Title: Scientific American Supplement, No. 795, March 28, 1891

Author: Various

Release date: September 12, 2004 [eBook #13443]

Most recently updated: October 28, 2024

Language: English

Credits: Produced by Don Kretz, Juliet Sutherland, Victoria Woosley and the

Online Distributed Proofreading Team.

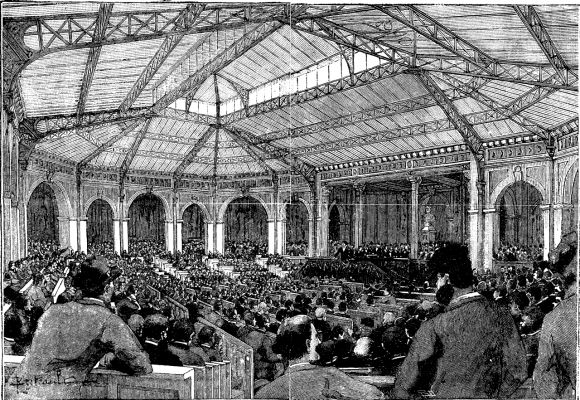

There will soon be inaugurated (probably about the 14th of July) a new establishment that has long been demanded by the laboring population, that is to say, a new labor exchange, the buildings of which, situated on Chateau d'Eau Street, are to succeed the provisional exchange installed in the vicinity of Le Louvre Street. The new structures have been erected from plans by Mr. Bouvard, and occupy an area of seventeen hundred meters.

The main work is now entirely terminated, but the interior decorations are not yet completely finished. The distribution comprises a vast meeting room, committee rooms for the various syndicates, offices in which the workmen of the various bodies of trades will find information and advice, and will be enabled to be put in relation with employers without passing through the more or less recommendable agencies to which they have hitherto been obliged to have recourse.

Upon the whole, the institution, if wisely conducted, is capable of bearing fruit and ought to do so, and the laboring population of Paris should be grateful to the municipal council for the six million francs that our ediles have so generously voted for making this interesting work a success. On seeing the precautions, perhaps necessary, that the laborer now takes against the capitalist, we cannot help instituting a comparison with the antique and solid organization of labor that formerly governed the trades unions. Each corporation possessed a syndic charged with watching over the management of affairs, and over the receipts and the use of the common resources. These syndics were appointed for two years, and had to make annually, at least, four visits to all the masters, in order to learn how the laborers were treated and paid, and how loyally the regulations of the corporation were observed. They rendered an account of this to the first assembly of the community and cited all the masters in fault.

Evidently, the new Labor Exchange will not cause a revival of these old ways of doing things (which perhaps may have had something of good in them), but we may hope that laborers will find in it protection against those who would require of them an excess of work, as well as against those who would preach idleness and revolt to them.—Le Monde Illustré.

NEW LABOR EXCHANGE—HALL FOR MEETINGS.

The controlling motive and direct purpose of the average newspaper are financial profit. One is now and then founded, and conducted even at a loss, to serve party, social, religious or other ends, but where the primary intent is unselfish there remains hope for monetary gain.

The first newspapers never dreamed of teaching or influencing men, but were made to collect news and entertainment and deal in them as in any other commodity. But because this was the work of intelligence upon intelligence, and because of conditions inherent in this kind of business, it soon took higher form and service, and came into responsibilities of which, in its origin, it had taken no thought. Wingate's "Views and Interviews on Journalism" gives the opinions of the leading editors and publishers of fifteen years ago upon this point of newspaper motive and work. The first notable utterance was by Mr. Whitelaw Reid, who said the idea and object of the modern daily newspaper are to collect and give news, with the promptest and best elucidation and discussion thereof, that is, the selling of these in the open market; primarily a "merchant of news." Substantially and distinctly the same ideas were given by William Cullen Bryant, Henry Watterson, Samuel Bowles, Charles A. Dana, Henry J. Raymond, Horace White, David G. Croly, Murat Halstead, Frederick Hudson, George William Curtis, E.L. Godkin, Manton Marble, Parke Godwin, George W. Smalley, James Gordon Bennett and Horace Greeley. The book is fat with discussion by these and other eminent newspaper men, as to the motives, methods and ethics of their profession, disclosing high ideals and genuine seeking of good for all the world, but the whole of it at last rests upon primary motives and controlling principles in nowise different or better or worse than those of the Produce Exchange and the dry goods district, of Wall Street and Broadway, so that, taking publications in the lump, it is neither untrue nor ungenerous, nor, when fully considered, is it surprising, to say that the world's doing, fact and fancy are collected, reported, discussed, scandalized, condemned, commended, supported and turned back upon the world as the publisher's merchandise.

The force and reach of this controlling motive elude the reckoning of the closest observation and ripest experience, but as somewhat measuring its strength and pervasiveness hear, and for a moment think, of these facts and figures.

The American Newspaper Directory for 1890, accepted as the standard compiler and analyst of newspaper statistics, gives as the number of regularly issued publications in the United States and territories, 17,760. Then when we know that these have an aggregate circulation for each separate issue—not for each week, or month, or for a year, but for each separate issue of each individual publication, a total of 41,524,000 copies—many of them repeating themselves each day, some each alternate day, some each third day and the remainder each week, month or quarter, and that in a single year they produce 3,481,610,000 copies, knowing, though dimly realizing, this tremendous output, we have some faint impression of the numerical strength of this mighty force which holds close relation to and bears strong influence upon life, thought and work, and which, measured by its units, is as the June leaves on the trees—in its vast aggregate almost inconceivable; a force expansive, aggressive, pervasive; going everywhere; stopping nowhere; ceasing never.

I am to speak to you of "The Business End" of the American newspaper; that is of the work of the publisher's department—not the editor's. At the outset I am confronted with divisions and subdivisions of the subject so many and so far reaching that right regard for time compels the merest generalization; but, as best I can, and as briefly as I can, I shall speak upon the topic under three general divisions:

First.—The personal and material forces which make the newspaper.

Second.—The sources of revenue from the joint working of these forces.

Third.—The direct office, bearing and influence of these forces.

It is but natural that the general public has limited idea of the personality and mechanism of the publication business, for much of its movement is at night, and there is separation and isolation of departments, as well as complicated relation of the several parts to the whole. Not many years ago a very few men and boys could edit, print and distribute the most important of newspapers, where now hundreds are necessary parts in a tremendous complexity. But even to-day, of the nearly 18,000 publications in the United States, more than 11,000 are of that class which, in all their departments, are operated by from two to four or five persons, and which furnish scant remuneration even for these. Among the thin populations and in the remote regions are thousands of weekly papers—and you may spell the weekly either with a double e or an ea— where there are two men and a boy, one of whom does a little writing and much scissoring, loafing among the corner groceries and worse, begging for subscribers, button-holing for advertisements, and occasionally and indiscriminatingly thrashing or being thrashed by the "esteemed contemporary" or the "outraged citizen;" the second of whom sets the type, reads the proofs, corrects them more or less, makes the rollers, works the old hand press, and curses the editor and the boy impartially; and the third of whom sweeps the office weekly, bi-weekly or monthly, inks the forms and sometimes pis them, carries the papers, and does generally the humble and diversified works of the "printer's devil," while between the three the whole thing periodically goes to the ---- level pretty sure to be reached now and then by papers of this class. Yet there are many of these country papers that Mr. Watterson once styled the "Rural Roosters" which are useful and honored, and which actively employ as editors and publishers men of fair culture and good common sense, with typographical and mechanical assistants who are worthy of their craft.

But the personal workers upon the great magazines and the daily newspapers are for each a battalion or a regiment, and in the aggregate a vast army. The Century Magazine regularly employs in its editorial department three editors and eight editorial assistants, of whom five are women; in the art department two artists in charge and four assistants, of whom three are women; in the business department fifty-eight persons, men and women—a total of seventy six persons employed on the magazine regularly and wholly, while the printers and binders engaged in preparing a monthly edition of 200,000 magazines are at least a duplicate of the number engaged in the editorial, art and business divisions.

The actual working force upon the average large daily newspaper, as well as an outline idea of the work done in each department, and of its unified result in the printed sheet, as such newspapers are operated in New York, Chicago and Boston, may be realized from an exhibit of the exact current status in the establishment of a well known Chicago paper.

In its editorial department there are the editor-in-chief, managing editors, city editors, telegraph editors, exchange editors, editorial writers, special writers and about thirty reporters—56 in all. Working in direct connection with this department, and as part of it, are three telegraph operators and nine artists, etchers, photographers and engravers; in the Washington office three staff correspondents, and in the Milwaukee office one such correspondent—making for what Mr. Bennett calls the intellectual end a force of 72 men, who are usually regarded by the business end as a necessary evil, to be fed and clothed, but on the whole as hardly worth the counting.

In the business and mechanical departments the men and women and their work are these:

The business office, for general clerical work, receiving and caring for advertisements, receiving and disbursing cash, and for the general bookkeeping, employs 24 men and women.

On the city circulation, stimulating and managing it within the city and the immediate vicinity, 10 persons.

On the country circulation, for handling all out-of-town subscriptions and orders of wholesale news agents, 30 persons.

On mailing and delivery, for sending out by mail and express of the outside circulation, and for distribution to city agents and newsboys, 31 persons.

In the New York office, caring for the paper's business throughout the East, the Canadas, Great Britain and Europe, two persons.

