workmen. I have already adverted to one Scotch bridge; I now have to mention another, viz., the Tay Bridge, also now in course of construction. Here the cylinders are sunk, while being guided, through wrought-iron pontoons, which are floated to their berths, and are then secured at the desired spot by the protrusion, hydraulically, of four legs, which bear upon the bottom, and thus, until they are withdrawn, convert the pontoon from a floating into a fixed structure.

I regret that time will not admit of my giving any description of the modes of "cut and cover" which have been proposed for the performance of subaqueous works; sometimes the proposition has been to do this by means of coffer-dams, and with the work therefore open to the day-light during execution, and sometimes by movable pneumatic appliances. Consideration of subaqueous works necessarily leads the mind to appliances for diving, and although its date is considerably anterior to 1862, I feel tempted, as I believe the construction is known to very few of our members, to say a few words about the diving apparatus known as the "Bateau-plongeur," and used at the "barrage" on the Nile. This consists of a barge fitted with an air-tight cabin provided with an air-lock, and having in the center of its floor a large oval opening, surrounded by a casing standing up above the water-line. In this casing, another casing slides telescopically, the upper part of which is connected to the top of the fixed casing by a leather "sleeve." When it is desired to examine the bottom of the river, the telescopic tube is lowered till it touches the bottom, and then air is pumped into the cabin until the pressure is sufficient to drive out the water, and thus to expose the bottom. This appears to be a very convenient arrangement for shallow draughts of water.

Reverting for a moment to Mr. Stoney's work, I may mention that he uses for the greatest depths he has to deal with, when preparing the bed to receive his blocks, a diving apparatus which (while easily accessible at all times) dispenses with the necessity of raising and lowering, needed in an ordinary diving-bell to allow of the entrance and exit of the workmen. Mr. Stoney employs a bell of adequate size, from the summit of which rises a hollow cylinder, furnished at the top with an air-lock, by which access can be obtained to the submerged bell. Beyond the general improvement in detail and in the mode of manufacture, and with the exception of the application of the telephone, there is probably not much to be said in the way of invention or progress in connection with the ordinary dress of the diver.

But one great step has been made in the diver's art by the introduction of the chemical system of respiration, the invention of Mr. Fleuss. He has succeeded in devising a perfectly portable apparatus, containing a chemical filter, by means of which the exhaled breath of the diver is deprived of its carbonic acid; the diver also carries a supply of compressed oxygen from which to add to the remaining nitrogen oxygen, in substitution for that which has been burnt up in the process of respiration. Armed with this apparatus, a diver is enabled to follow his vocation without any air-tube connecting with the surface, indeed without any connections whatever. A notable instance of a most courageous use of this apparatus was afforded by a diver named Lambert, who, during one of the inundations which occurred in the construction of the Severn tunnel, descended into the heading, and proceeding along it for some 330 yards (with the water standing some 35 feet above him), closed a sluice door, through which the water was entering the excavations, and thus enabled the pumps to unwater the tunnel. Altogether, on this occasion, this man was under the water, and without any communication with those above, for one hour and twenty-five minutes. The apparatus has also proved to be of great utility in cases of explosion in collieries, enabling the wearer to safely penetrate the workings, even when they have been filled with the fatal choke-damp, to rescue the injured or to remove the dead.

With respect to the subject of tunneling thus incidentally introduced, in subaqueous work of this kind, I have already alluded to that which is done by "cut and cover," but where the influx of water is a source of great difficulty, as it was in the old Thames tunnel (though in this case for water one should read silt or mud), I do not know that anything has been devised so ingenious as the Thames tunnel shield; improvement has, however, been made by the application of compressed air.