In the composing room, where the copy is put into type, and in the linotype room, where a part of the type-setting is done by machinery, 95 persons.

In the stereotype foundry, where the plates are cast (for the type itself never is put on the press), 11 persons.

In the press room, where the printing, folding, cutting, pasting and counting of the papers is done, 30 persons.

In the engine and dynamo room, 8 persons.

In the care of the building, 3 persons.

These numbers include only the minimum and always necessary force, and make an aggregate of 316 persons daily and nightly engaged for their entire working time, and borne on a pay roll of six thousand dollars a week for salaries and wages alone.

But this takes no account of special correspondents subject to instant call in several hundred places throughout the country; of European correspondents; of 1,900 news agents throughout the West; of 200 city carriers; of 42 wholesale city dealers, with their horses and wagons; of 200 branch advertisement offices throughout the city, all connected with the main office by telephone; and of more than 3 000 news boy—ash;all making their living, in whole or in part, from work upon or business relations with this one paper—a little army of 6,300 men, women, and children, producing and distributing but one of the 1,626 daily newspapers in the United States.

The leading material forces in newspaper production are type, paper, and presses.

Printing types are cast from a composition which is made one-half of lead, one-fourth of tin, and one-fourth of antimony, though these proportions are slightly reduced, so as to admit what the chemist calls of copper "a trace," the sum of these parts aiming at a metal which "shall be hard, yet not brittle; ductile, yet tough; flowing freely, yet hardening quickly." Body type, that is, those classes ever seen in ordinary print, aside from display and fancy styles, is in thirteen classes, the smallest technically called brilliant and the largest great primer.

In the reading columns of newspapers but four classes are ordinarily used—agate for the small advertisements; agate, nonpareil, and minion for news, miscellany, etc., and minion and brevier for editorials—the minion being used for what are called minor editorials, and the brevier for leading articles, as to which it may be said that young editorial writers consider life very real and very earnest until they are promoted from minion to brevier.

A complete assortment of any one of these classes is called a font, the average weight of which is about 800 pounds. Whereas our alphabet has 26 letters, the compositor must really use of letters, spaces, accent marks, and other characters in an English font 152 distinct types, and in each font there are 195,000 individual pieces. The largest number of letters in a font belongs to small e—12,000; and the least number to the z—200. The letters, characters, spaces, etc., are distributed by the printer in a pair of cases, the upper one for capitals, small capitals, and various characters, having 98 boxes, and the lower one, for the small letters, punctuation marks, etc., having 54 boxes.

A few newspapers are using typesetting machines for all or part of their composition. The New York Tribune is using the Linotype machine for all its typesetting except the displayed advertisements, and other papers are using it for a portion of their work, while still others are using the Rogers and various machines, of which there are already six or more. It seems probable that within the early future newspaper composition will very generally be done by machinery.

It has been suggested to me that many of my hearers this evening know little or nothing of the processes of the printer's art, and that some exposition of it may interest a considerable portion of this audience.

The vast number of these little "messengers of thought" which are required in a single modern daily newspaper is little known to newspaper readers. Set in the manner of ordinary reading, a column of the New York Tribune contains 12,200 pieces, counting head lines, leads, and so on; while, if set solidly in its medium-sized type, there are 18,800 pieces in one column, or about 113,000 in a page, or about 1,354,000 in one of its ordinary 12-page issues. A 32-page Sunday issue of the New York Herald contains nearly, if not quite, 2,500,000 distinct types and other pieces of metal, each of which must be separately handled between thumb and finger twice—once put into the case and once taken out of it—each issue of the paper. No one inexperienced in this delicate work has the slightest conception of the intensity of attention, fixity of eye, deftness of touch, readiness of intelligence, exhaustion of vitality, and destruction of brain and nerve which enters into the daily newspaper from type-setters alone.

Each type is marked upon one side by slight nicks, by sight and touch of which the compositor is guided in rapidly placing them right side up in the line. They are taken, one by one, between thumb and forefinger, while the mind not only spells out each word, but is always carrying phrases and whole sentences ahead of the fingers, and each letter, syllable and word is set in its order in lines in the composing stick, each line being spaced out in the stick so as to exactly fit the column width, this process being repeated until the stick is full. Then the stickful is emptied upon a galley. Then, when the page or the paper is "up," as the printers phrase it, the galleys are collected, and the foreman makes up the pages, article by article, as they come to us in the printed paper—the preliminary processes of printing proofs from the galleys, reading them by the proof readers, who mark the errors, and making the corrections by the compositors (each one correcting his own work), having been quietly and swiftly going on all the while. The page is made up on a portable slab of iron, upon which it is sent to the stereotyping room. There wet stereotyping paper, several sheets in thickness, is laid over the page, and this almost pulpy paper is rapidly and dexterously beaten evenly all over with stiff hair brushes until the soft paper is pressed down into all the interstices between the type; then this is covered with blankets and the whole is placed upon a steam chest, where it is subjected to heat and pressure until the wet paper becomes perfectly dry. Then, this dried and hardened paper, called a matrix, is placed in a circular mould, and melted stereotype metal is poured in and cooled, resulting in the circular plate, which is rapidly carried to the press room, clamped upon its cylinder, and when all the cylinders are filled, page by page in proper sequence, the pressman gives the signal, the burr and whirr begin, and men and scarcely less sentient machines enter upon their swift race for the early trains. As a matter of general interest it may be remarked that this whole process of stereotyping a page, from the time the type leaves the composing room until the plate is clamped upon the press, averages fifteen minutes, and that cases are upon record when the complex task has been accomplished in eleven minutes.

The paper is brought from the mill tightly rolled upon wooden or iron cores. Some presses take paper the narrow way of the paper, rolls for which average between 600 and 700 pounds. Others work upon paper of double the width of two pages, that is, four pages wide, and then the rolls are sometimes as wide as six feet, and have an average weight of 1,350 pounds. Each roll from which the New York Tribune is printed contains an unbroken sheet 23,000 feet (4-1/3 miles) long. A few hours before the paper is to be printed, an iron shaft having journal ends is passed through the core, the roll is placed in a frame where it may revolve, the end of the sheet is grasped by steel fingers and the roll is unwound at a speed of from 13 to 15 miles an hour, while a fan-like spray of water plays evenly across its width, so that the entire sheet is unrolled, dampened, for the better taking of the impression to be made upon it, and firmly rewound, all in twenty minutes. Each of these rolls will make about 7,600 copies of the Tribune.

When all is ready, paper and stereotyped pages in place, and all adjustments carefully attended to, the almost thinking machine starts at the pressman's touch, and with well nigh incredible speed prints, places sheet within sheet, pastes the parts together, cuts, folds and counts out the completed papers with an accuracy and constancy beyond the power of human eye and hand.

The printing press has held its own in the rapid advance of that wonderful evolution which, within the last half century, in every phase of thought and in every movement of material forces placed under the dominion of men, has almost made one of our years the equivalent of one of the old centuries. Within average recollection the single cylinder printing machine, run by hand or steam, and able under best conditions to print one side of a thousand sheets in one hour, was the marvel of mankind. In 1850, one such, that we started in an eastern Ohio town, drew such crowds of wondering on-lookers that we were obliged to bar the open doorway to keep them at a distance which would allow the astonishing thing to work at all.

To-day, in the United States alone, five millions of dollars are invested in the building of printing presses, many of which, by slightest violence to figure of speech, do think and speak. Inspiration was not wholly a thing of long-gone ages, for if ever men received into brain and worked out through hand the divine touch, then were Hoe, and Scott, and Campbell taught of God.

Under existing conditions newspapers of any importance, in the smaller cities, use one and sometimes two presses, capable of producing from 7,000 to 9,000 complete eight page papers each hour, each machine costing from $10,000 to $15,000. Papers of the second class in the large cities use treble or quadruple this press capacity, while the great papers, in the four or five leading cities, have machinery plants of from four to ten presses of greatest capacity, costing from $32,000 to $50,000 each, and able to produce papers of the different numbers of pages required, at a speed of from 24,000 to 90,000 four page sheets, or of from 24,000 to 48,000 eight, ten, or twelve page sheets per hour, each paper complete as you receive it at your breakfast table—printed, pasted, cut and folded, and the entire product for the day accurately counted in lots of tens, fifties, hundreds or thousands, as may be required for instantaneous delivery, while, as if to illustrate and emphasize the ever upward trend of public demand for the day's news, quick and inclusive, Hoe & Co. are now building machines capable of producing in all completeness 150,000 four page papers each hour.

All this tremendous combination of brain, nerve, muscle, material, machinery and capital depends for its movement and remuneration upon but two sources of income—circulation and advertisements—the unit measurements of which are infinitesimal—for the most part represented by wholesale prices; from one-half a cent to two cents per copy for the daily newspaper, and in like proportion for the weeklies and monthlies; and by from one-tenth of a cent to one cent per line per thousand of circulation for advertising space. Verily, in a certain and large sense, the vast publishing interests rest upon drops of water and grains of sand. Under right conditions no kind of business or property is more valuable, and yet no basis of values is more intangible. Nothing in all trade or commerce is so difficult to establish or more environed by competitions, and yet, once established, almost nothing save interior dry rot can pull it down. It depends upon the judgment and favor of the million, yet instances are few where any external force has seriously and permanently impaired it.