In the instance of the Hudson River tunnel, the work was done in the manner proposed so long ago as the year 1830 by Lord Cochrane (Earl Dundonald) in that specification of his, No. 6,018, wherein he discloses, not merely the crude idea, but the very details needed for compressed air cylinder-sinking and tunneling, included air-locks and hydraulically-sealed modes for the introduction and extraction of materials. I may, perhaps, be permitted to mention that some few years ago I devised for a tunnel through the water-bearing chalk a mode of excavation by the use of compressed air to hold back the water, and combined with the employment of a tunneling machine. This work, I regret to say, was not carried out. But there are, happily, cases of subaqueous tunneling where the water can be dealt with by ordinary pumping power, more or less extensive, and where the material is capable of being cut by a tunneling machine. This was so in the Mersey tunnel, and would be in the Channel tunnel. In the Mersey tunnel, and in the experimental work of the Channel tunnel, Colonel Beaumont and Major English's tunneling machine has done most admirable work. In the 7 foot 4 inch diameter heading, in the new red sandstone of the Mersey tunnel, a speed of as much as 10 yards forward in twenty-four hours has been averaged, while a maximum of 11-2/3 yards has been attained; while in the 7 foot heading for the Channel tunnel, in the gray chalk, a maximum speed of as much as 24 yards forward in the twenty-four hours has been attained on the English side; and with the later machine put to work at the French end, a maximum speed of as much as 27-1/3 yards forward in the twenty-four hours has been effected. In ordinary land tunneling since 1862 there has been great progress, by the substitution of dynamite and preparations of a similar nature for gunpowder, and by the improvements in the rock-drills worked by compressed air, which are used in making the holes into which the explosive is charged. For boring for water, and for many other purposes, the diamond drill has proved of great service, and most certainly its advent should be welcomed by the geologist, as it has enabled specimens of the stratum passed through to be taken in the natural, unbroken condition, exhibiting not only the material and the very structure of the rock, but the direction and the angle of the dip of the beds.

Closely connected with tunneling machines are the machines for "getting" coal. This "getting," when practiced by manual labor, involves, as we know, the conversion into fragments and dust of a very considerable portion of the underside of the seam of coal, the workman laboring in a confined position, and in peril of the block of coal breaking away and crushing him beneath it. Coal-getting machines, such as those of the late Mr. Firth, worked by compressed air, reduce to a minimum the waste of coal, relieve the workman of a most fatiguing labor in a constrained position, and save him from the danger to which he is exposed in the hand operation. It is a matter of deep regret on many grounds, but especially as showing how little the true principles of political economy are realized by working men, who are usually well informed on many other points, that the commercial failure of these machines is due to their opposition. In connection with colliery work, and indeed in connection with explosives, in the sense of a substitution for them of sources of expansion acting more slowly, mention should be made of the hydraulic wedges. The employment of these in lieu of gunpowder, to force down the block of coal that had been undercut, is one of the means to be looked to for diminishing the explosions in collieries. Another substitute for gunpowder is found in the utilization of the expansion of lime when wetted. This has given birth to the lime cartridge, the merits of which are now universally recognized, but it is feared that trade prejudices may also prevent its introduction. While on this subject of "accidents in mines," it will be well to call attention to the investigations that have been made into the causes of these disasters, and into the probable part played by the minute dust which prevails to so great an extent in dry collieries.

The experiments of our honorary member, Sir Frederick Abel, on this point have been of the most striking and conclusive character, and corroborate investigations of the late Macquorn Rankine into the origin of explosions in flour mills and rice mills, which had previously been so obscure. The name of Mr. Galloway should also be mentioned as one of the earliest workers in this direction. At first sight, pile driving appears to have but little connection with explosives, but it will be well to notice an invention which has been brought into practical use, although not largely (in this country at all events), for driving piles, by allowing the monkey to fall on a cartridge placed in the cavity in the cap on top of the pile; the cartridge is exploded by the fall, and in the act of explosion drives down the pile and raises the monkey; during its ascent, and before the completion of its descent, time is found for the removal of the empty cartridge and the insertion of a new one.