About two hundred years have gone since the publication of the first number of the first American newspaper. It was a monthly, called Publick Occurrences, both Foreign and Domestic, first printed September 25, 1690, by Richard Pierce, and founded by Benjamin Harris. At that time public favor did seem to control newspaper interests, for that first paper aroused antagonism, and it was almost immediately suppressed by the authorities. Only one copy of it is now in existence, and that is in London. The first newspaper to live, in this country, was the Boston News Letter, first issued in 1704 and continued until 1776. New York's first newspaper, the New York Gazette, appeared October 16, 1725. At the outbreak of the revolution there were 37 newspapers, and in 1800 there were 200, of which several were dailies. In 1890 there were 17,760, of which there were 13,164 weeklies, 2,191 monthlies, 1,626 dailies, 280 semi-monthlies, 217 semi-weeklies, 126 quarterlies, 82 bi-weeklies, 38 bi-monthlies, and 36 tri-weeklies.

The circulations belong largely to the weeklies, monthlies and dailies, the weeklies having 23,228,750, the monthlies 9,245,750, the dailies 6,653,250, leaving only 2,400,000 for all the others.

The largest definitely ascertainable daily average circulation for one year, in this country, has been 222,745. Only one other daily paper in the world has had more—Le Petit Journal, in Paris, which really, as we understand it, is not a newspaper, but which regularly prints and sells for one sou more than 750,000 copies. The largest American weekly is the Youth's Companion, Boston, 461,470. The largest monthly is the Ladies' Home Journal, Philadelphia, 542,000. The largest among the better known magazines is the Century, 200,000. Of the daily papers which directly interest us—those of the city of New York—the actual or approximate daily averages of the morning papers are given by "Dauchy's Newspaper Catalogue" for 1891, as follows: Tribune, daily, 80,000; Sunday, 85,000. Times, daily, 40,000; Sunday, 55,000. Herald, daily, 100,000; Sunday, 120,000. Morning Journal, 200,000. Press, daily, 85,000; Sunday, 45,000. Sun, daily, 90,000; Sunday, 120,000. World, daily, 182,000; Sunday, 275,000. Of the afternoon papers, Commercial Advertiser, 15,000; Evening Post, 18,000; Telegram, 25,000; Graphic (not the old, but a new one), 10,000; Mail and Express, 40,000; News, 173,000; Evening Sun, 50,000; Evening World, 168,000. The entire circulation of New York dailies, including with those named others of minor importance, and the German, French, Italian, Bohemian, Hebrew and Spanish daily newspapers, is 1,540,200 copies.

Obviously, there is and must be ceaseless, incisive and merciless competition in securing and holding circulations, as well as in the outward statements made of individual circulations to those who purchase advertising space. In this, as in all other forms of enterprise, there are honest, clean-cut and business-like methods, and there are the methods of the time-server, the trickster and the liar.

The vastly greater number of publications secure and hold their clientage by making the best possible goods, pushing them upon public patronage by aggressive and business-like means, and selling at the lowest price consistent with excellence of product and fairness alike to producer and consumer. But of the baser sort there are always enough to make rugged paths for those who walk uprightly, and to contribute to instability of values on the one hand, and on the other to flooding the country with publications which the home and the world would be better without. Every great city has more of the rightly made and rightly sold papers than of the other sort, and the business man, the working man, the professional man, the family, no matter of what taste, or political faith, or economic bias, or social status, or financial plenty or paucity, can have the daily visits of newspapers which are able, brilliant, comprehensive, clean and honest. But all the time, these men and families will have pressed upon their attention and patronage, by every device and artifice of the energetic and more or less unscrupulous publisher, other papers equally able and brilliant and comprehensive, but bringing also their burden of needless sensationalism and mendacity, undue expansion of all manner of scandal, amplification of every detail and kind of crime, and every phase of covert innuendo or open attack upon official doing and private character—the whole infernal mass procured, and stimulated and broadcast among the people by the "business end of it," with the one and only intent of securing and holding circulation.

Take a representative and pertinent example. Eight years ago there were in New York ten or eleven standard newspapers, as ably and inclusively edited and as energetically and successfully conducted, business-wise, as they are now. Even at their worst they were decently mindful of life's proprieties and moralities and they throve by legitimate sale of the most and best news and the best possible elucidation and discussion thereof. The father could bring the paper of his choice to his breakfast table with no fear that his own moral sense and self-respect might be outraged, or that the face of his wife might be crimsoned and the minds of his children befouled. But there came from out of the West new men and new forces, quick to see the larger opportunity opened in the very center of five millions of people, and almost in a night came the metamorphosis of the old World into the new. It was deftly given out that existing conditions were inadequate to the better deserts of the Knickerbocker, the Jersey-man, and the Yankee, and that a new purveyor of more highly seasoned news and a more doughty champion of their rights and interests was hither from the land of life and movement—at two cents per copy. There was a panic in New York newspaper counting rooms, and prices tumbled in two days from the three and four cents of fair profit to the two and three cents of bare cost or less. The new factors in demoralization cared nothing for competition in prices or legitimate goods, for they had other ideas of coddling the dear people. Ready to their purpose lay disintegrated Liberty, waiting for a rock upon which to plant her feet and raise her torch, and the new combination between the world, the flesh and the devil, waiting and ready for access to the pockets of the public, was only too ready to set up Liberty and itself at one stroke, if only the joint operation could be done without expense to itself. The people said, "What wonderful enterprise!" "What a generous spirit!" The combination, with tongue in cheek and finger laid alongside nose, said to itself as it saw its circulation spring in one bound from five figures into six, "Verily we've got there! for these on the Hudson are greater gudgeons than are they on the Mississippi." From then until now, with an outward semblance and constant pretense of serving the people; with blare of trumpet and rattle of drum; with finding Stanley, who never had been lost; with scurrying peripatetic petticoats around the globe; with all manner of unprofessional and illegitimate devices; with so-called "contests" and with all manner of "schemes" without limit in number, kind, or degree; with every cunningly devised form of appeal to curiosity and cupidity —from then until now that combination has been struggling to hold and has held an audience of the undiscriminating and the unthinking. But, further, and worse, a short-sighted instinct of self-preservation has led other papers to follow somewhat at a distance in this demoralizing race. None of them has gone to such lengths, but the tendency to literary, mental and moral dissipation induced by a hitherto unknown form of competition has swerved and largely recast the methods of every New York daily save only the Tribune, Times, Commercial Advertiser, and Evening Post, while the converse side of securing business clientage is illustrated in a way that would be amusing if it were not pathetic, by that abnormal and fantastic cross between news and pietetics which mails and expresses itself to the truly good. These are forms of competition which the business end of legitimately conducted newspapers is compelled to meet. In a certain way these methods do succeed, but how, and how long and how much shall they succeed except by unsettling the mental and moral poise of the people, and by setting a new and false pace for publishers everywhere whose thoughts take less account of means than of ends? Which shall we hold in higher esteem and in our business patronage—Manton Marble and Hurlbut, gentlemen, scholarly, wise leaders, conscientious teachers, with barely living financial income; or their successors, parvenus, superficial, meretricious, false guides, time-serving leaders, a thousand dollars a day of clear profit, housed in the tower of Babel?

Considered in the large, the circulation side of the American newspaper has many indefensible aspects. As "nothing succeeds like success," or the appearance of success, the prestige of not a few newspapers is ministered unto by rotund and deceptive representations of circulation. Then, as few can live, much less profit, on their circulations alone, it becomes greatly important to make the advertiser see circulations through the large end of the telescope, and so the fine art of telling truth without lying is a live and perennial study in many counting rooms. Discussing the circulation question not long ago with the head of a leading religious paper, he told me that the number of copies he printed was a thing that he never stated definitely, because the publishers of the other religious newspapers lied so about their circulations that he would do himself injustice if he were to tell the truth about his own. The secular papers should set an example for their religious brethren, but they do not, for from many of them there is lying—systematic, persistent, and more or less colossal. Not long ago, within a few days of each other, three men who were simultaneously employed on a certain paper told me their actual circulation, confidentially, too. One of them put it at 85,000, the second at 110,000, and the third at 130,000, and each of them lied, for their lying was so diversified and entertaining that I felt a real interest in securing the truth, and so I took some trouble to ask the pressman about it. He told me, very confidentially, that it was 120,000—and he lied.

By this time my interest was so heightened that I told my personal friend, the publisher, about the inartistic and incoherent mendacity of his subordinates, whereupon he laughingly showed me his circulation book, which clearly, and I have no doubt truthfully, exhibited an average of 88,000. The wicked partner is nearly always ready to show the actual record of the counting machines on the presses, and "figures never lie" but the truth-telling machines which record actual work of the impression cylinders make no mention of damaged copies thrown aside, of sample copies, files, exchanges, copies kept against possible future need, copies unsold, copies nominally sold but sooner or later returned and finally sold to the junk shop, and all that sort of thing. One prints a large extra issue on a certain day for some business corporation which has its own purpose to serve by publication of an article in its own interest, whereby many thousands of copies are added to that day's normal output, and he makes the exceptional number for that day serve as the exponent of his circulation until good fortune brings him a similar and possibly larger order, and his circulation is reported as "still increasing." Another struck a "high-water mark" of "190,500" the day after Mr. Cleveland was elected, and that has been the implied measure of circulation for the last six years. Another, during a heated political campaign, or a great financial crisis, or some other dominant factor in public interest, makes a large and genuine temporary increase, but the highest mark gained does enforced duty in the eyes of the marines until another flood tide sweeps him to a greater transient height. These are types of the competitions of the circulation liar. At this very hour there are four daily newspapers each of which has the largest circulation in the United States. Of the nearly 18,000 American publications only 103 furnish detailed, open, and entirely trustworthy statements of circulation.

As to the general public this is no great matter, but to the vast number of business men who buy the real or fancied publicity afforded by newspaper advertising it is of exceeding importance. That the large buyers of advertising space are not more and oftener swindled is because they understand the circulation extravaganza and buy space according to their understanding. The time is coming, and it should come soon, when newspaper circulations shall be open to the same inspection and publicity as is now the case with banks and insurance companies, and when the circulation liar and swindler shall be amenable to the same law and liable to the same penalty as stands against and is visited upon any other perjurer and thief.

(To be continued.)

In the May (1890) number of the Therapeutic Gazette I furnished some contribution to the "Treatment of Hay Fever." I reported therein a favorable result in the treatment of this mysterious disease in the experience of my last year's cases.

My experience of this year is far more gratifying, and worthy of receiving a wide publicity.

I treated six cases in all, four of which have been habitual for years to hay fever proper without complications, while the other two used to have the disease aggravated with reflex asthma and bronchial catarrh. I succeeded in preventing the outbreak of the disease in every individual case. The treatment I applied was very simple, and consisted of the following:

From the fact that I had known all my patients from previous years, I ordered them to my office two weeks before the usual onset of the disease. I advised them to irrigate the nose with a warm solution of chloride of sodium four times a day—morning, noon, evening, and on retiring; and, a few minutes after the cleansing of the parts, had the nares thoroughly sprayed with peroxide of hydrogen and c.p. glycerin, half and half. Those subject to a conjunctivitis I prescribed a two per cent. solution of boric acid as a wash. At this period no internal medication was given, but three days previous to the usual onset of the disease I prescribed phenacetin and salol, five grains of each three times a day.

On the respective expected days, to the great surprise of all the members concerned successively, who have been in the habit of getting the disease almost invariably at a certain date, no hay fever symptoms appeared, though everyone had been the victim of the disease for a great number of years, varying from five to nineteen years' standing.

It is self-understood that this treatment was kept up all through the season, and, as no symptoms developed, the applications were reduced, toward the termination, to twice and once a day. The internal medication, however, was stopped after the expiration of the first week, and all the patients could attend to their various respective vocations, something they never have been able to do in previous years.

In two cases, though no nasal symptoms developed, about two weeks after the calculated onset, slight symptoms of asthma made their appearance. However, I could easily suppress them at this time with the aid of the hand atomizer and ozonizer, a very ingenious little apparatus, of which I gave a thorough description in my last year's article. I used the ozone inhalations every four hours, in connection with the internal administration of the following prescription:

Rx Iodide of ammonia, 8;

Fl. ex. quebracho, 30;

Fl. ex. grindelia robusta, 15;

Tr. lobelia, 12;

Tr. belladonna, 8;

Syr. pruni, virg., q.s., ad 120.

Sig.—Teaspoonful three or more times during twenty-four

hours.

However, toward the end of the fourth week, especially in one case—a stout, heavy-set gentleman—very grave asthmatic symptoms developed, which compelled me to apply Chapman's spinal ice bag, as well as resort to the internal administration of large doses of codeine during the paroxysm, with the most beneficial result.

I gave also oxygen inhalations a fair trial in the two cases. I find them to act very soothingly in the simple asthma, facilitating respiration after a few minutes; but during the paroxysmal stage they cannot be utilized, for the reason that respiration is short and rapid, and does not permit of a control in the quantity of the gas to be inhaled. Consequently, it is either of little use as a remedy; or, if too much is taken, a disagreeable headache will be the consequence.

During the catarrhal stage, which, however, was very mild compared with last year, I derived great benefit from the administration of codeine, in combination with terpine hydrate, in the pill form. The codeine has the advantage over all other opium preparations that it does not affect the digestive organs, and still acts in a soothing manner. While during last year's sickness my patients lost from ten to twenty pounds of their bodily weight, this year but one lost eight pounds and the other five pounds.

As the etiology of this troublesome disease is yet enveloped in obscurity, we may fairly conclude, by the success of my treatment, if it should meet with the confirmation of the profession, that the much pretended sensitive area, situated, according to Dr. Sajous, "at the posterior end of the inferior turbinated bones and the corresponding portion of the septum," or, according to Dr. John Mackenzie, who locates this area "at the anterior extremity of the inferior turbinated bone," need not necessarily be removed or destroyed by cautery, in order to accomplish a cure of hay fever proper.

I examined my patients twice a week, and the closest rhinoscopical exploration would not reveal the slightest pathological change in the mucous membrane of the nares.

Now, what is the etiological factor of the disease? Is it a specific germ conveyed by the air to the parts and—locus minoris resistencia—deposited at the pretended area, or is the germinal matter present in the nasal mucous membrane with certain persons, and requires only at a certain time and under certain conditions physiological stimulation to manifest periodical pathological changes, which give rise to the train of symptoms called hay fever? Dropping all hypothetical reasoning, I think some outside vegetable germ is causing the disease in those predisposed, and peroxide of hydrogen acts on them as it does on the pus corpuscles, i.e., drives them out when and wherever it finds them. I hope the profession will give this new measure a thorough trial and report their results.—Therapeutic Gazette.

In the Kew Bulletin for January an interesting account is given of the identification of the plant yielding the rhizome employed to make the well-known Chinese preserved ginger. As long ago as 1878 Dr. E. Percival Wright, of Trinity College, Dublin, called the attention of Mr. Thiselton Dyer to the fact that the preserved ginger has very much larger rhizomes than Zingiber officinale, and that it was quite improbable that it was the product of that plant. The difficulty in identifying the plant arose from the fact that, like many others cultivated for the root or tuber, it rarely flowers. The first flowering plant was sent to Kew from Jamaica by Mr. Harris, the superintendent of the Hope Garden there. During the past year the plant has flowered both at Dominica in the West Indies and in the Botanic Garden at Hong-Kong. Mr. C. Ford, the director of the Botanic Garden at Hong-Kong, has identified the plant as Alpinia Galanga, the source of the greater or Java galangal root of commerce. Mr. Watson, of Kew, appears to have been the first to suggest that the Chinese ginger plant is probably a species of Alpinia, and possibly identical with the Siam ginger plant, which was described by Sir J. Hooker in the Botanical Magazine (tab. 6,946) in 1887 as a new species under the name of Alpinia zingiberina. Mr. J.G. Baker, in working up the Scitamineæ for the "Flora of British India," arrived at the conclusion that it is not distinct from the Alpinia Galanga, Willd. The Siam and Chinese gingers are therefore identical, and both are the produce of Alpinia Galanga, Willd.

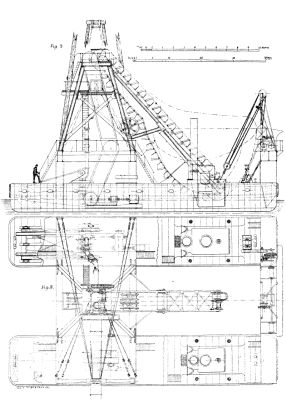

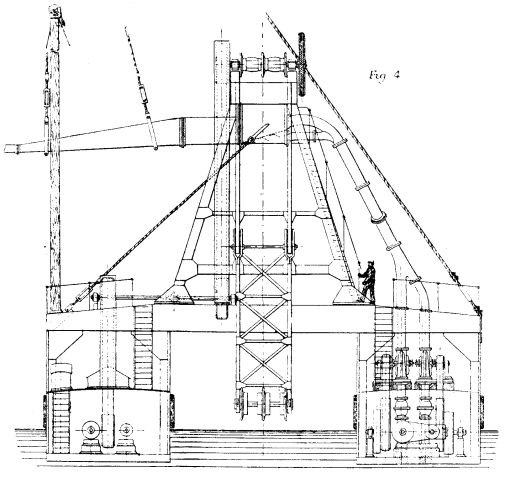

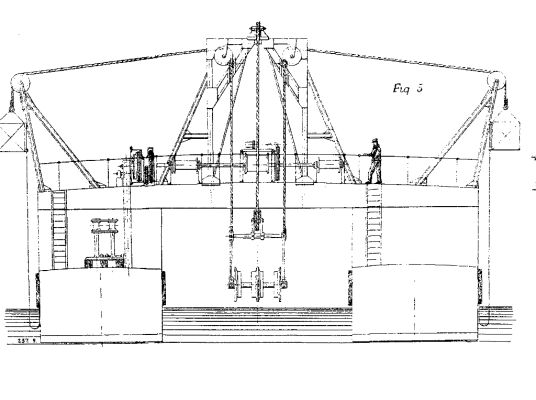

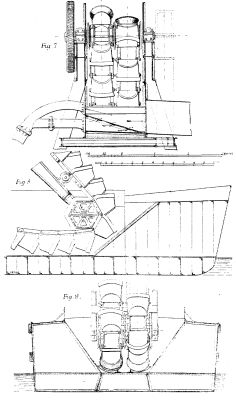

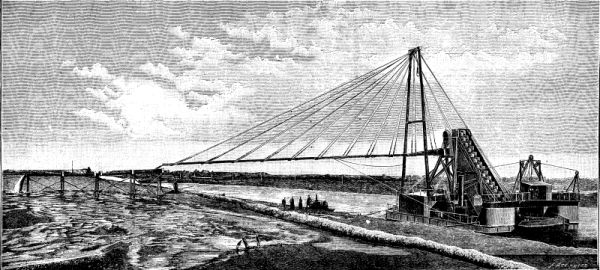

We illustrate a floating elevator and spoil distributor constructed by Mr. A.F. Smulders, Utrecht, Holland, for removing dredged material out of barges at the Baltic Sea Canal Works. We give a perspective view showing the apparatus at work, and on a page plate are given plans, longitudinal and cross sections, with details which are from Engineering. The dredged material is raised out of the launches or barges by means of a double ranged bucket chain to a height of 10.5 meters (34 ft. 5 in.) above the water line, from whence it is pushed to the place of deposition by a heavy stream of water supplied by centrifugal pumps.