In the days of Brindley and of Smeaton, and of the other fathers of our profession, whose portraits are on these walls, canals and canalized rivers formed the only mode of internal transit which was less costly than horse traction, and, thanks to their labors, the country has been very well provided with canals; but the introduction of railways proved, in the first instance, a practical bar to the extension of the canal system, and, eventually, a too successful competitor with the canals already made. Frequently the route that had been selected by the canal engineer was found (as was to be expected) a favorable one for the competing railway, and the result was, the towns that had been served by the canal were served by the railway, which was thus in a position to take away even the local traffic of the canal. For some time it looked as though canal and canalized river navigations must come to an end; for although heavy goods could be carried very cheaply on canals, and with respect to the many works and factories erected on the canal banks, or on bases connected therewith, there was with canal navigation no item of expense corresponding to the cost of cartage to the railway stations, yet the smallness of the railway rates for heavy goods, and the greater speed of transit, were found to be more than countervailing advantages. But when private individuals have embarked their capital in an undertaking, they do not calmly see that capital made unproductive, nor do they refrain from efforts to preserve their dividends, and thus canal companies set themselves to work to add to their position of mere owners of water highways, entitled to take toll for the use of those highways, the function of common carriers, thus putting themselves on a par with the railway companies, who, as no doubt is within the recollection of our older members, were in the outset legalized only as mere owners of iron highways, and as the receivers of toll from any persons who might choose to run engines and trains thereon, a condition of things which was altered as soon as it was pointed out that it was utterly incompatible either with punctuality or with safe working. This addition to the legal powers of the canal companies, made by the acts of 1845 and 1847, has had a very beneficial effect upon the value of their property, and has assisted to preserve a mode of transport competing with that afforded by the railways. Further, the canal proprietors have from time to time endeavored to improve the rate of transport, and with this object have introduced steam in lieu of horse haulage, and by structural improvements have diminished the number of lockages. Many years before the period we are considering, there was employed, to save time in the lockages and to economize water, the system of inclined planes, where, either water-borne in a traveling caisson, as on the Monklands incline, or supported on a cradle, as in the incline at Newark, in the State of New Jersey, the barges were transferred from one level to another; but an important improvement on either of these modes of overcoming a great difference of level is the application of direct vertically lifting hydraulic power. A notable instance of this system was brought before the Institution in a paper read on the "Hydraulic Canal Lift at Anderton, on the River Weaver," by S. Duer,2 and another instance exists on the Canal de New Fosse, at Fontinettes, in France, the engineers being Messrs. Clark and Standfield, who have other lifts in progress. This system reduces the consumption of water and the expenditure of time to a minimum.

With respect to canalized rivers, the difficulty that must always have existed when these rivers (as was mostly the case) were provided with weirs to dam up the water for giving power to mills has been augmented of late years by the change in the character of floods. It has frequently been suggested that in these days of steam motors in lieu of water power, and of railways in lieu of water carriage, the injury done by obstructing the delivery of floods is by no means compensated by the otherwise all but costless power obtained, or by the preservation of a mode of transport competing with railways. It has thereupon been suggested that it would be in the interests of the community to purchase and extinguish both the manufacturing and the navigating rights, so as to enable the weirs to be removed, and free course to be provided for floods. It need hardly be said, however, that if means could be devised for giving full effect to the river channels for flood purposes, while maintaining them for the provision of motive power and of navigation, it is desirable that this should be done. The great step in this direction appears to be the employment of readily or, it may be, of automatically movable weirs. Two very interesting papers on this subject by Messrs. Vernon-Harcourt and E. B. Buckley were read and discussed in the session 1879-1880. These dealt, I fear exclusively, with foreign, notably with French and Indian, examples. I say I fear, not in the way of imputing blame to the authors for not having noticed English weirs, but because the absence of such notice amounts to a confession of backwardness in the adoption of remedial measures on English rivers. An instance, however, of improvement since then has been the construction by Mr. Wiswall, the engineer to the Bridgewater Navigation Company (on the Mersey and Irwell section of that navigation), of the movable Throstle Nest weir at Manchester. It does seem to me that by the adoption of movable weirs, rivers in ordinary times may be dammed up to retain sufficient water to admit of a paying navigation and water for the mills on their banks; while in time of flood they shall allow channels as efficient for relief as if every weir had been swept away.

But the great feature of late years in canal engineering is not the preservation or improvement of the ordinary internal canal, but the provision of canals, such as the completed Suez canal, the Panama canal in course of construction, the contemplated Isthmus of Corinth canal—all for saving circuitous journeys in passing from one sea to another; or in the case nearer home of the Manchester ship canal, for taking ocean steamers many miles inland.