FLOATING ELEVATOR AND SPOIL DISTRIBUTOR FOR THE BALTIC SEA CANAL.--FIGS. 2, 3

The necessary machinery and superstructure are supported on two vessels connected, as shown in Figs. 4 and 5, with cross girders, a sufficient width being left between each vessel to form a well large enough for a barge to float into, and for the working of the bucket ladder utilized in raising the material from the barges. The girders are braced together and carry the framing for the bucket chains, gears, etc.

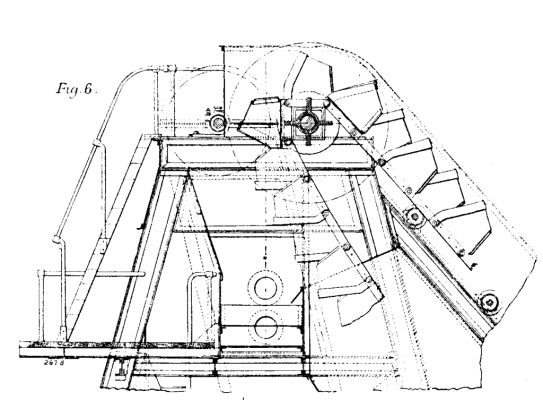

The port vessel is provided with a compound engine of 150 indicated horse power, with injection condenser actuating two powerful centrifugal pumps, raising water which enters by a series of holes into the bottom of the shoots underneath the dredged material, carrying the material to the conduit (as indicated on Fig. 4 and in detail on Figs. 6 and 7).

FLOATING ELEVATOR AND SPOIL DISTRIBUTOR FOR THE BALTIC SEA CANAL.--FIGS. 4.

A steel boiler of 80 square meters (860 square feet) heating surface, and 6 atmospheres (90 lb.) working pressure, supplies steam to the engine. Forward on the deck of the same vessel there is a vertical two-cylinder high pressure engine of 30 indicated horse power, which helps to bring the barge to the desired position between the parallel vessels. A horizontal two-cylinder engine of the same power, fitted with reversing gear, placed in the middle of the foremost iron girder, raises and lowers the bucket ladder by the interposition of a strongly framed capstan, as shown on Fig. 5. The gearing throughout is of friction pulleys and worm and wormwheel. It is driven by belts.

FLOATING ELEVATOR AND SPOIL DISTRIBUTOR FOR THE BALTIC SEA CANAL.--FIG. 5.

In the starboard vessel there is a compound engine of 100 indicated horse power, with injection condenser, working the bucket chain by means of belts and wheel gearing, as shown on Fig. 2. A marine boiler of 46 square meters (495 square feet) heating surface and 6 atmospheres (90 lb.) working pressure, supplies steam. In this vessel, it may be added, there is a cabin for the crew.

FLOATING ELEVATOR AND SPOIL DISTRIBUTOR FOR THE BALTIC SEA CANAL.--FIG. 6.

The dimensions of the vessels are as follows; Extreme length, 25 meters (82 ft.); breadth, 4.5 meters (14 ft. 9 in.); depth (moulded), 2.7 meters (6 ft. 6¾ in.); average draught of water, 1.4 meters (4 ft. 7 in.); space between the ships, 6.55 meters (21 ft. 6 in.) The iron structure connecting the ships is composed of four upright box-form stanchions on both ships, connected at the top by two strong box girders with tie pieces supporting the main framing. This main framing, also of the "box girder" form, is strengthened with angle irons and braced together at the tops by a platform supporting the gearing of the bucket chains, as shown on Fig. 5. The buckets have a capacity of 160 liters (5.65 cubic feet) and the speed in travel is at the rate of 25 to 30 buckets per minute, so that with both ladders working, 50 to 60 buckets are discharged per minute. The top tumbler shaft is placed at a height of 13 meters (42 ft. 8 in.) above the water line (Fig. 4), and the dredge conduit has a length of 50 meters (164 ft.), Fig. 1. The shooting is done at a height of 8.5 meters (27 ft. 10 in.) above the water line, and the shoot catches the dredged products at a height of 10.5 meters (34 ft. 5 in.) above the water line, the sliding gradient being 4 to 100. The dredge conduit is carried by timberwork resting on two of the upright box form stanchions.

FLOATING ELEVATOR AND SPOIL DISTRIBUTOR FOR THE BALTIC SEA CANAL.--FIGS. 7,8,9.

All cables are of galvanized steel and provided with open twin buckles. The main parts of the apparatus are of steel, and all pieces subject to wear and tear are fitted with bushes so formed that they can be easily replaced.

IMPROVED FLOATING ELEVATOR AND SPOIL DISTRIBUTOR.

The quantity of suitable soil removed by these apparatus amounts to 350 cubic meters (12,360 square feet) per hour. Four plants of similar construction have been built for the new Baltic Sea Canal, besides a fixed elevator of the same power and disposition, with the exception that the top tumbler shaft was suspended at a height of 16.1 meters (51 ft. 10 in.) above the water line, and the dredge conduit placed at a distance of 13 meters (43 ft.) from it.

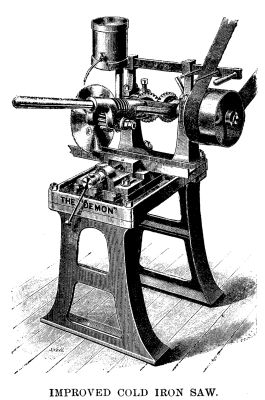

The engraving given herewith shows a general view

of the "Demon" cold saw, designed for cutting iron,

mild steel, or other metals of fairly large sections, that

is, up square or round, and any rectangular section up

to 8 in. by 4 in. The maker, Mr. R.G. Fiege, of London,

claims for this appliance that it is a cold iron saw,

at once powerful, simple and effective. It is always in

readiness for work, can be worked by inexperienced

workmen. The bed plate has T slots, to receive a parallel

vise, which can be fixed at any angle for angular

cutting. The articulated lever carries a saw of 10 in.

or 12 in. diameter, on the spindle of which a bronze

pinion is fixed, gearing with the worm shown. The

latter derives motion from a pair of bevel wheels,

which are in turn actuated from the pulley shown in

the engraving. The lever and the saw connected with

it can be raised and held up by a pawl while the work

is being fixed. In small work the weight of the lever

itself is found sufficient to feed the saw, but in heavier

work it is found necessary to attach a weight on the

end of the lever. The machine is fitted with fast and

loose pulleys, strap fork and bar. We are informed

that one of these machines is capable of making 400

cuts through bars of Bessemer steel 4 in. diameter,

each cutting occupying six minutes on an average,

without changing the saw.—Industries.

The engraving given herewith shows a general view

of the "Demon" cold saw, designed for cutting iron,

mild steel, or other metals of fairly large sections, that

is, up square or round, and any rectangular section up

to 8 in. by 4 in. The maker, Mr. R.G. Fiege, of London,

claims for this appliance that it is a cold iron saw,

at once powerful, simple and effective. It is always in

readiness for work, can be worked by inexperienced

workmen. The bed plate has T slots, to receive a parallel

vise, which can be fixed at any angle for angular

cutting. The articulated lever carries a saw of 10 in.

or 12 in. diameter, on the spindle of which a bronze

pinion is fixed, gearing with the worm shown. The

latter derives motion from a pair of bevel wheels,

which are in turn actuated from the pulley shown in

the engraving. The lever and the saw connected with

it can be raised and held up by a pawl while the work

is being fixed. In small work the weight of the lever

itself is found sufficient to feed the saw, but in heavier

work it is found necessary to attach a weight on the

end of the lever. The machine is fitted with fast and

loose pulleys, strap fork and bar. We are informed

that one of these machines is capable of making 400

cuts through bars of Bessemer steel 4 in. diameter,

each cutting occupying six minutes on an average,

without changing the saw.—Industries.

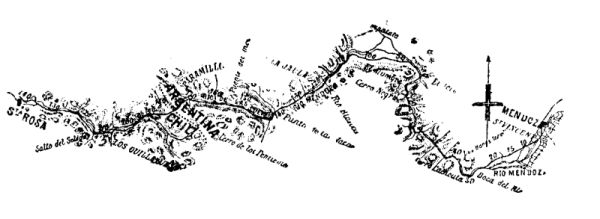

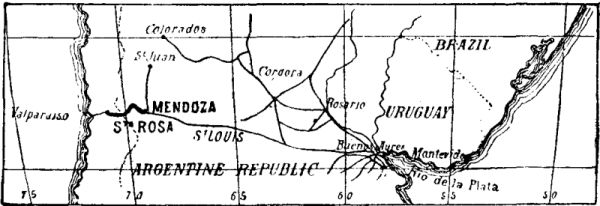

The railway system of the Argentine Republic is separated from the Chilian system by the chain of the Andes. The English contractors, Messrs. Clark & Co., have undertaken to connect them by a line which starts from Mendoza, the terminus of the Argentine system, and ends at Santa Rosa in Chili, with a total length of 144 miles. The distance from Buenos Ayres to Valparaiso will thus be reduced to 816 miles. The Argentine lines are of 5.4 foot gauge, and those of Chili of 4.6 foot.