But the old fight between the canal engineer and the railway engineer, or, more properly speaking, between the engineer when he had his canal "stop" on and the same individual when he has his railway "stop"—you will see that I am borrowing a figure, either from Dombey & Son, where Mr. Feeder, B.A., is shown to us with his Herodotus "stop" on, or, as is more likely, I am thinking of the organs to be exhibited in the Second division, "Music," of that exhibition of which I have the honor to be chairman—I am afraid this is a long parenthesis breaking the continuity of my observations, which related to the old rivalry between canal and railway engineering. I was about to say that this rivalry was revived, even in the case of the transporting of ocean vessels from sea to sea, for we know that our distinguished member, Mr. Eads, is proposing to connect the Atlantic and Pacific oceans by means of a ship railway across the Isthmus of Panama. He suggests that the largest vessels should be raised out of the water, in the manner commonly employed in floating docks, and should then be transferred to a truck-like cradle on wheels, fitted with hydraulic bearing blocks (this being, however, not a new proposition as applied to graving docks), so as to obtain practical equality of support for the ship, notwithstanding slight irregularities in the roadway, while he proposes to deal with the question of changes of direction by the avoidance of curves and by the substitution of angles, having at the point of junction of the two sides turntables on which the cradle and ship will be drawn; these can be moved with perfect ease, notwithstanding the heavy load, because the turntable will be floating in water carried in circular tanks.

The question of preserving the level of the turntable, whether unloaded, partially loaded, or loaded, is happily met by an arrangement of water ballast and pumping. I cannot pass away from the mention of Mr. Eads' work without just reminding you of the successful manner in which he has dealt with the mouth of the Mississippi, by which he has caused that river to scour and maintain a channel 30 feet deep at low water, instead of that 8 feet deep which prevailed there before his skillful treatment. Neither can I refrain from mentioning the successful labors of our friend Sir Charles Hartley, in improving the navigation of that great European river, the Danube. I am sure we are all rejoiced to see that one of the lectures of the forthcoming series, that on "Inland Navigation," is to be delivered by him, and I do earnestly trust he will remember it is his duty to the Institution not to leave important and successful works unreferred to because those works happen to be his own.

I regret that time does not admit of my noticing the many improved machines for excavating, to be used either below water or on dry land. I also regret, for similar reasons, I must omit all mention of ship construction, whether for the purpose of commerce or of war, a subject that would naturally follow that of rivers and of ship railways and canals, and would have enabled me to speak of the great debt this branch of civil engineering owes to the labors of our late member, William Froude, and would have enabled me also to deal with the question of material for ships, and with the question of armor plating, in which, and in the construction of ordnance, our past president, Mr. Barlow, and myself, as the two lay members of the Ordnance Committee, are so specially interested.

The mention of armor plates inevitably brings to our minds the consideration of ordnance, but I do not intend to say even a few words on this head of invention and improvement—a topic to which a whole evening might well be devoted—because only three years ago my talented predecessor in this chair, Sir William Armstrong, made it the subject of his inaugural address, and dealt with it in so masterly and exhaustive a style as to render it absolutely impossible for me to usefully add anything to his remarks. I cannot, however, leave this branch of the subject without mentioning, not a piece of ordnance, but a small arm, invented since the date of Sir William's address. I mean the Maxim machine gun. This is not only one of the latest, but is certainly one of the most ingenious pieces of mechanism that has been devised. The single barrel fires the Martini-Henry ammunition; the cartridges are placed in loops upon a belt, and when this belt is introduced to the gun, and some five or six cartridges have been drawn in by as many reciprocations of a handle, the gun is ready to commence firing. After the first shot, which must be fired by the pulling of a trigger in the ordinary way, the gun will automatically continue to send out shot after shot, until the whole of the cartridges on the belt are exhausted; and if care is taken before this happens to link on to the tail of the first belt the head of a second one, and another belt to this, and so on, the firing will be automatically continuous, and at a rate anywhere between one shot per minute and six hundred shots per minute, dependent on the will of the person in charge of the gun, the whole of the operations of loading, firing, and ejecting the cartridge being performed by the energy of the recoil. This perfectly automatic action enables the man who works the gun to devote his whole attention to directing it, and as it is carried on a pivot and can be elevated and depressed, he can, while the gun is firing, aim the bullets to any point he may choose.

Since 1862 the power of defending seaports has been added to by the application of submarine mines, arranged to be fired by impact alone, or to be fired on impact when (under electrical control) the firing arrangement is set for the purpose, or to be fired electrically from the shore by two persons stationed on cross-bearings, both of whom must concur in the act of explosion. These mines are charged with gun-cotton, the development of which owes so much to Sir Frederick Abel, while for purposes of attack the same material, not yet in practical use for shells, is taken as the charge for torpedoes, which are either affixed to a spar or are carried in the head of a submerged cigar-shaped body. By a compressed air or by a direct steam impulse arrangement these weapons are started on their course and are directed, and then the running is taken up by their own engines operating on screw propellers, driven by a magazine of compressed air contained in the body of the torpedo. Means are also provided to maintain the designed level below the water surface. The torpedo may either be projected from the war ship itself or from one of those launches which owe their origin to our member, Mr. John Isaac Thornycroft, who first demonstrated the feasibility of that which was previously considered to be impossible, viz., the obtaining a speed of twenty miles and over from a vessel not more than 80 feet long. Experiments have been carried on in the United States by Captain Ericsson to dispense with the internal machinery of the torpedo, and to rely for its traverse through the water upon the original impulse given to it by a breech-loading gun, carried at the requisite depth below the water level in a torpedo boat. This gun, having a feeble charge of powder at a low gravimetric density, fires the torpedo, and, it is said, succeeds in sending it many yards, and with a sufficient terminal velocity to explode the charge by impact. Also, in the United States, experiments have been made with a compressed air gun of 40 feet in length and 4 inches in diameter (probably by this time replaced by a gun of 8 inches in diameter), to propel a dart through the air, in the front of which dart there is a metallic chamber containing dynamite. Although no doubt the best engineer is the man who does good work with bad materials, yet I presume we should not recommend any member of our profession to select unsuitable materials with the object of showing how skillfully he can employ them. On the contrary, an engineer shows his ability by the choice of those materials which are the very best for his purpose, having regard, however, to the relative facilities of carriage, to the power of supply in sufficiently large quantities, to the ease with which they can be worked up or built in, and to the cost.

Probably few materials have been found more generally useful to the civil engineer, in works which are not of metal, than has been Portland cement. It should be noticed that during the last twenty-two years great improvements have been made in the grinding and in the quality of the cement. These have been largely due to the labors in England of our member, Mr. John Grant, to the labors of foreign engineers following in his footsteps, and to the zeal and intelligence with which the manufacturers have followed up the question, from a scientific as well as from a practical point of view, not resting until they were able with certainty to produce a cement such as the engineer needed. I do not know that there is very much to be said in the way of progress (so far as the finished results are concerned) in the materials which Portland cement and other mortars are intended to unite. Clean gravel and ballast and clean sand are, I presume, very much the same in the year 1884 as they were not only in the year 1862, but as they were in the year 1. The same remark applies to stone and to all other natural building materials; and, indeed, even the artificial material brick cannot in these days be said to surpass in quality the bricks used by the Romans in this island nineteen hundred years ago, but as regards the mode of manufacture and the materials employed there is progress to be noted. The brick-making machine and the Hoffmann kiln have economized labor and fuel, while attempts have been made, which I trust may prove successful, for utilizing the clay which is to be found in the form of slate in those enormous mounds of waste which disfigure the landscape in the neighborhood of slate quarries. Certain artificial stones, moreover, appear at last to be made with a uniformity and a power of endurance, and in respect of these qualities compare favorably with the best natural stone, and still more favorably having regard to the fact that they can be made of the desired dimensions and shape, thus being ready for use without labor of preparation.