The line in course of construction traverses an extremely hilly region. The starting and terminal points are at the levels of 2,338 feet (Mendoza) and 2,706 feet (Santa Rosa) above the sea; the lowest neck of the chain is at the level of 11,287 feet.

Study having shown that a direction line without tunnels, and even with the steepest gradients for traction by adhesion, would lead to a considerable lengthening of the line, and would expose it to avalanches and to obstructions by snow, there was adopted upon a certain length a rack track of the Abt system, with gradients of 8 per cent., and the neck is traversed by a tunnel 3 miles in length and 1,968 feet beneath the surface. The number and length of the tunnels upon the two declivities, moreover, are considerable. They are all provided with rack tracks. The first 80 miles, starting from Mendoza, are exploited by adhesion, with maximum gradients of 2½ per cent. Upon the remaining 64 miles, traction can be effected either by adhesion or racks.

FIG. 1.—REGION TRAVERSED BY THE RAILWAY THROUGH THE ANDES.

The track is of 3.28 foot gauge, and this will necessitate trans-shipments upon the two systems. The rails weigh 19 pounds to the running foot in the parts where the exploitation can be effected either through adhesion or racks, and 17 pounds in those in which adhesion alone will be employed.

FIG. 2.—DIRECTION LINE OF THE RAILWAY THROUGH THE ANDES.

The special locomotives for use on the rack sections will weigh 45 tons in service and will haul 70 ton trains over gradients of 8 percent. Those that are to be employed upon the parts where traction will be by adhesion will be locomotives with five pairs of wheels, three of them coupled. The weight distributed over these latter will be 28 tons. These engines will haul 140 ton trains over gradients of 2 per cent.

The earthwork is now finished over two-thirds of the length, and the track has been laid for a length of 58 miles from Mendoza. It is hoped that it will be possible to open the line to traffic as far as to the summit tunnels in 1891, and to finish the tunnels in 1893. These tunnels will have to be excavated through hard rock. To this effect, it is intended to use drills actuated by electricity through dynamos driven by waterfalls. The Ferroux system seems preferable to the Brandt and other hydraulic systems, seeing the danger of the water being frozen in the conduits placed outside of the tunnels.—Le Genie Civil.

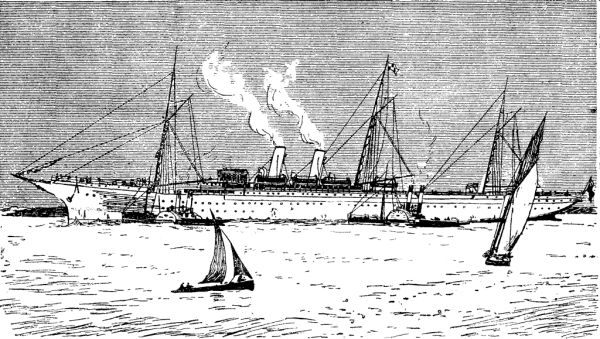

THE NEW BRITISH PACIFIC LINE EMPRESS OF INDIA.

The Empress of India is intended to be the pioneer of three fast mail steamers, built by the Barrow Shipbuilding Company for service in connection with the Canadian Pacific Railway, between Vancouver and the ports of China and Japan, thus forming the last link in the new route to the East through British territory. Her sister ships, the Empress of China and Empress of Japan, are to be ready in April next. These three ships all fulfill the requirements of the Board of Trade and of the Admiralty and Lloyd's, and are classed as 100 A1. They will also be placed on the list of British armed cruisers for service as commerce protectors in time of war. For this service each vessel is to be thoroughly fitted. There are two platforms forward and two aft, for mounting 7 in. Armstrong guns. These weapons, in the case of the Empress of India, are already awaiting the vessel at Vancouver. The Empress of India is painted white all over, has three pole masts to carry fore and aft sails. She has two buff-colored funnels and a clipper stern, and in external build much resembles the City of Rome. Her length over all is 485 feet; beam, 51 feet; depth, 36 feet; and gross tonnage, 5,920 tons. The hull, of steel, is divided into fifteen compartments by bulkheads, and has a cellular double bottom 4 feet in depth and 7 feet below the engine room. There are four complete decks. The ship is designed to carry 200 saloon passengers, 60 second cabin, and 500 steerage—these last chiefly Chinese coolies, for whose special delectation an "opium room" has been provided on board.—Daily Graphic.

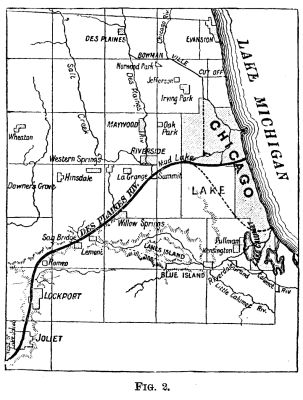

The prairie land in the southwest corner of Lake Michigan, which, seventy years ago, was half morass from the overflowing of the sluggish creek, whose waters, during flood, spread over the low-lying, level plain, or were supplemented in the dry season by the inflow from the lake, showed no sign of any future development and prosperity. The few streets of wooden houses that had been built by their handful of isolated inhabitants seemed likely rather to decay from neglect and desertion than to increase, and ultimately to be swept away by fire, to make room for the extravagant and gigantic buildings that to-day characterize American civilization and commercial prosperity. Nearly 1,000 miles from the Atlantic, a greater distance from the Gulf of Mexico, and 2,000 miles from the Pacific, no wilder dream could have been imagined fifty years ago than that Chicago should become a seaport, the volume of whose business should be second only to that of New York; that forty miles of wharves and docks lining the branches of the river should be insufficient for the wants of her commerce, and that none of the magnificent lake frontage could be spared to supply the demand.

Yet this is the situation to-day, the difficulties of which must increase many fold as years pass and business grows, unless some changes are made by which increased accommodation can be obtained. The nature of these changes has long engrossed the attention of the municipality and their engineers, and necessity is forcing them from discussion to action. As such action is likely to be taken soon, the subject is of sufficient interest to the English reader to devote some space to its consideration.

The most important problem, however, which the works to be undertaken—and which must of necessity be soon commenced—will have to solve, is not one of wharf accommodation or of increased facilities of commerce. It is the better disposal of the sewage of the city, the system in use at present being inadequate, and growing more and more imperfect as the city and its population increase. During the early days of Chicago, and indeed long after, the sewage question was treated with primitive simplicity, and with a complete disregard of sanitary laws.

The river and the lake in front of the city were close at hand and convenient to receive all the discharge from the drains that flowed into them. But this condition of things had to come to an end, for the lake supplied the population with water, and it became too contaminated for use. To obtain even this temporary relief involved much of the ground level of the city being raised to a height of 14 ft. above low water, a great undertaking carried out a number of years ago. To obtain an adequate supply of pure water, Mr. E.S. Chesborough, the city engineer, adopted the ingenious plan of driving a long tunnel beneath the bed of the lake, connected at the outer end to an inlet tower built in the water, and on shore to pumping engines. This plan proved so successful that it is now being repeated on a larger scale, and with a much longer tunnel, to meet the increased demands of the large population.

But to improve the sanitary condition of the city has been a much more difficult undertaking, as may be gathered from the following extract from an official report: "The present sanitary condition calls loudly for relief. The pollution of the Desplaines and the Illinois Rivers extends 81 miles, as far as the mouth of the Fox (see plan, Fig. 1) in summer low water, and occasionally to Peoria (158 miles) in winter. Outside of the direct circulation the river harbor is indescribable. The spewing of the harbor contents into the lake, the sewers constantly discharging therein, clouds the source of water supply (the lake) with contamination. Relief to Chicago and equity to her neighbors is a necessity of the early future." To make this quotation clear it is necessary to explain the actual condition of the Chicago sewage question.

Long before the present metropolis had arrived at the title and dignity of a city, the advantage to be derived from a waterway between Lake Michigan and the Illinois River, and thence to the Mississippi, was well understood. The scheme was, in fact, considered of sufficient importance to call for legislation as early as 1822, in which year an act was passed authorizing the construction of a canal having this object. It was not commenced, however, till 1836, and was opened to navigation in the spring of 1848. This canal extended from Chicago to La Salle, a distance of 97¼ miles, and it had a fall of 146 ft. to low water in the Illinois River (see Fig. 1). It was only a small affair, 6 ft. deep, and 60 ft. wide on the surface; the locks were 110 ft. long and 18 ft. wide. The summit level, which was only 8 ft. above the lake, was 21 miles in length. This limited waterway remained in use for a number of years, until, in fact, the growth of Chicago rendered it impossible to allow the sewage to flow any longer into the lake. In 1865 the State of Illinois sanctioned widening and lowering the canal so that it should flow by gravity from Lake Michigan. The enlargement was completed in 1871, by the city of Chicago, and the sewage was then discharged toward the Illinois River. But the flow was insufficient, and in 1881 the State called on the city to supplement the flow by pumping water into the canal.