Reverting to natural materials, there remains to be mentioned that great class, timber. In new countries the engineer is commonly glad to avail himself of this material to an extent which among us is unknown. For here, day by day, owing to the ready adaptability of metals to the uses of the engineer, the employment of wood is decreasing. Far, indeed, are we from the practice of not more than a hundred years ago, when it was not thought improper to make the shell of a steam engine boiler of wooden staves. The engineer of to-day, in a country like England, refrains from using wood. He cannot cast it into form, he cannot weld it. Glue (even if marine) would hardly be looked upon as an efficient substitute for a sound weld; and the fact is, that it is practically impossible to lay hold of timber when employed for tensile purposes so as to obtain anything approaching to the full tensile strength. If it be desired to utilize metals for such a purpose, they can be swollen out into appropriate "eyes" to receive the needed connection; but this cannot be done with wood, for the only way of making an enlarged eye in wood is by taking a piece that is big enough to form the eye, and then cutting away the superfluous portion of the body. Moreover, when too much exposed to the weather, and when too much covered up, wood has an evil habit of rotting, compared with the rapidity of which mode of decay the oxidizing of metals is unimportant. Further, one's daily experience of the way in which a housemaid prepares a fire for lighting is suggestive of the undesirability of the introduction of resinous sticks of timber, even although they may be large sticks, into our buildings. Many attempts, as we know, have been made to render timber proof against these two great defects of rapid decay and of ready combustibility, and, as it appears to me, it is in these directions alone one can look for progress in connection with timber. With respect to the first, it was only at the last meeting of the Institution we presented a Telford medal and a Telford premium to Mr. S. B. Boulton for his paper "On the Antiseptic Treatment of Timber," to which I desire to refer all those who seek information on this point. With respect to the preservation from fire of inflammable building materials, the processes, more or less successful, that have been tried are so numerous that I cannot even pretend to enumerate them. I will, however, just mention one, the asbestos paint, because it is used to coat the wooden structures of the Inventions Exhibition. To the employment of this, I think, it is not too much to say those buildings owed their escape, in last year's very dry summer, from being consumed by a fire that broke out in an exhibitor's stand, destroying every object on that stand, but happily not setting the painted woodwork on fire, although it was charred below the surface. I do not pretend to say that a surface application can enable wood to resist the effects of a continued exposure to fire, but it does appear that it can prevent its ready ignition.

(To be continued.)

[1] Address of Sir Frederick Joseph Bramwell, F.R.S., on his election as president of the Institution of Civil Engineers. January 13, 1885.

[2] Minutes of Proceedings Inst. C. E., vol. xlv., p. 107.

The Cathedral of the Incarnation, at Garden City, N. Y., the memorial of Mrs. Cornelia M. Stewart to her husband, Alexander T. Stewart, was opened April 9, 1885, by impressive religious ceremonies. At precisely 11 o'clock the chimes in the cathedral tower rang out a clear and resonant peal, and the people thronged into the building through its tower and transept entrances.

The effort has been made to reproduce in the cathedral a pure type of the Gothic architecture of the thirteenth century, without its ruder and less refined characteristics. The strained and coarse images designed to illustrate "the world, the flesh, and the devil," which seem so strange and unapt to American visitors to the great Continental cathedrals, are almost entirely omitted in this reproduction. The carving, too, in deference to the more sensitive tastes and better skill of this age, is far more artistic and natural than in the old originals. Flowers in stone are made to resemble flowers, and heads are fashioned after a human pattern, and clusters of figures are modeled in a congruous and modern manner. But aside from changes of this kind, the new and magnificent edifice upon Hempstead Plains is a perfect example of the elaborate and picturesque Gothic structures of mediæval days.

It is built of brown sandstone raised in colossal blocks. The spire, floriated richly and graduated with a precise symmetry, rises to an extreme altitude of 220 feet 6 inches. The extreme length is about 170 ft. The massive oaken front doors are carved handsomely, and contain the arms of the Stewart family, the Clinch family (Mrs. Stewart's maiden name), the Hilton family, and those of Bishop Littlejohn, the Episcopal head of the Long Island Diocese. The porch or tower entrance, which is the main entrance to the building, is paved with white marble. In the center of the floor the Stewart arms are enameled in brass, showing a shield with a white and blue check, supported by the figures of a wild Briton and a lion. The crest is a pelican feeding its young, and the motto is "Prudentia et Constantia." These heraldic figures are made a special feature of the main aisle. Directly in the center of the auditorium floor the Stewart and Clinch arms are impaled, enameled in brass. On the floor in the choir the Hilton arms are placed. They bear the patriotic motto "Ubi libertas ibi patria," with a deer for a crest. The floor of the ante-chancel presents the arms of the diocese. Its insular character is especially prominent. The shield of barry wavy contains three crosslets, the peculiar sign of the cathedral. It is supported by dolphins. The crest is a ship, and under all is the sacred motto, "I will set his dominion in the sea." The workmanship of all these arms is superb.

By far the most wonderful works of art in the edifice are the windows of stained glass and the musical facilities. Every window presents a theme suggestive of the Incarnation. The windows of the porch present several of the Old Testament characters and events which prefigured the birth of Christ, and over the door leading to the nave are figures of Adam and Eve and of Abraham and Sarah. The four windows on the south side of the nave show the Annunciation, the dream of Joseph, the salutation of Elizabeth, and the refusal of the stable to the parents of the infant Redeemer. In the first window of the transept is presented the inn-keeper's refusal of refuge to Joseph and Mary. The great window of the south transept, in all about thirty feet high, one of the largest windows in the world, shows the family of Jesse, the ancestor of Jesus. Jesse is resting at full length; above him is King David, and all around are figures of his descendants leading up to the Virgin Mary with the Holy Child in her arms. Above all, in the apex of the windows, are the emblems used in prophecies of Christ's coming. The third window of the south transept shows the Nativity, with the Babe in the manger. Two windows in the choir are chosen with special reference to the regular service of the church. The first represents the appearance of the star in the east to the shepherds of Bethlehem, introducing the "Gloria in Excelsis," and the second shows the presentation of Christ in the temple, suggesting the "Nunc Dimittis," the "Magnificat," and the "Benedictus." Then beautiful representations are given in the north transept windows of the Magi bringing gifts to the infant Saviour, and the wise men before King Herod. The windows of the nave show the flight into Egypt, the massacre of the innocents, and the return to Nazareth.

The north window of the transept is the most magnificent of all. It presents Christ in glory, thus suggesting the "Te Deum." Jesus sits enthroned with the angels and archangels, prophets, apostles and martyrs of the church in all ages bending in adoration before Him, while the heavenly choir are waving palms and chanting music in honor of Heaven's King. The smaller windows under the roof show the hierarchy of heaven indicating by music and dances the joy of the celestial world at the scenes of the Incarnation depicted below. Upon a bright, sunny day the cathedral is made exquisitely beautiful by the mellowed radiance of these windows. They were designed and manufactured by Clayton & Bell, of London, and are esteemed to present the perfection of their work. Their colors, rich and varied, blend in perfect harmony, and the intricacy of the groupings makes each one as interesting as an oil painting.

Six different organs have been built in different parts of the building. The most important of these is the great organ in the north apse. It is furnished with four keyboards and 124 stops, with twenty-four combination stops that admit of more than a million combinations of sound. On either side of the choir is another organ, with a fourth of great power in the crypt, a fifth in the tower, and an echo organ built under the vaulting of the roof. This produces a soft and weird music. All the organs are operated from the keyboard of the great apse organ, which also plays the chimes of thirteen bells in the tower. The choir instruments are made to correspond by means of iron tubes filled with wind by a bellows engine in the crypt of the apse. A second engine in the crypt of the tower operates the bellows that inflate the instruments in the crypt, the tower, and the vaulting. All the organs and the chimes are connected by electric wires, about twenty-six miles of which are employed, supplied with electricity by a motor in the tower engine room. Sublime and grand are the only terms which can suggest the effect of the volume of harmony produced by these instruments in united action. They were made by Hilborne L. Roosevelt, of this city.

The ante-chancel contains the bishop's throne, the dean's seat, and the stalls of the clergy and canons, all of carved mahogany. A superb work of art is the altar, in the chancel, which is separated from the ante-chancel by a heavy bronze railing. The altar is of statuary marble manufactured by Cox & Sons, of London. Its corner columns are of black marble, supported by others of flecked marble, with panels of Sienna and Griote. Between the panels are rich carvings, done in Antwerp, representing the temptation and fall in Eden; Abraham's offering of his son Isaac; Moses raising the brazen serpent in the wilderness; the annunciation to the Virgin; the birth scene in the stable; the Crucifixion and the Resurrection. The slab of the altar is inlaid with five crosslets, representing the five wounds, and the symbol "I. H. S."