In 1884, engines delivering 60,000 gallons a minute

were set to work and remedied the evil for a time, so

far as the city of Chicago was concerned, but the large

discharge of sewage through the sluggish current of

the canal and into the Illinois River proved a serious

and ever-increasing nuisance to the inhabitants in the

adjoining districts. To enlarge the existing canal, increase

the volume and speed of its discharge, and to

alter the levels, so that there shall be a relatively rapid

stream flowing at all times from Lake Michigan, appears

the only practical means of affording relief to

the city, and immunity to other towns and villages lying

along the route of the stream.

In 1884, engines delivering 60,000 gallons a minute

were set to work and remedied the evil for a time, so

far as the city of Chicago was concerned, but the large

discharge of sewage through the sluggish current of

the canal and into the Illinois River proved a serious

and ever-increasing nuisance to the inhabitants in the

adjoining districts. To enlarge the existing canal, increase

the volume and speed of its discharge, and to

alter the levels, so that there shall be a relatively rapid

stream flowing at all times from Lake Michigan, appears

the only practical means of affording relief to

the city, and immunity to other towns and villages lying

along the route of the stream.

The physical nature of the country is well suited for carrying out such a project on a scale far larger than that required for sewage purposes, and works thus carried out would, to a small extent, restore the old water regime in this part of the continent. Before the vast surface changes produced during the last glacial period, three of the great lakes—Michigan, Huron and Superior—discharged their waters southward into the Gulf of Mexico by a broad river. The accumulation of glacial debris changed all this; the southern outlet was cut off, and a new one to the north was opened near where Detroit stands, making a channel to Lake Erie, which then became the outlet for the whole chain by way of Niagara. A very slight change in levels would serve to restore the present regime. Around Lake Michigan the land has been slightly raised, the summit above mean water level being only about 8 ft. Thirty miles from the south shore the lake level is again reached at a point near Lockport (see Fig. 2); the fall then becomes more marked. At Lake Joliet, 10 miles further, the fall is 77 ft.; and at La Salle, 100 miles from Chicago, the total fall reaches 146 feet. At La Salle the Illinois River is met, and this stream, after a course of 225 miles, enters the Missouri. In the whole distance the Illinois River has a fall of 29 ft. "It has a sluggish current; an oozy bed and bars, formed chiefly by tributaries, with natural depths of 2 ft. to 4 ft.; banks half way to high waters, and low bottoms, one to six miles wide, bounded by terraces, overflowed during high water from 4 ft. to 12 ft. deep, and intersected in dry seasons by lake, bayou, lagoon, and marsh, the wreck of a mighty past."

The rectification of the Illinois and the construction of a large canal from La Salle to Lake Michigan are, therefore, all that is necessary to open a waterway to the Gulf of Mexico, and to make Chicago doubly a port; on the one hand, for the enormous lake traffic now existing; on the other, for the trade that would be created in both directions, northward to Lake Michigan, and southward to the Gulf.

As a matter of fact this great scheme has long occupied the attention of the United States government. A bill in 1882 authorized surveys for "a canal from a point on the Illinois River, at or near the town of Hennepin, by the most practical route to the Mississippi River ... and a survey of the Illinois and Michigan Canal connecting the Illinois River with Chicago, and estimates from its enlargements." This scheme only contemplated navigation for boats up to 600 tons. In 1885 the Citizens' Association, of Chicago caused a report to be made for an extended plan. The name of Mr. L.E. Cooly, at that time municipal sanitary engineer, was closely associated with this report, as it is at the present time for the agitation for carrying out the works. This report recommended that "an ample channel be created from Chicago to the Illinois River, sufficient to carry away in a diluted state the sewage of a large population. That this channel may be enlarged by the State or national government to any requirement of navigation or water supply for the whole river, creating incidentally a great water power in the Desplaines valley." Following this report and that of a Drainage and Water Supply Commission, a bill was introduced into Congress supporting the recommendations that had been made, and providing the financial machinery for carrying it into execution. Since that date much discussion has taken place, and some little action; meanwhile the sanitary requirements of the city are growing more urgent, and the pressure created from this cause will enforce some decision before long. Whether the new waterway is to be practically an open sewer or a ship canal remains yet to be seen, but it is tolerably certain that its dimensions and volume of water must approximate to the latter, if the large populations of other towns are to be satisfied. In fact the actual necessities are so great as regards sectional area of canal and flow of water—at least 600,000 ft. a minute—that comparatively small extra outlay would be needed to complete the ship canal.

The attention of engineers in Chicago, as well as of

the United States government, is consequently closely

directed at the present time to such a solution of the

problem as shall secure to Chicago such a waterway

as will dispose of the sewage question for very many

years to come; that shall relieve the inhabitants on

the line of the canal from all nuisances arising from

the sewage disposal, and shall provide a navigable

channel for vessels of deep draught. The maps, Figs.

1 and 2, give an idea of the most favored scheme—that

of Mr. Cooley.

The attention of engineers in Chicago, as well as of

the United States government, is consequently closely

directed at the present time to such a solution of the

problem as shall secure to Chicago such a waterway

as will dispose of the sewage question for very many

years to come; that shall relieve the inhabitants on

the line of the canal from all nuisances arising from

the sewage disposal, and shall provide a navigable

channel for vessels of deep draught. The maps, Figs.

1 and 2, give an idea of the most favored scheme—that

of Mr. Cooley.

As will be seen, the canal commencing near the mouth of the Chicago River passes through a cut in the low ridge forming the summit level; then it runs to Lake Joliet, and through the valleys of the Desplaines and Illinois Rivers, to the Mississippi at Grafton, a distance of 325 miles. The elevations and distances of the principal points are as follows:

| Miles from Lake Michigan. | Low Water Level below Chicago Datum. | High Water above Low Water. | ||

| ft. | ft. | |||

| Lake Michigan | 4.7 | |||

| Lake Joliet | 40 | 77 | 5 to 6 | |

| Kankakee River | 51.30 | 93.70 | 18 to 20 | |

| Morris | 61 | 100.3 | 21 | |

| Marseilles | 77 | 102.8 | 4 to 5 | |

| Ottawa | 84.5 | 132.1 | 26 | |

| La Salle | 100.3 | 146.6 | 28 | |

| Hennepin | 115.8 | 148.7 | 25 | |

| Peoria | 161.4 | 151.3 | 21 | |

| Mouth of the Illinois | 325 | 172.4 | 20 |

The project in contemplation provides that the depth of the canal as far as Lake Joliet (which is about six miles long) shall be not less than 22 ft., and on to La Salle not less than 14 ft. at first, with facilities to increase it to 22 ft. Beyond La Salle to the mouth of the Illinois, dredging and flushing by the large volume of water pouring in from Lake Michigan would make and maintain ultimately a similar depth.

As it appears recognized that the sewage channel of Chicago must be 15 ft. deep, and as provision is now being made all over the great lake system for vessels drawing 20 ft. of water, a comparatively small additional outlay would provide for a channel available for the largest lake vessels. It is claimed that by the co-operation of the Chicago municipality and the general government—the latter to advance a sum of not less than $50,000,000—a ship (and sanitary) canal 22 ft. deep could be made from the lake to Joliet, extended thence to Utica, 20 ft. deep, and from there to the Mississippi, 14 ft. deep.

That such a work would vastly enhance the commerce, not only of Chicago, but of the whole section of the country through which the canal would pass, admits of but little doubt, and probably the outlay would be justified by results similar to those achieved with other great canal works and rectified rivers in the United States.

The following figures, showing the tonnage carried in 1888-89, give some idea of the volumes of water-borne traffic in America:

| Tons. | |

| Detroit River | 19,099,060 |

| Erie Canal | 5,370,369 |

| Sault Ste. Marie | 7,516,022 |

| Welland Canal | 828,271 |

| St. Lawrence Canal | 1,500,096 |

| Mississippi to New Orleans | 3,177,000 |

| Mississippi below St. Louis | 845,000 |

| Ohio | 2,236,917 |

| Chicago Canal and lake | 11,029,575 |

Except on the Mississippi, it may be reckoned that navigation is closed by ice during five months a year. It may be mentioned, by way of comparison, that the traffic on the Suez Canal during the year 1888-89 was 6,640,834 tons.

One very interesting point in connection with this work is the effect that the diversion of so large a body of water from the lakes will have upon their regime. At least 10,000 cubic feet a second would be taken from Lake Michigan and find its way into the Mississippi; this is approximately 4½ per cent. of the total amount that now passes through the St. Clair River and thence over Niagara.

The following table gives some particulars of the great lakes and the discharge from them:

| Cubic Feet per Second | ||||||

| Lake. | Elevation above Mean Tide. | Area of Basin, Square Miles. | Area of Lake, Square Miles. | Rainfall. | Evaporation | Discharge. |

| Superior | 601.78 | 90,505 | 38,875 | 187,386 | 34,495 | 80,870 |

| Huron and Mich. | 581.28 | 121,941 | 50,400 | 262,964 | 66,754 | 216,435 |

| Erie | 572.86 | 40,298 | 10,000 | 96,654 | 13,870 | 235,578 |

| Ontario | 246.61 | 31,558 | 7,220 | 75,692 | 10,568 | 272,095 |

The average variation in level of the lakes is from 18 in. to 24 in. during the year, and the range in evaporation from year to year is also very considerable; thus the evaporation per second on Huron and Michigan, as given in the table above, is nearly 67,000 ft., but the figures for another year show nearly 89,000 ft. per second, which would represent a difference of 6½ in. in water level. As a discharge of 10,000 cubic feet a second into the new canal would lower the level of these two lakes by 2.87 in. in a year, it follows that the difference between a year of maximum and one of minimum evaporation is more than twice as great as would be required for the canal, and even under the most unfavorable conditions the volume taken from the whole chain of lakes would not lower them an inch.