None of the cathedral windows are richer than those which circle the chancel. They present Christ as the Good Shepherd and the apostolic college. An excellent piece of chiseling is done by Sibbel, the sculptor of this city, in the panels over the credence. They are figures of the high priest with a slain lamb, the type of the bloody sacrifice, and Christ with sheaves of wheat and clusters of grapes, the unbloody sacrifice. Beneath them is the text, "Thou art a prophet forever after the order of Melchisedec." The chancel is paved with red and yellow Sienna marble as center pieces, flanked with squares of red Griote and white marble, the whole bordered with strips of red and black marble. The ante-chancel is paved with blocks of red Griote and verd antique. Two magnificent pieces of statuary stand on either side of the transept. The first represents Religion holding a little model of the cathedral. The other is an image of Hope. They were done by Park, the Florentine sculptor.

In the south apse is the baptistery, built with a tower furnished with chimes. Its supporting columns are of Languedoc marble clustered with smaller ones of Sienna and verd antique. Six columns support the dome. Each is of a different marble, crowned with sculptured capitals in high relief. The windows are appropriate in theme. They represent Noah with the ark; the building of the ark; Moses holding the tables of the law; the passage of the Red Sea; John the Baptist; the Baptism of the eunuch; St. Philip, the deacon; and the Baptism of Christ. In the center of the room stands the font upon an octagonal base of two steps. Its pedestal and bowl are traced with symbolic carvings. Over it is a canopy of elaborately carved mahogany drawn into a spire bearing a gold crown, studded with rubies and amethysts.

At the foot of the chancel is the pulpit, of bronze, designed by Sibbel. Its base is surrounded by figures representing hearers of the Word. Mr. Sibbel has incorporated an anachronism in one of these figures that will be exceedingly interesting in coming years. It shows the features of Henry G. Harrison, of this city, the architect of the cathedral. The lectern stands on the other side of the ante-chancel, representing Christ blessing little children. Superb bronze columns with brass coronas of natural flowers support the roof of the building. The triforium is carved in the richest style with passion flowers, fuchsias, roses, and lilies.

In the crypt below are the robing rooms of the clergy and the choir and the Sunday-school room. Its windows show the arms of every American diocese. Beneath the choir is the chantry, furnished in carved oak. Adjoining this room is the famous mausoleum erected to the memory of Alexander T. Stewart. It is constructed of statuary marble, and consists of fourteen bays, at the angles of which are triple columns of the most richly colored imported marbles arched above the elegantly carved capitals, with open tracery, through which the headlights of the colored glass are seen. The subjects of the thirteen windows relate to the passion, death, resurrection, and subsequent appearances of Christ, and are executed in admirable design and color. They were made by Heaton, Butler & Bayne, of London. Above the window openings rises a dome-shaped ceiling, in carved marble, with a pendent canopy in the center. The pavement, of black and white marbles, radiates from the center of the sides of this polygonal structure, and a large white urn, delicately draped after Sibbel's designs, stands under the pendent canopy. It bears Mr. Stewart's name. The two entrances to the mausoleum are guarded by open-work bronze gates of elegant design and workmanship.—N. Y. Tribune.

The furnishing of food supplies has always been a question of great importance to cities, and there are few of the latter, great or small, where the establishment of markets is not the order of the day.

At Paris especially, by reason of the massing of the population, which is annually increasing, the multiplicity of the wants to be satisfied renders the solution of this question more and more difficult. The old markets, some of the types of which still exist in various parts of Paris, were built of masonry and wood. They were massive structures into which the air and light penetrated with difficulty, and which consequently formed a dangerous focus of infection for those who occupied them, and for the inhabitants of the neighboring houses. So the introduction of iron into the construction of markets will bring about a genuine revolution whose influence will soon make itself felt in all branches of the builder's art.

The Central Markets were to have been built of masonry, and the work had even been begun, when, under the pressure of public opinion, the architect, Mr. Baltard, was led to use iron. Evidently, the metal that permits of covering vast spaces with the use of distant bearing points that present a small surface in plan, and leaves between them wide openings that the sun and air can enter in quantity, was the only thing that was capable of giving the solution sought. So it has been said, and rightly, that the Central Markets are, as regards the distribution and rational use of materials, the most beautiful of the structures of modern Paris. This system of construction at once met with great success, and the old markets are everywhere gradually disappearing, in order to give place to the new style of buildings.