When the variations in level due to different causes—rain, wind, and evaporation being the chief—are taken into consideration, the effect of 10,000 cubic feet a second abstracted would probably not be noticeable. That this would be so is the opinion, after careful investigation, of many eminent American engineers. On the other hand there is a similar unanimity of opinion as to the advantages that would be obtained in the condition of the Mississippi by adding to it a tributary of such importance as the proposed canal.—Engineering.

The inventor and patentee of all water wheels known as the Burham turbine died from Bright's disease of the kidneys at his home, York, Pa., Dec. 22, 1890, aged 68 years 9 months and 9 days. He was born in the city of New York, March 13, 1822, and was of English-Irish and French descent. His father was a millwright and with him worked at the trade in Orange county, N.Y., until he was 16 years old. He then commenced learning the watchmakers' business, which he was obliged to relinquish, after three years, on account of his health. He then went to Laurel, Md., in 1844, and engaged with Patuxent & Co. as mercantile clerk and bookkeeper. In 1856 he commenced the manufacture of the French turbine water wheel. In 1879 he sold out his Laurel interests, went to New York and commenced manufacturing his own patents. On May 22, 1883, he founded the Drovers' and Mechanics' National Bank of York, and was elected its first president, which position he held at the time of his death. In 1881, with others, he built the York opera house, at a cost of $40,000. He was a Knight Templar, and past master of the I.O.O.F., and past sachem of Red Men.

He was the oldest turbine wheel manufacturer living, having been actually engaged in the manufacture of turbines since 1856. He first made and sold the French Jonval turbine, which was then the best turbine made, but being complicated in construction, it soon wore out and leaked. From the experience he had from this wheel he invented and patented Feb. 22, 1859, his improved Jonval turbine, which was very simply constructed and yielded a greater percentage of power than the French Jonval turbines. Hundreds of these improved wheels, which were put in operation between the years 1859 and 1868, are still in use. (We show no cut of this wheel, but it had four chutes instead of six, as shown in March 24, 1863, patent.)

The first wheel (72 inch) made after the patent was granted was sold to Brightwell & Davis, Farmville, Va., and put into their flour mill under six feet head. In 1870, Brightwell & Davis sold their mill to Scott & Davis. Afterward G.W. Davis owned and operated the mill and put in one 1858 patent "New Turbine." In 1889 the Farmville Mill Company bought and remodeled the mill to roller process and required more power than the old 1856 Jonval turbine and 1868 "New Turbine" would yield, and on Aug. 30, 1889, sold the Farmville Mill Company two 54 inch new improved Standard turbines to displace the two old wheels. In 1860 he commenced experimenting with different forms of buckets and chutes, and used six chutes instead of four as first made, and was granted patent March 24, 1863.

This addition of chutes proved beneficial, as the wheel worked better with the gates partly opened than it did with four chutes. His next invention was granted him Dec. 24, 1867, which he called Burnham's improved central and vertical discharge turbine.

This improvement consisted in making the guide blade straight on the outside (instead of rounding, as then made by all others), from inner point back to bolt or gudgeon, and thick enough at the latter point to let water pass without being obstructed by said bolt and the arrangement for shifting the water guides. Two 42-inch wheels of this pattern were built and put into operation, but they soon commenced leaking water and became troublesome on account of the many small pieces of castings and bolts, and were abandoned as worthless. There are several manufacturers of this style of wheel that advertise them as "simple and durable." Such a complicated case with twelve chutes cannot be made to operate unless by a large number of castings, bolts and studs. With these adjustable water guides, one of the objects was obtained. Admitting the water to the wheel through chutes corresponding in height to the outer edge of buckets exposed, but not placing the water against the face of the buckets at right angles with the center of the wheel, except when the guide blades were full opened, for as the guides are changed so is the current of the water likewise changed.

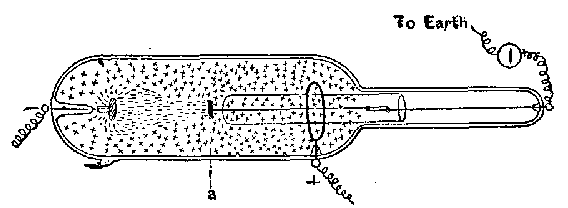

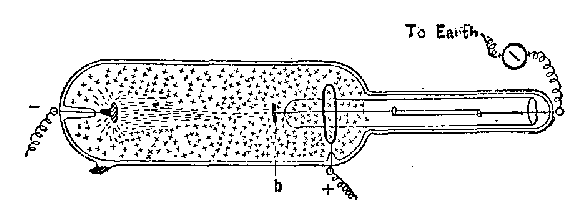

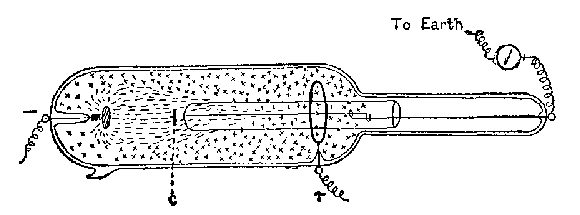

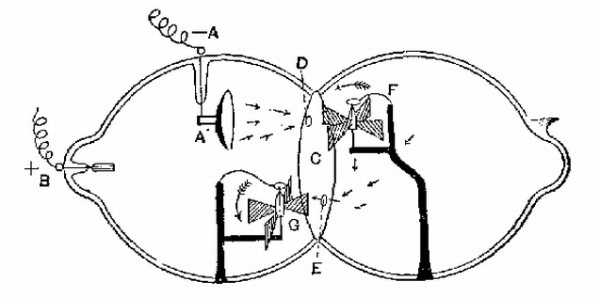

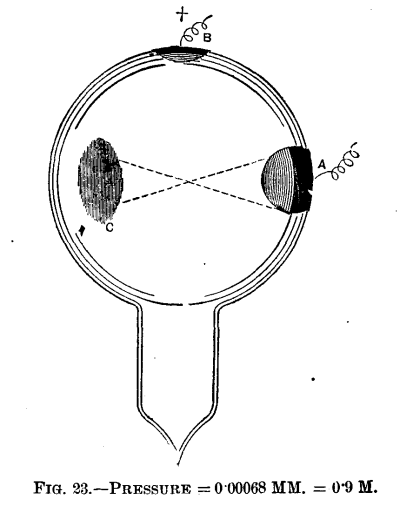

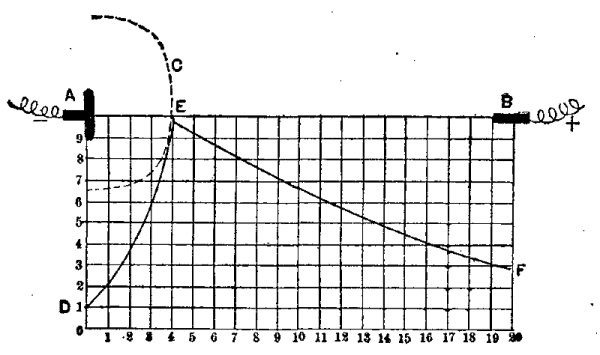

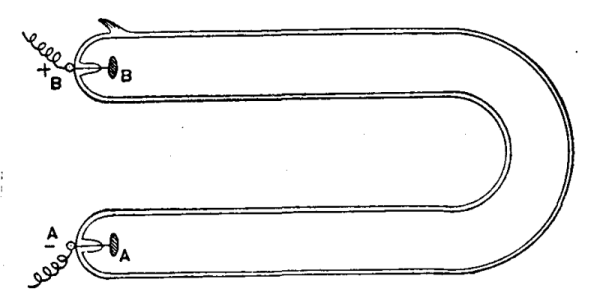

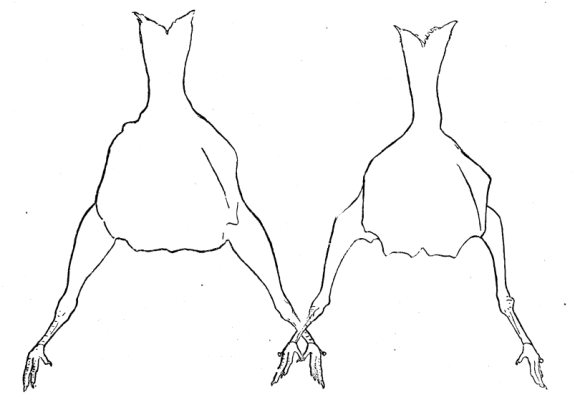

After making several differently constructed wheels and testing them a number of times, he selected the best one and obtained a patent for it March 3, 1868, and called it "new turbine," which he still further improved and patented May 9, 1871. This "new turbine" consisted of the former improved Jonval wheel, hub and buckets, with a new circular case and new form of chutes, having a register gate entirely surrounding the case and having apertures corresponding to those in the case for admitting water to the wheel. This register gate was moved by means of a segment and pinion.